Patents

Literature

48results about How to "Raise the dew point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

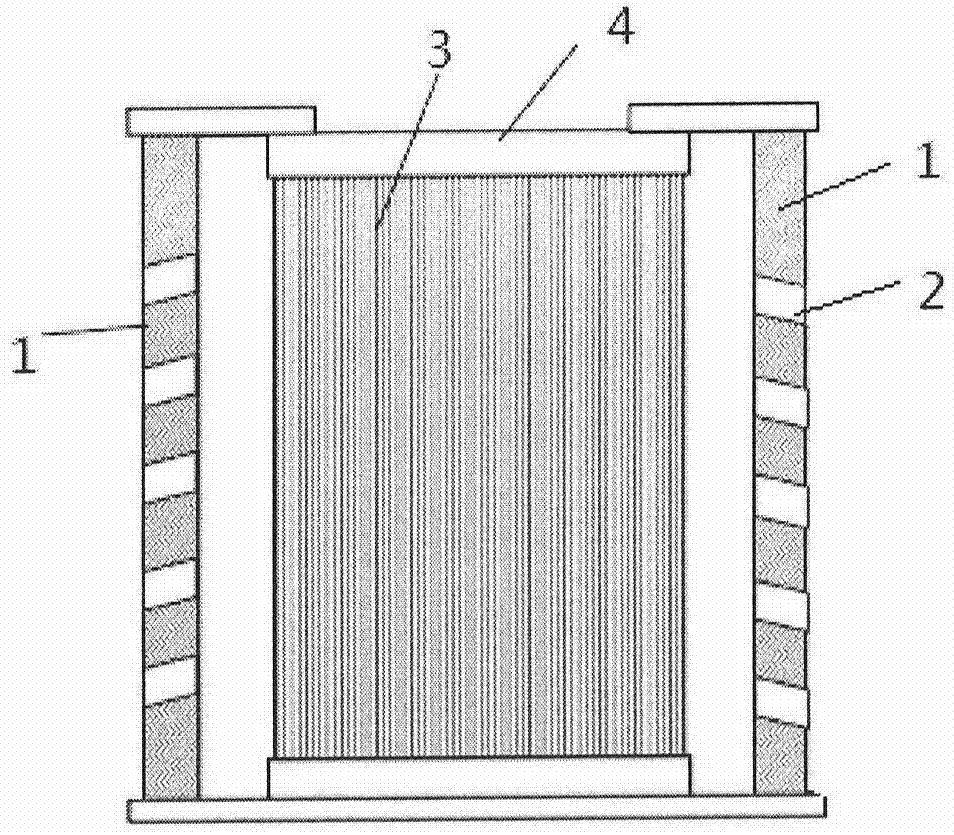

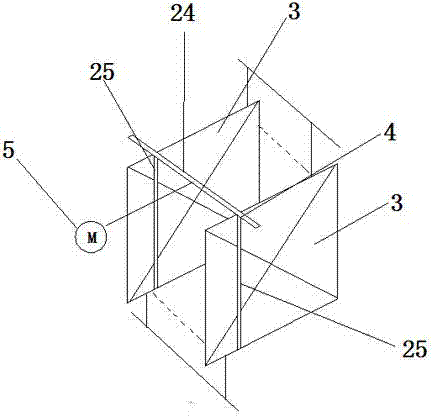

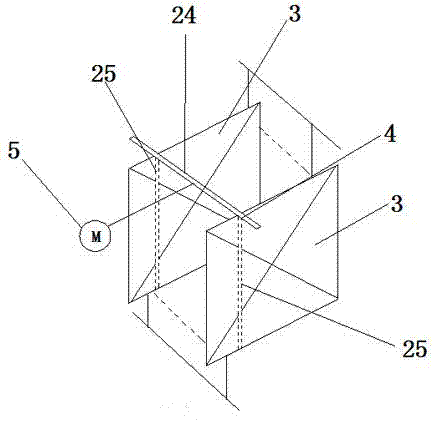

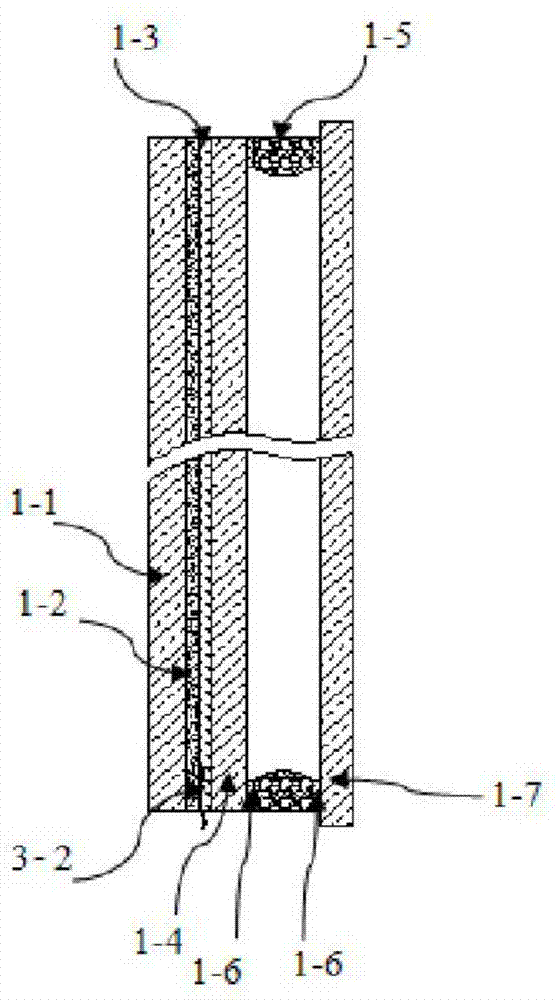

Temperature/humidity exchanger

InactiveUS7585355B2Raise the dew pointImprove efficiencyUsing liquid separation agentSolid sorbent liquid separationEngineeringMoisture

