Patents

Literature

31results about How to "Reduce pipe clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

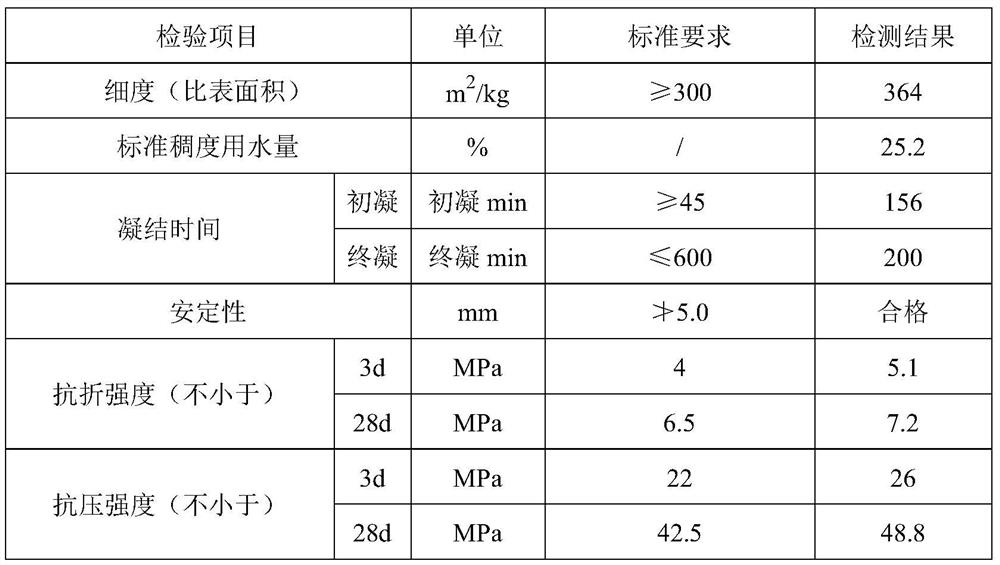

Early-strength sprayed concrete

The invention discloses early-strength sprayed concrete and belongs to the technical field of concrete. The early-strength sprayed concrete is prepared from, by weight, 400-450 parts of sulphate aluminium cement, 20-50 parts of silicon powder, 800-1000 parts of medium sand, 800-1000 parts of crushed stone, 1-2.5 parts of a water reducer, 0.03-0.09 part of lithium carbonate and 180-225 parts of water. The concrete is particularly suitable for quick repairing, emergency maintenance and supporting engineering of weak surrounding rock, and has the advantages of being quick in setting and early in strength, high in hour strength, high in resilience and low in production cost.

Owner:JIAHUA SPECIAL CEMENT

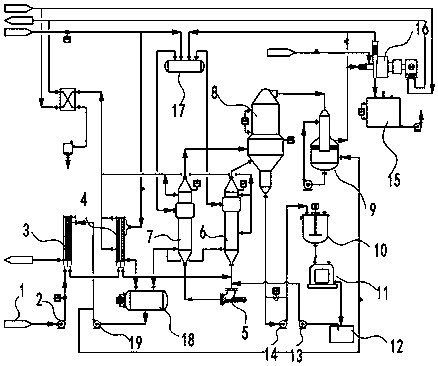

Device for producing hydrated lithium hydroxide on basis of MVR and production method thereof

InactiveCN108298569ASmall amount of lithiumReduce fouling frequencyEvaporation with vapour compressionEvaporator accessoriesLithium hydroxideForced circulation

The invention discloses a device for producing hydrated lithium hydroxide on the basis of MVR. The device includes a raw material tank, a condensate water preheater, a vapor preheater, a forced circulation evaporator, a thickener, a centrifugal machine, a compressor and a vapor separating bag. Raw materials in the raw material tank are conveyed into the condensate water preheater through a feedingpump, and the condensate water preheater is communicated with the vapor preheater through a pipe; the raw materials in the vapor preheater are conveyed into the forced circulation evaporator througha pipe, and the forced circulation evaporator comprises a first heater, a second heater and a crystal separator. The device has the advantages that the interior of a heat exchanging pipe of a forced circulation heater is polished, the adhesive force of crystals adhering to a wall in a solution can be effectively reduced, it is ensured that the flow velocity of the solution in the heat exchanging pipe can reach 2.5 m / s or above, and meanwhile the pipe wall is flushed to further reduce the scaling frequency in the heat exchanging pipe; at the same time, the superheat degree of an outlet of the heater is lowered, flash evaporation and pipe blockage are effectively prevented from occurring in the pipes, and a pipe blockage situation caused by locally massive crystallization due to an excessively high superheat degree is reduced.

Owner:SHANGHAI ZHONGTENG ENVIRONMENTAL PROTECTION TECH CO LTD

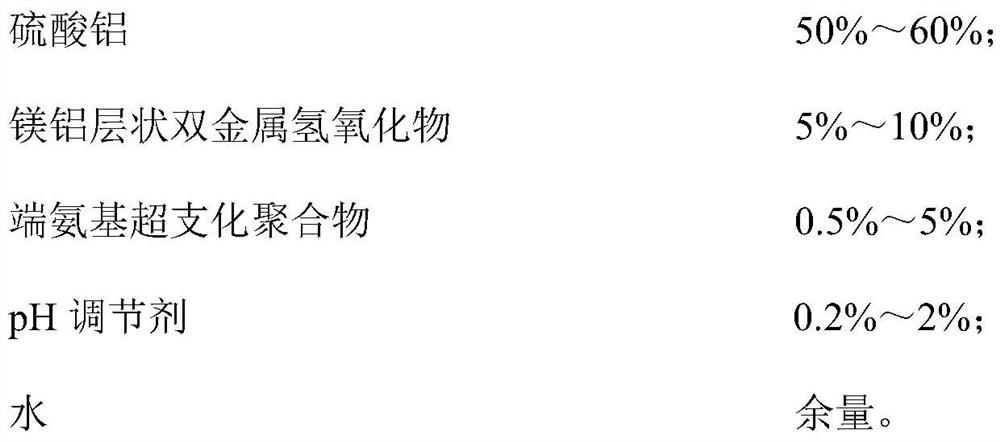

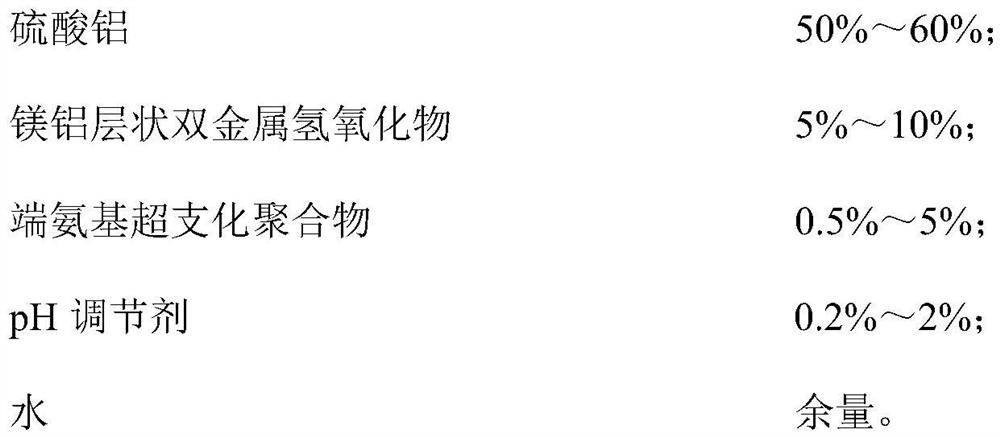

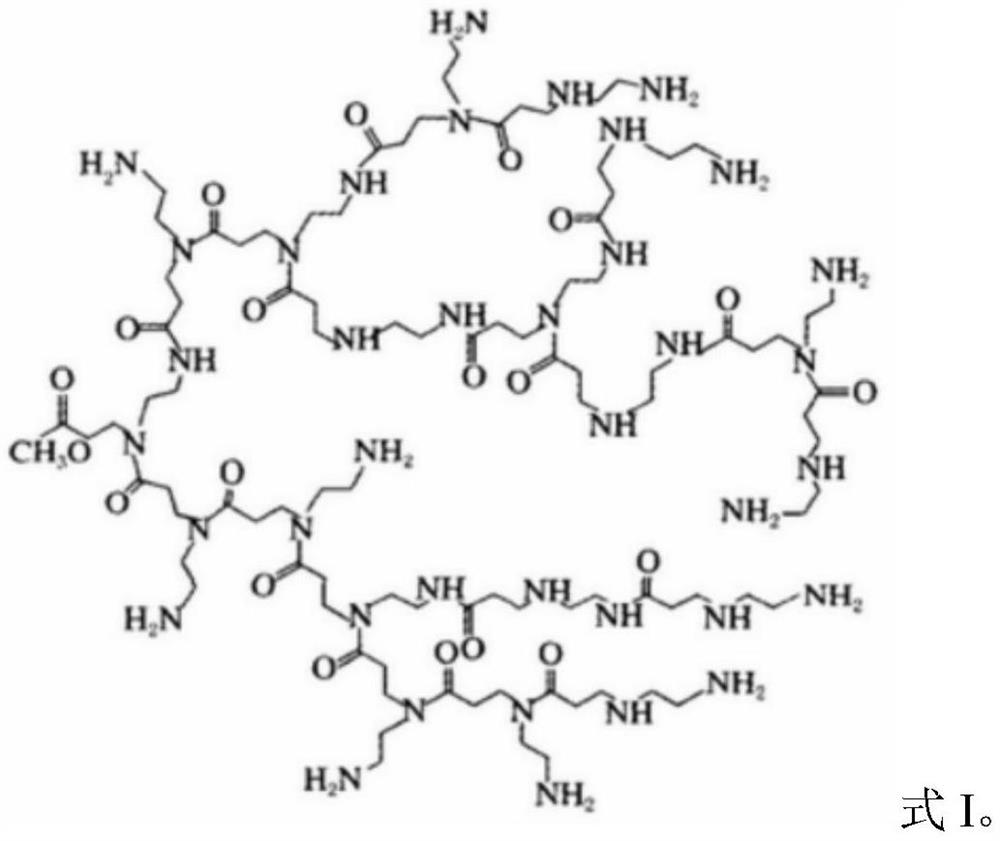

Suspended alkali-free liquid accelerator and preparation method thereof

The invention belongs to the technical field of concrete admixtures, and discloses a suspension type alkali-free liquid accelerator and a preparation method thereof. The preparation method comprises the following steps: firstly, respectively preparing magnesium-aluminum layered double hydroxide and an amino-terminated hyperbranched polymer, then adding the magnesium-aluminum layered double hydroxide and the amino-terminated hyperbranched polymer into water, stirring and dispersing uniformly, and then adding aluminum sulfate and a pH regulator, stirring and dispersing uniformly to obtain the suspension type alkali-free liquid accelerator. The magnesium-aluminum layered double-metal hydroxide with high dispersing performance and high specific surface area is further cooperated with the amino-terminated hyperbranched polymer to form a co-stabilizing system and a tackifying system of an inorganic-organic polymer, so that a high-concentration supersaturated aluminum sulfate solution system can be subjected to suspension stabilization; and a good quick-setting effect can be achieved, the early strength of the concrete is improved, the rebound rate of the sprayed concrete is reduced, and the pipe blocking phenomenon in the application process of the sprayed concrete is effectively improved.

Owner:佛山市凯隽新建材科技有限公司

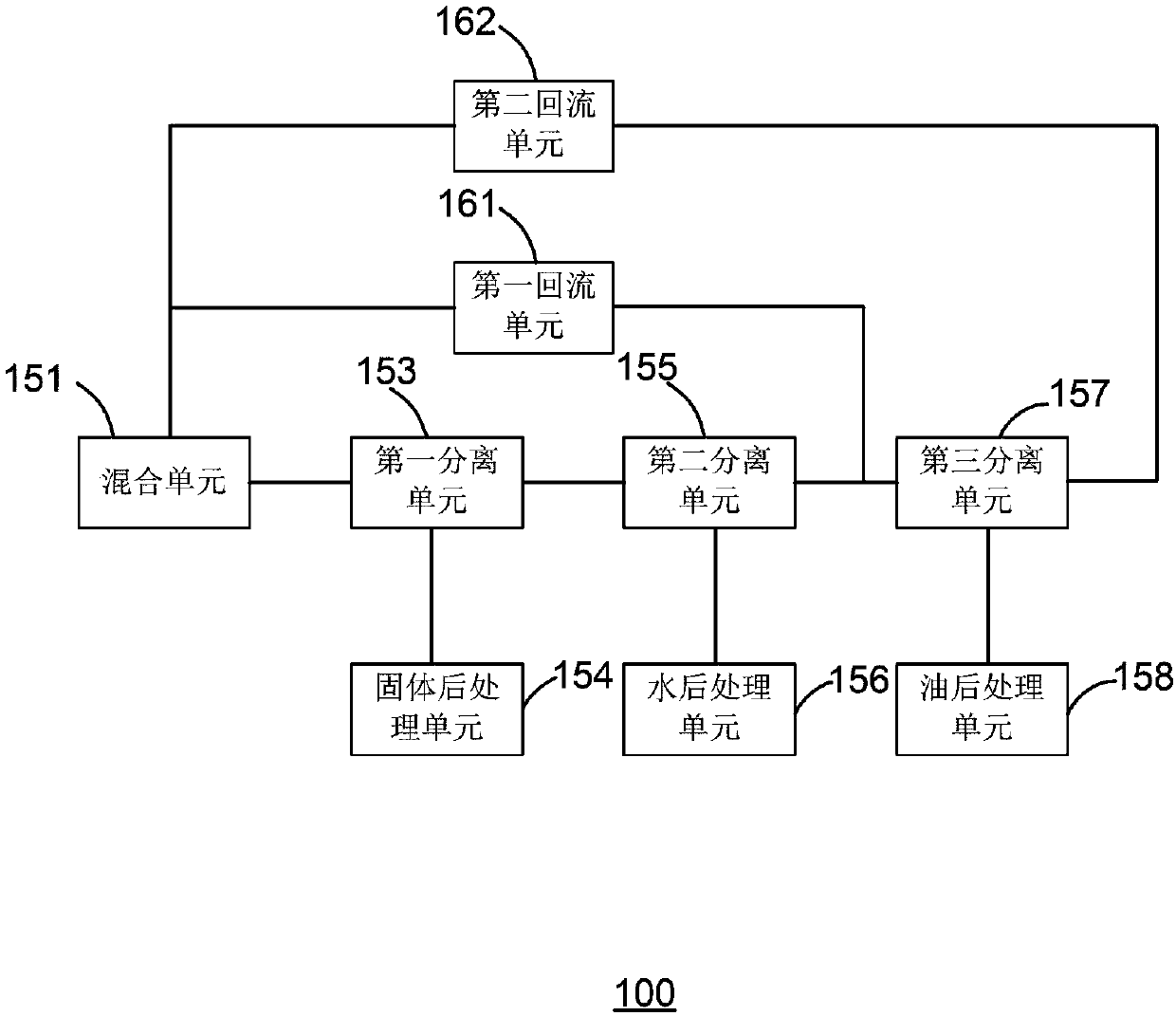

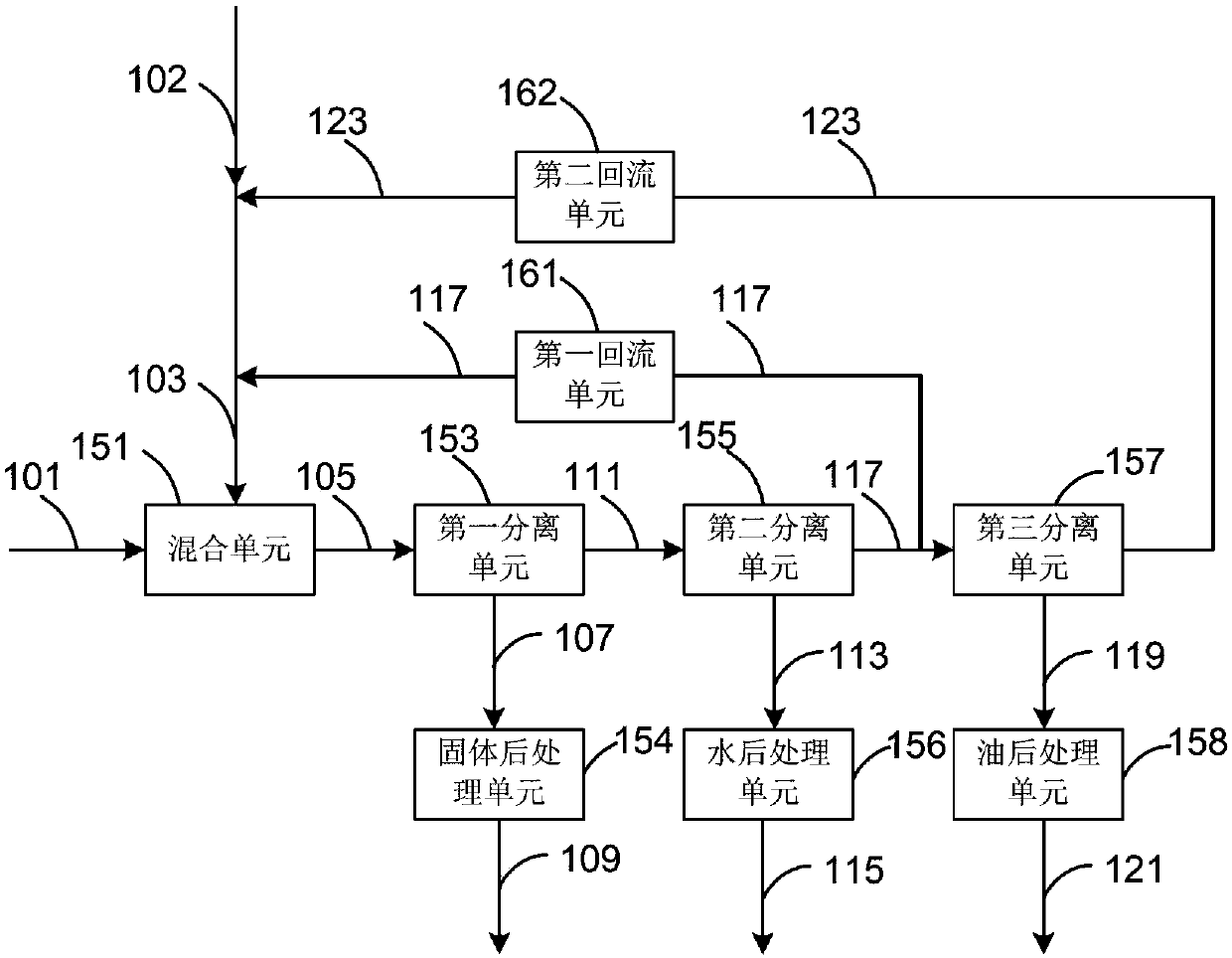

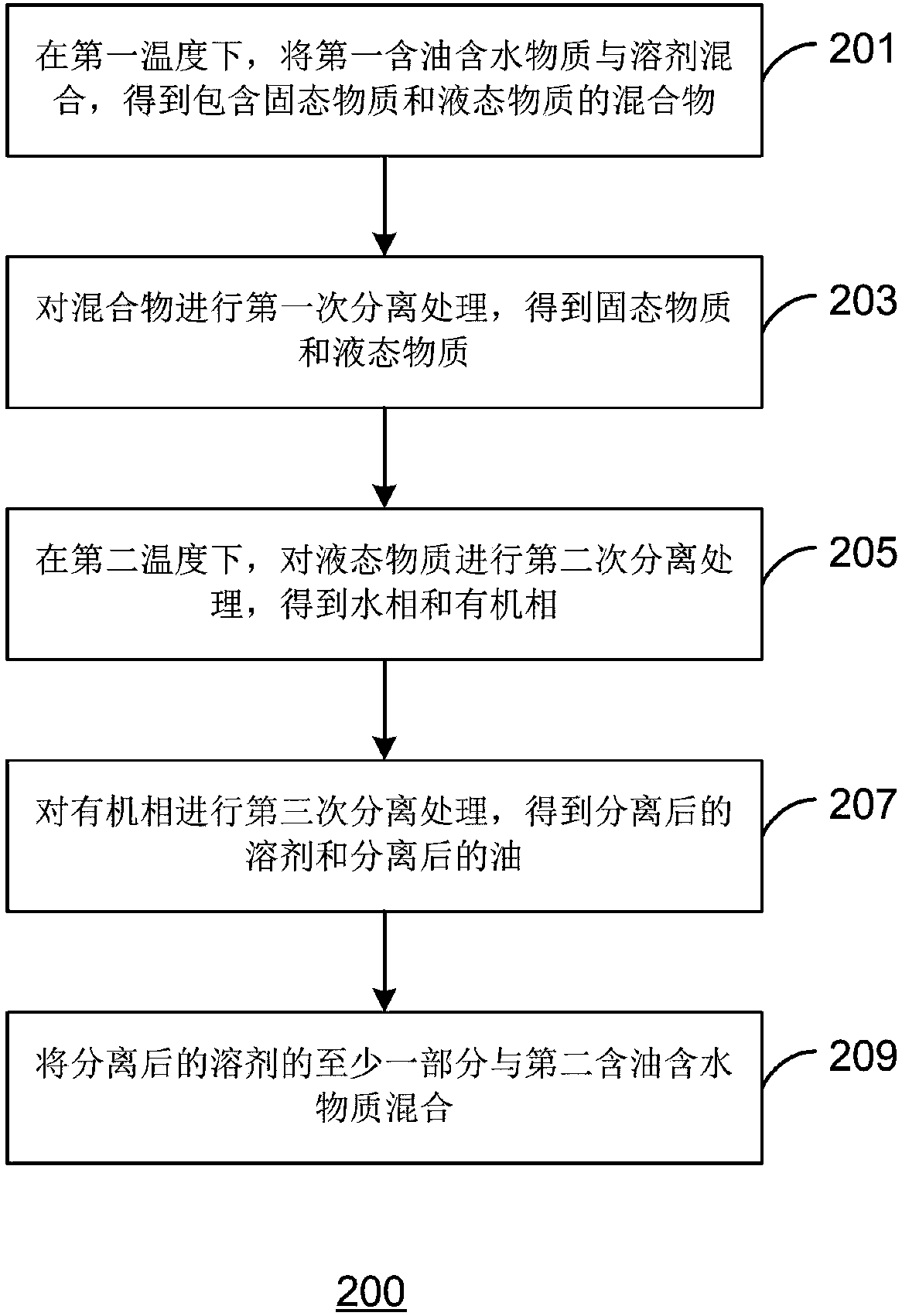

Method and apparatus for treating oil-containing water-containing material

PendingCN110395857AReduce pipe cloggingReduce riskSludge treatment by de-watering/drying/thickeningSolvent extractionLiquid stateSolvent

A method for treating an oil-containing water-containing material includes mixing the oil-containing water-containing material with a solvent at a first temperature to obtain a mixture containing a solid material and a liquid material; subjecting the mixture to a first time of separation to obtain the solid material and the liquid material; subjecting the obtained liquid material to a second timeof separation at a second temperature to obtain a water phase and an organic phase; and subjecting the obtained organic phase to a third time of separation to obtain the separated solvent and separated oil. The intersolubility between the solvent and water at the first temperature is higher than that at the second temperature so that water separation and recovery in the method do not undergo phaseconversion, but are achieved through liquid-liquid separation, thus effectively reducing energy consumption. The invention further relates to a corresponding apparatus.

