Process for preparing anhydrous magnesium chloride by dewatering bischofite

An anhydrous magnesium chloride, bischite technology, applied in magnesium chloride, magnesium halide and other directions, can solve the problems of no process equipment discussion, no proposed implementation method, and many impurities in the product, and achieves simple structure, convenient operation, and reduced production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

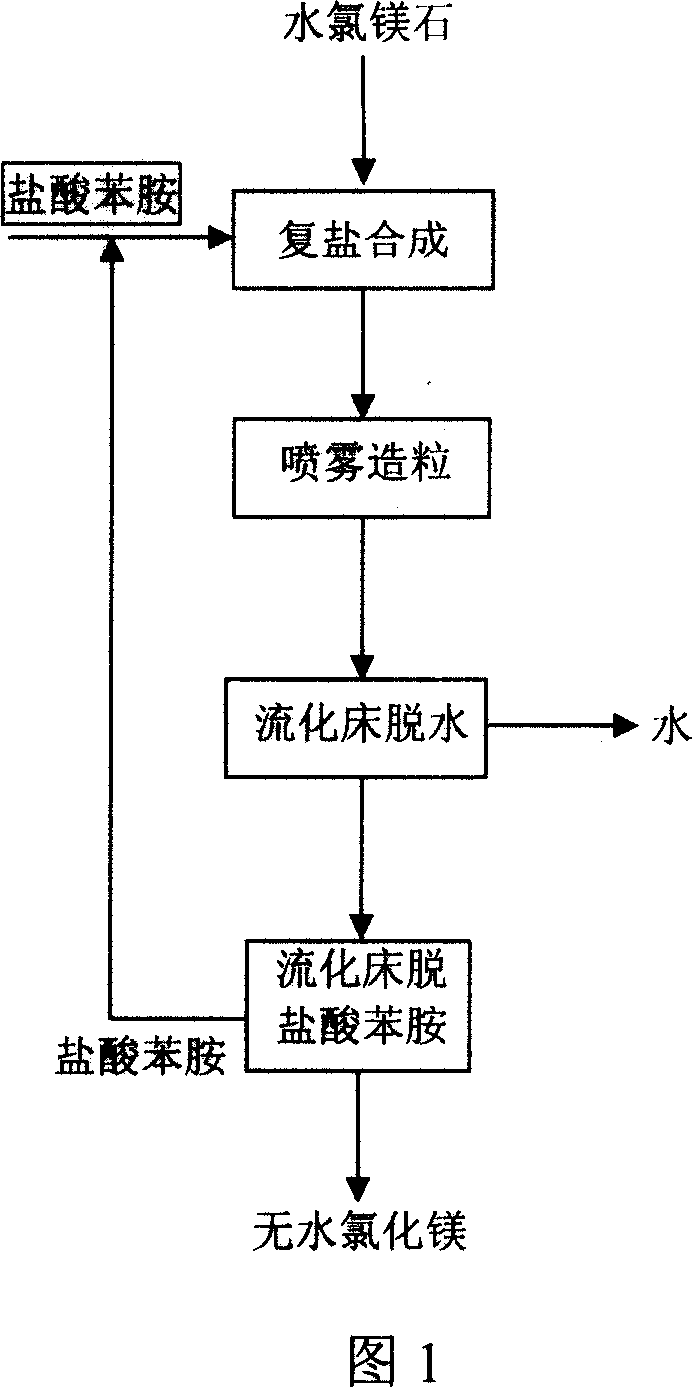

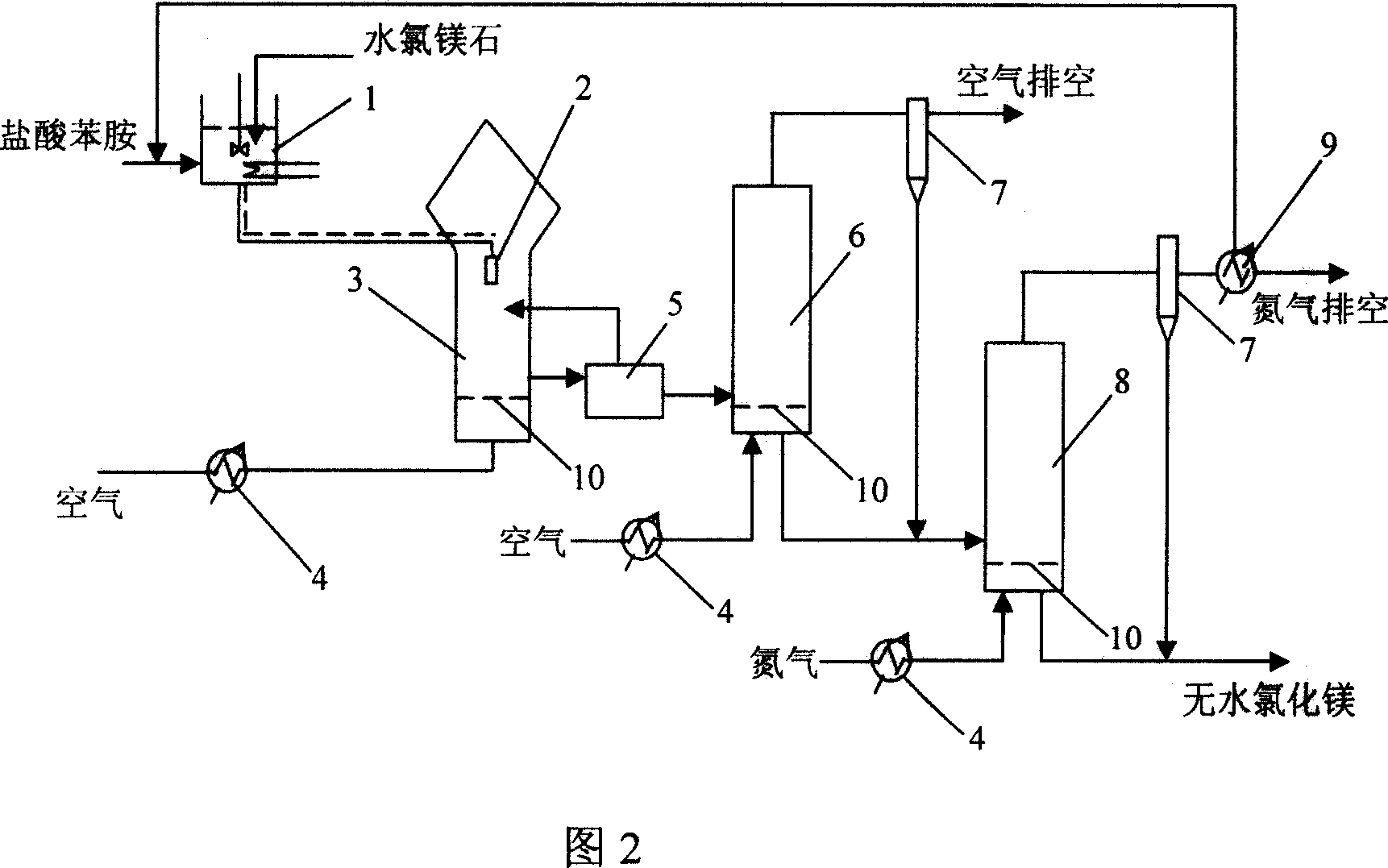

[0030] 2) Preparation of aniline hydrochloride-magnesium chloride hexahydrate double salt: mix bischofite and aniline hydrochloride in a mol ratio of 1.1:1, in order to mix evenly for each material, add water with a molar ratio of 0.2 to 2 relative to aniline hydrochloride, Stir at 85°C and dissolve into a homogeneous phase.

[0031] 3) Drying and granulation of double salt: adopt the spray drying granulation method, send the double salt solution into the granulation nozzle, spray it into the high-temperature drying tower, control the temperature within the range of 100-130°C, and use the high-speed flow in the tower The hot air dries the double salt solution sprayed out of the granulation nozzle instantly to form particles of uniform size. The double salt particles with uniform size are collected by the principle of gravity, and cooled to form double salt particles suitable for fluidization without adsorbed water.

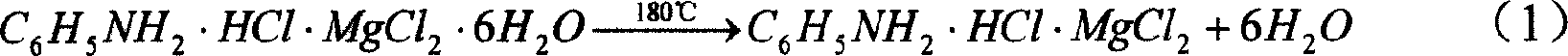

[0032] 4) Dehydration of double salt in a fluidized bed: Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com