Exhaust gas water recycling and white smoke eliminating system through condensation method

A technology of water recovery and condensation method, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., to achieve the effects of reducing white smoke phenomenon, simplifying flue system, and reducing anti-corrosion requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

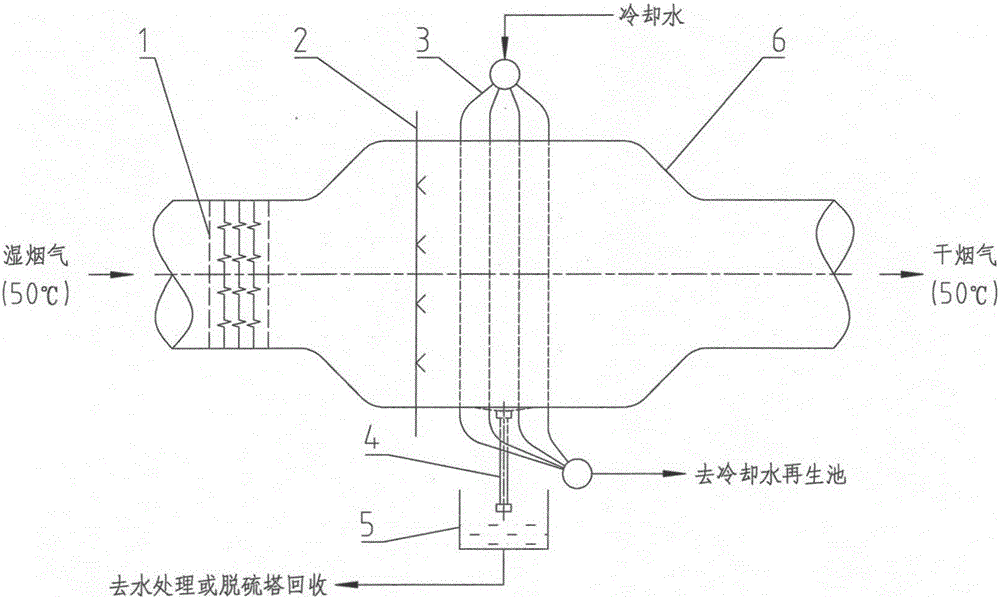

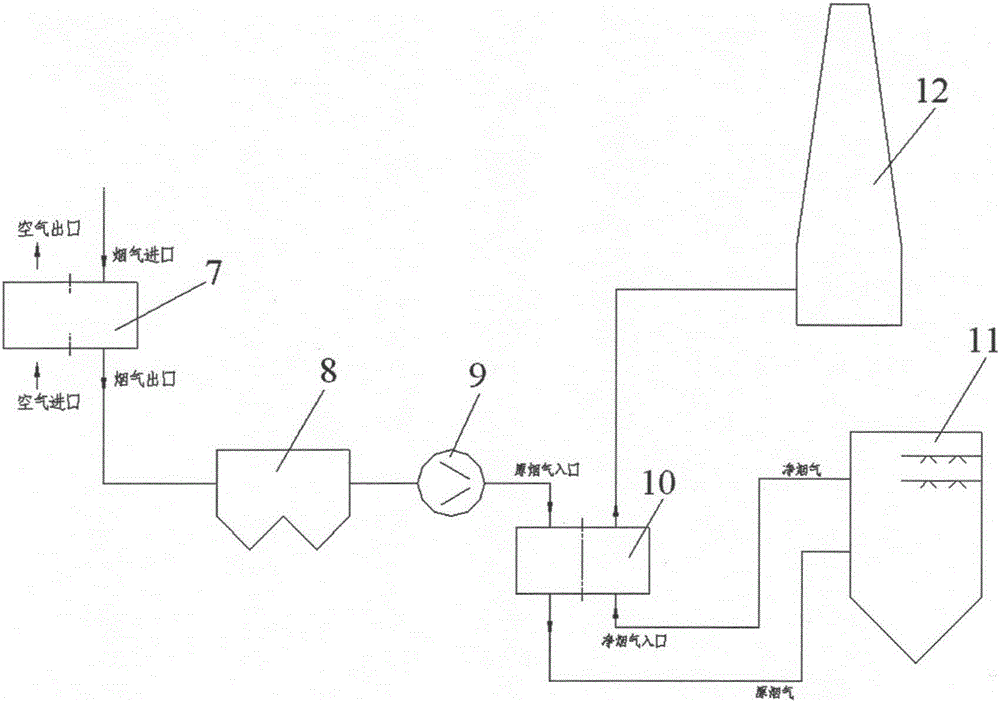

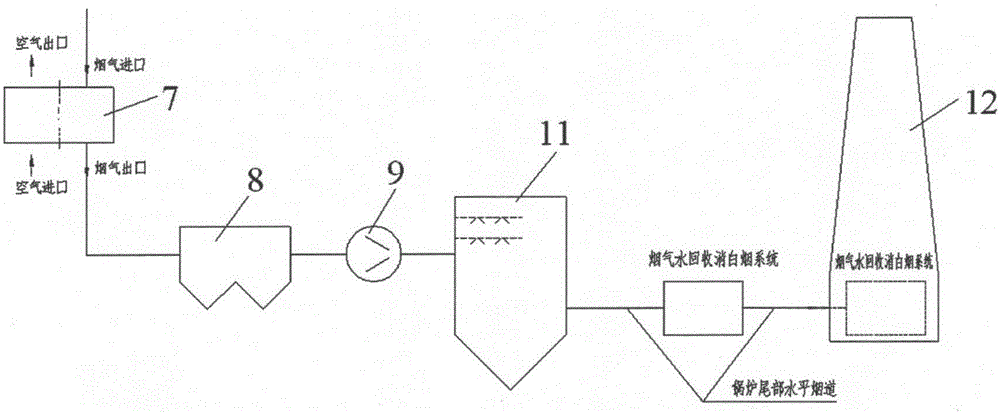

[0022] The present invention is a condensation method flue gas water recovery and white smoke elimination system, such as figure 1 As shown, a flue gas condensation chamber 6 is arranged in the flue gas channel at the entrance section of the chimney 12, and a mist eliminator 1 is arranged at the entrance of the flue gas condensation chamber 6 (if the desulfurization system already exists and the effect is satisfactory, it is not necessary to repeat the mist eliminator here. ) and a condensing tube bundle 3, after the wet flue gas from the wet desulfurization tower 11 enters the flue gas condensing chamber 6, the speed of the flue gas is reduced to 3-5m / s or below, and first passes through the demister 1 to remove the medium size of the flue gas Larger liquid droplets pass through the condensing tube bundle 3, and the inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com