Method for treating steel plant zinc-containing smoke dust through wet process to realize enrichment of zinc sulfide concentrate

A zinc sulfide concentrate and wet processing technology, applied in the direction of improving process efficiency, can solve the problems of difficult to achieve deep separation of iron and zinc, insufficient solubility of zinc ferrite, and high requirements for equipment anti-corrosion, and achieve low equipment anti-corrosion requirements. , The human body and the environment have less toxic and side effects, and the leaching system has a mild effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

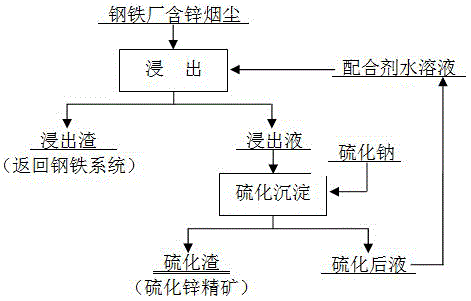

Image

Examples

Embodiment 1

[0028] Blast furnace dust in a steel plant, its main components (wt%): Zn 1.85, Fe 25.63, CaO 10.40, MgO 5.07, Cd 0.15 and Pb 0.03; Reagent: Food grade glycine, content ≥ 99%; Analytical pure NaOH, content ≥ 99.9%; Analytical pure sodium sulfide (Na 2 S·9H 2 O), Na 2 S·9H 2 O content ≥ 98%.

[0029] (1) Leaching: at 60°C, the pH value is 8 prepared with aminoacetic acid and sodium hydroxide, and the total concentration of aminoacetic acid is 0.3mol L -1 According to the liquid-solid ratio of 5:1, 50g of dust was added for leaching. After reacting for 5 hours, the solid and liquid were separated to obtain 210mL of leaching solution; among them, the concentration of Zn was 4.1g L -1 , Pb concentration 67.9mg·L -1 , Cd concentration 337.9 mg·L -1 , Fe concentration 43.3 mg·L -1 , Zn, Pb and Cd leaching rates are greater than 93%, Fe leaching rate is less than 0.1%.

[0030] (2) Sulfide precipitation: the above leachate is at 25°C, and the stirring speed is 300r·min-1 When...

Embodiment 2

[0032] Electric furnace dust in a steel plant, its main components (wt%): Zn 6.35, Fe 31.63, CaO 5.12, MgO 3.84, Cd 1.20 and Pb 0.95; reagent: food grade glycine, content ≥ 99%; industrial grade sodium glycine, Content ≥ 98%; Analytical pure sodium sulfide (Na 2 S·9H 2 O), Na 2 S·9H 2 O content ≥ 98%.

[0033] (1) Leaching: at 75°C, the pH value of glycine and sodium glycine is 8.5, and the total concentration of glycine is 1.2mol L -1 400mL aqueous solution of compounding agent, according to the liquid-solid ratio of 8:1, add 50g of smoke and dust for leaching, after reacting for 5 hours, separate the solid and liquid to obtain 320mL of leachate; among them, the concentration of Zn is 9.4g L -1 , Pb concentration 1.4g L -1 , Cd concentration 1.8g L -1 , Fe concentration 69.5mg·L -1 , Zn, Pb and Cd leaching rates are greater than 93%, Fe leaching rate is less than 0.1%.

[0034] (2) Sulfide precipitation: the above leachate is at 45°C, and the stirring speed is 350r·mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com