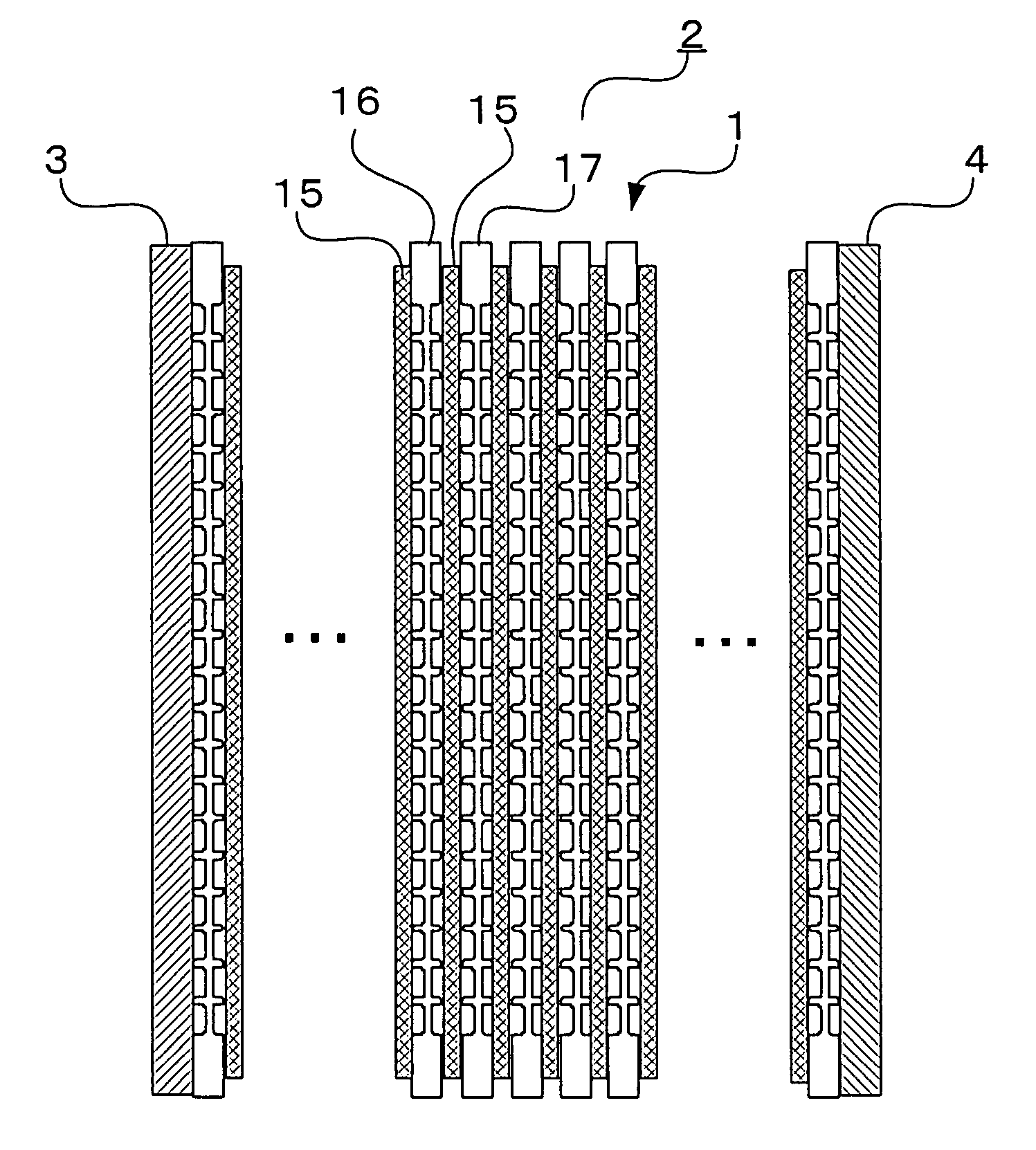

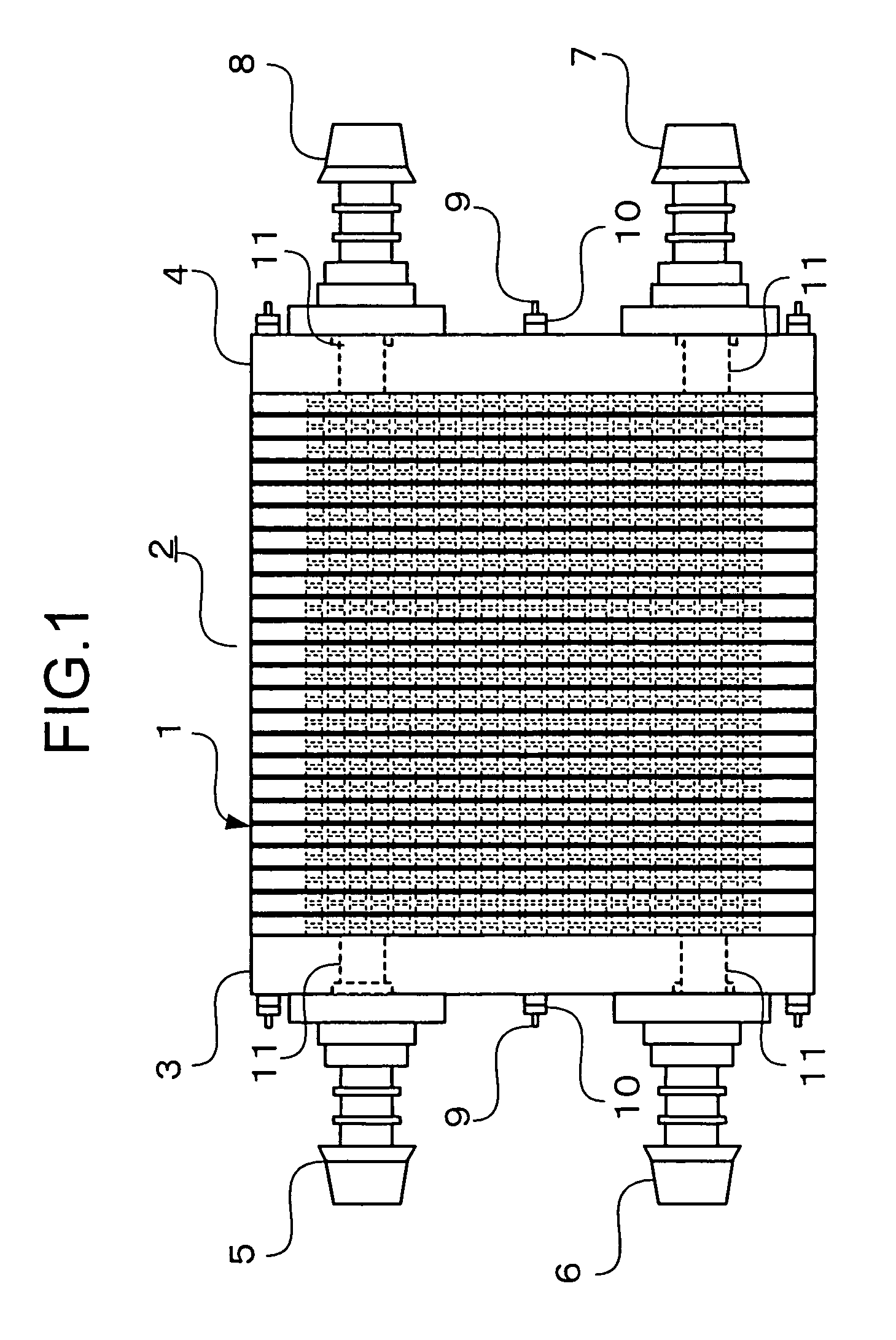

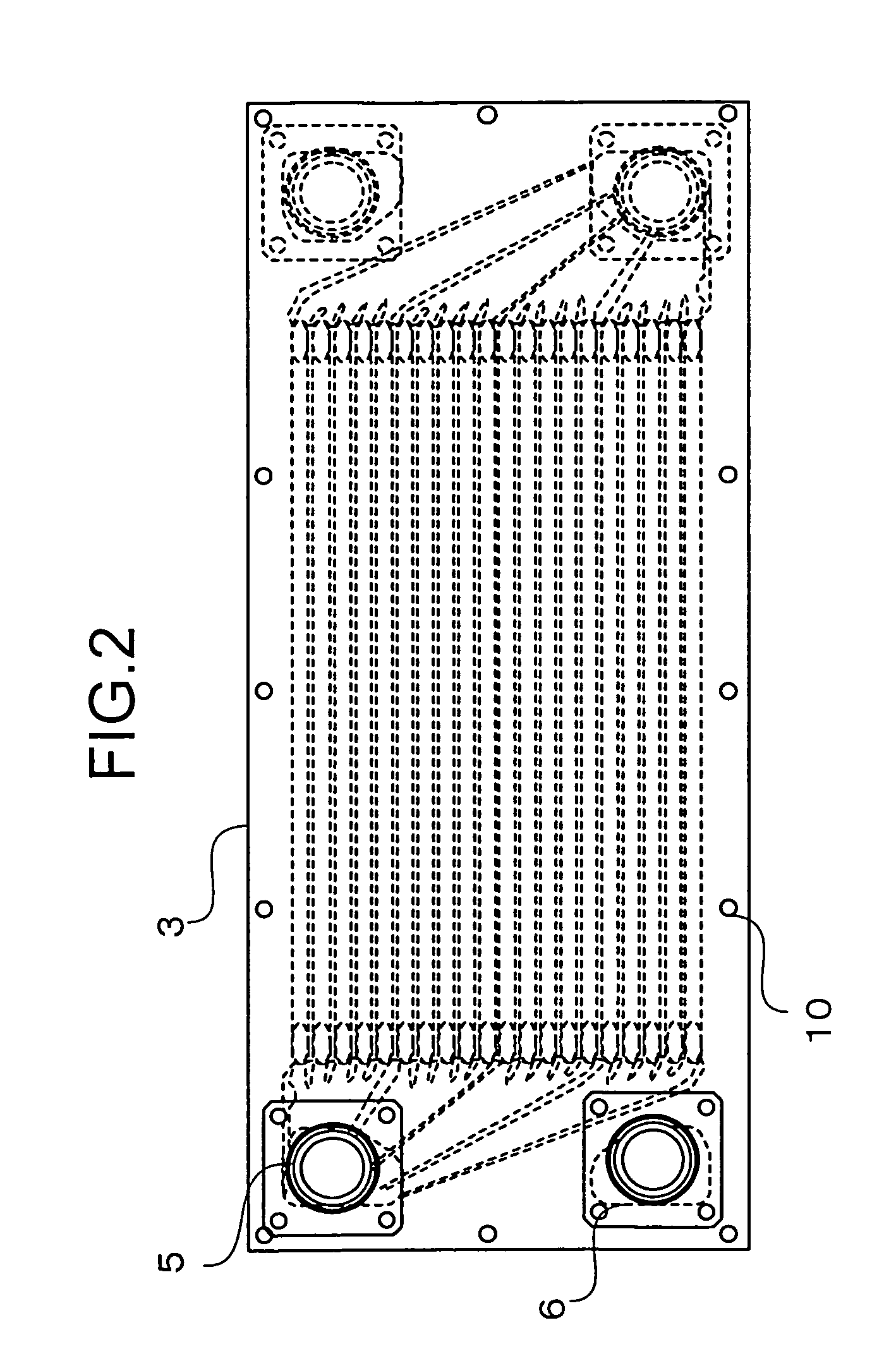

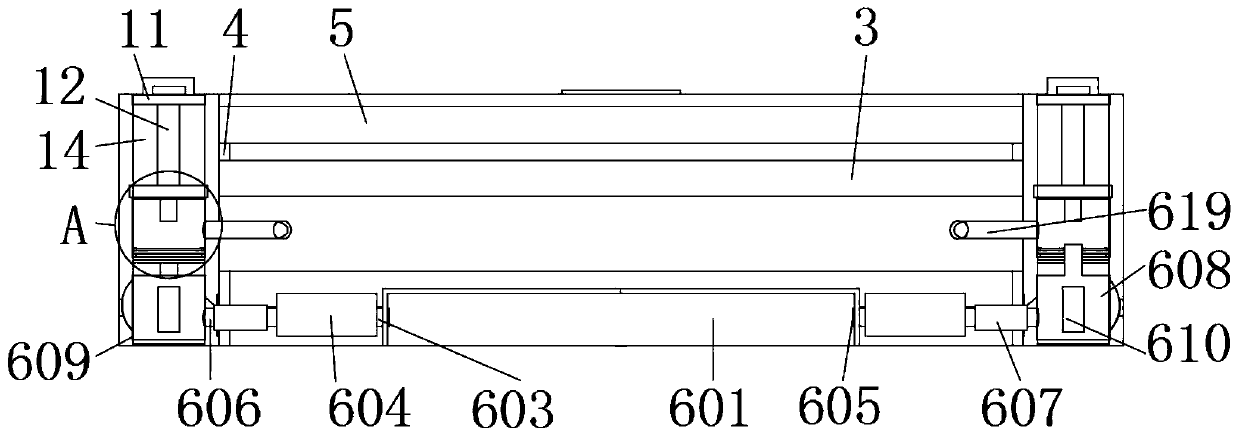

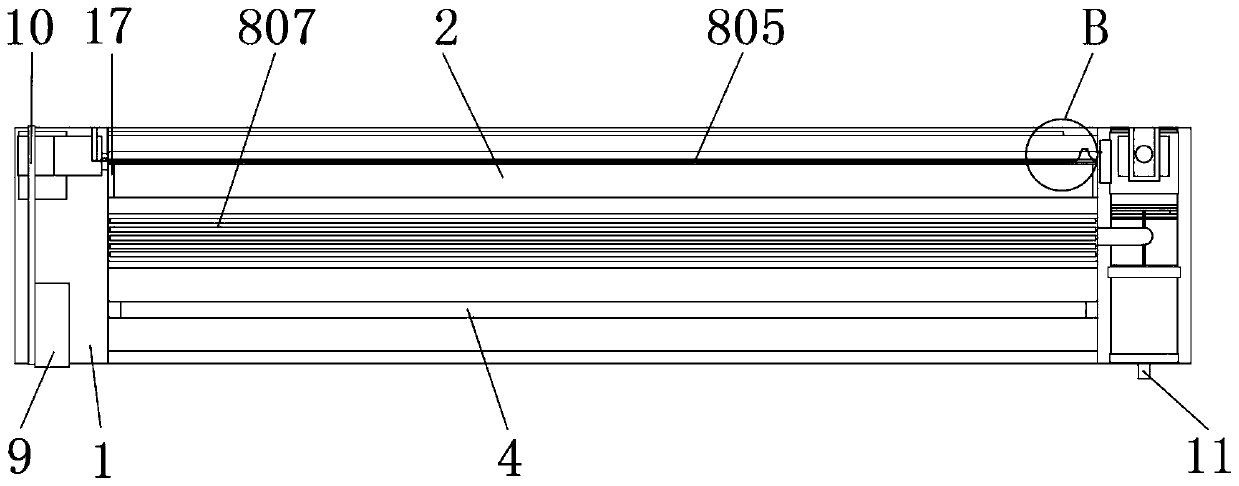

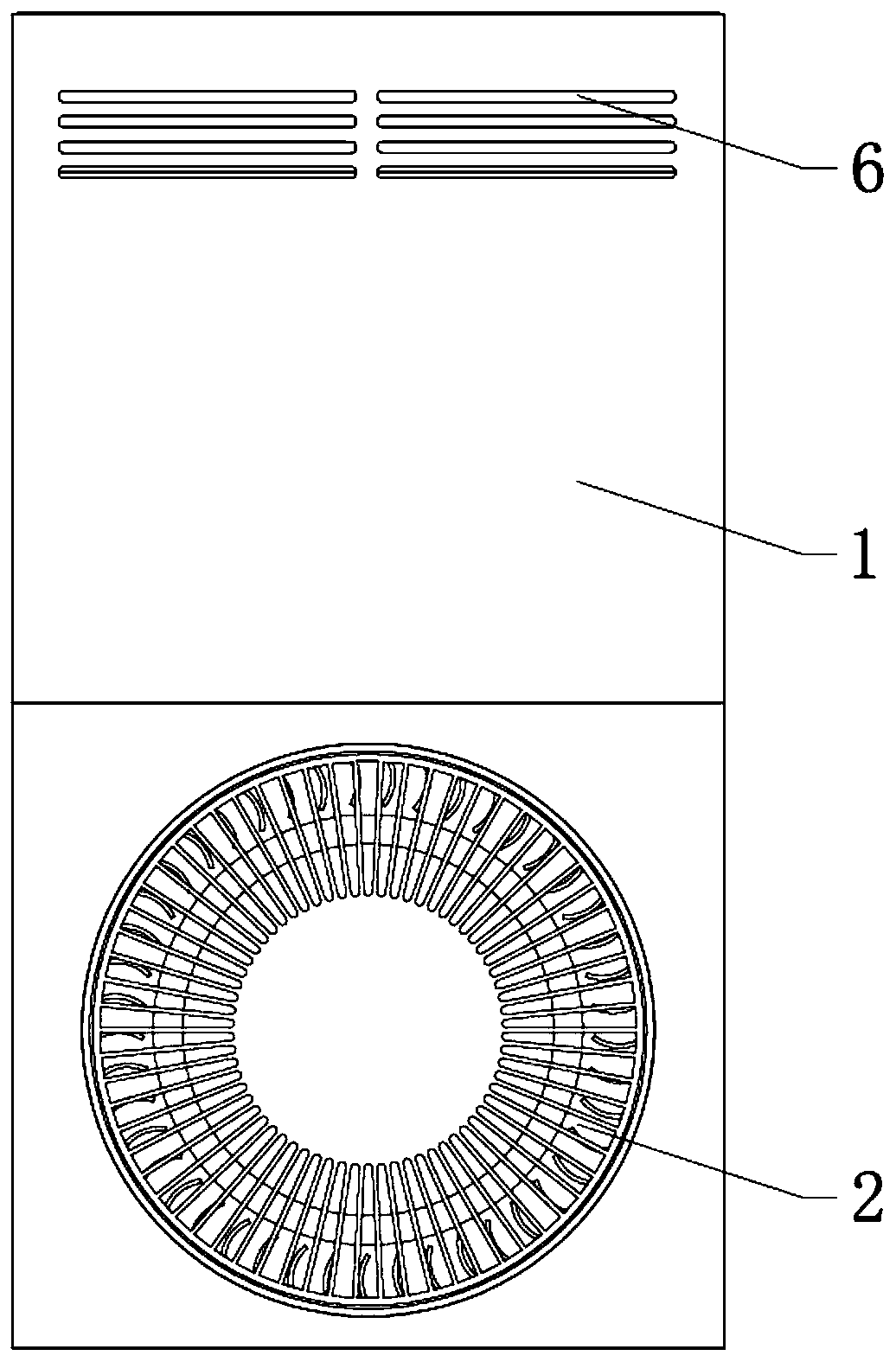

A temperature-humidity exchanger comprising: a moisture permeable membrane which transmits moisture therethrough; a dry gas separator in which low-temperature dry gas is caused to flow; and a wet gas separator in which high-temperature wet gas is caused to flow, in which the moisture permeable membrane, the dry gas separator, the moisture permeable membrane, and the wet gas