Owner:北京中科环通工程科技有限公司

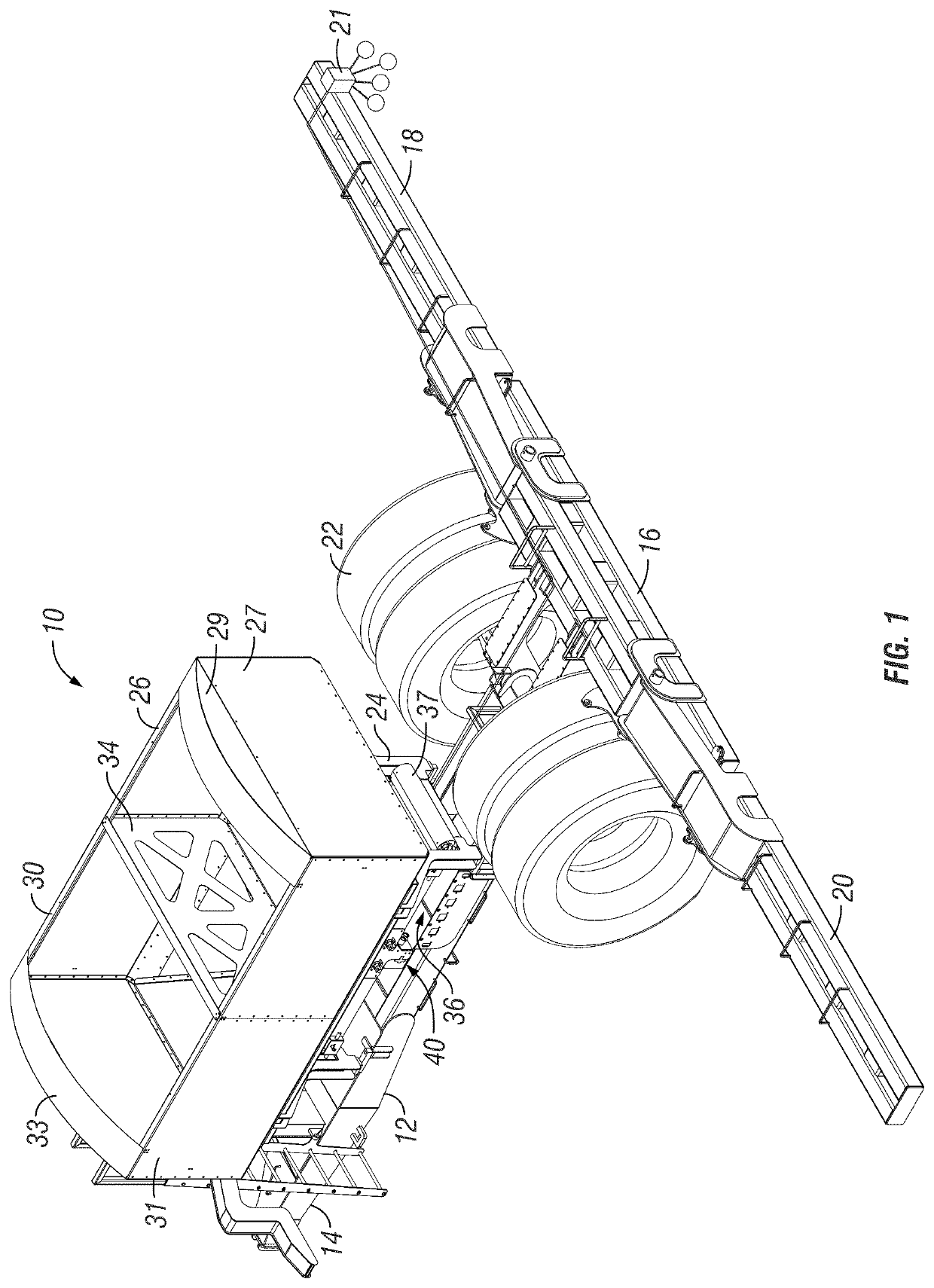

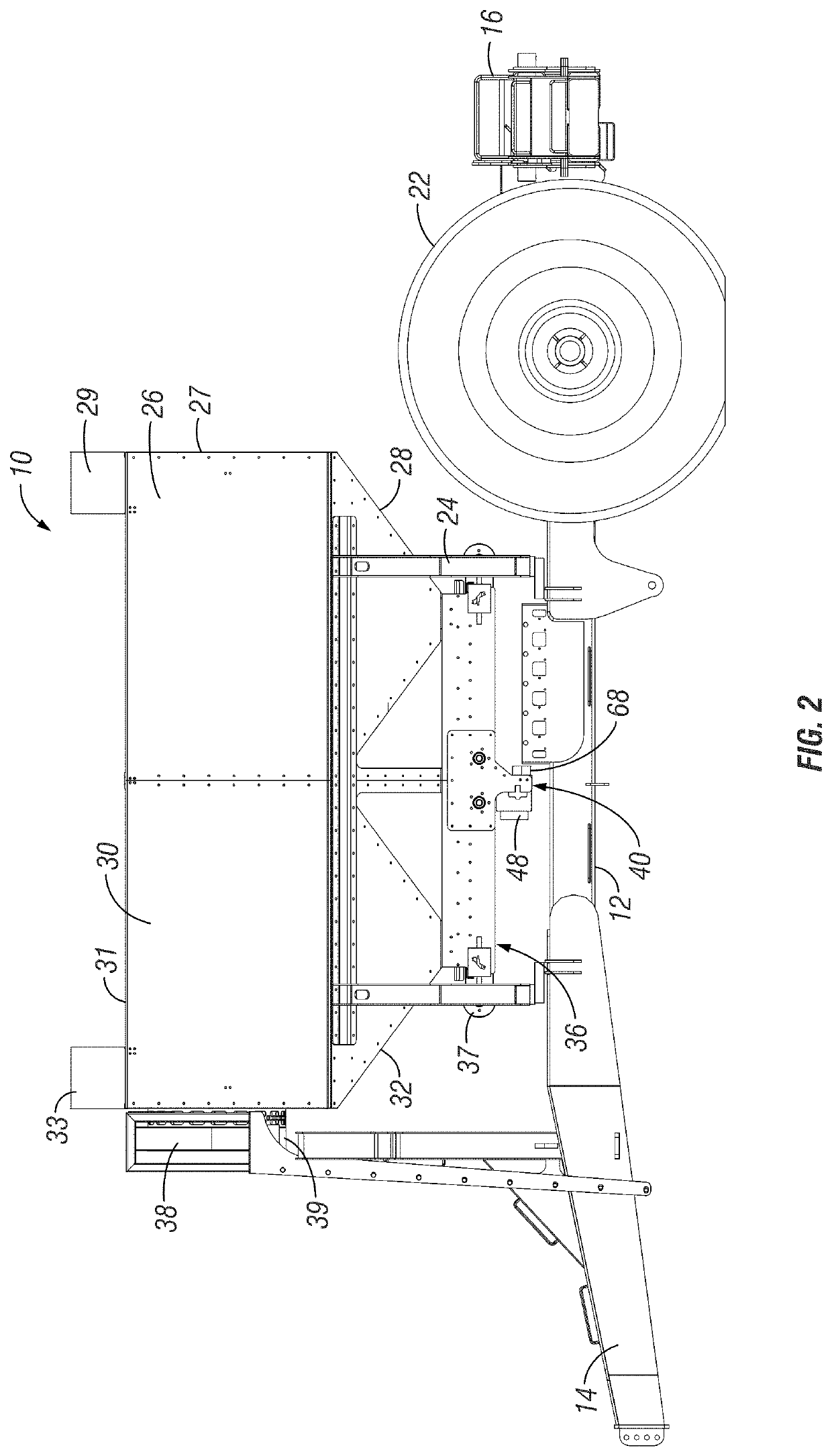

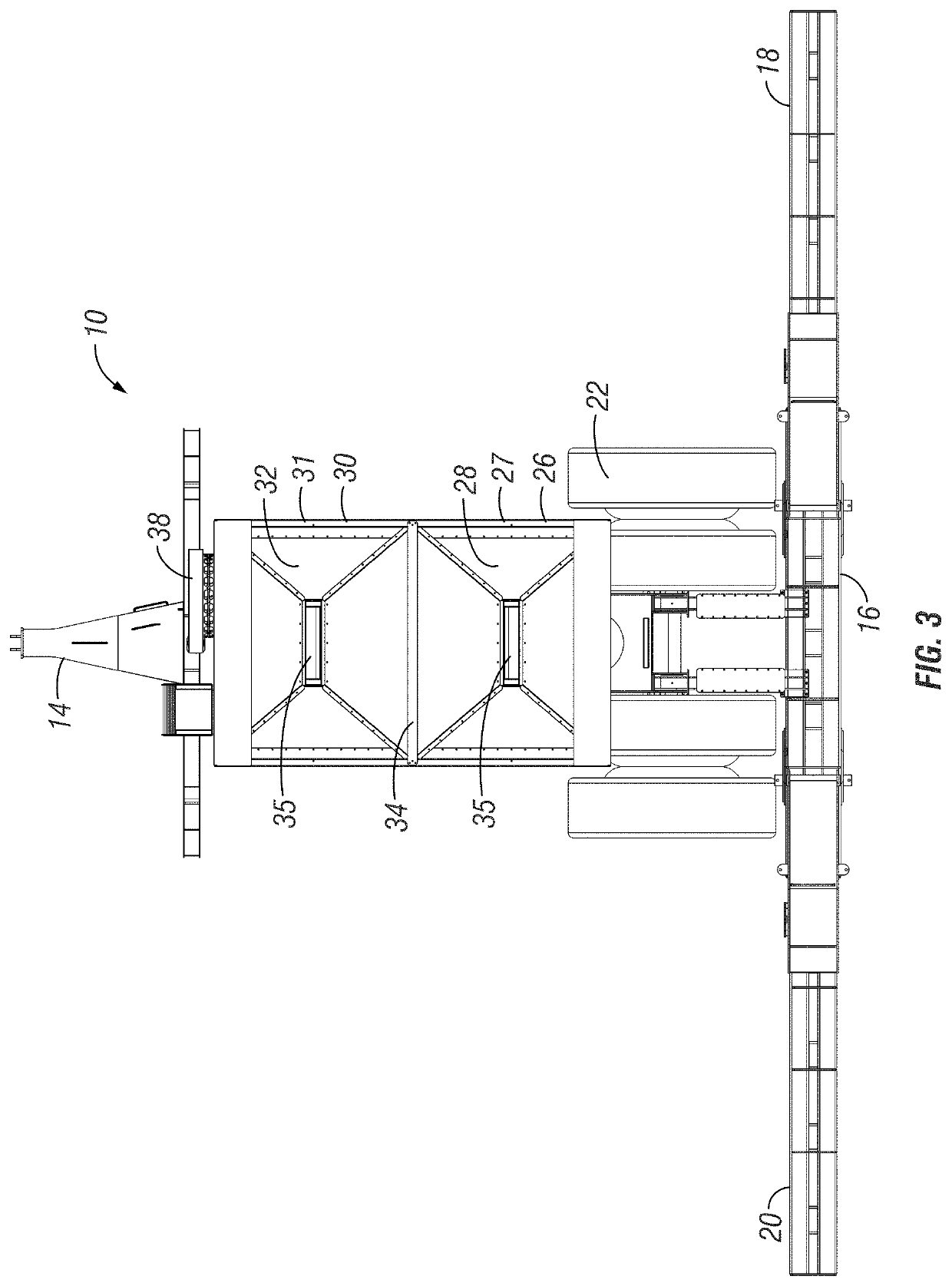

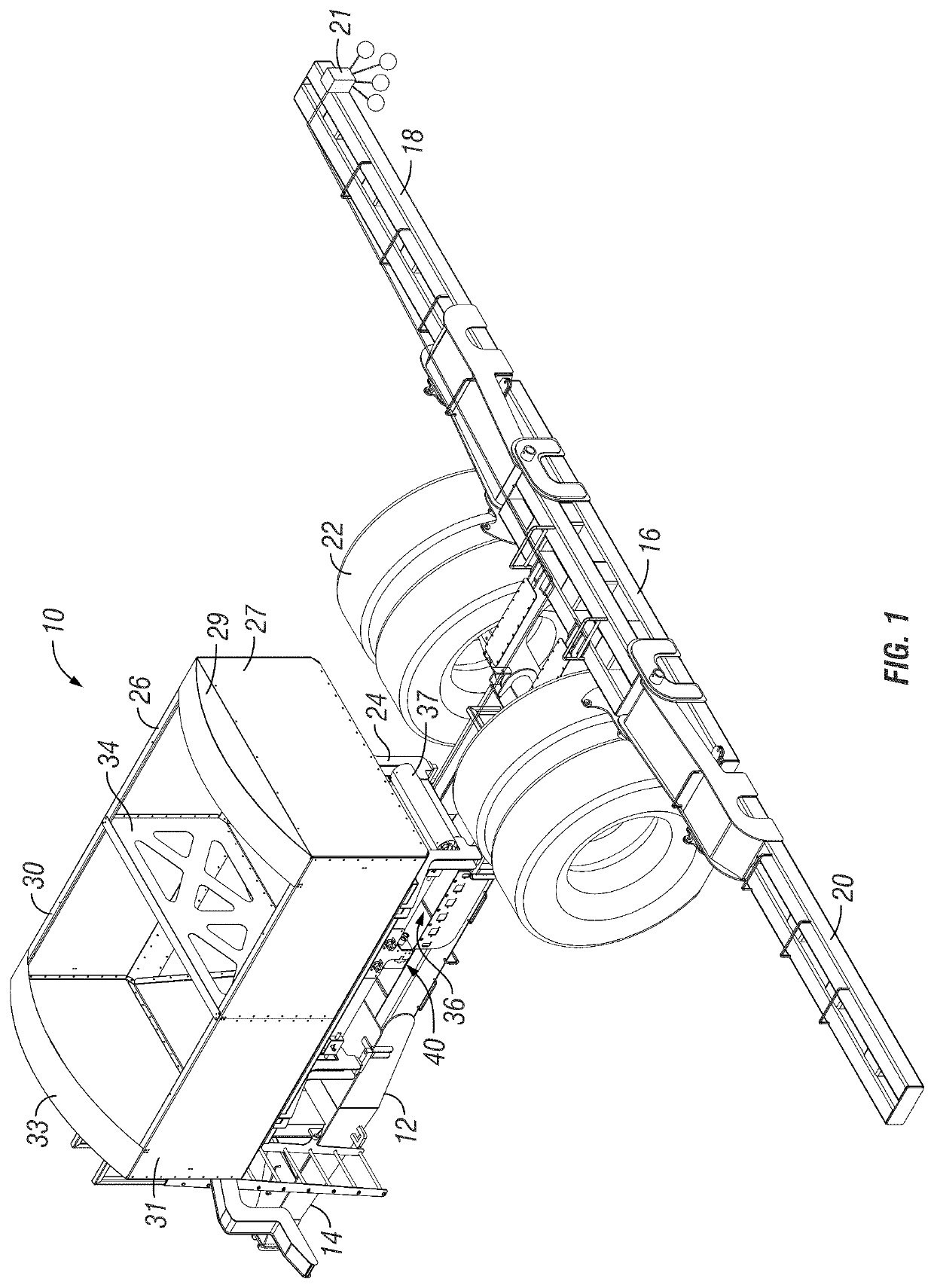

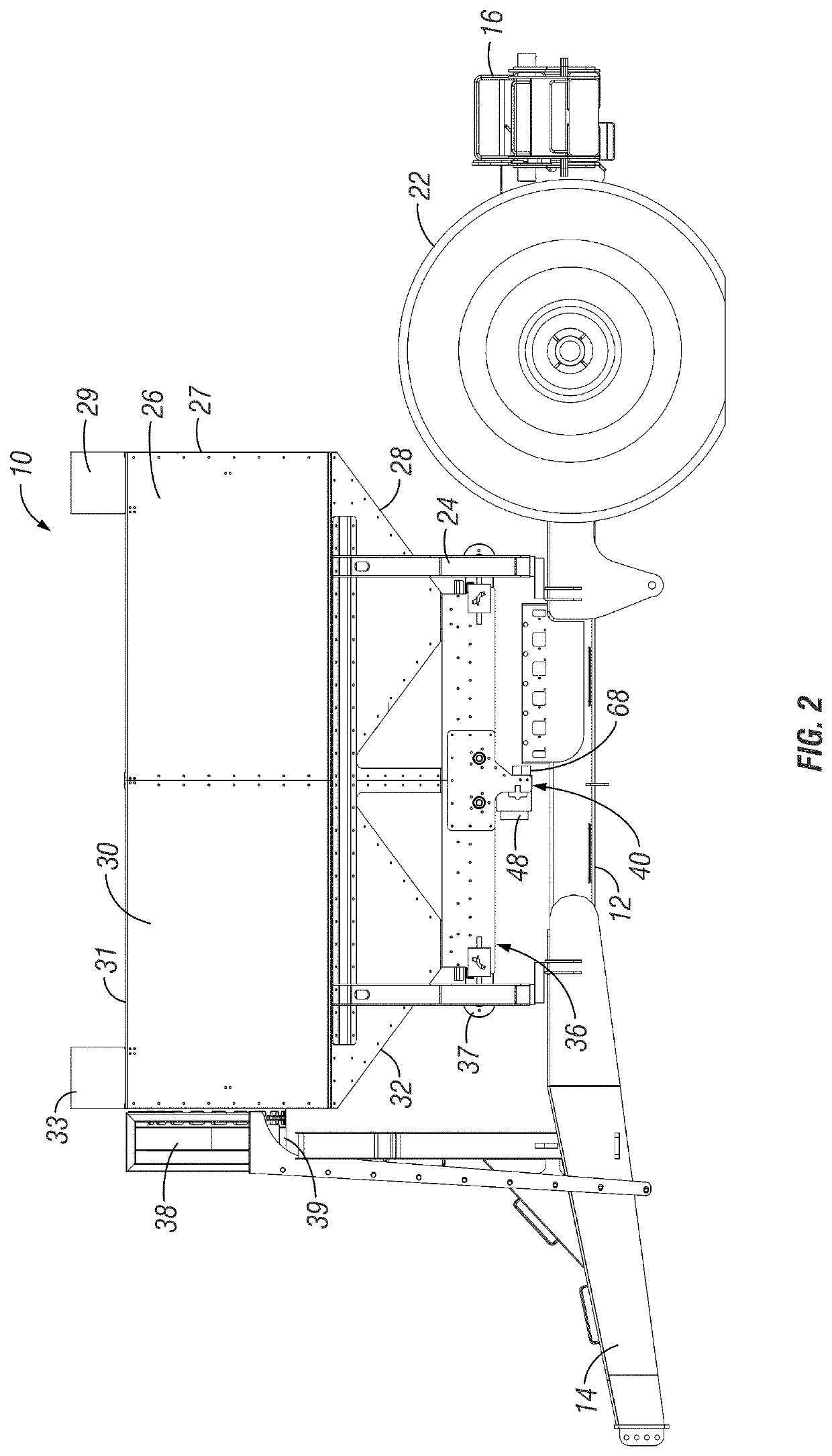

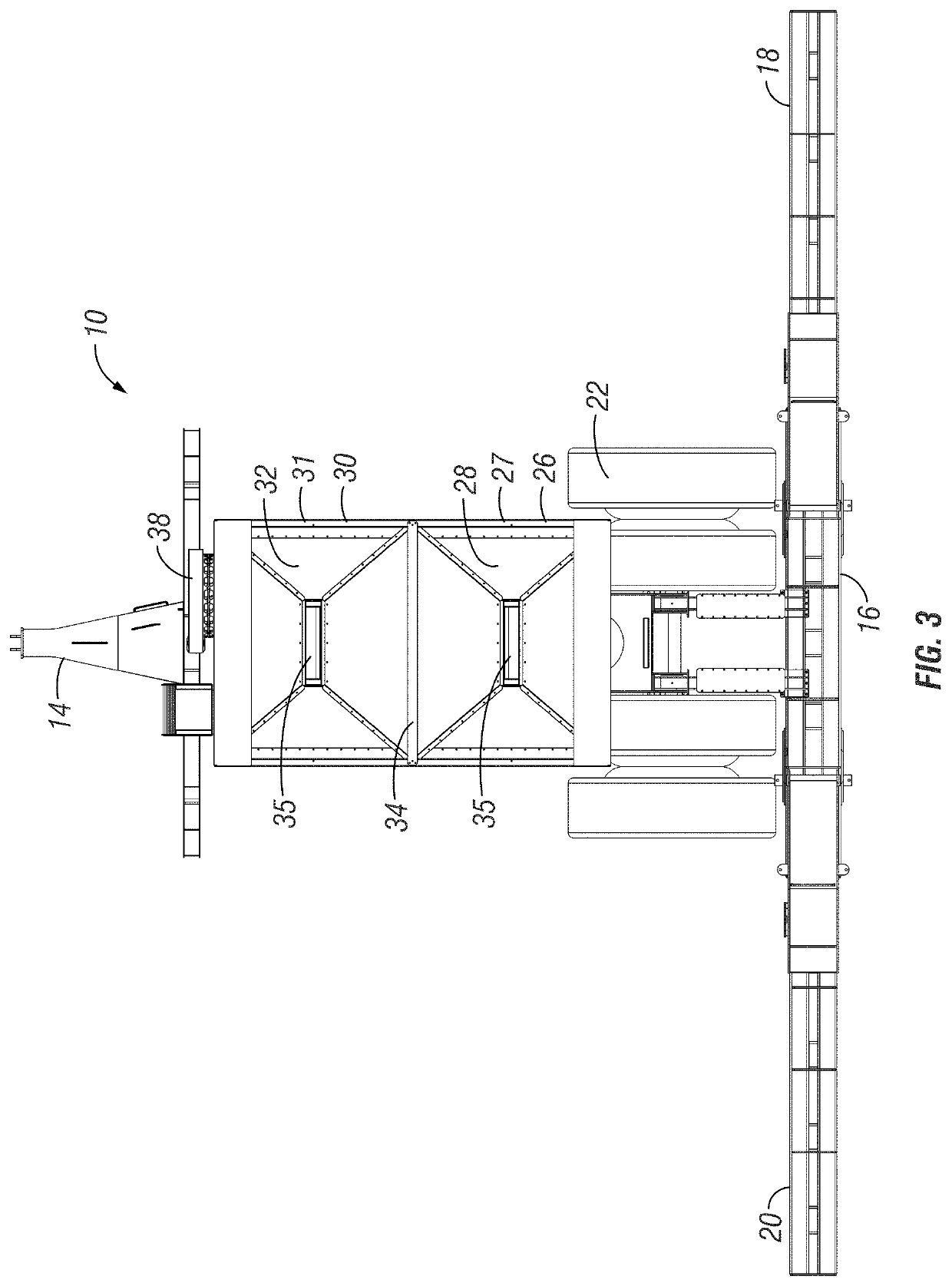

High flow fertilizer/air meter with secondary nozzling

ActiveUS11343958B2Reduce pipe cloggingIncrease volumePlantingLiquid seeding techniquesAgricultural scienceSuction force

Agricultural implements are used to transport material, such as inputs in the form of fertilizer, seed, treatment, or some combination thereof, to row units that apply the material to an area of a field. Metering systems can aid in metering and providing a desired amount of material, such as on-demand, to the row units. The metering systems move the metered material to the row units, such as with pneumatics or other fluids. The metering system can be improved by having primary and secondary nozzles of different sizes, which aid in increasing the speed of the fluid moving the material towards the row units. For example, a smaller diameter for the secondary nozzle will provide improved suction and air speed.

Owner:LYNX AG LLC

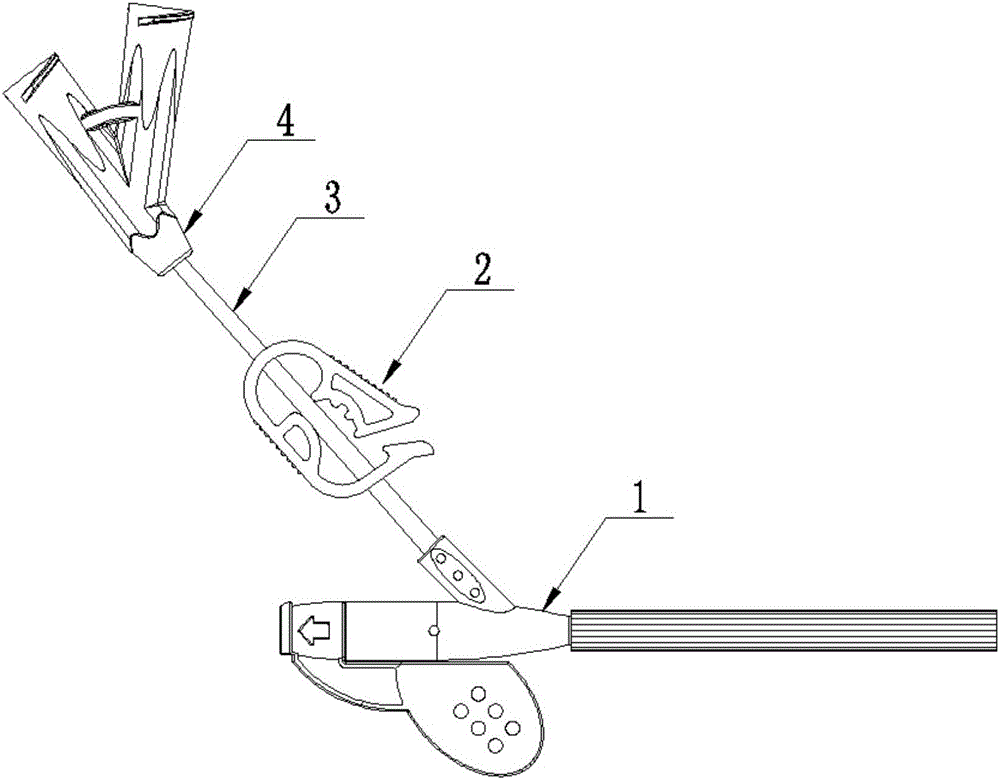

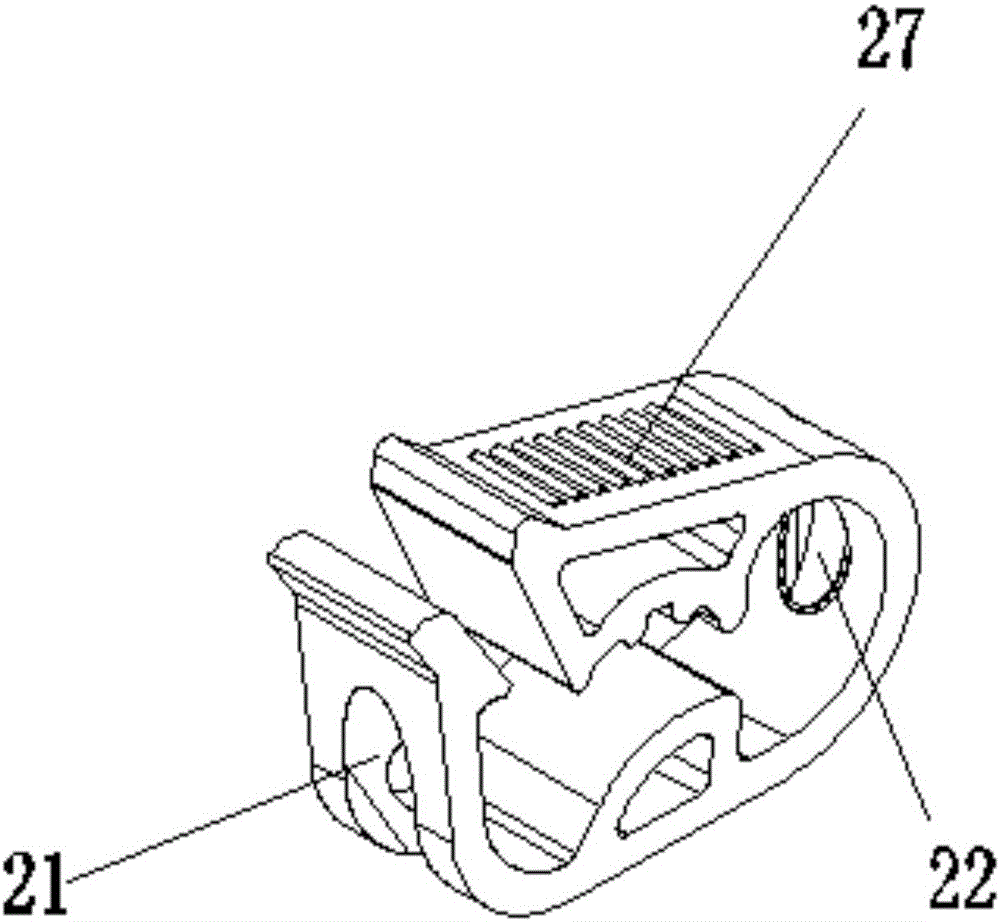

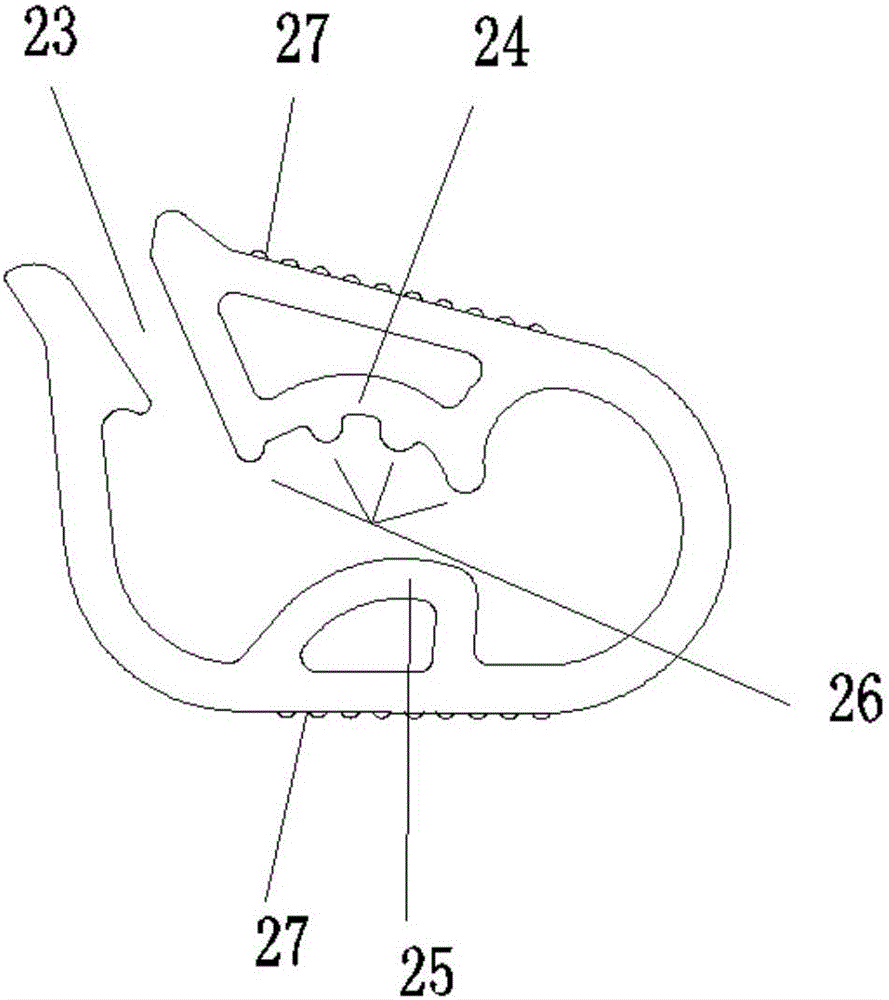

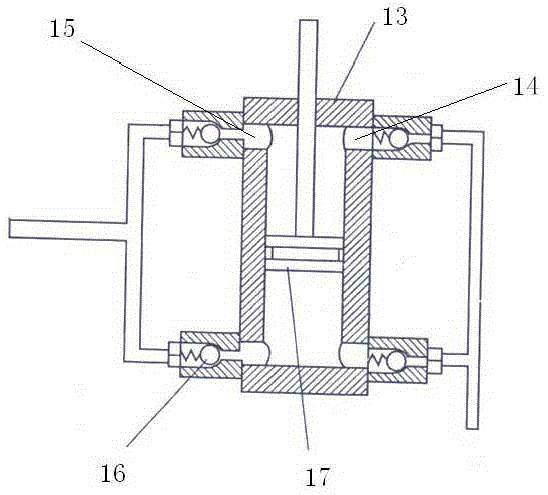

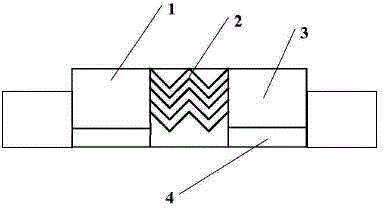

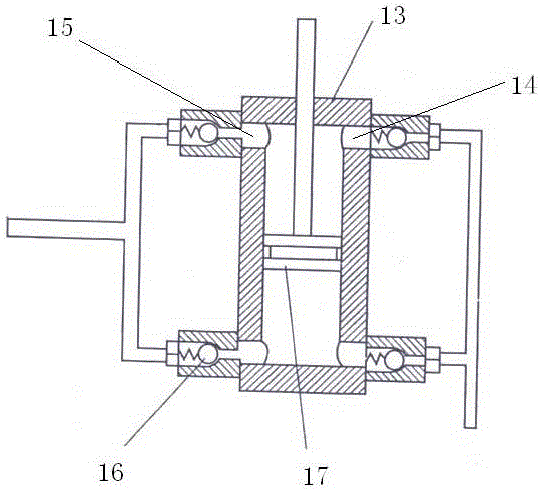

Pulse type positive-pressure single hand clamp remaining needle

PendingCN105797236AIncrease positive pressureReduce blood returnInfusion needlesPositive pressureEngineering

The invention relates to a pulse type positive-pressure single hand clamp remaining needle. The pulse type positive-pressure single hand clamp remaining needle comprises a sleeve base, an extension tube, a pulse type positive-pressure single hand clamp and a tee joint, wherein one end of the extension tube is connected with a side branch tube of the sleeve base, and the other end of the extension base is connected with the tee joint; the pulse type positive-pressure single hand clamp is located on the extension tube; through holes are formed in the front part and the rear part of the pulse type positive-pressure single hand clamp, the middle part of the pulse type positive-pressure single hand clamp is provided with a tube sealing clamping piece and a clamping base, and a press and touch part between the tube sealing clamping piece and the clamping base is provided with at least two cross beam type convex parts. According to the pulse type positive-pressure single hand clamp remaining needle disclosed by the invention, because the pulse type positive-pressure single hand clamp is adopted, the tube sealing clamping piece of the pulse type positive-pressure single hand clamp is enabled to be closely attached to the clamping base so as to clamp the extension tube, pulse type positive pressure which is generated by sequentially pressing the extension tube downwards by utilizing the at least two cross beam type convex parts is used for extruding liquid in a tube to enter the extension tube, the positive pressure of tube sealing liquid is increased, and blood return and tube blocking phenomena are greatly reduced.

