Pumping concrete blowing tube and method of use thereof

A technology for pumping concrete and concrete, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., to achieve the effects of convenient and quick cleaning, simple structure, and easy and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

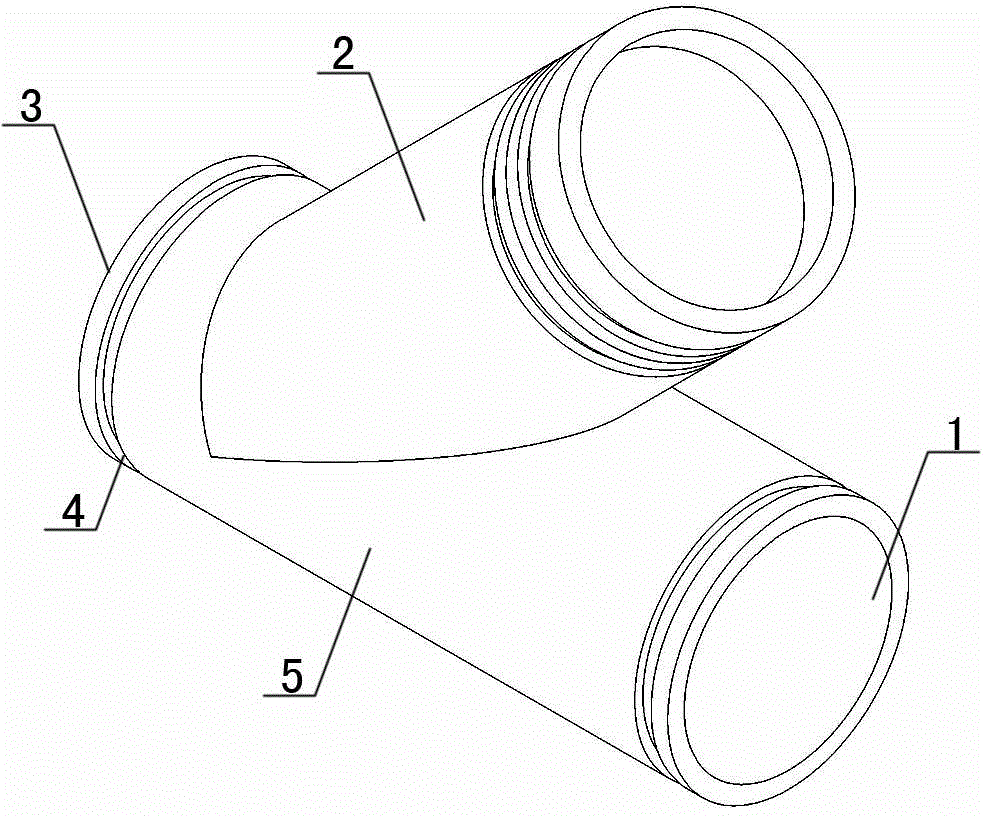

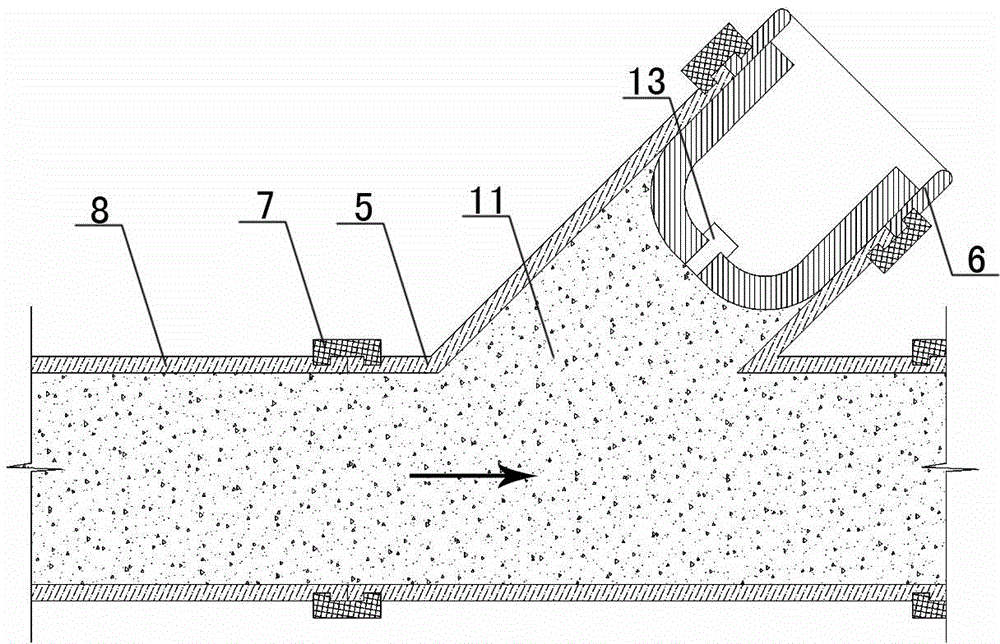

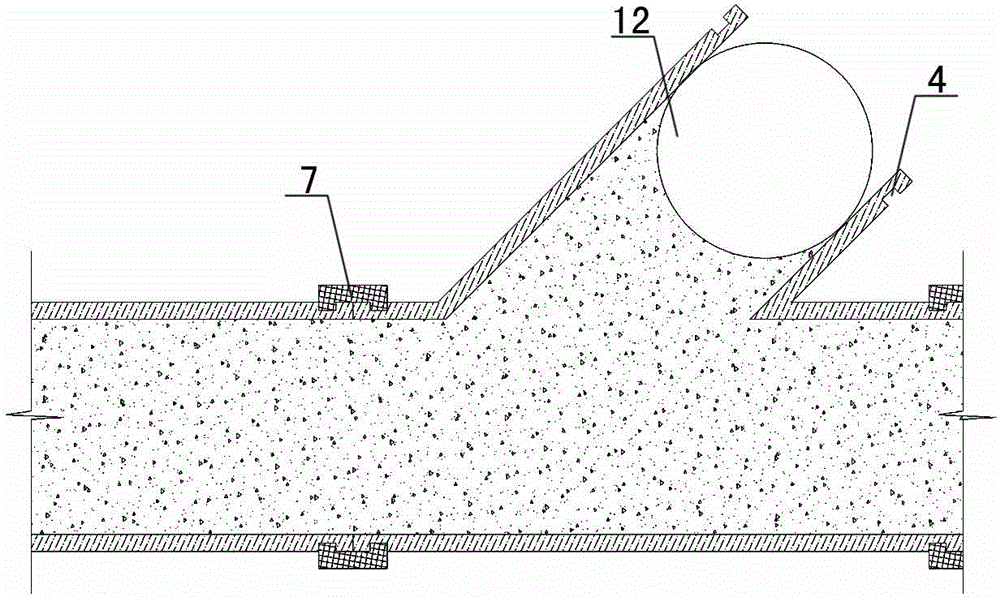

[0029] Examples see figure 1 As shown, this pumping concrete blowing bulb pipe is connected to the concrete conveying pump pipe 8 through a ring buckle. The pumping concrete blowing bulb pipe is a three-way pipe, including a straight pipe 5 for conveying concrete and a straight pipe 5 A branch pipe 2 for the sponge ball 12 to enter from above, the angle between the branch pipe 2 and the straight pipe 5 is 45 degrees, the input port 3, the output port 1 and the pipe mouth of the branch pipe 2 of the straight pipe 5 The outer wall is provided with a groove 4 for connecting with an annular buckle 7, and the nozzle of the branch pipe 2 is connected with a plug-in blower cap 6 through the annular buckle, and the end of the blower cap 6 is opened with A bolt hole with internal threads, and a plugging bolt 13 is provided in the bolt hole of the blow ball cap 6.

[0030] The bolt hole of the ball blowing cap 6 can be connected to an air nozzle 9 when in use. One end of the air nozzle 9 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com