separator are repeatedly stacked in the stated order, wherein in the dry gas separator and the wet gas separator: a plurality of channel grooves which are divided by half in the stacking direction, are open to a direction in which the channel grooves come into contact with the moisture permeable membrane, and are arrayed parallel to one another are provided; an aggregate communication groove which is made to communicate with both end portions of the plurality of channel grooves, for aggregating gas caused to flow through the channel grooves to at least one is provided; and a supply manifold and an exhaust manifold which are made to communicate with the aggregate communication groove and penetrate the separators in the stacking direction are provided; and a flow of the dry gas caused to flow in the channel grooves of the dry gas separators and a flow of the wet gas caused to flow in the channel grooves of the wet gas separators are counterflows.

Owner:MITSUBISHI ELECTRIC CORP

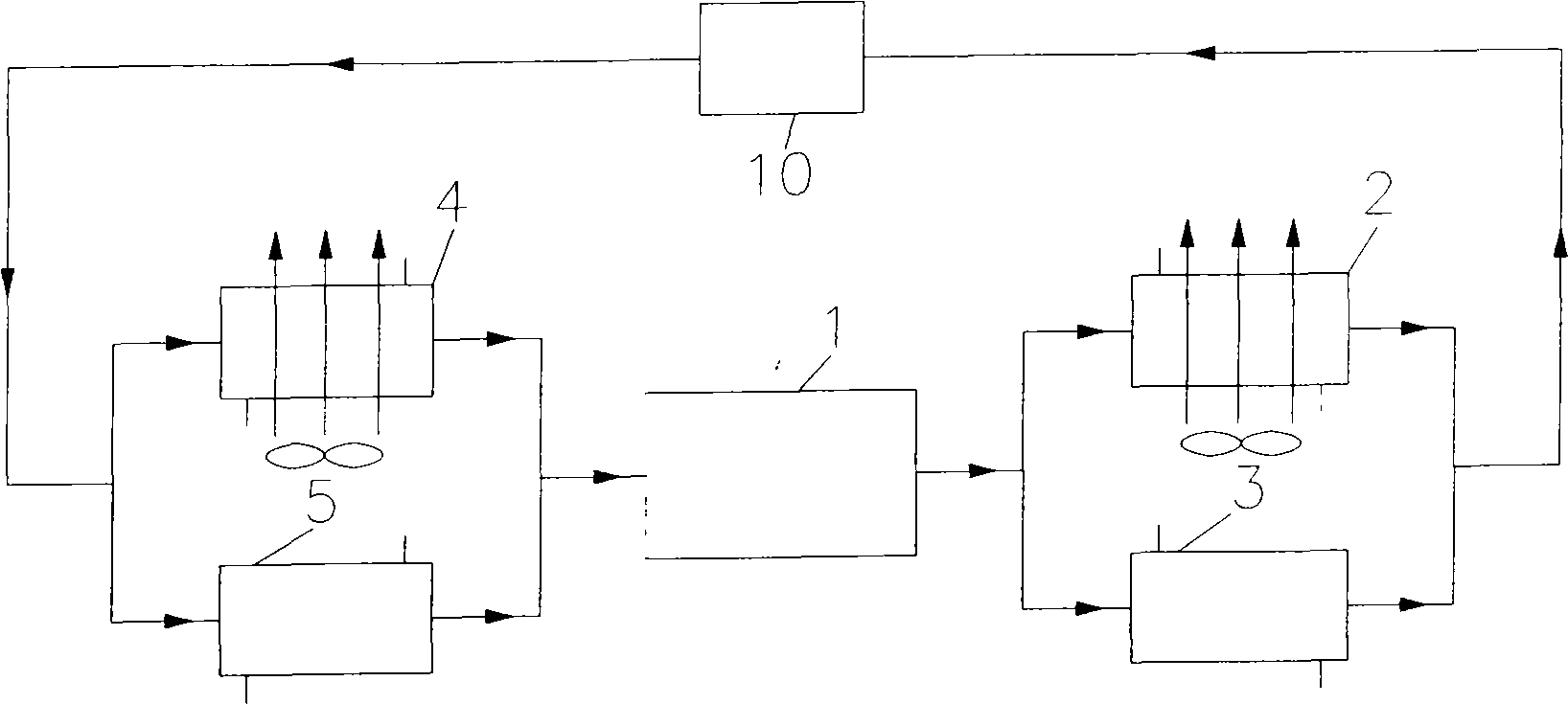

Cold/heat source integrated unit

ActiveCN101498499AReduce waste heat or waste cold emissionsReliable machine dew pointEnergy recovery in ventilation and heatingCompression machines with several condensersEvaporatorEngineering