Owner:GUANGDONG AIDI MEDICAL TECH CO LTD

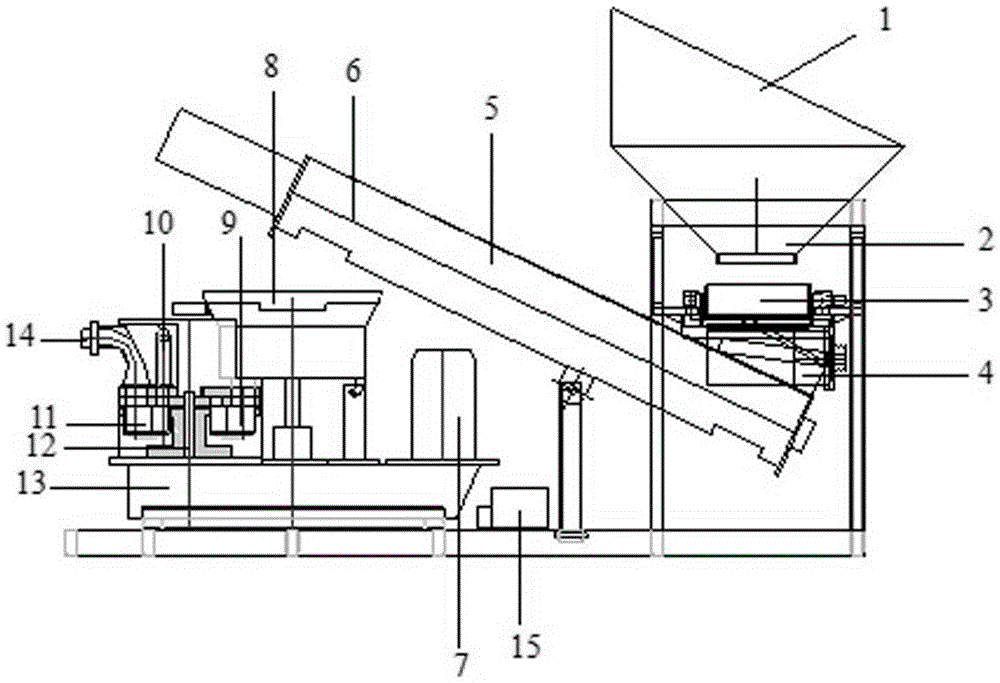

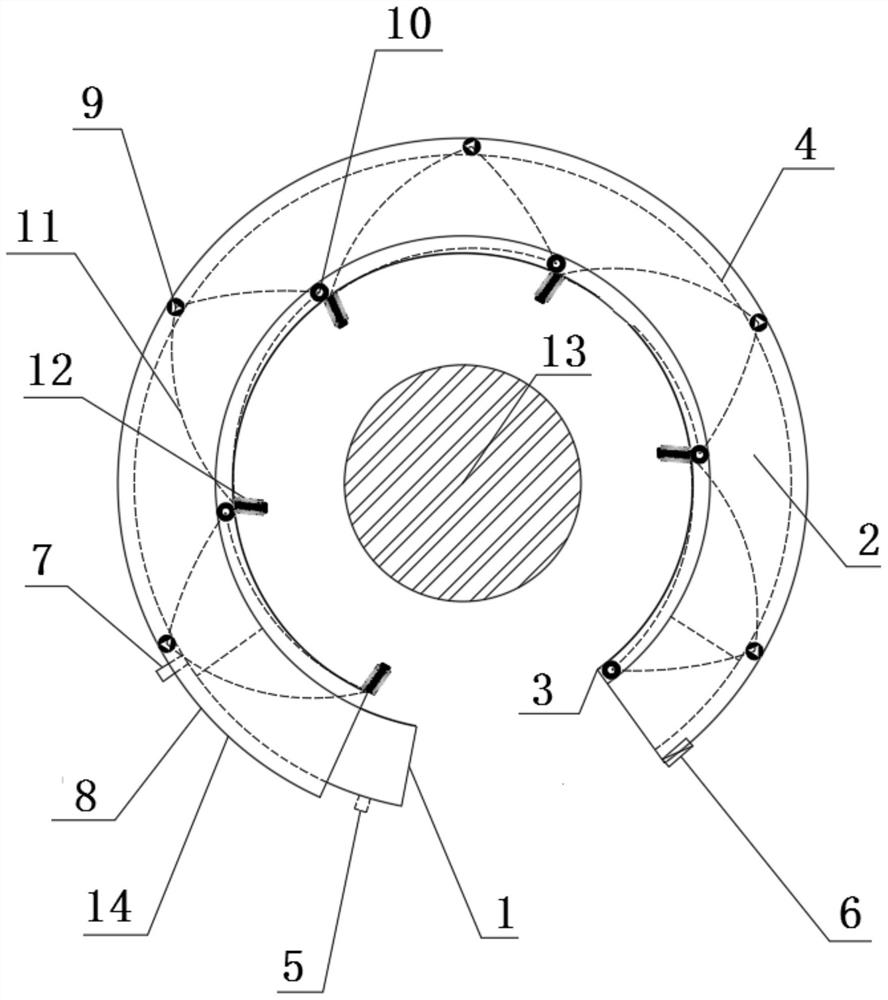

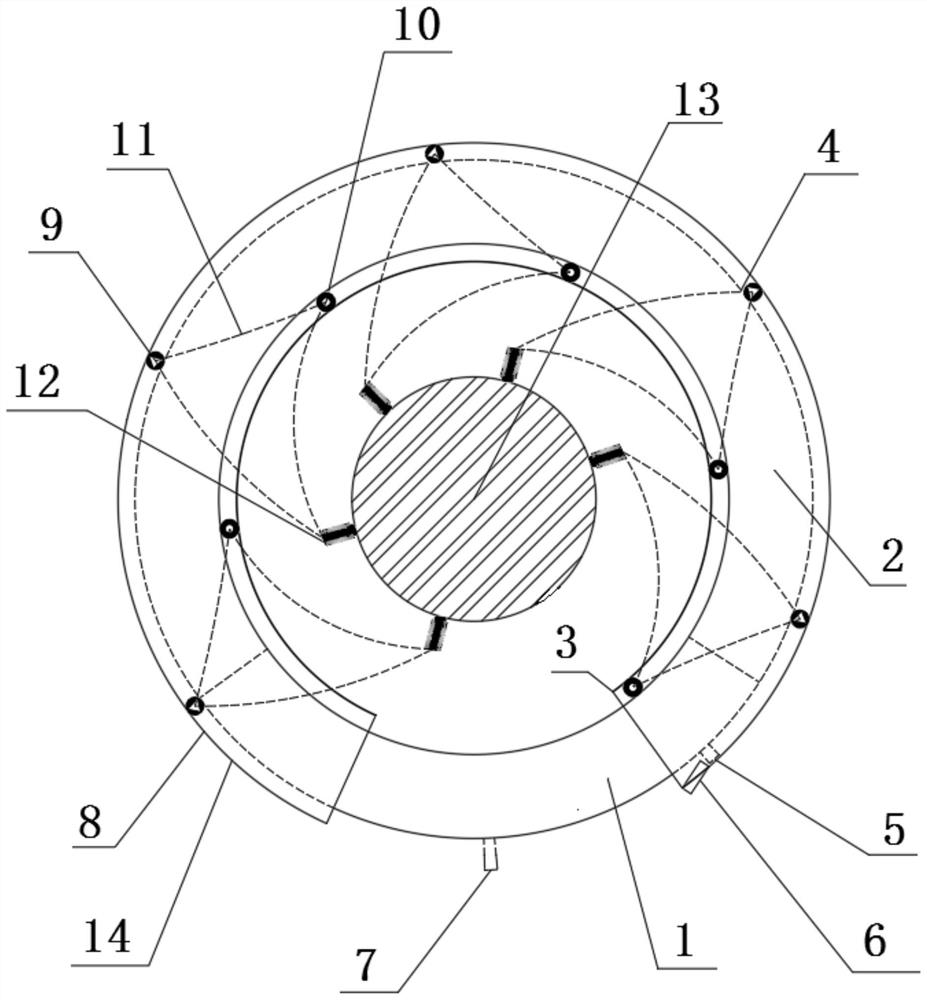

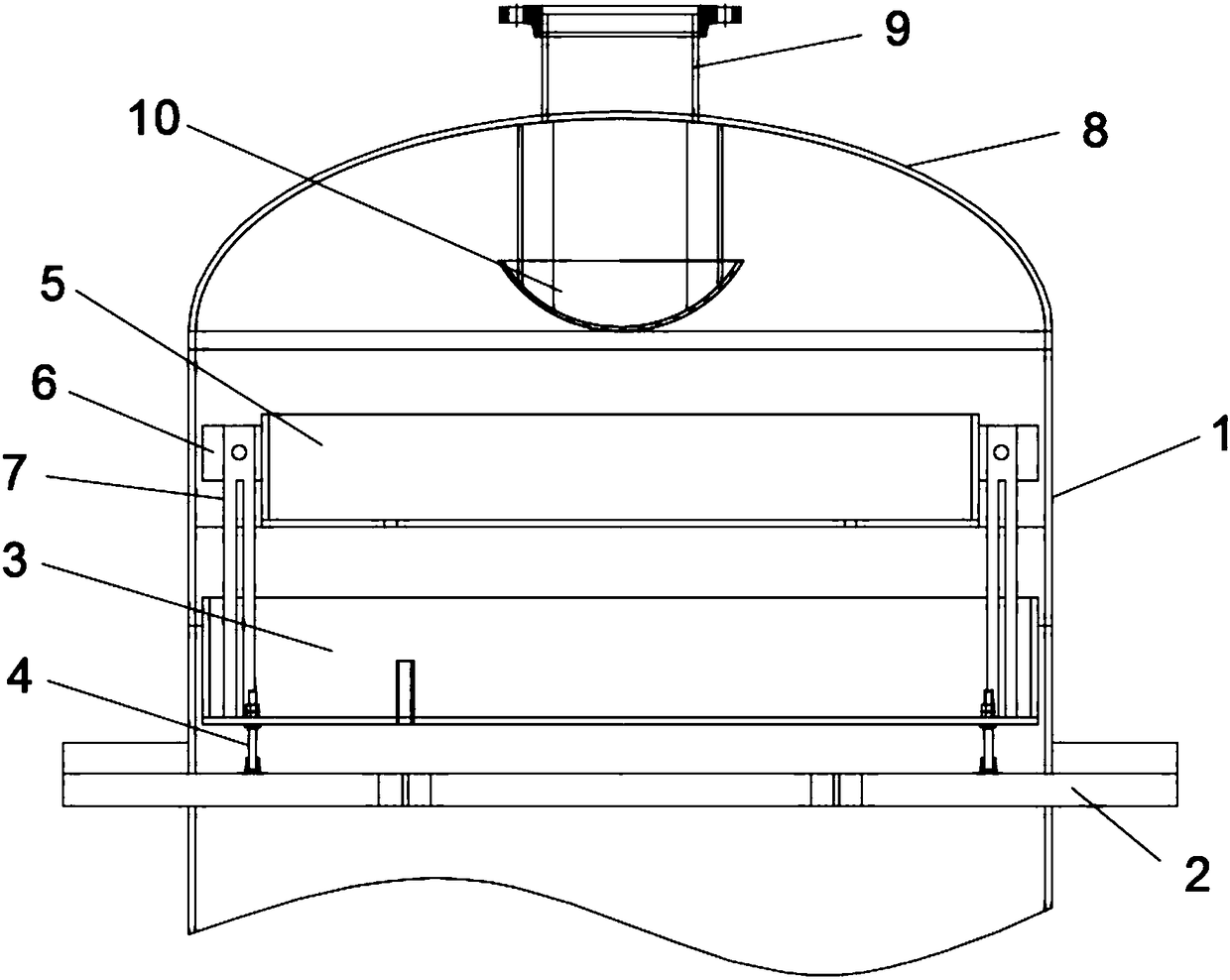

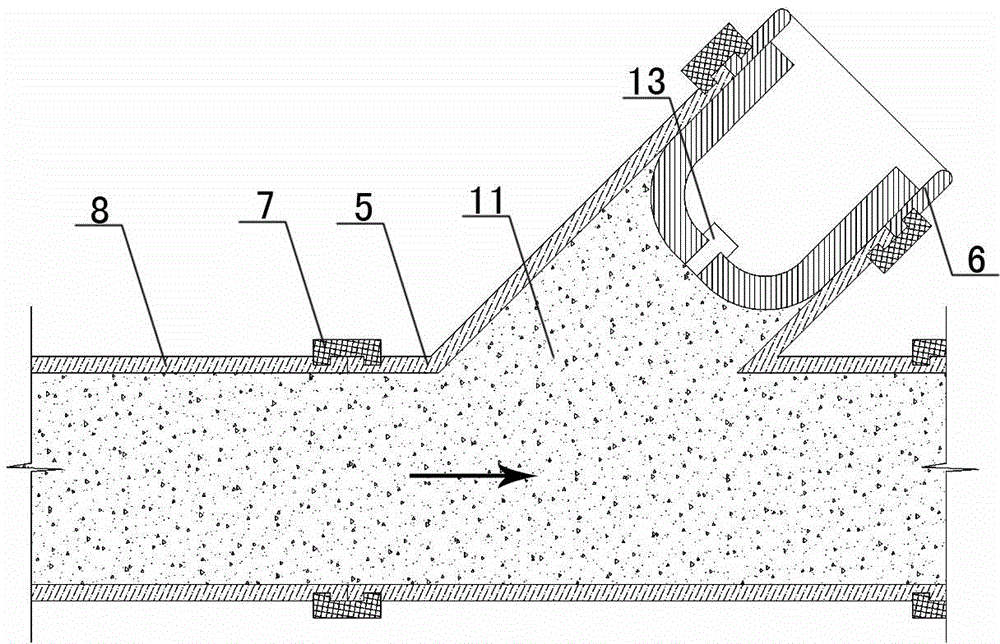

U-shaped cavity rotor type concrete spraying machine for dry spraying and wet spraying

InactiveCN105888695AHighlight substantiveSignificant progressUnderground chambersBuilding material handlingSprayerEngineering

The invention discloses a U-shaped cavity rotor type concrete spraying machine for dry spraying and wet spraying. The concrete spraying machine comprises a storage unit, wherein the storage unit is connected with a charging unit; a spraying unit is arranged at a lower part of the charging unit; a U-shaped cavity is formed in the spraying unit and is rotatably connected with a discharging unit; the discharging unit is provided with a liquid accelerating agent supply pump. The concrete spraying machine has the advantages that the structure is simple; during dry spraying, powder accelerating agents are quantitatively added to a powder accelerating agent stock bin above a charging machine, the powder accelerating agents and concrete mixes are transported to a sprayer for watering together, and a mixture is sprayed to a sprayed surface; during wet spraying, liquid accelerating agents are mixed with wet concrete at the sprayer via a supply pump, the mixture is sprayed to the sprayed surface, thus dry spraying and wet spraying are realized, and the problems of a lot of dust and large rebound quantity of dry spraying concrete can be effectively solved; meanwhile the problems of complex wet spraying process, difficulty in washing and high possibility of plugging can be solved.

Owner:北京新桥技术发展有限公司 +1

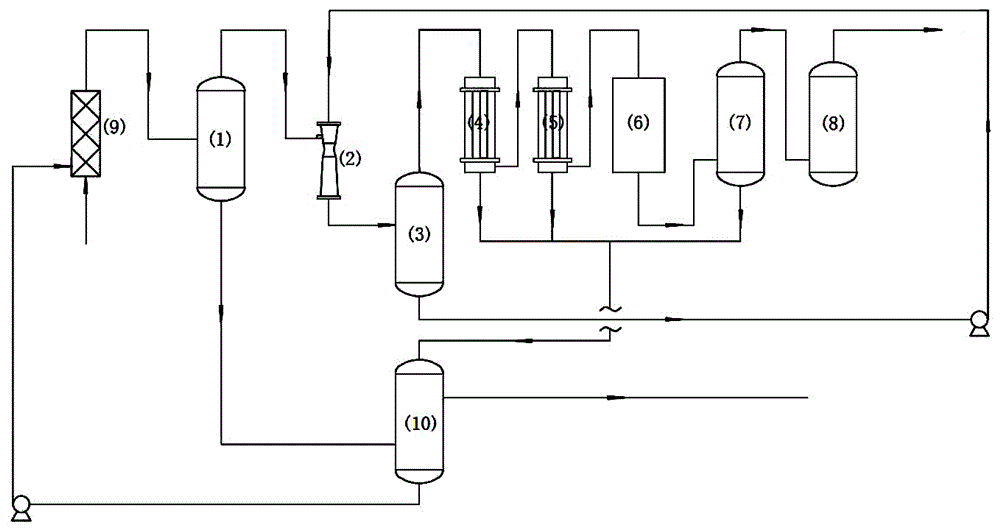

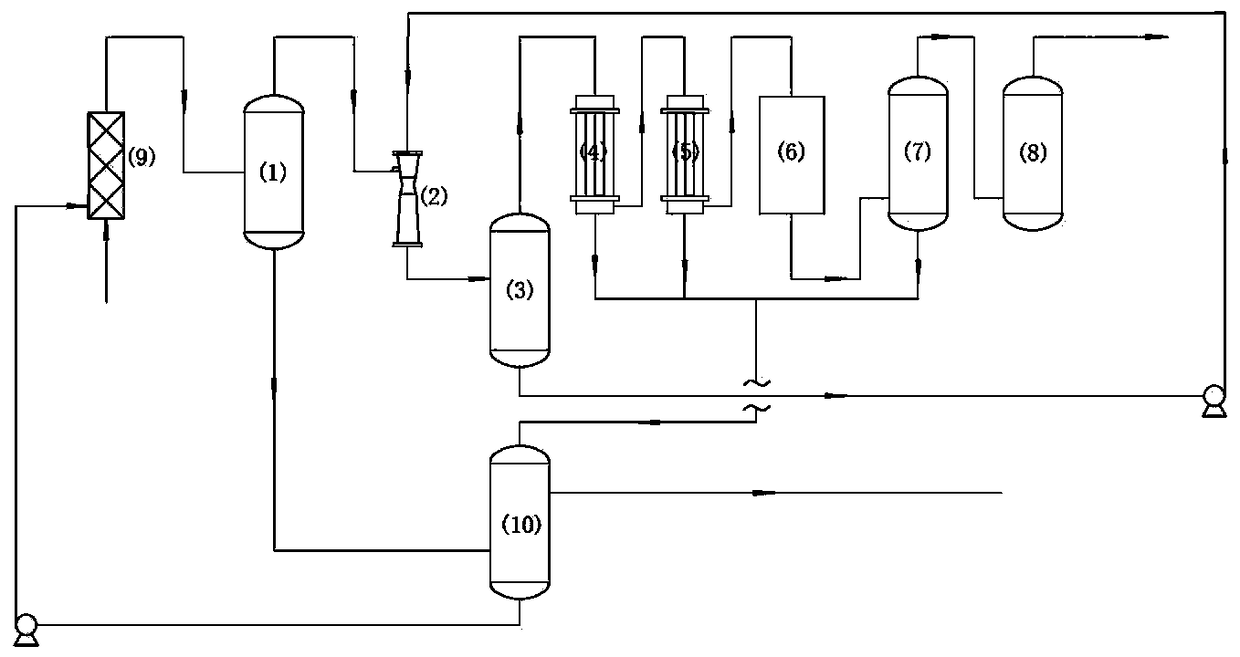

Hydrolysis technology and device for concentrated hydrochloric acid

ActiveCN106317095AInhibition of local excessImprove ring yieldSilicon organic compoundsHydrolysateAcid hydrolysis

The invention provides a concentrated-acid hydrolysis technology. The concentrated-acid hydrolysis technology includes the steps that after hydrolysis raw materials of dimethyldichlorosilane and saturated concentrated hydrochloric acid are reacted in a static mixer, the obtained gas-liquid mixture enters a gas-liquid separation tank A, gas recovered out of the top of the gas-liquid separation tank A, carried dimethyldichlorosilane and carried hydrolysate liquid drops enter a venturi mixer from the side face, the gas-liquid mixture deeply mixed in a main concentrated-hydrochloric-acid fluid enters a gas-liquid separation tank B, concentrated hydrochloric acid recovered out of the bottom of the gas-liquid separation tank B is returned to the venturi mixer through a material pump, the gas recovered out of the top sequentially enters a primary condenser and a secondary condenser, gas-liquid mixture condensed by the primary condenser and the secondary condenser enters a collecting device to collect liquid drops, and after the liquid drops are removed through a demister, the product is delivered to a chloromethane synthesis working section through a buffering tank. By means of the concentrated-acid hydrolysis technology, in the concentrated-acid hydrolysis process, the insufficient reacting problem, the low efficiency problem and the like caused when materials are unevenly mixed are solved, and meanwhile the problems that as gas and liquid are carried, a pipe and a device are blocked are solved.

Owner:HUBEI XINGFA CHEM GRP CO LTD

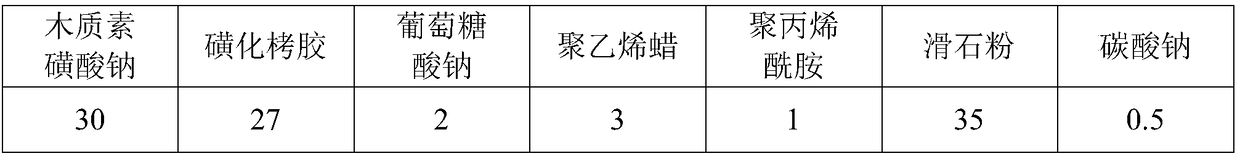

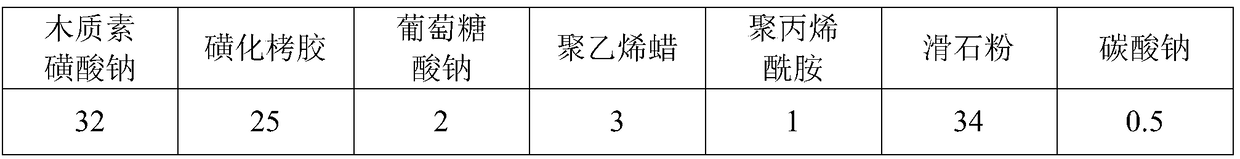

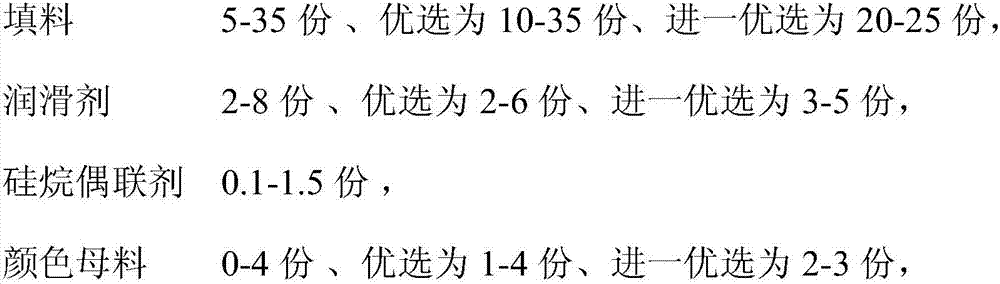

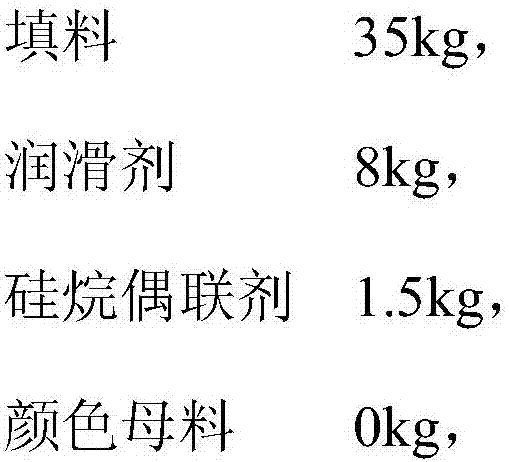

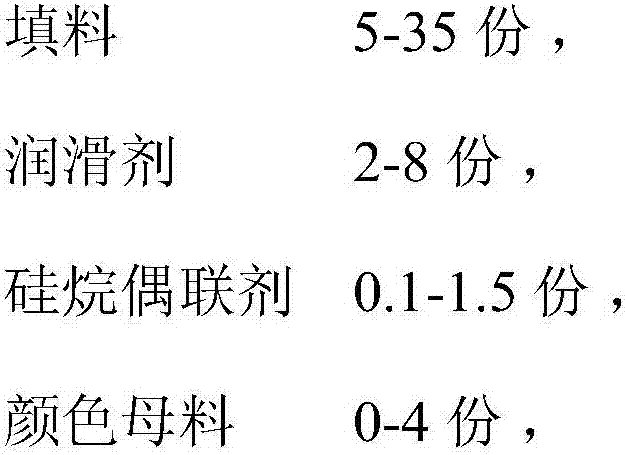

Pumping agent for hydraulic reclamation of silt solidified soil and preparation method thereof

InactiveCN109502936AIncrease moisture contentIt can have good fluidity under the condition of moisture contentFixation/solidifcation sludge treatmentSulfonateLignosulfonates

The invention discloses a pumping agentfor blowing silt solidified soil and a preparation method thereof. The provided pumping agent is compounded by lignin sulfonate, sulfonated tannin extract, sodium gluconate, polyethylene wax, polyacrylamide, talc and sodium carbonate. The weight part of each component is: 30 to 35 parts of the lignin sulfonate, 25 to 35 parts of the sulfonated tannin extract,2 to 4 parts of the sodium gluconate, 3 to 4 parts of the polyethylene wax, 1 to 2 parts of the polyacrylamide, 30 to 35 parts of the talc and 0.5 to 1 parts of the sodium carbonate. The pumping agent for hydraulic reclamation of silt solidified soil provided by the invention has the advantages of low addition amount, simple adding process and good environmental protection, and the addition of the pumping agent can significantly improve the fluidity, lubricity and stability of the fresh silt solidified soil, makes the low-water content fresh silt solidified soil (water content of 100 percentto 150 percent) to maintain good fluidity within 2h, ensures the late strength of the solidified soil and prolongs the pumpable time of the silt solidified soil, which helps to improve the efficiencyand quality of silt solidified soil hydraulic reclamation construction, and has obvious technical, economic and environmental advantages.

