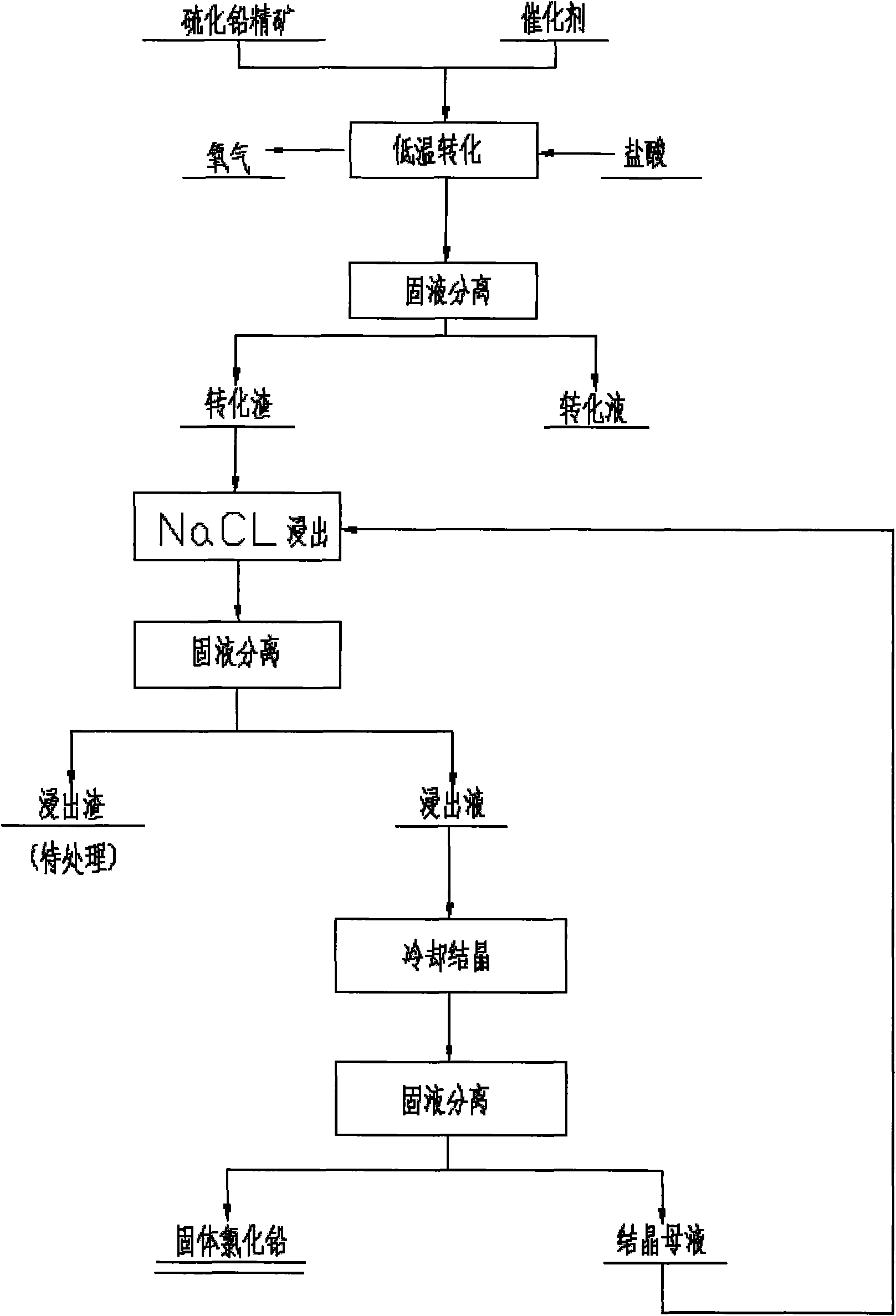

Method for extracting lead from lead sulfide ore concentrate by HCl-O2-NaCl system

A lead sulfide and concentrate technology, which is applied in the fields of chlorination leaching and wet leaching of lead, can solve the problems of high cost of lead sulfide concentrate and environmental pollution, and achieves low requirements for equipment anticorrosion, good working environment and low corrosiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Put 500Kg of lead sulfide concentrate into the reaction tank according to the solid-liquid ratio = 1:4, and carry out the solid-phase conversion reaction under the action of copper ion catalyst, oxygen and hydrochloric acid, wherein the catalyst dosage is 1.25g / L, and the reaction temperature is 70 ℃, the pH value of the solution is 0.5~1, the oxygen flow rate is 200ml / min, the reaction time is 7h, the reaction is completed, the solution is cooled to room temperature and the solid-liquid separation is carried out, and the solid-phase conversion slag is placed in the solid-liquid ratio of 1:4 Sodium chloride leaching is carried out in the leaching tank, wherein the concentration of sodium chloride is 6mol / L, the leaching temperature is 90°C, and the leaching time is 4h. After the leaching reaction is completed, solid-liquid separation is carried out, and the leachate is cooled and crystallized to produce solid lead chloride.

[0018] Result: Lead leaching rate 98.58%

[...

Embodiment 2

[0023] Put 500Kg of lead sulfide concentrate into the reaction tank according to the solid-liquid ratio = 1:3, and carry out the solid-phase conversion reaction under the action of catalyst, oxygen and hydrochloric acid, wherein the catalyst dosage is 1.45g / L, and the reaction temperature is 70°C. The pH value of the solution is 0.5-1, the oxygen flow rate is 200ml / min, the reaction time is 6.5h, the reaction is completed, the solution is cooled to room temperature, and the solid-liquid separation is carried out, and the solid-phase conversion slag is leached according to the solid-liquid ratio of 1:4. Sodium chloride leaching is carried out in the tank, wherein the concentration of sodium chloride is 6mol / L, the leaching temperature is 95°C, and the leaching time is 4h. After the leaching reaction is completed, solid-liquid separation is carried out, and the leaching liquid is cooled and crystallized to produce solid lead chloride.

[0024] Result: Lead leaching rate 98.75%

...

Embodiment 3

[0029] Put 500Kg of lead sulfide concentrate into the reaction tank according to the solid-liquid ratio=1:4, and carry out the solid-phase conversion reaction under the action of catalyst, oxygen and hydrochloric acid, wherein the catalyst consumption is 1.35g / L, and the reaction temperature is 65°C. The pH value of the solution is 0.5-1, the oxygen flow rate is 200ml / min, the reaction time is 7h, and the reaction is completed. After the solution is cooled to room temperature, the solid-liquid separation is carried out, and the solid-phase conversion slag is placed in the leaching tank according to the solid-liquid ratio of 1:4. Sodium chloride leaching is carried out in the medium, the concentration of sodium chloride is 6mol / L, the leaching temperature is 93°C, and the leaching time is 4h. After the leaching reaction is completed, solid-liquid separation is carried out, and the leaching solution is cooled and crystallized to produce solid lead chloride.

[0030] Result: Lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com