Convertor coal gas recovery method

A recovery method and converter gas technology, applied in separation methods, chemical instruments and methods, gas dust removal, etc., can solve problems such as water waste, achieve the effects of improving quality, reducing anti-corrosion requirements, and reducing initial investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

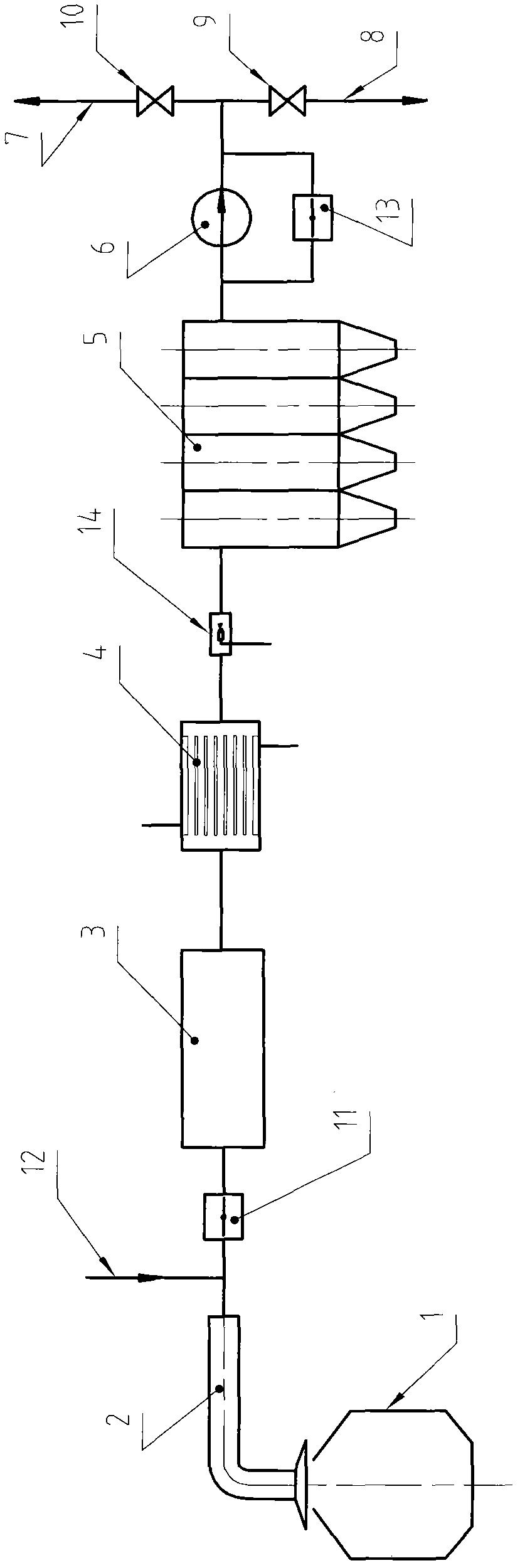

[0034] Example 1, such as figure 1 Shown.

[0035] in figure 1 Among them, 1 is the converter. 2 is the flue heat exchange device of the converter. 3 is a combined device that has the functions of coarse dust removal, heat storage and combustion chamber (for the convenience of ash discharging, if necessary, it can be arranged in parallel with two, one is prepared and the other is used, so as not to affect the converter production). 4 is a heat exchange device. Specifically, it uses a fire tube heat exchange device or a fire tube boiler, and it is recommended to install it vertically to avoid or reduce dust accumulation. 5 is a fine dust removal device, specifically, it is a bag filter. 6 is the fan. 7 is the recovery channel of converter gas. 8 is the combustion and release channel of converter gas to facilitate emergency and / or release of residual gas that has no recovery value. 9 and 10 are control valves arranged on the release channel 8 and the recovery channel 7 res...

Embodiment 2

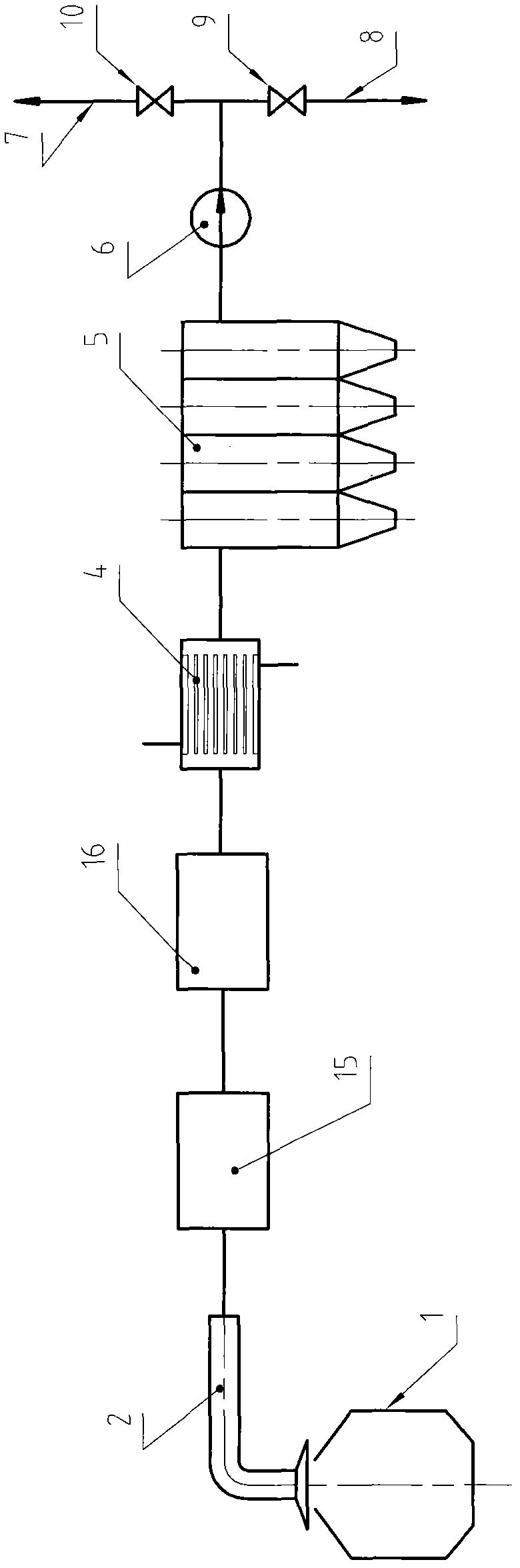

[0058] Example 2, such as figure 2 Shown.

[0059] This embodiment is a simplification of Embodiment 1.

[0060] Compared with Embodiment 1, it eliminates the combination device 3, the on-off valve 11, the inert gas input channel 12, the return on-off valve 13 of the fan 6 and the water mist generator 14; and uses a newly-added separate coarse dust collector 15 And a separate combustion chamber 16 instead of the combined device 3. The separate coarse dust collector 15 and the separate combustion chamber 16 are preferably added with the function of heat storage in order to obtain a better use effect.

[0061] The working process of this embodiment is: the converter flue gas discharged from the flue heat exchange device 2 first enters the separate coarse dust collector 15 for preliminary dust removal, and keeps it at a higher temperature, and can carry out gas and oxygen in it. Then, the flue gas enters the separate combustion chamber 16, and continues the process of the reaction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com