Owner:JIANGSU NATURE WAY TECH

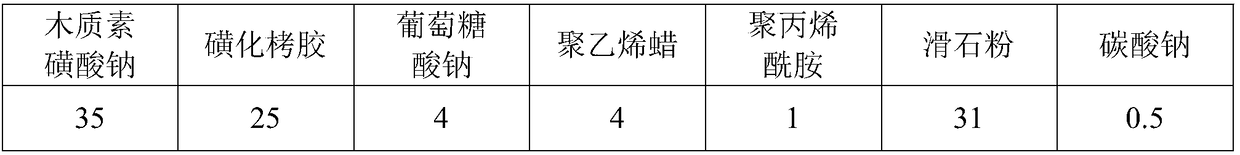

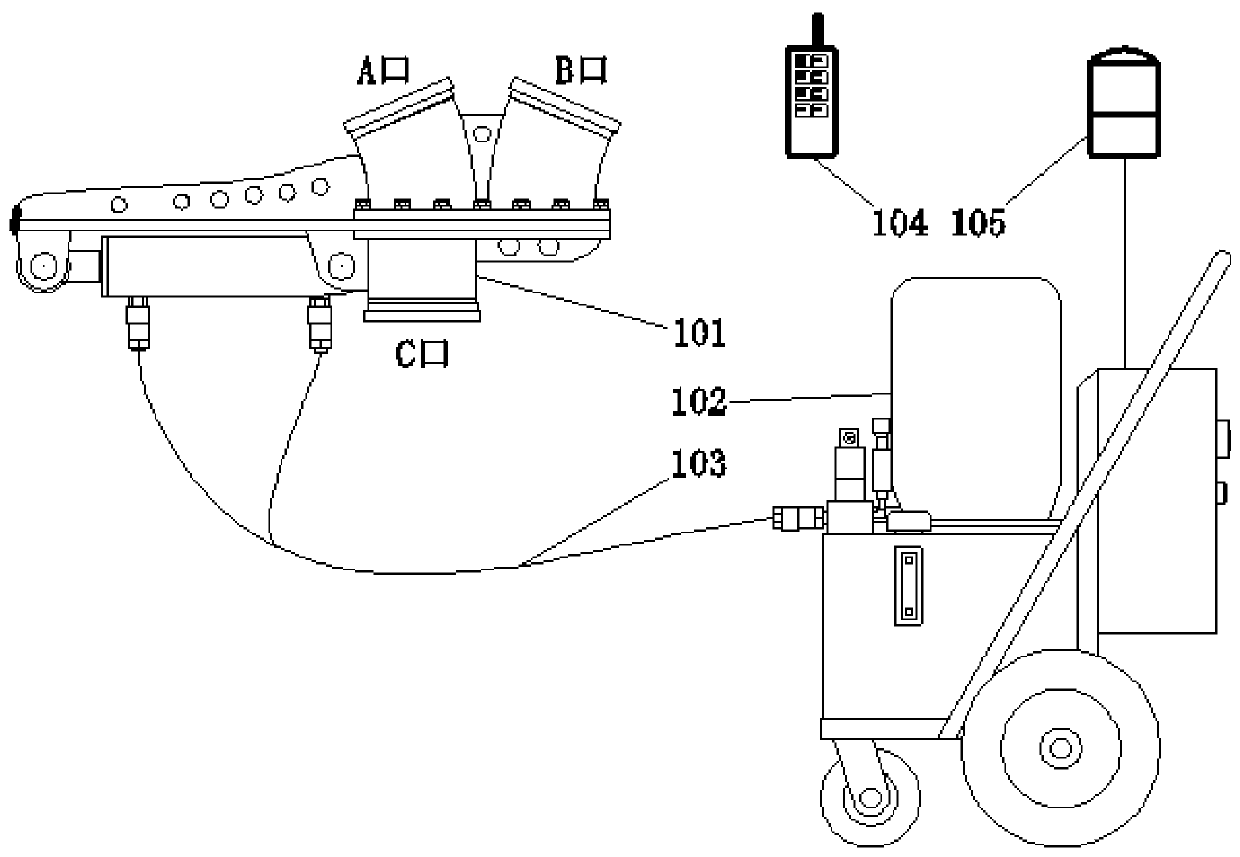

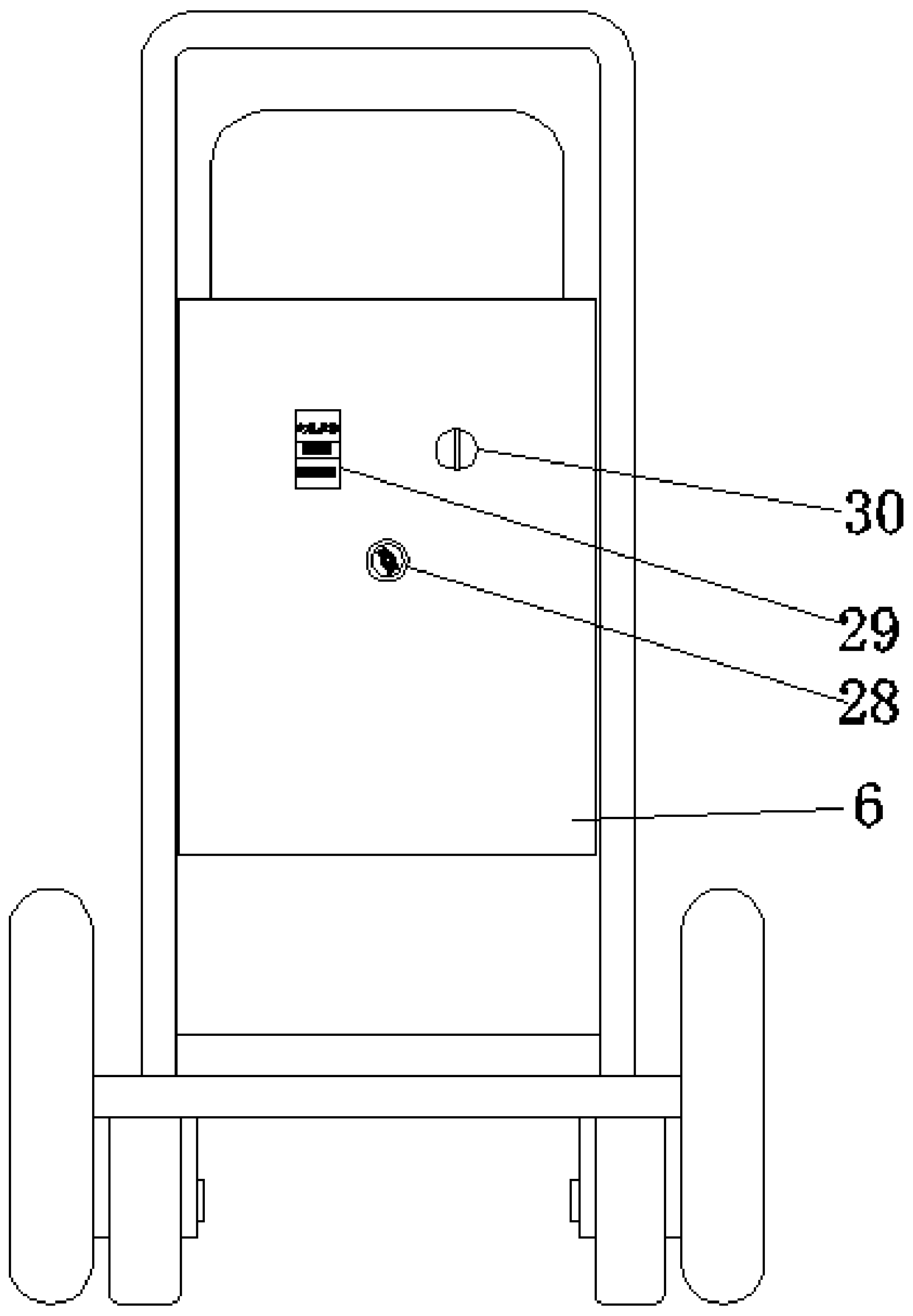

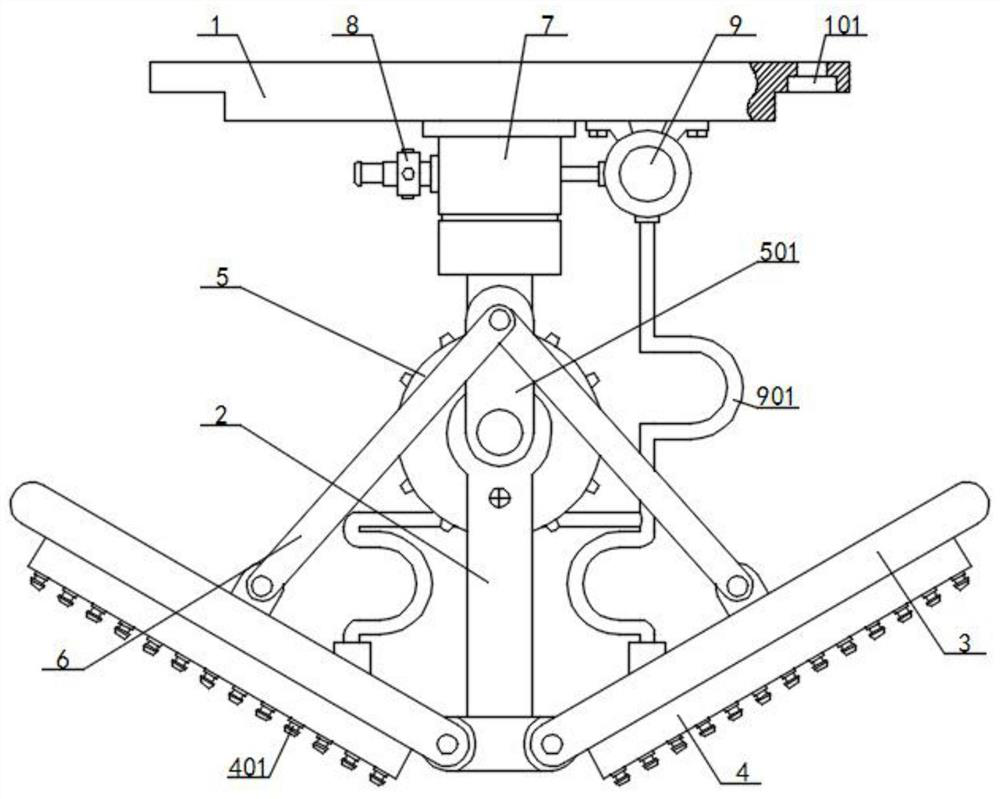

Remote-control sliding-type pulp distributor

InactiveCN109798134AReduce labor intensityReduce pipe cloggingFluid-pressure actuator safetyPortable framesElectricityRemote control

The invention discloses a remote-control sliding-type pulp distributor which comprises a sliding-type pulp distributor body, a movable remote-control pump station, a remote-control unit and an acousto-optic alarm. The sliding-type pulp distributor body and the movable remote-control pump station are connected with a hydraulic oil pipe with a quick joint, the acousto-optic alarm is arranged outsidethe movable remote-control pump station and electrically connected with the same through a cable, and the remote-control unit remotely controls the movable remote-control pump station through a radiosignal and controls running of the same to realize reliable switching of the sliding-type pulp distributor body. The remote-control sliding-type pulp distributor is reasonable in design, convenient and quick in mounting and demounting, safe, reliable, high in universality and easy in realizing function expanding.

Owner:邱城彬

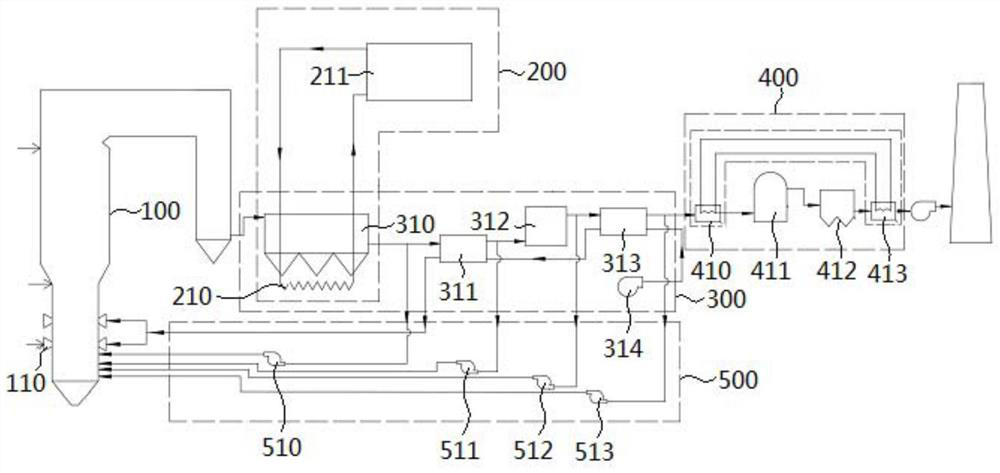

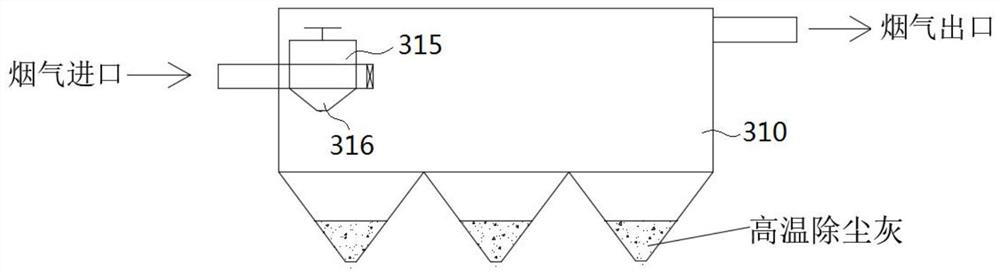

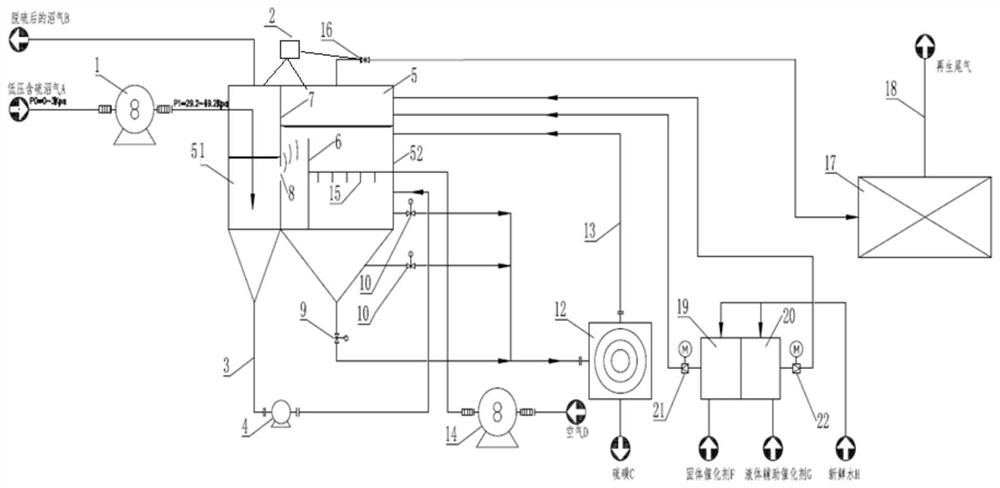

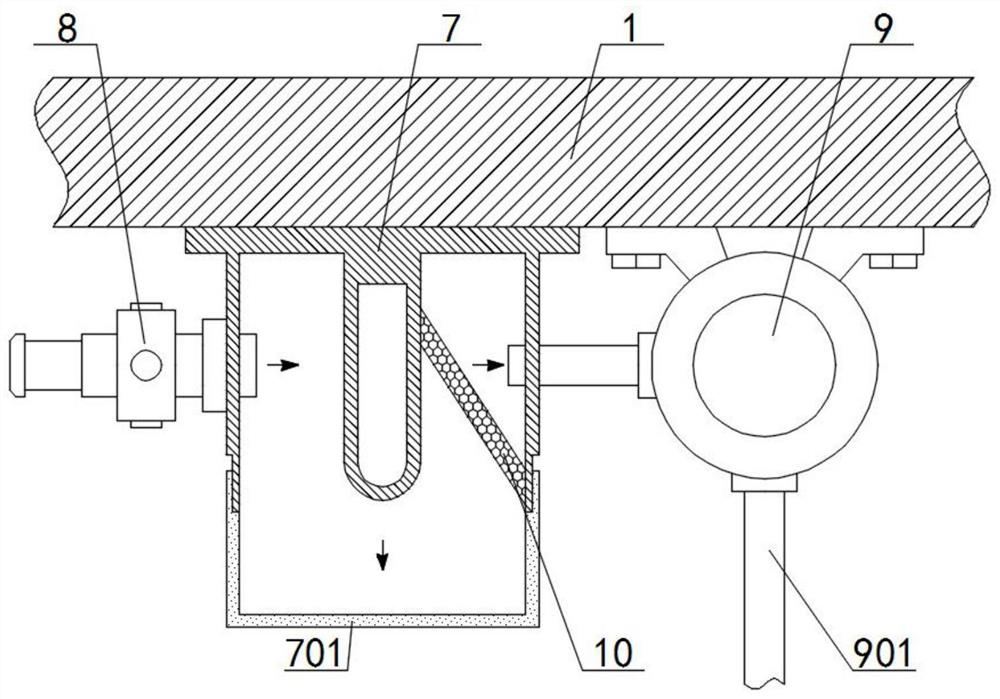

Ultra-low emission integrated system of supercritical carbon dioxide coal-fired boiler

PendingCN112066403AExtended service lifeReduce pipe cloggingIndirect carbon-dioxide mitigationIncinerator apparatusFlue gasLow emission

The invention discloses an ultra-low emission integrated system of a supercritical carbon dioxide coal-fired boiler, and belongs to the technical field of ultra-low emission. The system comprises a boiler unit and a dust removal and denitration unit, wherein the boiler unit comprises an ammonia spraying combustor; the dust removal and denitration unit comprises a high-temperature dust remover, a high-temperature air preheater, an SCR denitration reactor, a low-temperature air preheater and an air blower which are sequentially connected; the high-temperature dust remover is arranged in front ofthe high-temperature air preheater; and an adjustable constant pressure valve is additionally arranged on the inner side of an inlet of the high-temperature dust remover and used for maintaining theflue gas pressure when the high-temperature dust remover normally works. The high-temperature dust remover is arranged in front of the high-temperature air preheater, the service life of the high-temperature air preheater can be greatly prolonged when flue gas subjected to dust removal passes through the high-temperature air preheater, and meanwhile the problem of pipeline blockage of the high-temperature air preheater is solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

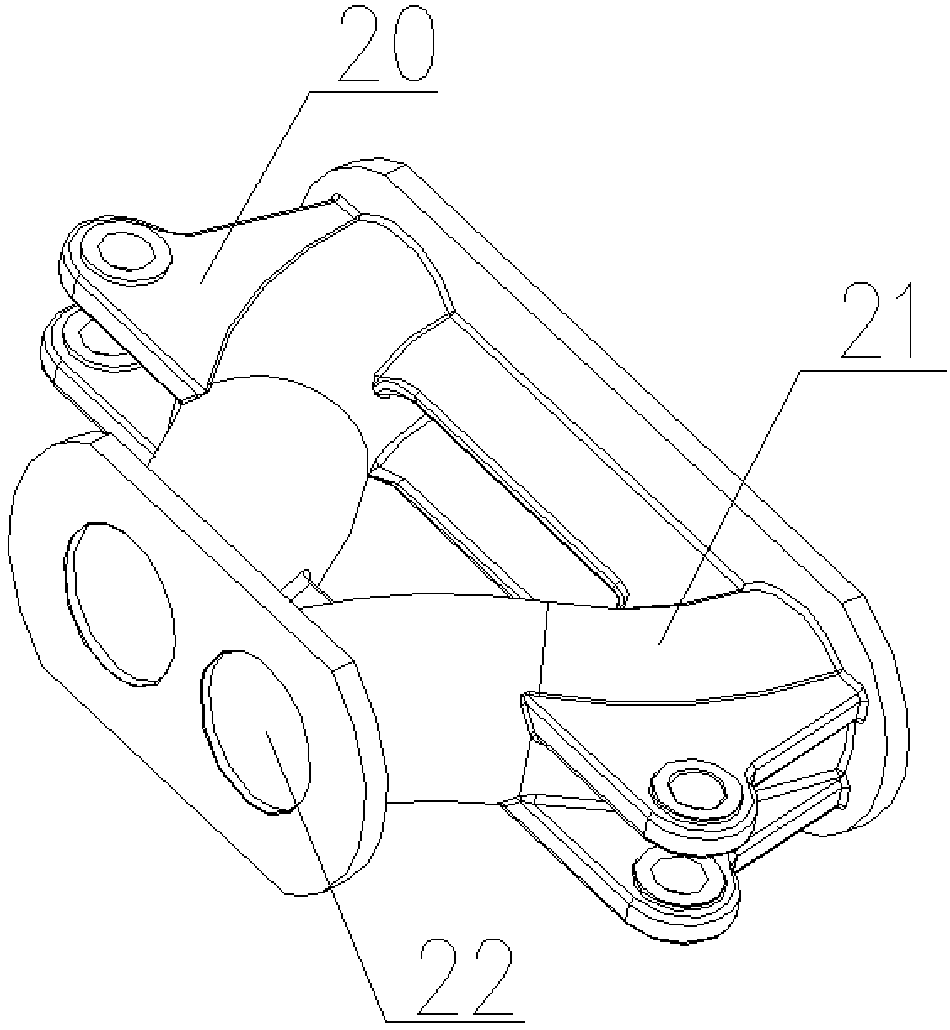

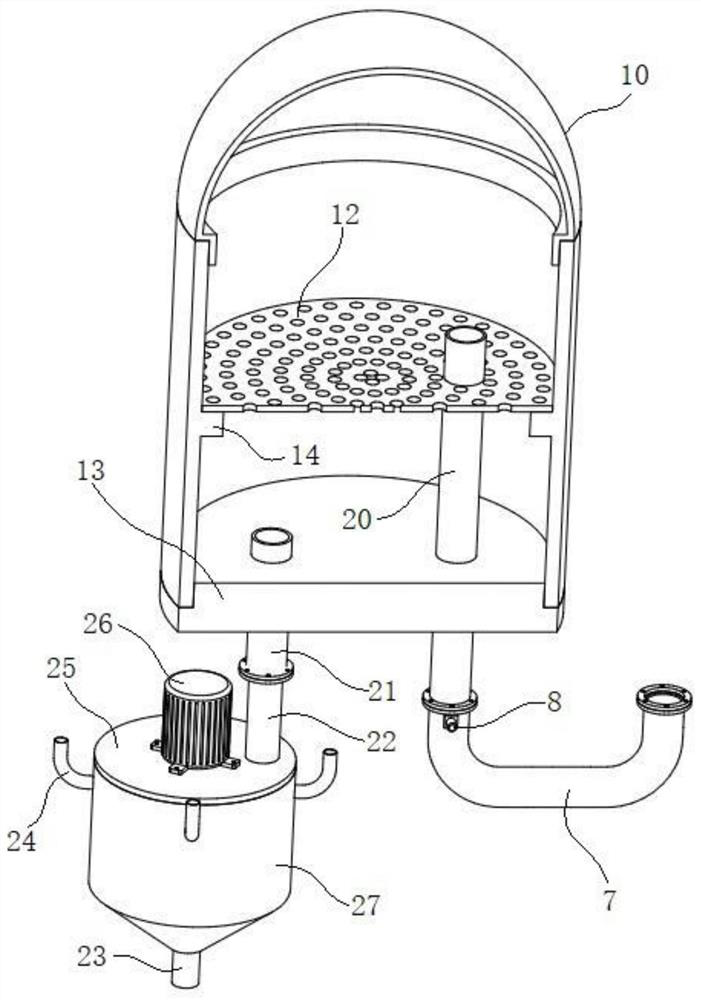

Kitchen waste allocation valve

PendingCN108426061AReduce pipe cloggingGuaranteed sortingMultiple way valvesReciprocating motionEngineering

The invention relates to the technical field of kitchen waste treatment equipment and particularly relates to a kitchen waste allocation valve which comprises a valve body, a valve core and a drivingsystem, wherein the valve body comprises a valve cavity, and one feeding hole and a plurality of discharge holes which are respectively communicated with the valve cavity; the valve core is arranged inside the valve cavity and comprises allocation channels of which the number is identical to that of the discharge holes; the driving system is connected with the valve core and used for driving the valve core to do reciprocation movements inside the valve cavity; when the valve cores do the reciprocation movements, the feeding hole can be communicated with the discharge holes corresponding to theallocation channels through different allocation channels. By adopting the kitchen waste allocation valve provided by the invention, kitchen wastes which are screened can be rapidly and reliably conveyed to a plurality of treatment stations, and the problem that a kitchen waste conveying outlet is in a single position can be solved.

