Fatty oil ethoxylate and process for preparing the same

A technology of ethoxylates and oils, applied in chemical instruments and methods, chemical/physical processes, dissolution, etc., can solve problems such as potassium hydroxide is difficult to achieve catalytic effect, difficulty in non-ionic products, low reaction conversion rate, etc., to achieve Excellent oil solubilization ability, HLB value can be adjusted freely, good low temperature solubility effect

Active Publication Date: 2006-02-08

中轻日化科技有限公司

View PDF1 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This process has a long process route, and the preparation of methyl ester still needs to go through operations such as washing, dehydration, and distillation, and the process is cumbersome.

Due to the collection of by-product methanol, a frozen brine system needs to be configured, and methyl ester hydrogenation requires high temperature and high pressure, so the equipment is complicated, resulting in high product costs. In addition, the irritation and ecotoxicity of alcohol ether nonionic surfactants are not ideal. The foam is too rich, it is not easy to rinse

However, it is difficult to synthesize non-ionic products directly from the one-step method of ethoxylation of fats and oils.

Natural oils are mainly triglycerides, not only the raw materials themselves have no active hydrogen connected with heteroatoms, but also contain three long chains in the molecule, with large molecular weight and large steric hindrance. Traditional ethoxylation catalysts such as sodium hydroxide , Potassium hydroxide is difficult to achieve an effective catalytic effect, the catalytic speed is extremely slow, the reaction conversion rate is low, the content of unreacted oil is high, and the content of by-products such as polyethylene glycol is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

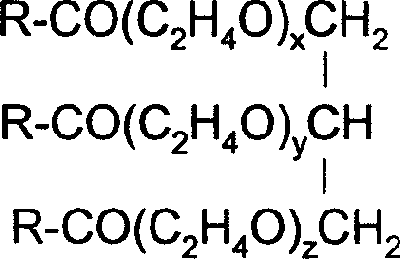

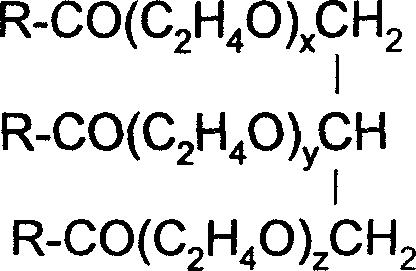

The grease ethoxylate is characterized in that it comprises the following forms: R is C1-30 hydrocarbon radicals or their mixtures; x, y, z are the same or different; x + y + z=1-180. The invention comprising the following steps: mixing grease and catalyst with each other; replacing the air in reactor with nitrogen; Adjusting the mixture to reaction temperature and operating pressure; leading-in ethylene oxide while keeping reaction pressure; aging for 10-20 minutes and cooling to get product. The invention has the advantages of non-toxicity, non-irritating and good compatibility with skin.

Description

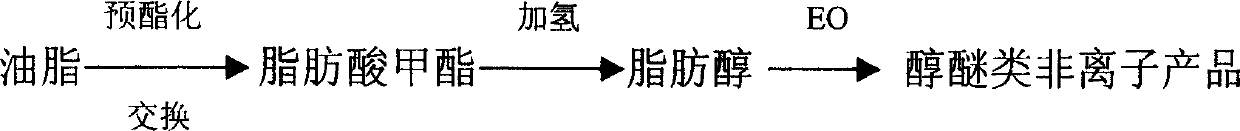

technical field The invention belongs to a kind of non-ionic surfactant, in particular to a kind of ethoxylate of oil and its preparation method. Background of the invention Oleochemicals in the traditional sense generally pre-esterify and transesterify oils and fats to obtain fatty acid methyl esters, hydrogenate methyl esters to obtain fatty alcohols, and then prepare alcohol ether nonionic surfactants through ethoxylation. . The process route is long, and the preparation of methyl ester also needs to go through operations such as washing, dehydration, and distillation, and the process is cumbersome. Due to the collection of by-product methanol, a frozen brine system needs to be configured, and methyl ester hydrogenation requires high temperature and high pressure, so the equipment is complicated, resulting in high product costs. In addition, the irritation and ecotoxicity of alcohol ether nonionic surfactants are not ideal. The foam is too rich and not easy to rinse ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F17/08C09K23/08

Inventor 孙永强罗毅张高勇田春花刘广宇

Owner 中轻日化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com