A kind of gypsum-based self-leveling mortar that can realize pumping and preparation method thereof

A self-leveling mortar and gypsum-based technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems that building gypsum is easily affected by impurities, low product strength, unstable performance, etc., to achieve improved The effect of drag reduction and sand carrying capacity, stable product performance and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

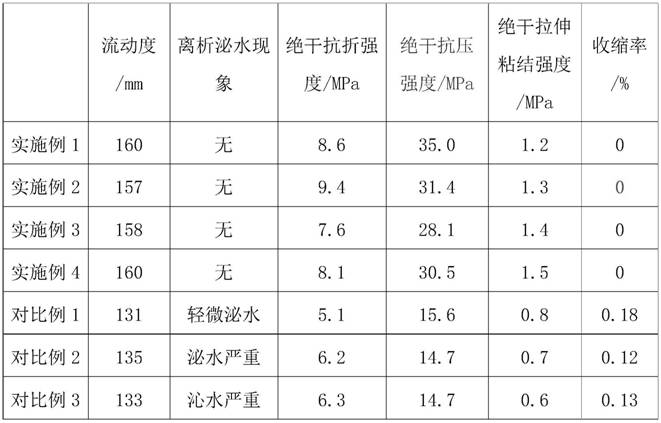

Examples

Embodiment 1

[0027] (1) The methyl methacrylate monomer, silica sol and water were mixed and added into the shearing emulsifier at a mass ratio of 1:0.25:20 at room temperature, and emulsified at a high speed at a speed of 11000r / min for 5h , and then left to stand for 8h to obtain a suspension;

[0028] (2) the above-mentioned suspension liquid obtained is heated to 50 ℃, then 10g of strong hydrophilic electrolyte sodium sulfate powder is added, thereby reducing the solubility of methyl methacrylate monomer and condensing out, forming the initial microcapsule, cooling to 10 ℃, the initial microcapsules disappeared, and then the temperature was raised to 50 ℃ again to obtain the shaped microcapsule suspension, and finally centrifuged, and the precipitate obtained by centrifugation was washed to neutrality and dried to obtain modified organic microcapsules ;

[0029] (3) In parts by weight, combine 535 parts of β-hemihydrate gypsum, 215 parts of α-hemihydrate gypsum, 5 parts of CA50 white ...

Embodiment 2

[0031] (1) The methyl methacrylate monomer, silica sol and water were mixed and added into the shearing emulsifier at a mass ratio of 1:0.25:20 at room temperature, and emulsified at a high speed at a speed of 11000r / min for 5h , and then left to stand for 8h to obtain a suspension;

[0032] (2) the suspension obtained above was heated to 50°C, then 10g of strong hydrophilic electrolyte sodium sulfate powder was added to form primary microcapsules, the temperature was lowered to 10°C, and the primary microcapsules disappeared, and then the temperature was raised to 50°C again to prepare The shaped microcapsule suspension is obtained, and finally centrifugation is performed, and the precipitate obtained by centrifugation is washed to neutrality and dried to obtain modified organic microcapsules;

[0033] (3) In parts by weight, 400 parts of β-hemihydrate gypsum, 160 parts of α-hemihydrate gypsum, 1 part of CA-50 white aluminate cement, 210 parts of machine-made sand, 210 parts ...

Embodiment 3

[0035] (1) The methyl methacrylate monomer, silica sol and water were mixed and added into the shearing emulsifier at a mass ratio of 1:0.25:20 at room temperature, and emulsified at a high speed at a speed of 11000r / min for 5h , and then left to stand for 8h to obtain a suspension;

[0036] (2) the above-mentioned suspension liquid obtained is heated to 50 ℃, then 10g of strong hydrophilic electrolyte sodium sulfate powder is added, thereby reducing the solubility of methyl methacrylate monomer and condensing out, forming the initial microcapsule, cooling to 10 ℃, the initial microcapsules disappeared, and then the temperature was raised to 50 ℃ again to obtain the shaped microcapsule suspension, and finally centrifuged, and the precipitate obtained by centrifugation was washed to neutrality and dried to obtain modified organic microcapsules ;

[0037] (3) In parts by weight, 535 parts of β-hemihydrate gypsum, 215 parts of α-hemihydrate gypsum, 1 part of 42.5 grade white ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com