Owner:BEIJING GOLDENWAY BIO TECH

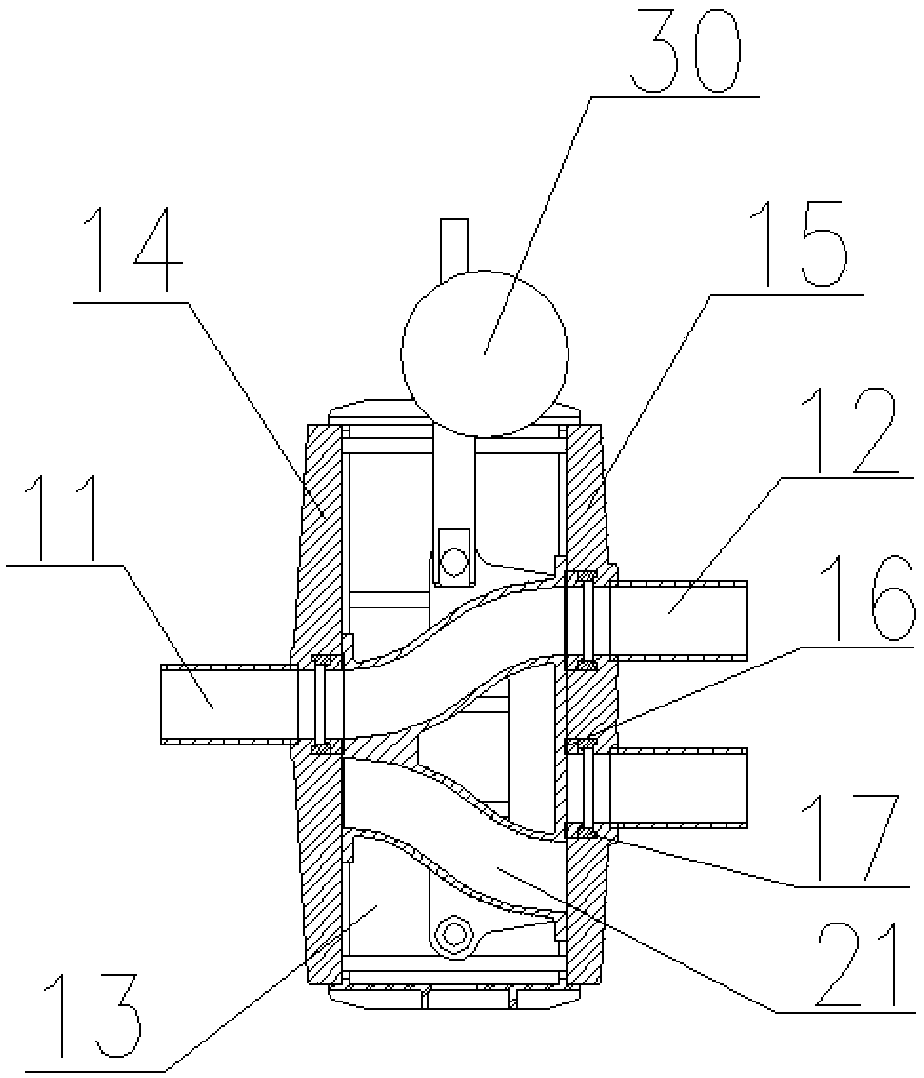

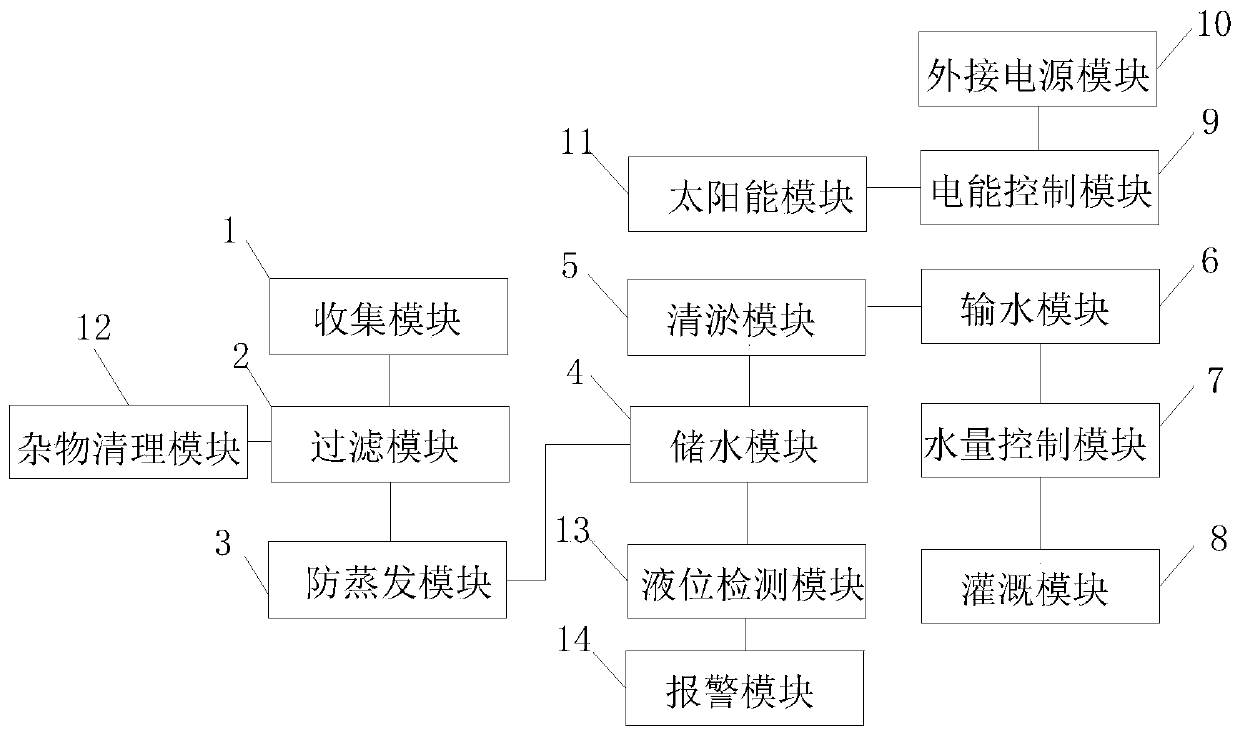

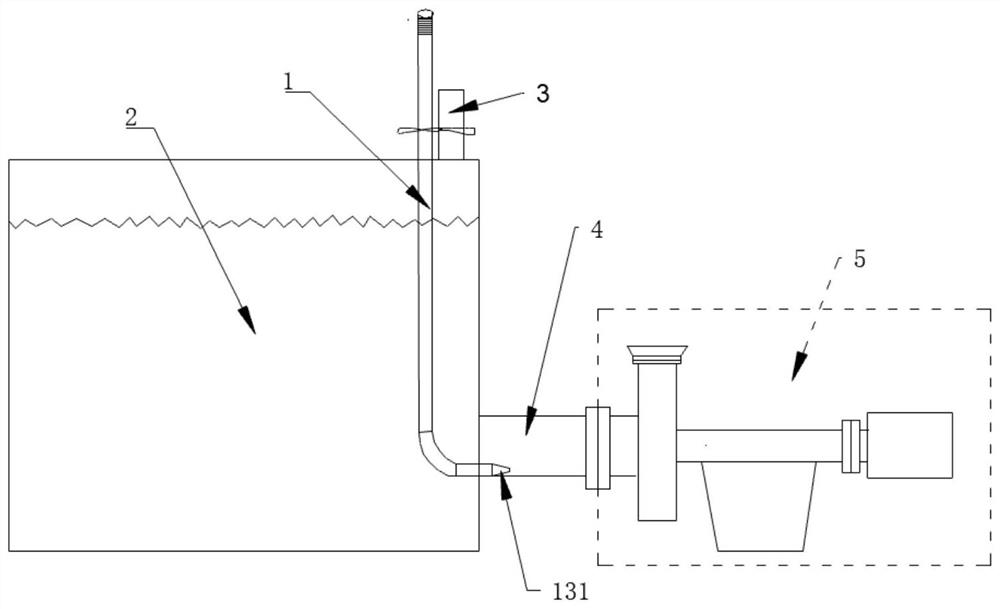

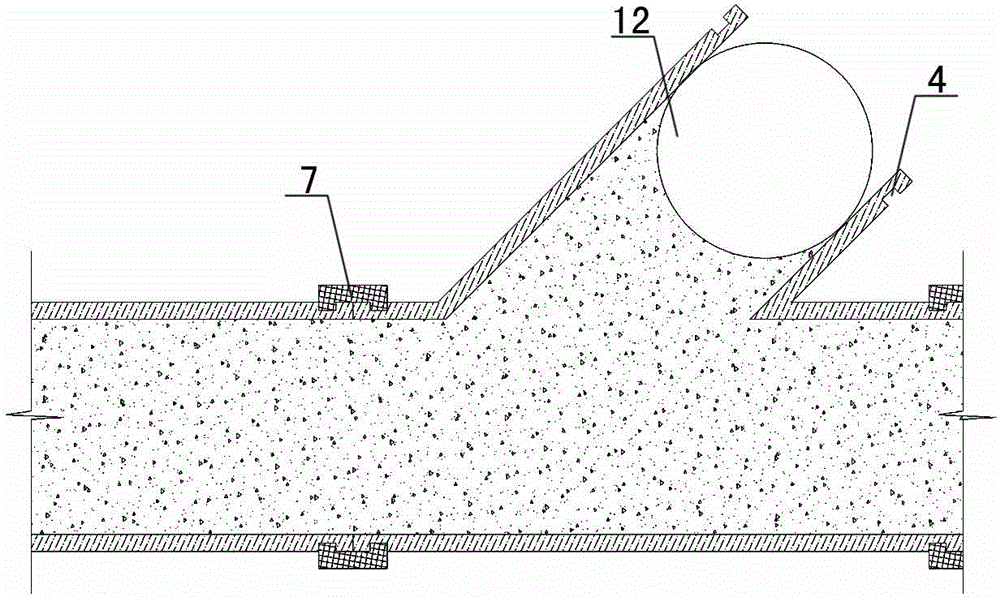

Sponge city rain collection and irrigation system

InactiveCN109797805AReduce water storageReduce pipe cloggingRoot feedersGeneral water supply conservationPower controlStormwater

The invention applies to the technical field of sponge city irrigation and provides a sponge city rain collection and irrigation system, comprising a collection module, a filter module, an anti-evaporating module, a water storage module, a desilting module, a water delivery module, a water quantity control module, an irrigation module, a power control module, an external power module, and a solarmodule. The collection module collects rain and is connected with the filter module; the water quantity control module is connected with the irrigation module; the irrigation module irrigates plants;the external power module is connected with the power control module so as to supply a power source to the water delivery module via the power control module; the solar module is connected with the power control module to supply a power source to the water delivery module through the power control module; the power control module activates the external power module to supply water when the solar module has low power level.

Owner:南京林业大学工程规划设计院有限公司

High flow fertilizer/air meter with secondary nozzling

ActiveUS20200060070A1Reduce and mitigate pluggingHigh volumePlantingLiquid seeding techniquesFertilizerAgricultural engineering

Agricultural implements are used to transport material, such as inputs in the form of fertilizer, seed, treatment, or some combination thereof, to row units that apply the material to an area of a field. Metering systems can aid in metering and providing a desired amount of material, such as on-demand, to the row units. The metering systems move the metered material to the row units, such as with pneumatics or other fluids. The metering system can be improved by having primary and secondary nozzles of different sizes, which aid in increasing the speed of the fluid moving the material towards the row units. For example, a smaller diameter for the secondary nozzle will provide improved suction and air speed.

Owner:LYNX AG LLC

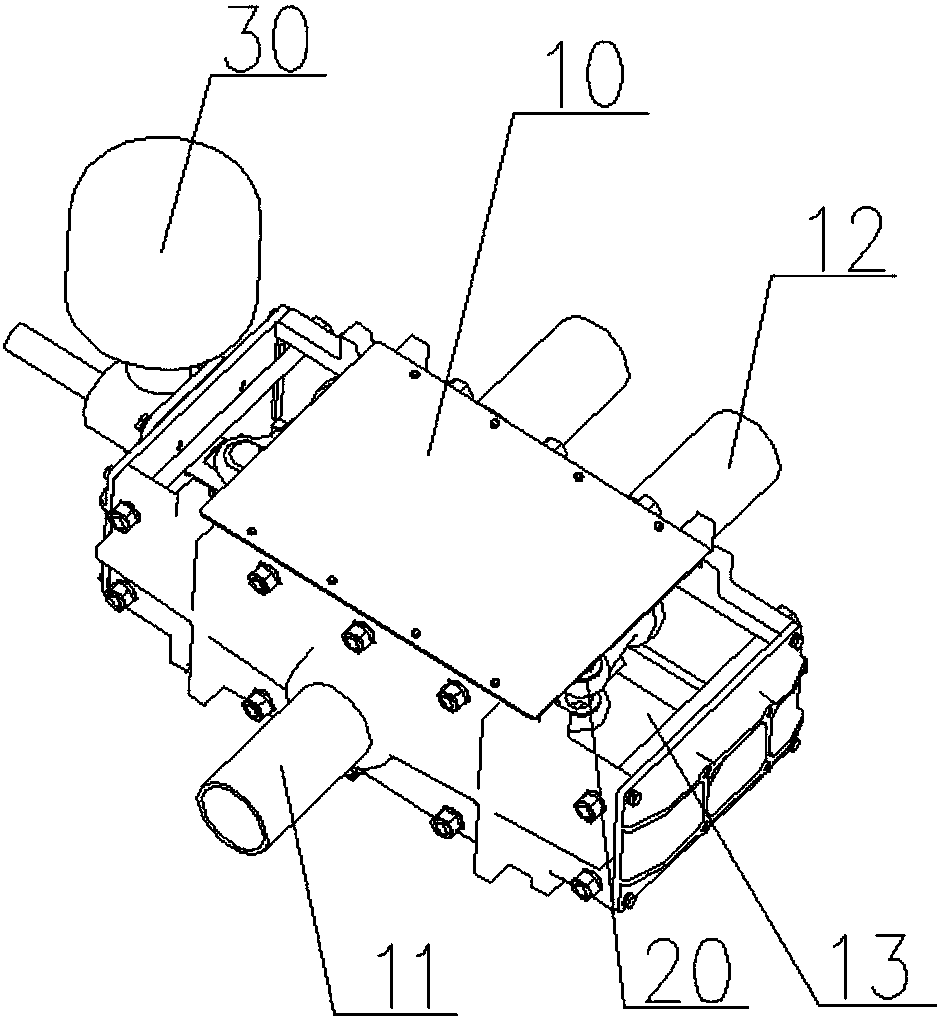

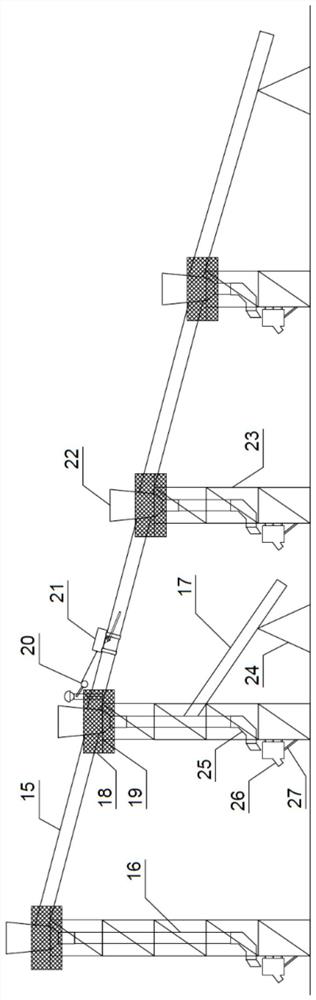

Elephant trunk method-based anti-blocking dredging system and construction method thereof

PendingCN114029288AEase congestionAvoid high requirements for open framesHollow article cleaningPipe elementsRemote controlControl theory

The invention discloses an elephant trunk method-based anti-blocking dredging system and a construction method thereof. The system comprises a probing and dredging device; the probing and dredging device comprises a case, a hoop type ring and a handheld end control device; the case is provided with a detector, and the bottom of the case is provided with an electric vibrating rod; one end, far away from a sleeve opening, of the hoop type ring is connected to the bottom of the case, a mounting hole for an elephant trunk to penetrate through is formed in the inner side of the ring, and a plurality of electric rollers are movably mounted in the mounting hole; and the handheld end control device is electrically connected to the electric vibrating rod, the electric rollers and the detector. The matched probing and dredging device is installed on the elephant trunk and moves along the elephant trunk through manual rope traction operation or complete remote control operation, a specific pipe blocking position is probed through an elephant trunk opening and a camera, and the vibrating rod is remotely operated to rotate to a proper position for vibrating and dredging; and pipe disassembly dredging and high-altitude operation are avoided, safety is guaranteed, meanwhile, construction is convenient, cost is saved, and the construction period is shortened. The dredging system is easy and convenient to operate, high in applicability, facilitates the application and popularization of the elephant trunk, and greatly improves the construction efficiency of deep foundation pits and mass concrete.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