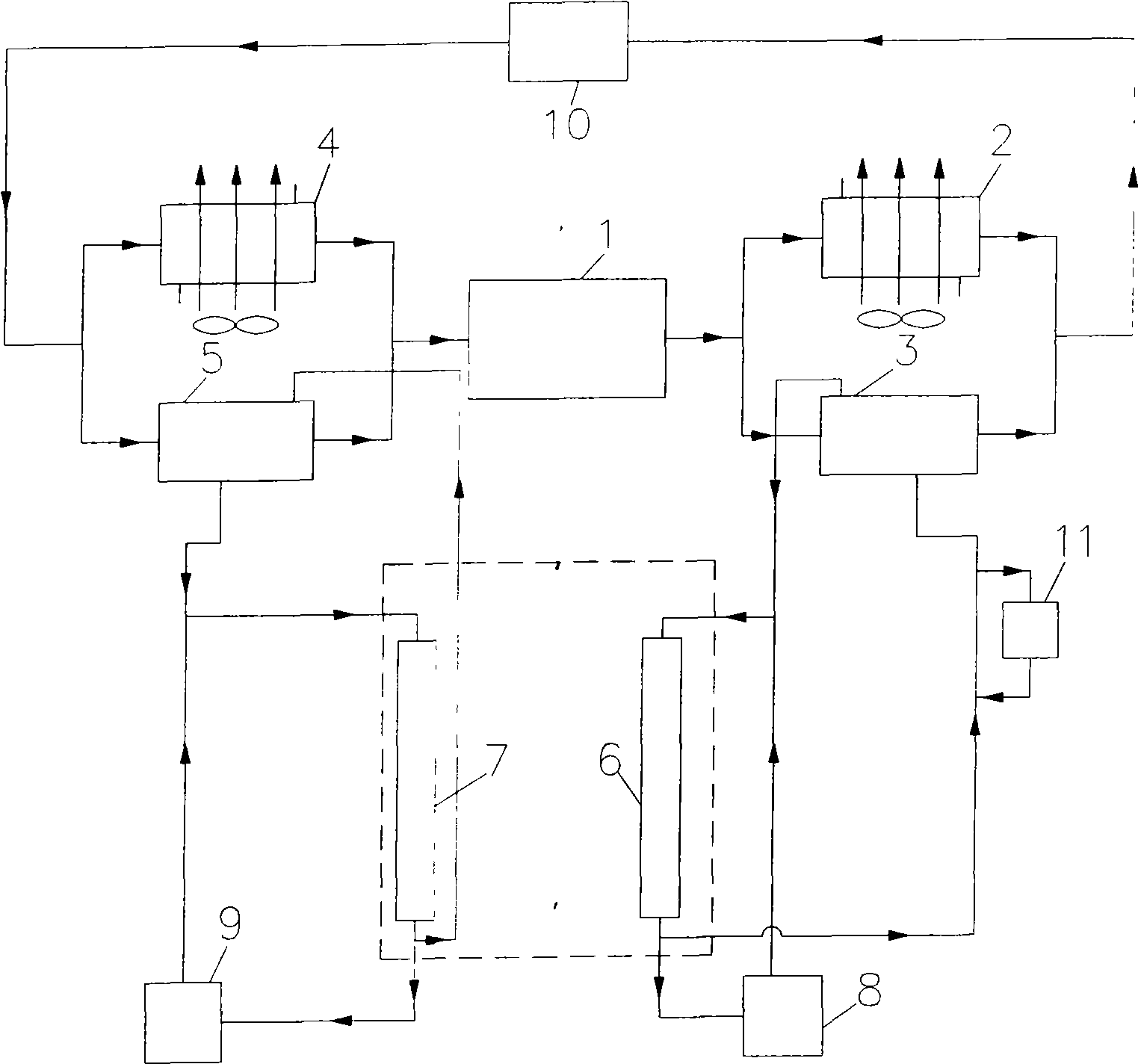

The invention relates to a cold / heat source integrated unit. The outlet of a compressor is respectively connected with an air-cooled condenser and a water-cooled condenser, the air-cooled condenser and the water-cooled condenser are jointed and then connected with a throttle device which is respectively connected with an air-cooled evaporator and a water-cooled evaporator, the air-cooled evaporator and the water-cooled evaporator are jointed and then connected with the inlet of the compressor, the outlet of the water-cooled evaporator is connected with the inlet of a cooling water user terminal, the outlet of the cooling water user terminal is circularly connected with the water-cooled condenser, the outlet of the water-cooled evaporator is connected with the inlet of a hot water user terminal, and the outlet of the hot water user terminal is circularly connected with the water-cooled evaporator. The invention changes the control target which traditionally is a specific space in a building into the control target which is the whole building, comprehensively plans the supply of a cold source and a heat source of the whole building, balances the cold energy and the heat energy, reduces the discharge of waste heat or waste cold, reduces the consumption of unrenewable resources to the minimum and forms a comprehensive energy-saving system.

