Biological-chemical combined conditioning equipment and method

A technology of chemical combination and chemical conditioning, applied in chemical instruments and methods, biological sludge treatment, sludge treatment, etc., can solve the corrosion of structures and equipment pipelines caused by conditioning sludge, the reduction of organic matter content in dewatered sludge, and the value of recycling Zero and other problems, to achieve the effect of improving oxidation effect, saving dosage, and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail now in conjunction with accompanying drawing.

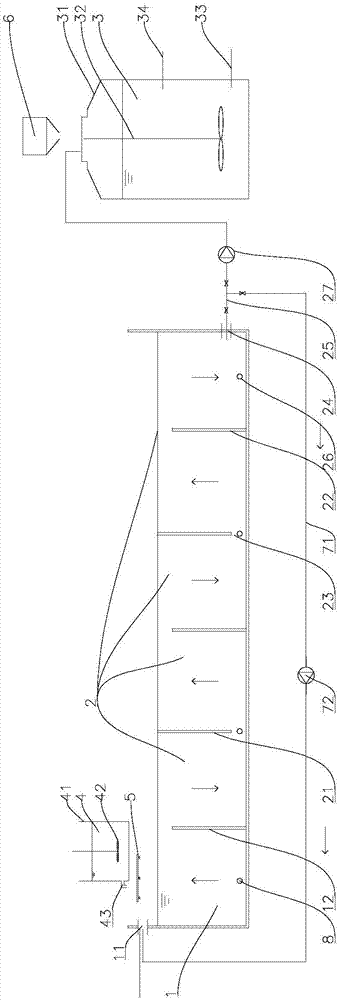

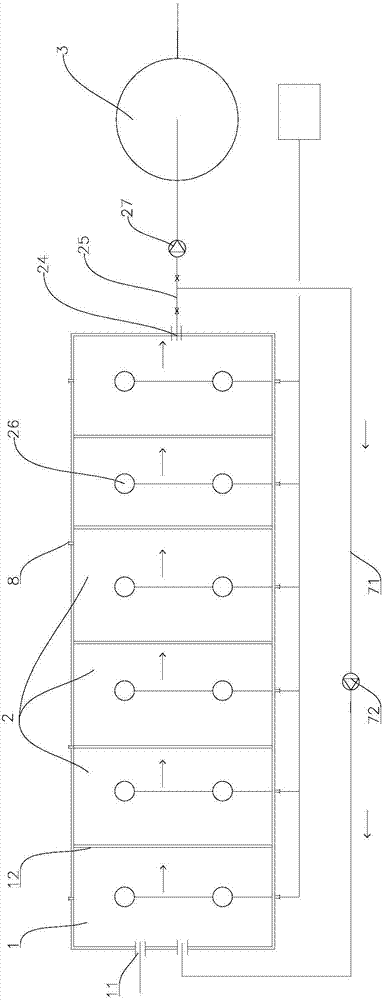

[0032] A biological-chemical combined conditioning equipment, including sequentially arranged: a biological selection tank 1, a bioleach reaction tank 2 and a chemical conditioning tank 3, the biological selection tank 1 is provided with a mud inlet 11, the biological selection tank 1 and the bioleach A partition 12 with a height lower than the side wall of the bioselective tank 1 and the side wall of the bioleaching reaction tank 2 is provided between the reaction tanks 2. The bioleaching reaction tank 2 is a square box structure with several alternately arranged upper walls. The baffle plate 21 and the lower baffle plate 22, the upper baffle plate 21 is fixedly connected with the side wall of the bioleaching reaction tank 2, and forms a gap 23 for the passage of sludge with the bottom plate of the bioleaching reaction tank 2, and the lower baffle plate 22 It is fixedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com