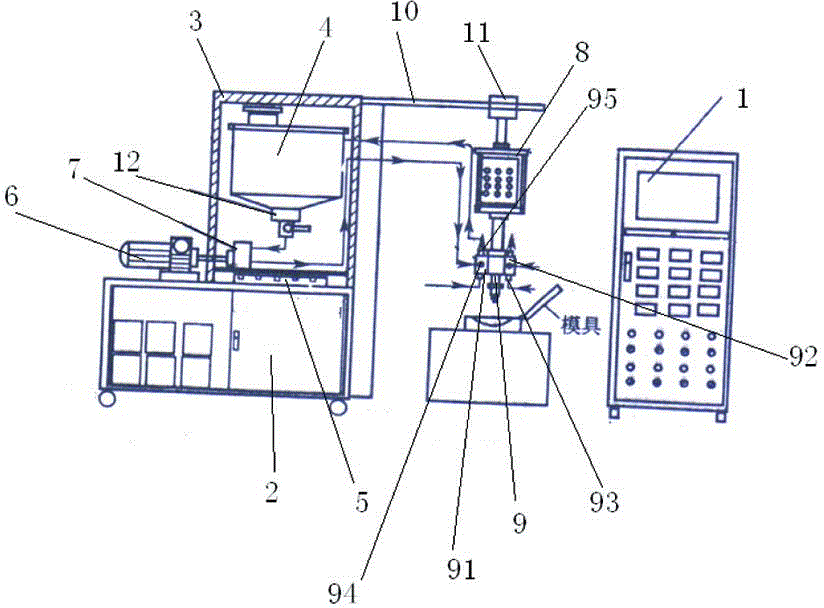

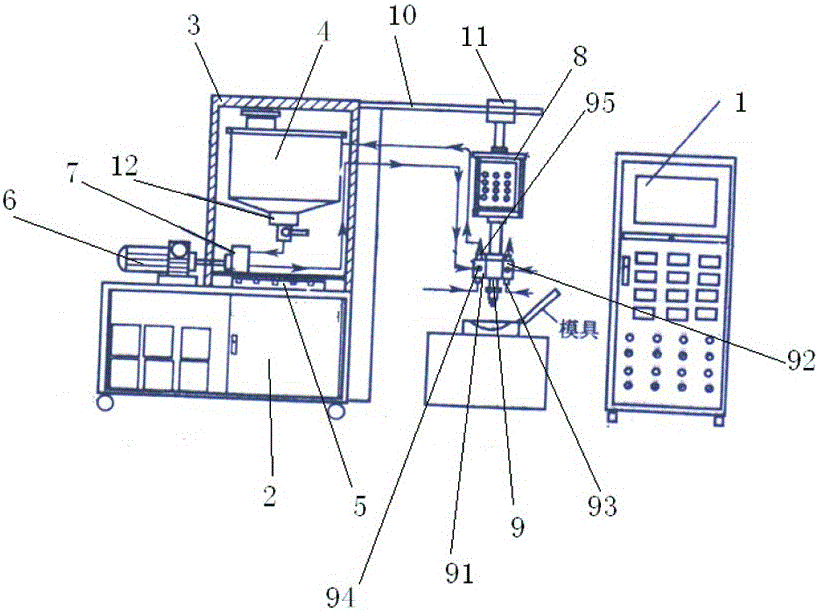

Central heating and temperature control system for PU shoe sole casting production line

ActiveCN104460745ARealize automatic controlImprove cooling effectTemperature control using electric meansInsulation layerHeat conservation

The invention discloses a central heating and temperature control system for a PU shoe sole casting production line. The system comprises a computer control cabinet and raw material drying ovens, a heating heat insulation box is arranged on the raw material drying ovens, a feed barrel is arranged in a cavity of the heating heat insulation box, heating boards are arranged at the bottom of the cavity of the heating heat insulation box, a speed regulating motor drives a metering pump to conveying feed liquid in the feed barrel to a temperature control box, a mixing casting head is arranged at a discharging outlet of the temperature control box, the temperature control box and the speed regulating motor are electrically connected with the computer control cabinet, a sliding support is arranged at the upper end of the heating heat insulation box and provided with a rotary valve, and the temperature control box is connected with the rotary valve. A pipeline of the central heating heat insulation system is much shortened than that of the traditional mode, and part of the pipeline is located in the heat insulation box. The feed pipeline of the mode is not provided with heating wires and heat insulation layers, use is convenient, and the pipe blocking phenomenon is reduced. Meanwhile, the raw material drying ovens are arranged at the lower portion of a casting molding machine to be concentrated, and by the adoption of the central heating heat insulation mode, energy consumption is reduced obviously.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

An economical and environment-friendly tunnel shotcrete and its construction technology

ActiveCN110627446BQuality is easy to controlImprove compactnessUnderground chambersTunnel liningShotcreteSlag

The invention discloses an economical and environment-friendly shotcrete for tunnels, which comprises the following raw materials in parts by weight: 400-500 parts of cement, 550-650 parts of river sand, 550-650 parts of stone chips, 400-500 parts of small stones, and 220-220 parts of water. 250 parts, 3.8-5.7 parts of water reducing agent, 1.4-9.4 parts of rebound control agent, 23-56 parts of quick-setting agent; among them, the particle size of small stones is less than 11mm, and the particle size of stone chips is less than 6mm. RC430 admixture produced by Shibo Chemical Materials Co., Ltd. The invention increases the content of the fine aggregate so that it has enough slurry to wrap the aggregate, thereby improving the compactness of the concrete, ensuring the strength of the concrete, and simultaneously improving the workability of the concrete. The invention also discloses a related construction process, which can reduce environmental pollution caused by waste slag, reduce production costs, and meet the requirements of high efficiency and low carbon in the construction industry.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG +1

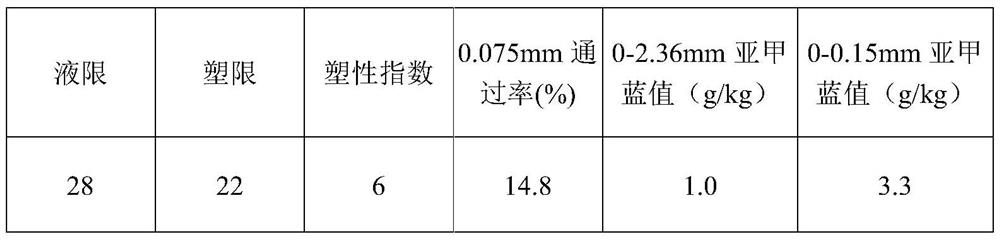

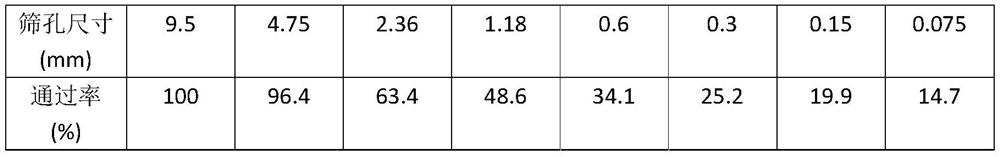

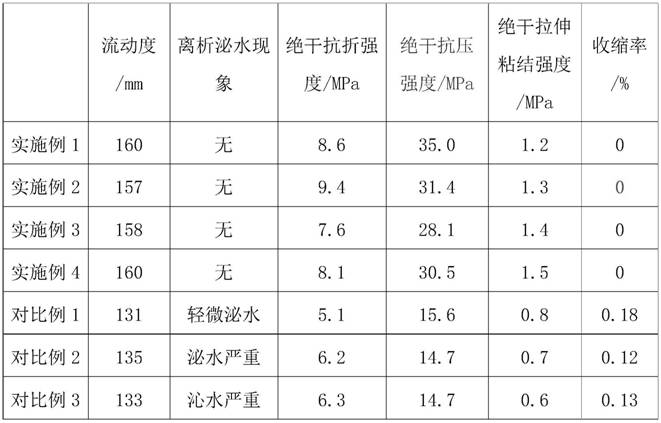

A kind of gypsum-based self-leveling mortar that can realize pumping and preparation method thereof

ActiveCN113004016BEffective adjustment ratioHas micro-expansion propertiesSolid waste managementPhysical chemistryEngineering

The invention discloses a gypsum-based self-leveling mortar that can be pumped. In parts by weight, it comprises the following components: 400-750 parts of hemihydrate gypsum; 1-15 parts of cement; 420-550 parts of aggregate; 10-40 parts of fly ash; 0.01-10 parts of polycarboxylate water reducing agent; 0.05-0.5 parts of dispersant; 0.5-2.5 parts of retarder; 0.5-5 parts of modified organic microcapsules; 250-300 parts of water. The invention also discloses a preparation method of the gypsum-based self-leveling mortar. The mortar provided by the invention does not soak in water, has good fluidity, and can be pumped; the invention also adds organic microcapsules modified by silica sol to the matrix, which effectively improves the drag-reducing and sand-carrying ability of the freshly mixed slurry and reduces blockage. tube phenomenon occurs.

Owner:临海市忠信新型建材有限公司

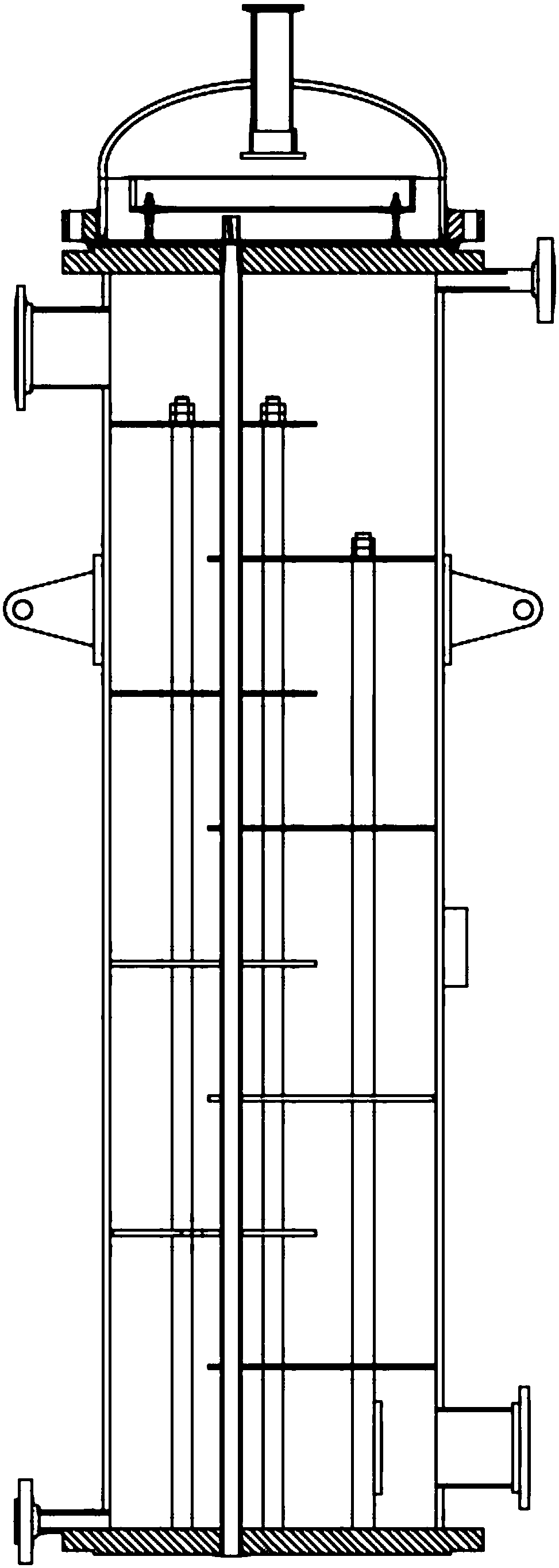

Falling film head improved structure of falling film reboiler

The invention relates to a falling film head improved structure of a falling film reboiler. The falling film head improved structure of the falling film reboiler comprises a cylinder body, a tube plate and a sealing head; a first tube nest is fixed on the upper part of the tube plate through a screw fixing structure; a second tube nest is fixed above the first tube sheet through a connecting plate; the first tube nest, the second tube nest and the tube plate are parallel; small holes of the first tube nest are opposite to the hole bridges of the tube plate; small holes of the second tube nestare opposite to holes of the tube plate; the top end of the sealing head is provided with a feeding flange; the end part, extending inside the sealing head, of the feeding flange is provided with a feeding baffle; and small holes are uniformly distributed in the feeding baffle. According to the falling film head improved structure of the falling film reboiler, an original falling film head is improved to have distribution of two-stage screen plates, and is arranged to have an arc material stopping mechanism, so that the feeding distribution is more uniform; and with the distribution of two-stage screen plates, impulsive force to the tube plate is reduced, the feeding distribution is further uniform, and the phenomena of inner-wall material accumulation and pipe blocking of heat exchange pipes are reduced.

Owner:JIANGSU GREENLEAVES BOILER

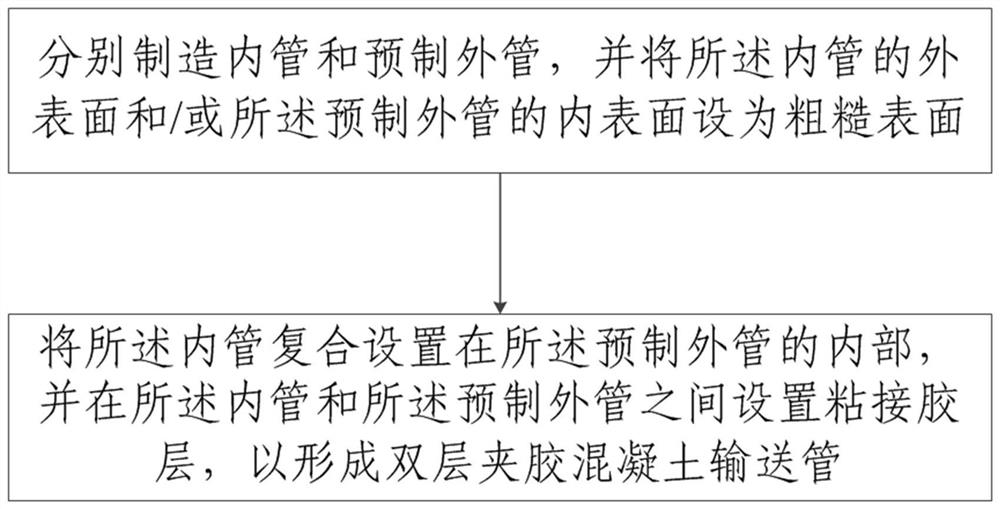

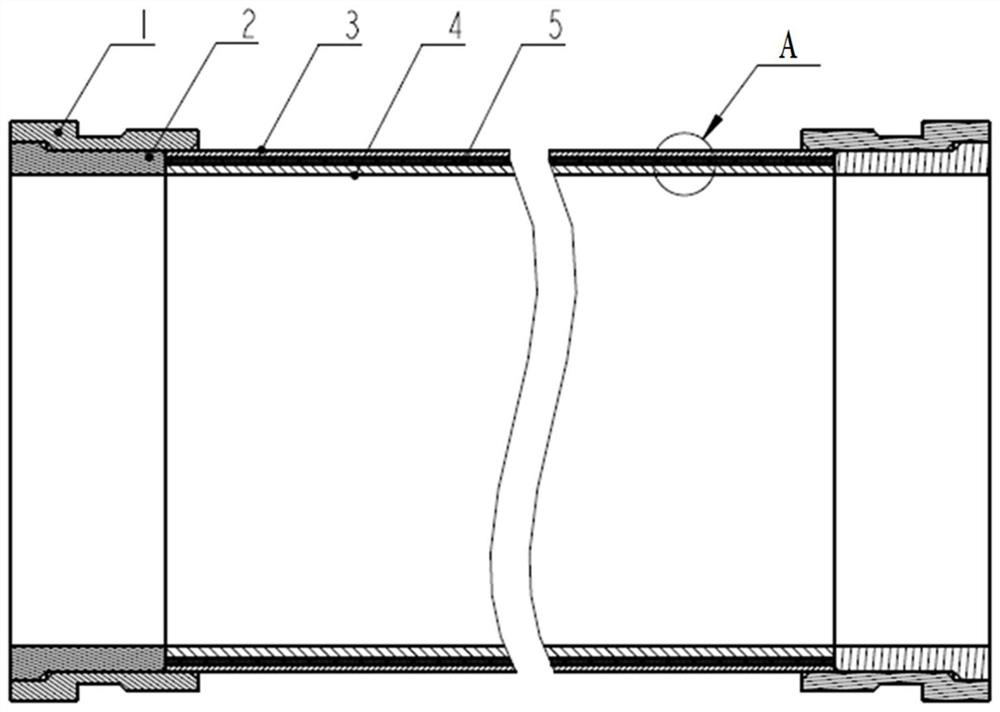

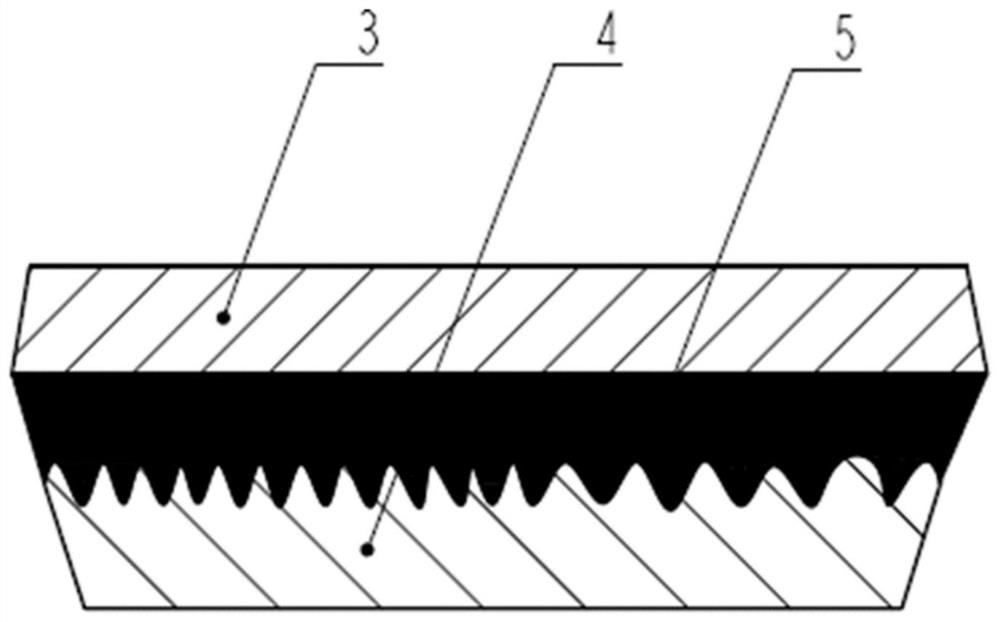

Concrete conveying pipe manufacturing method, concrete conveying pipe and pumping equipment

PendingCN114087429AAvoid block droppingReduce squibMaterial gluingRigid pipesRough surfaceEngineering

The invention provides a concrete conveying pipe manufacturing method, a concrete conveying pipe and pumping equipment. The concrete conveying pipe manufacturing method comprises the steps that an inner pipe and a prefabricated outer pipe are manufactured respectively, and the outer surface of the inner pipe and / or the inner surface of the prefabricated outer pipe are / is set to be rough surfaces; and the inner pipe is arranged in the prefabricated outer pipe in a composite mode, and a bonding glue layer is arranged between the inner pipe and the prefabricated outer pipe, so that the double-layer laminated concrete conveying pipe is formed. According to the concrete conveying pipe manufacturing method, the concrete conveying pipe and the pumping equipment, the bonding glue layer is arranged between the inner pipe and the outer pipe, and the rough surface is arranged to be connected with the bonding glue layer, so that firm compounding of the inner pipe and the outer pipe can be achieved, the phenomenon of chipping of the inner pipe can be avoided, the phenomena of pipe explosion and pipe blocking of the conveying pipe are reduced, the overall pressure bearing capacity of the conveying pipe is improved, and the cracking risk of the inner pipe is greatly reduced; and the conveying pipe is simple in structure, simple and convenient in production process, easy to implement, low in cost and suitable for mass production.

Owner:SANY AUTOMOBILE MFG CO LTD

Part for pump, replacement method and application thereof

The invention relates to a part for a pump, a replacement method and an application thereof, particularly relates to a spectacle plate, a cutting ring and an S-shaped pipe of an S-shaped pipe valve for the pump, a replacement method and an application thereof and belongs to the technical field of development of concrete pump trucks. The part for the pump contains polyethylene with ultrahigh molecular weight. The part is used for conveying and spraying concrete, coal slurry, other thick slurry residues and fire-fighting water. Compared with the existing spectacle plate with a steel substrate and an overlaying wear-resistant layer, the spectacle plate designed by the invention is 3-5 times larger than the existing spectacle plate, and when the spectacle plate designed by the invention is matched with the cutting ring for use, the pumping life of the pump reaches 100,000 cubic meters. Simultaneously, the polyethylene with the ultrahigh molecular weight is nonstick to mediums such as concrete, is convenient in cleaning, is non-corrosive and is easy in maintenance and replacement. The part designed by the invention is long in service life, simple in replacement, low in production cost, easy in control of production accuracy and convenient in large-scale industrial application.

Owner:王谷安

Flow baffling plate foam garbage removing apparatus

The present invention discloses a flow baffling plate foam garbage removing apparatus, which is characterized by comprising a water inlet cabinet, a flow baffling plate, a water outlet cabinet, and a garbage outlet, wherein the water inlet cabinet is positioned at the left side, the right side surface is completely connected to the left side surface of the flow baffling plate, the water outlet cabinet is positioned at the right side, the left side surface is completely connected to the right side surface of the flow baffling plate, and the garbage outlet is positioned in the water outlet cabinet. According to the present invention, when the water flow passes through the flow baffling plate, the foam garbage does not pass through the flow baffling plate due to the slow flow rate and flows into the garbage outlet; and with the apparatus, the high purity cooling water is achieved, and the failure of the pipeline clogging is reduced.