Owner:SHANGHAI SINKO AIR CONDITIONING EQUIP CO LTD

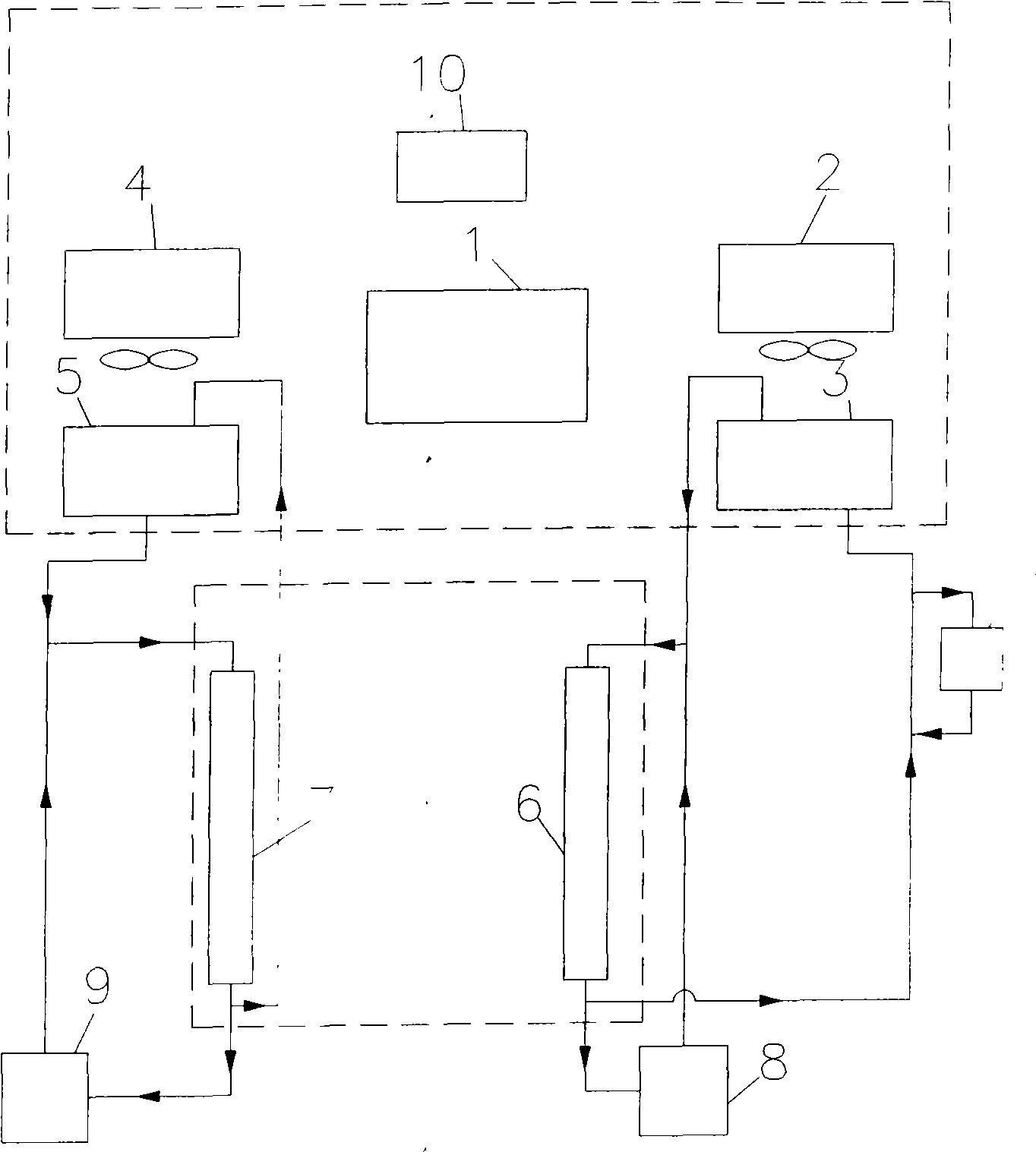

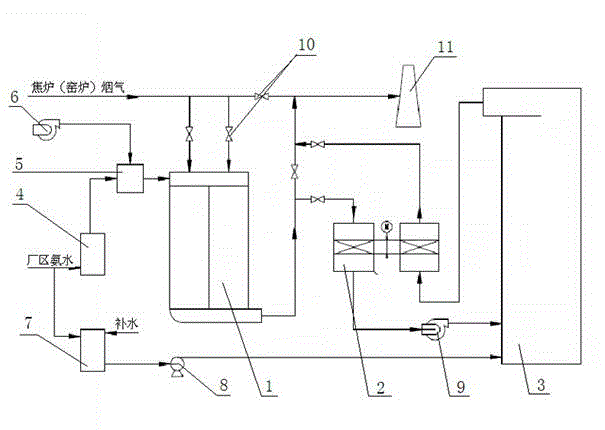

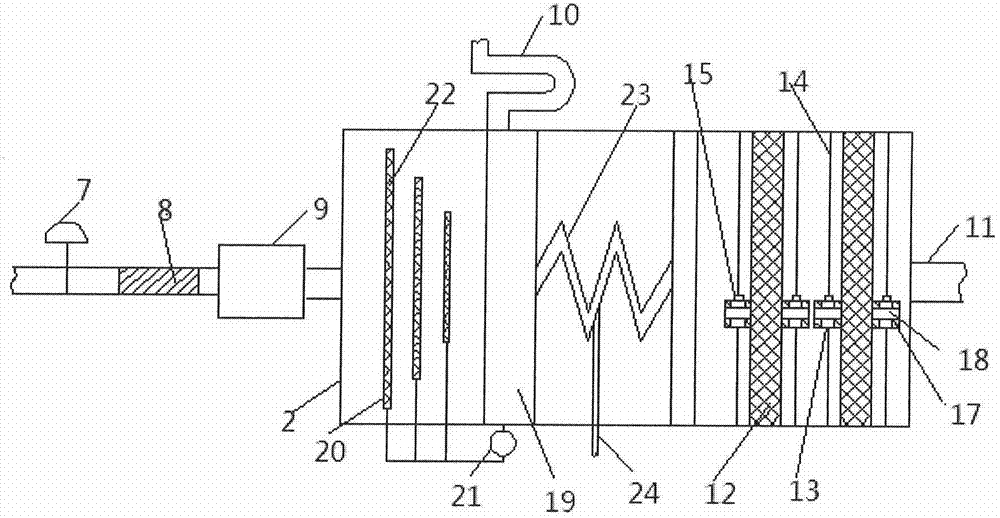

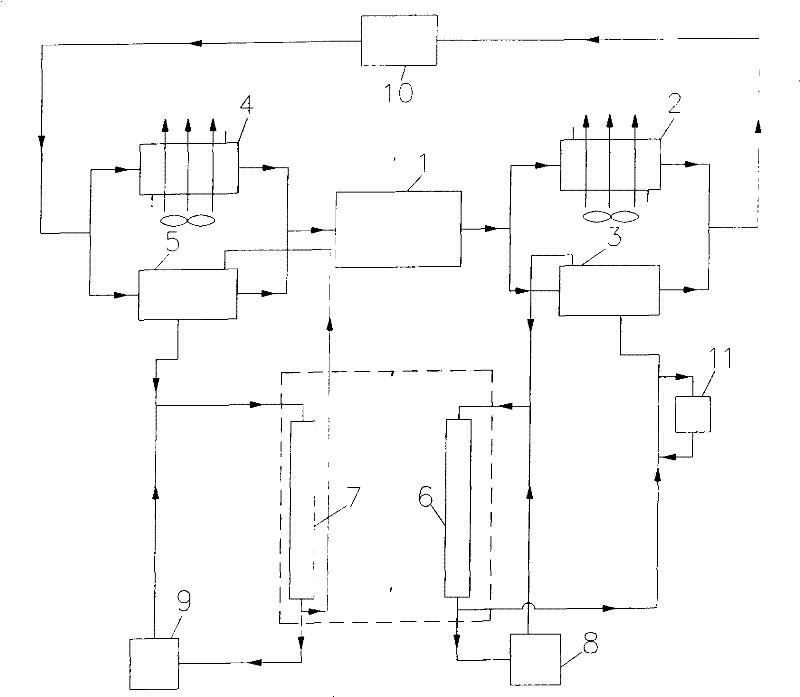

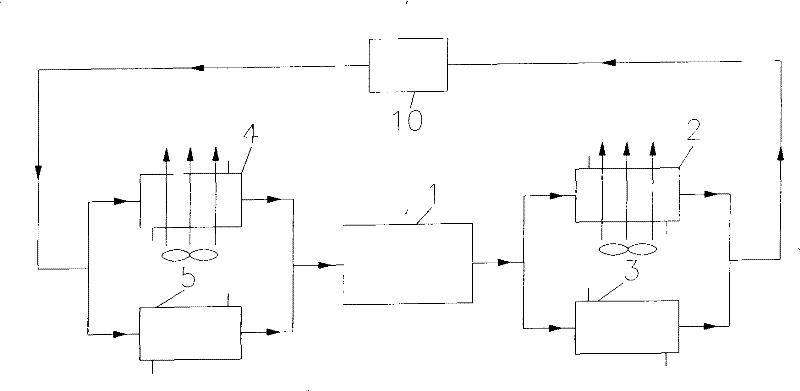

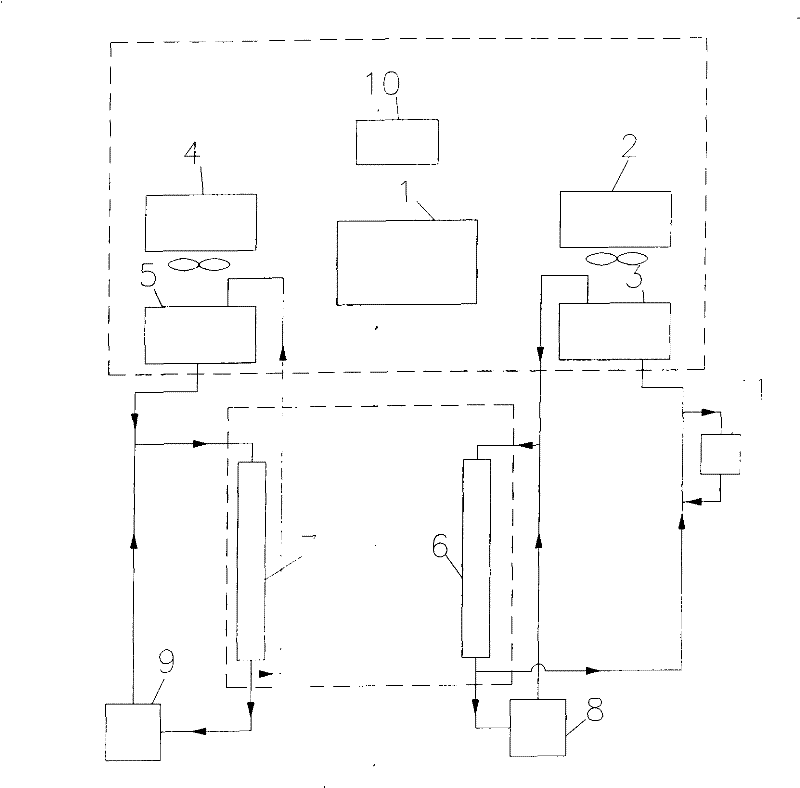

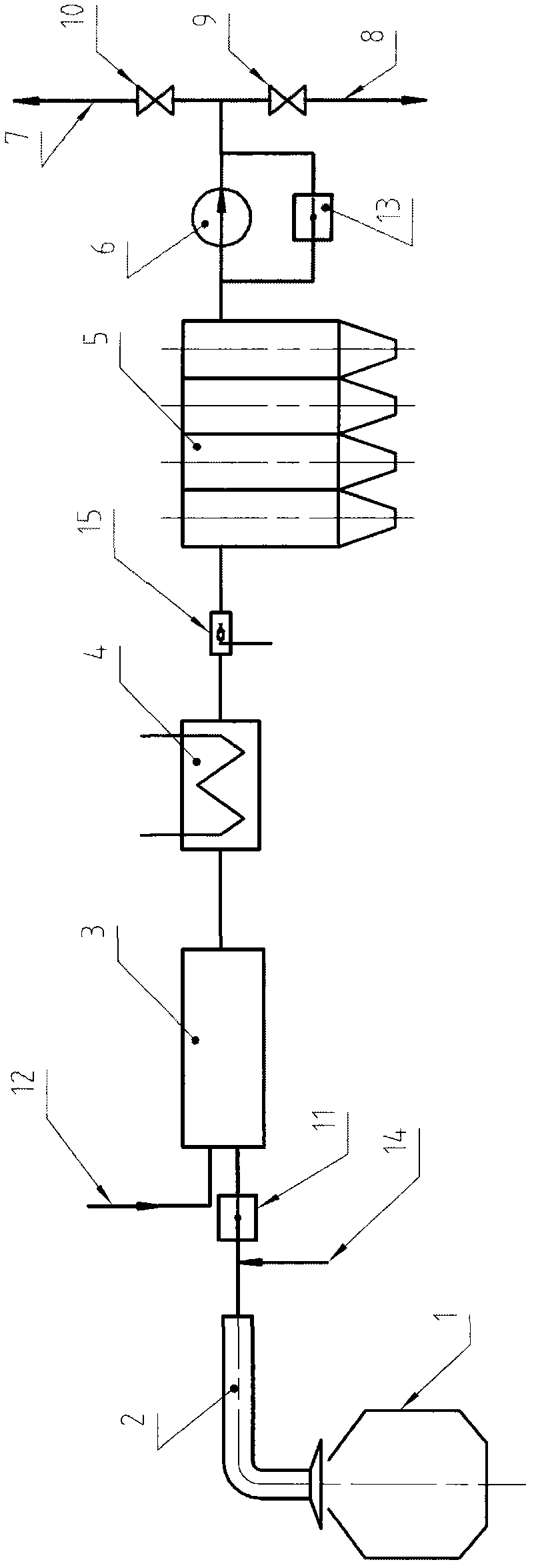

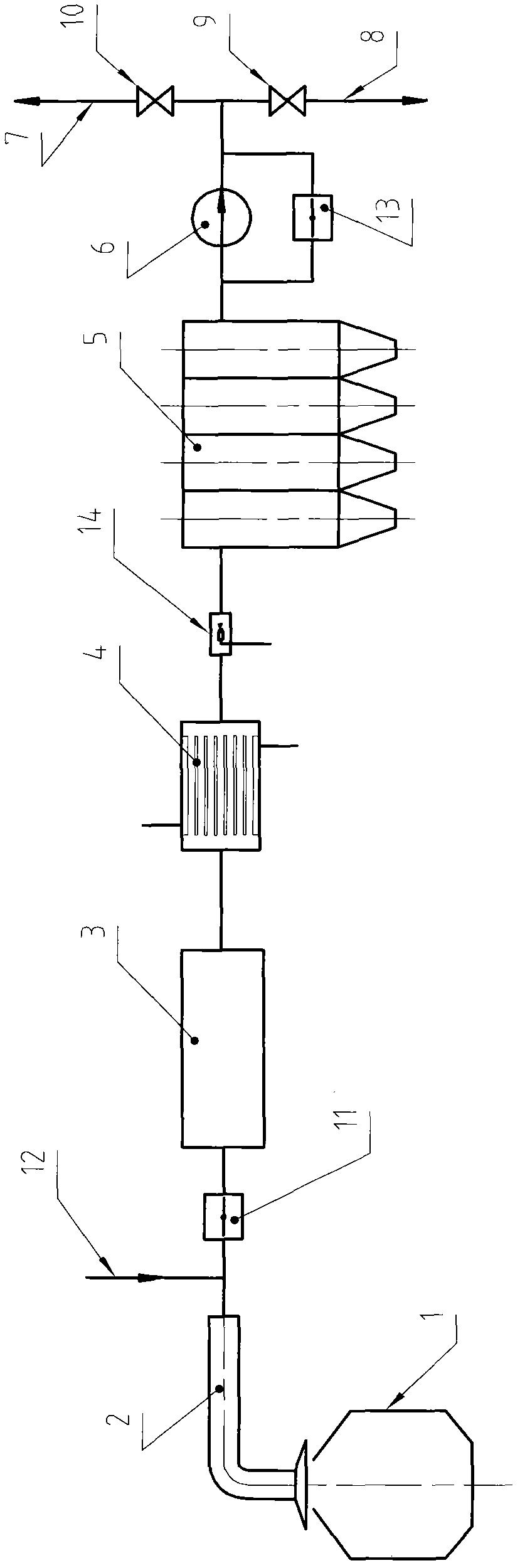

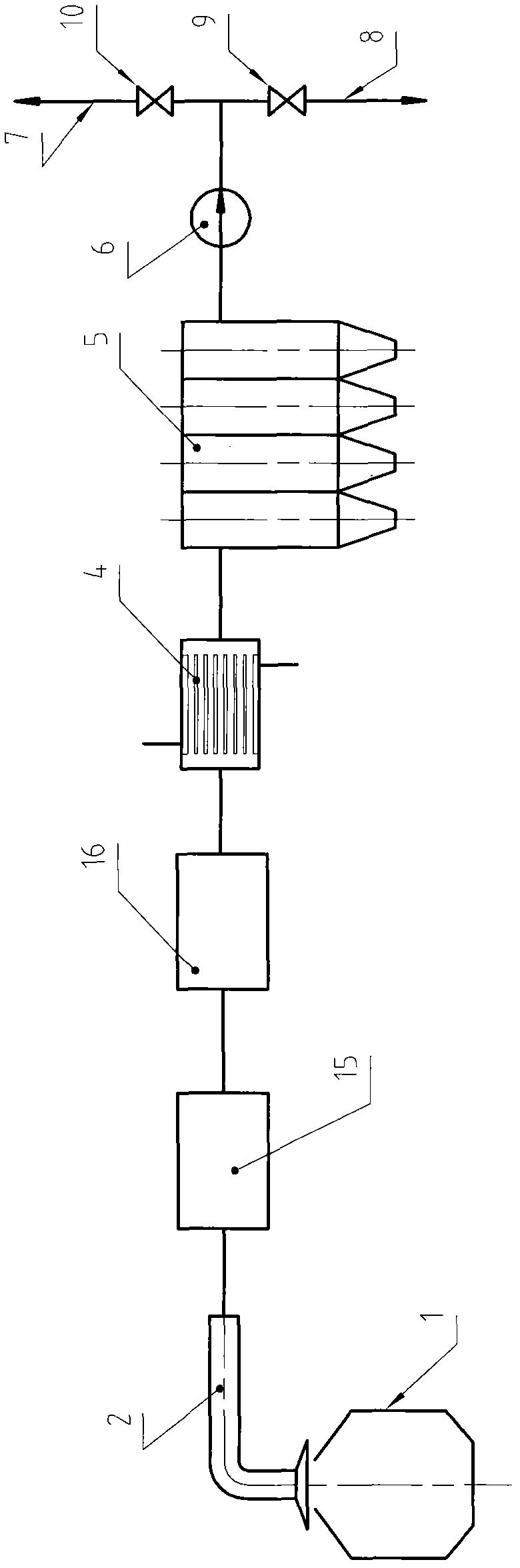

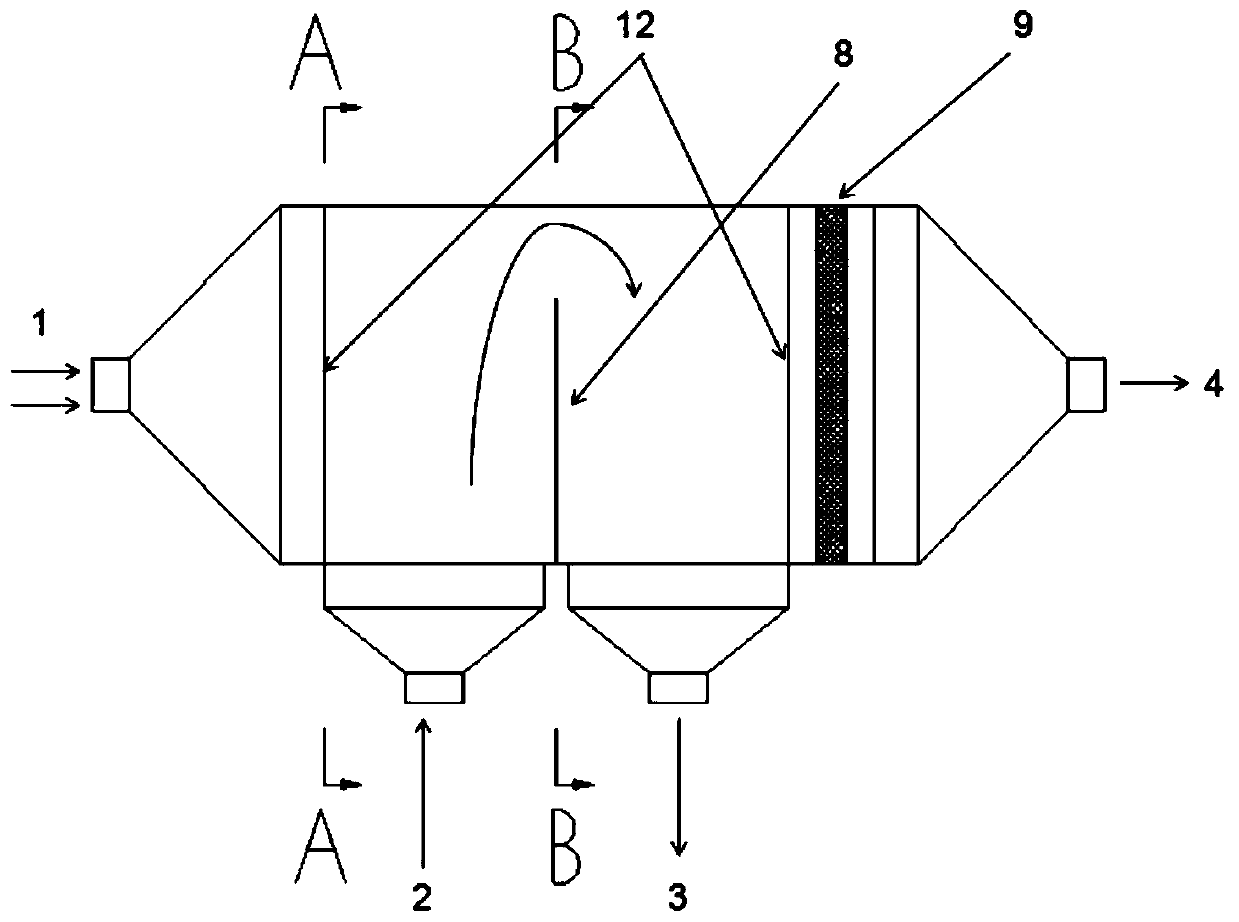

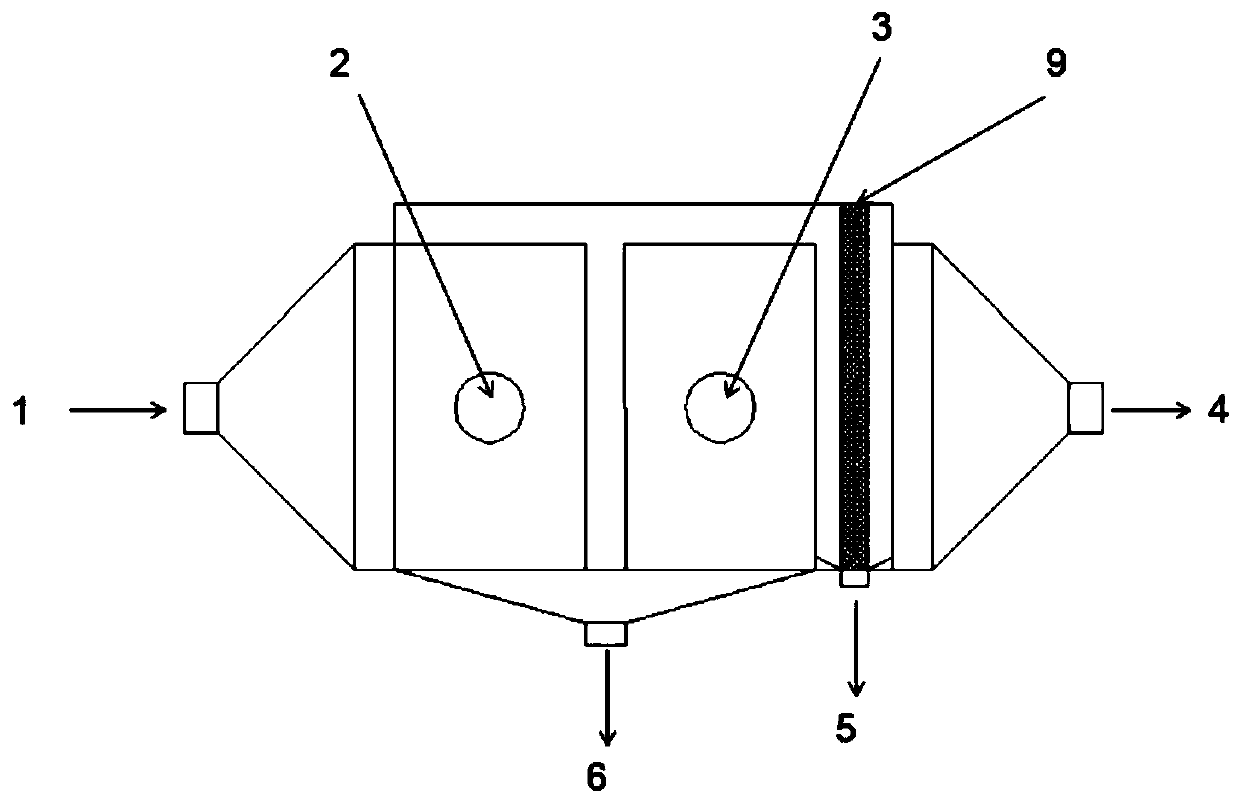

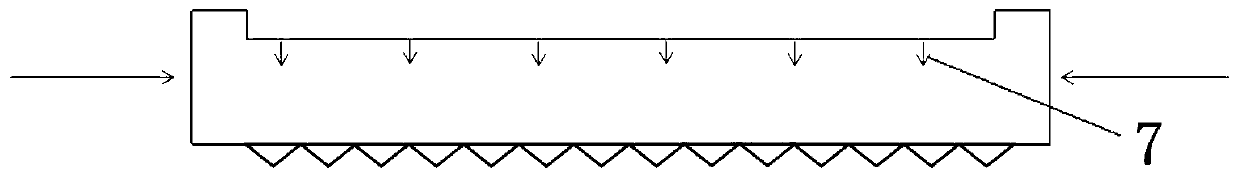