Owner:刘艳丽

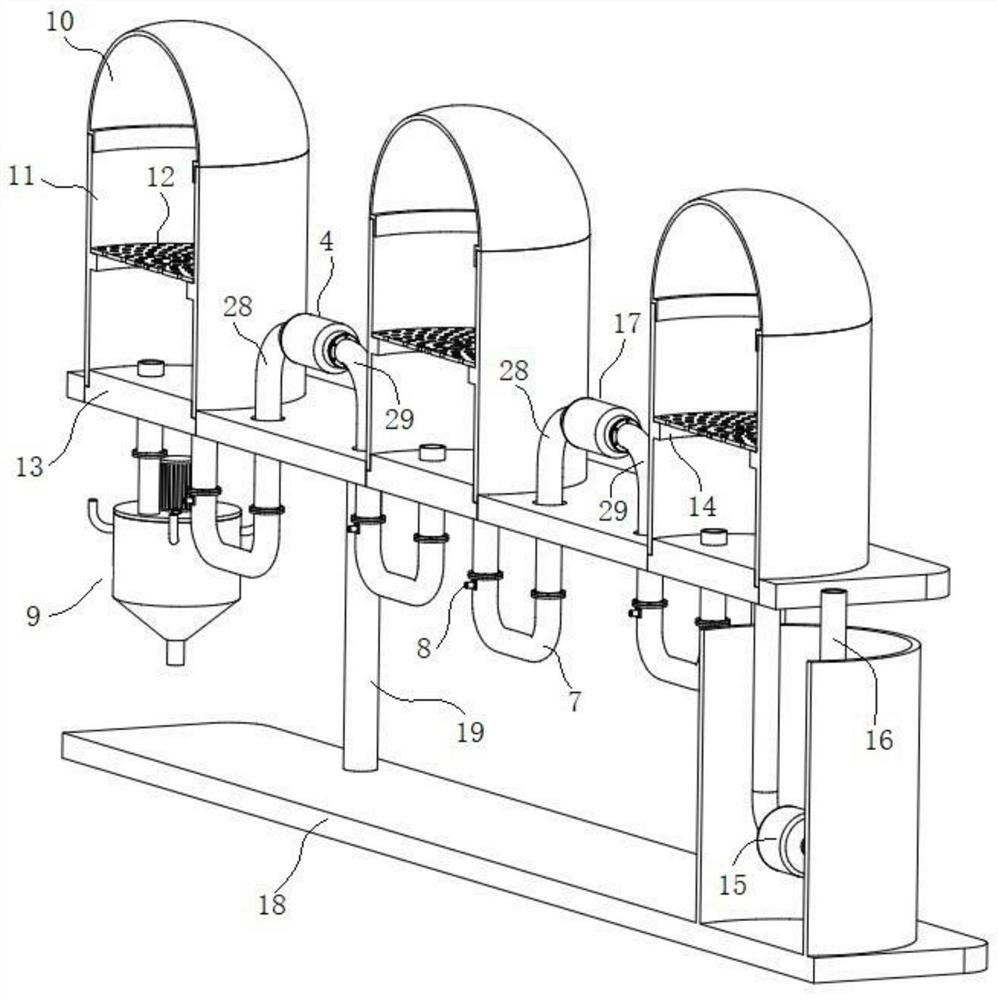

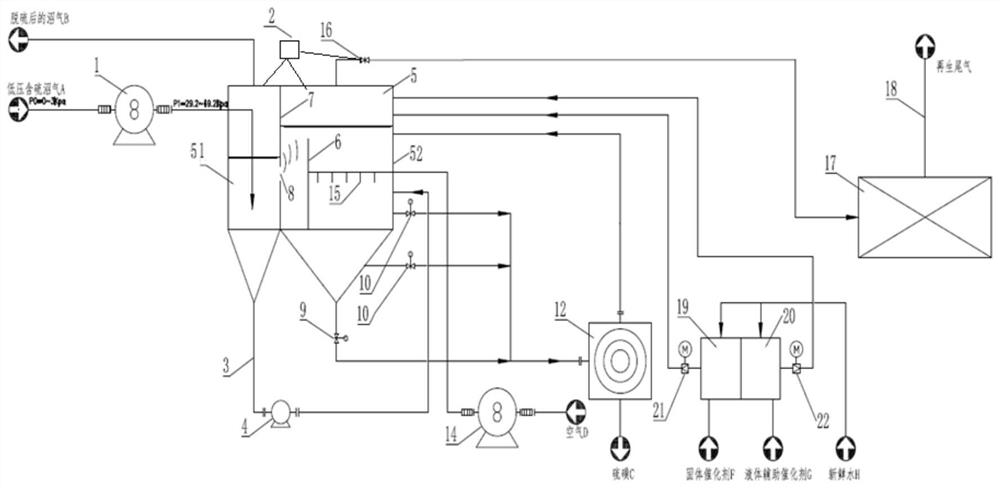

Biogas desulfurization and deodorization device and method

ActiveCN112940818AEasy to controlReduce cloggingGaseous fuelsSulfur preparation/purificationThermodynamicsProcess engineering

The invention relates to a biogas desulfurization and deodorization device and method, and belongs to the technical field of chemical engineering. The biogas desulfurization and deodorization device comprises a fan, a rich liquid pipeline, a circulating pump, a fan, an absorption and regeneration tower, a back pressure valve, a filter and a pressure controller; the absorption and regeneration tower comprises an absorption chamber and a regeneration chamber, the absorption chamber and the regeneration chamber are separated by a partition plate, and an overflow hole is formed in the partition plate; the fan is communicated with an air inlet of the absorption chamber, a liquid outlet of the absorption chamber is communicated with a liquid inlet of the regeneration chamber through the rich liquid pipeline, and a circulating pump is arranged on the rich liquid pipeline; a back pressure valve is arranged at an exhaust port of the regeneration chamber, and the pressure controller is connected with the back pressure valve and the absorption chamber; a blocking partition plate is arranged between the air inlet of the regeneration chamber and the overflow hole, and the fan is communicated with the air inlet of the regeneration chamber; and at least one liquid extraction opening is formed in the side wall of the regeneration chamber. The device disclosed by the invention can be used for continuous desulfurization production.

Owner:BEIJING RUNYU ENVIRONMENTAL PROTECTION ENG

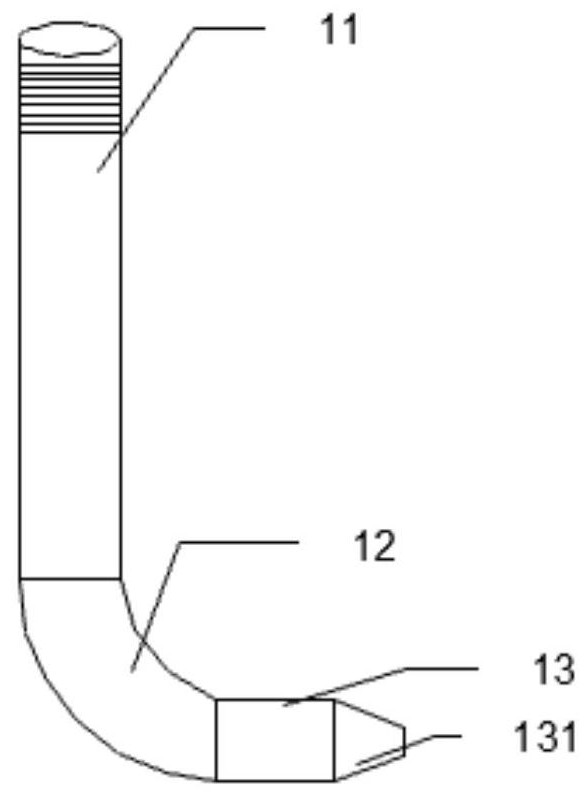

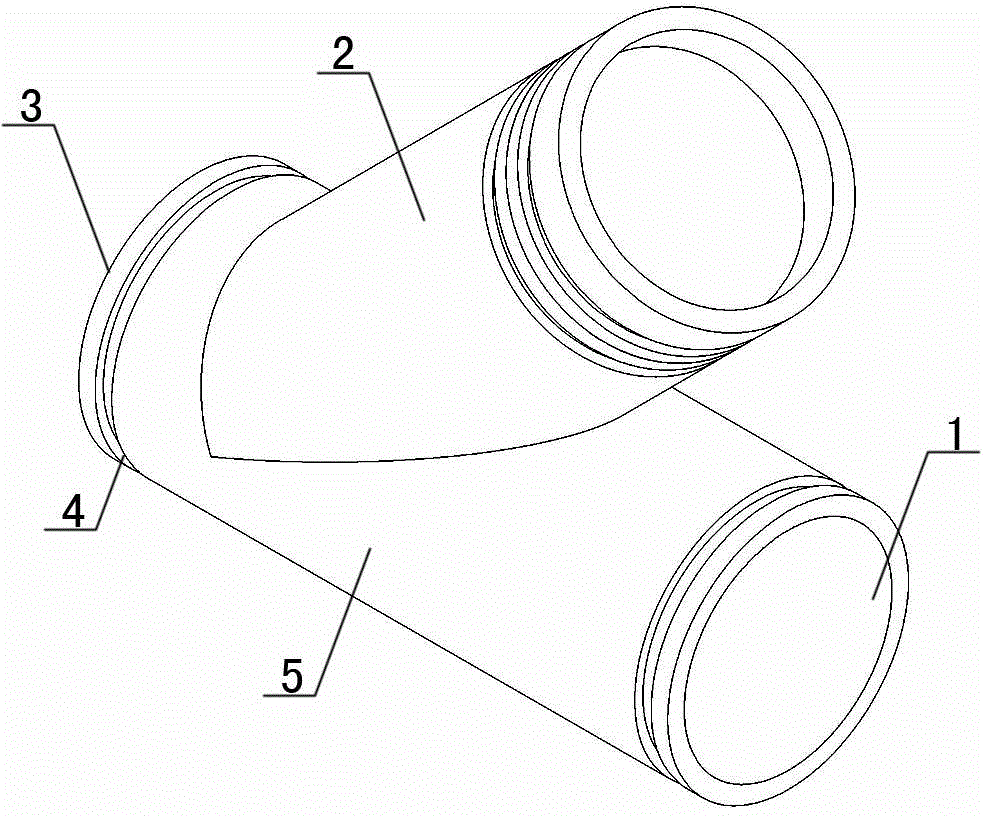

High-sulfur concentrate pump slurry feeding equipment and anti-blocking device and installation method thereof

PendingCN113908997ANo cloggingReduce the risk of pipe blockageHollow article cleaningSecuring devicesProcess engineeringSlurry

The invention provides a high-sulfur concentrate pump slurry inlet pipe anti-blocking device which comprises a first pipeline, a bent pipe and a second pipeline, wherein a water inlet of the bent pipe is communicated with a water outlet of the first pipeline, a water outlet of the bent pipe is communicated with a water inlet of the second pipeline, and the water inlet of the first pipeline is used for being communicated with a water outlet of a faucet. A water outlet of the pipeline II is formed in the bottom of the slurry inlet pipe of the sulfur concentrate pump. The invention further provides pulp feeding equipment of the high-sulfur concentrate pump. The invention further provides a mounting method of the anti-blocking device for the slurry inlet pipe of the high-sulfur concentrate pump. According to the anti-blocking device for the pulp inlet pipe of the high-sulfur concentrate pump, when sulfur concentrate pulp conditions change, the pulp inlet pipe of the sulfur concentrate pump cannot be blocked, and it is ensured that pulp in a pulp conveying pipe cannot be cut off, and the water pressure is enough to flush and disperse the pulp foam. The anti-blocking device for the slurry inlet pipe of the high-sulfur concentrate pump is simple in structure, small in size and convenient to install and operate.

Owner:SHUI KOU SHAN NONFERROUS METALS LTD

A kind of concentrated hydrochloric acid hydrolysis process and device

ActiveCN106317095BInhibition of local excessImprove ring yieldSilicon organic compoundsAcid hydrolysisStatic mixer

The invention provides a concentrated-acid hydrolysis technology. The concentrated-acid hydrolysis technology includes the steps that after hydrolysis raw materials of dimethyldichlorosilane and saturated concentrated hydrochloric acid are reacted in a static mixer, the obtained gas-liquid mixture enters a gas-liquid separation tank A, gas recovered out of the top of the gas-liquid separation tank A, carried dimethyldichlorosilane and carried hydrolysate liquid drops enter a venturi mixer from the side face, the gas-liquid mixture deeply mixed in a main concentrated-hydrochloric-acid fluid enters a gas-liquid separation tank B, concentrated hydrochloric acid recovered out of the bottom of the gas-liquid separation tank B is returned to the venturi mixer through a material pump, the gas recovered out of the top sequentially enters a primary condenser and a secondary condenser, gas-liquid mixture condensed by the primary condenser and the secondary condenser enters a collecting device to collect liquid drops, and after the liquid drops are removed through a demister, the product is delivered to a chloromethane synthesis working section through a buffering tank. By means of the concentrated-acid hydrolysis technology, in the concentrated-acid hydrolysis process, the insufficient reacting problem, the low efficiency problem and the like caused when materials are unevenly mixed are solved, and meanwhile the problems that as gas and liquid are carried, a pipe and a device are blocked are solved.

Owner:HUBEI XINGFA CHEM GRP CO LTD

A centralized heating temperature control system for pu shoe sole pouring production line

ActiveCN104460745BRealize automatic controlImprove cooling effectTemperature control using electric meansInsulation layerInsulation system

The invention discloses a central heating and temperature control system for a PU shoe sole casting production line. The system comprises a computer control cabinet and raw material drying ovens, a heating heat insulation box is arranged on the raw material drying ovens, a feed barrel is arranged in a cavity of the heating heat insulation box, heating boards are arranged at the bottom of the cavity of the heating heat insulation box, a speed regulating motor drives a metering pump to conveying feed liquid in the feed barrel to a temperature control box, a mixing casting head is arranged at a discharging outlet of the temperature control box, the temperature control box and the speed regulating motor are electrically connected with the computer control cabinet, a sliding support is arranged at the upper end of the heating heat insulation box and provided with a rotary valve, and the temperature control box is connected with the rotary valve. A pipeline of the central heating heat insulation system is much shortened than that of the traditional mode, and part of the pipeline is located in the heat insulation box. The feed pipeline of the mode is not provided with heating wires and heat insulation layers, use is convenient, and the pipe blocking phenomenon is reduced. Meanwhile, the raw material drying ovens are arranged at the lower portion of a casting molding machine to be concentrated, and by the adoption of the central heating heat insulation mode, energy consumption is reduced obviously.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

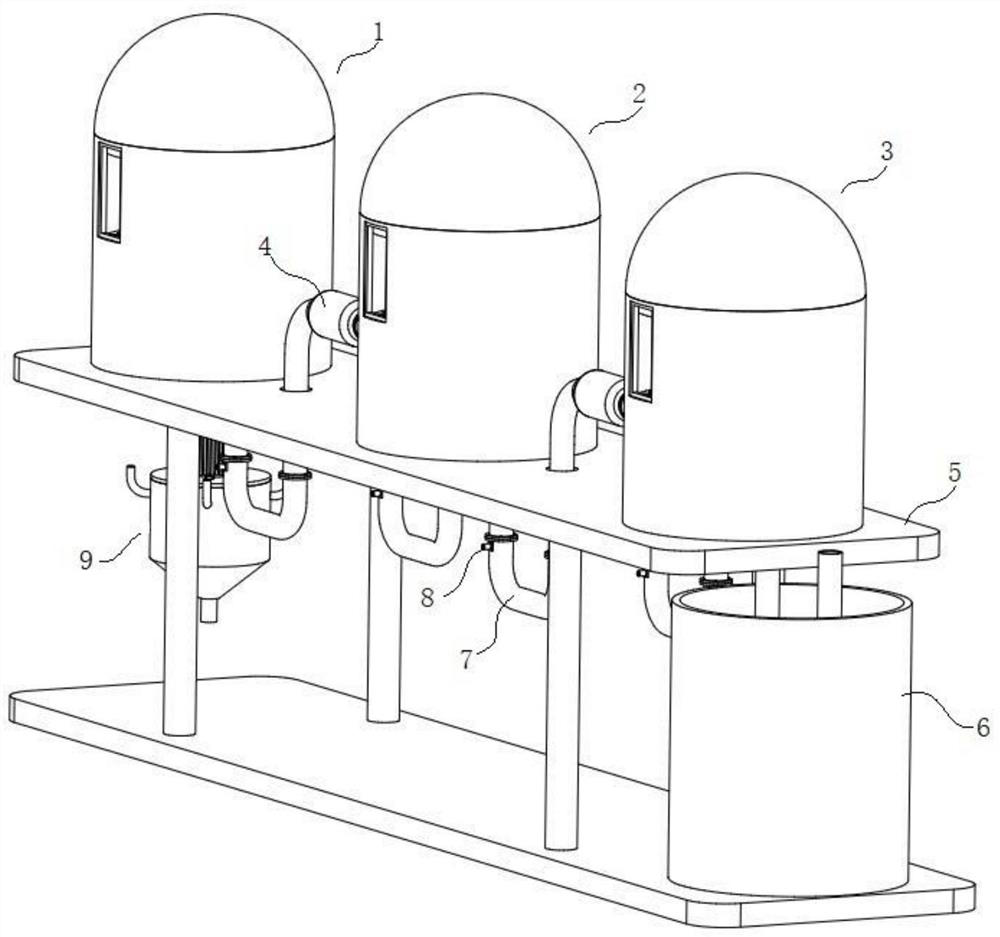

A kind of veterinary drug extraction tank

ActiveCN112263844BAchieve configurationGuaranteed cooling effectSolid solvent extractionFiltration circuitsFiltrationVeterinary Drugs

The invention discloses a veterinary drug extraction tank, which comprises a first extraction tank, a second extraction tank and a third extraction tank; Filter screens are provided in the extraction tanks; wherein, the outlet ends of the water inlet pipes located in the three extraction tanks are higher than the filter screens, and the water inlets of the outlet pipes in the three extraction tanks are The ends are all lower than the filter screen; and a stirrer is provided on the outlet pipe of the first extraction tank, and the water inlet pipe of the third extraction tank is located in the provided cooling tank; since the device utilizes each other The connected extraction tanks realize the layer-by-layer filtration of traditional Chinese medicine dregs, and at the same time, the medicinal liquid can be further purified by changing the mesh number of the filter inside the extraction tank; since the homogenizer is equipped with a dispensing tube, the filtered medicine The liquid and the medicament to be added are fully stirred evenly, and the cooling tank provided can cool the liquid medicine, so the present invention is worthy of popularization and application.

Owner:ANHUI ANFENGT ANIMAL MEDICINE IND CO LTD

Pumping concrete blowing tube and method of use thereof

The invention relates to a pump concrete ball blowing pipe and a use method thereof. The pump concrete ball blowing pipe is a section of tee type pipeline which is connected with a concrete delivery pump pipe through a ring-shaped buckle and comprises a straight pipe for conveying concrete and a branch pipe which is branched out from the straight pipe and used for allowing a sponge ball to enter, wherein a clamping groove used for being matched with ring-shaped buckle connection is formed in each of an input port and an output port of the straight pipe and the outer wall of a pipe port of the branch pipe; the pipe port of the branch pipe is connected with a plug-in type ball-blowing cap through the ring-shaped buckle; a bolt hole provided with inner threads is formed in the end head of the ball-blowing cap; and a plugging bolt is arranged in the bolt hole of the ball-blowing cap. The pump concrete ball blowing pipe is simple in structure and convenient to use, and can be connected to any position of a concrete conveying pump pipeline, so that the concrete conveying pipe is convenient and fast to clean, the possibility of blocking of the concrete conveying pump pipe is greatly reduced, and the work quality and the work efficiency are ensured; therefore, the pump concrete ball blowing pipe and the use method thereof can be widely applied to cleaning of the concrete conveying pump pipe.

Owner:CHINA XINXING CONSTR & DEV CO LTD

Air humidifying device for strawberry greenhouse planting

InactiveCN113330959AIncrease reachImproves the effect of moisturizing treatmentsClimate change adaptationMovable spraying apparatusFragariaGreenhouse

The invention discloses an air humidifying device for strawberry greenhouse planting. The device comprises a mounting frame, spraying discs and a water pump; a T-shaped frame is fixedly connected with the bottom of the mounting frame; two groups of rotating plates are symmetrically and rotatably connected with two sides of the bottom of the T-shaped frame; the spraying discs are mounted at the bottoms of the two groups of rotating plates; a driving motor is mounted in the middle of the T-shaped frame; and the front end of the driving motor is in transmission connection with a cam. According to the air humidifying device for strawberry greenhouse planting, firstly, a combined linkage type humidifying structure is adopted, so that uniform swing humidifying treatment can be conducted on air in a greenhouse, the covering face of humidifying treatment of the air humidifying device is improved, and therefore the greenhouse air humidifying treatment effect is improved; and a liquid inlet filter structure is arranged in the device, and liquid entering the humidifying device can be filtered, so that the phenomenon that solid impurities enter the humidifying device and block a pipeline is reduced, and therefore the working stability of the air humidifying device is improved.

Owner:湖南晶优农业科技开发有限公司

Biogas desulfurization and deodorization device and method

ActiveCN112940818BEasy to controlReduce cloggingGaseous fuelsSulfur preparation/purificationThermodynamicsProcess engineering

The invention relates to a biogas desulfurization and deodorization device and method, belonging to the technical field of chemical industry. The biogas desulfurization and deodorization device of the present invention includes a fan, a rich liquid pipeline, a circulation pump, a fan, an absorption regeneration tower, a back pressure valve, a filter, and a pressure controller. The absorption regeneration tower includes an absorption chamber and a regeneration chamber, The absorption chamber and the regeneration chamber are separated by a partition, and an overflow hole is arranged on the partition; the fan communicates with the air inlet of the absorption chamber, and the liquid outlet of the absorption chamber communicates with the regeneration chamber. The liquid inlet of the chamber is connected through the rich liquid pipeline, and a circulation pump is arranged on the rich liquid pipeline; a back pressure valve is set at the exhaust port of the regeneration chamber, and the pressure controller is connected with the back pressure valve and the absorption chamber ; A barrier partition is set between the air inlet of the regeneration chamber and the overflow hole, and the fan communicates with the air inlet of the regeneration chamber; at least one suction port is arranged on the side wall of the regeneration chamber. The device of the invention can continuously perform desulfurization production.

Owner:BEIJING RUNYU ENVIRONMENTAL PROTECTION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com