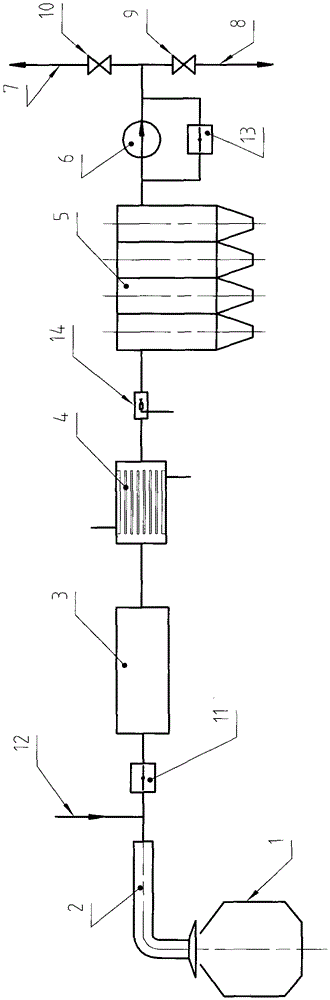

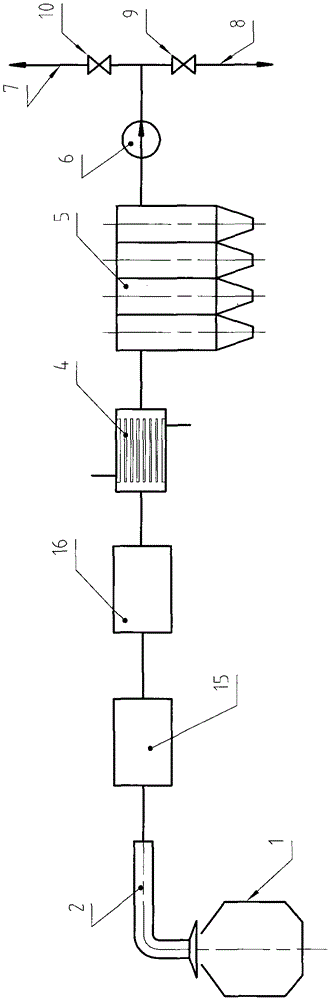

Process device of coke oven fume denitrification, desulfuration and reheating system

InactiveCN104548900ASolve efficiency problemsSolve the costDispersed particle separationCoke ovenTower

The invention provides a process device of a coke oven fume denitrification, desulfuration and reheating system. The process device consists of an SCR denitrification reactor (1), a GGH fume reheater (2), a desulfuration tower (3), an ammonia water evaporator (4), an ammonia air mixer (5), a dilution fan (6), an ammonia water dilution tank (7), an ammonia pump (8), a pressurizing fan (9), a fume switching valve (10), a chimney (11) and a pipeline which are connected together. The process device has the advantages that waste ammonia water and waste heat of fume in factories can be sufficiently utilized, the purposes of denitrification and desulfuration are achieved, the denitrificatio and desulfuration efficiency is improved, the operation cost is lowered, system corrosion is avoided, and the like.

Owner:大连贝斯特环境工程设备有限公司

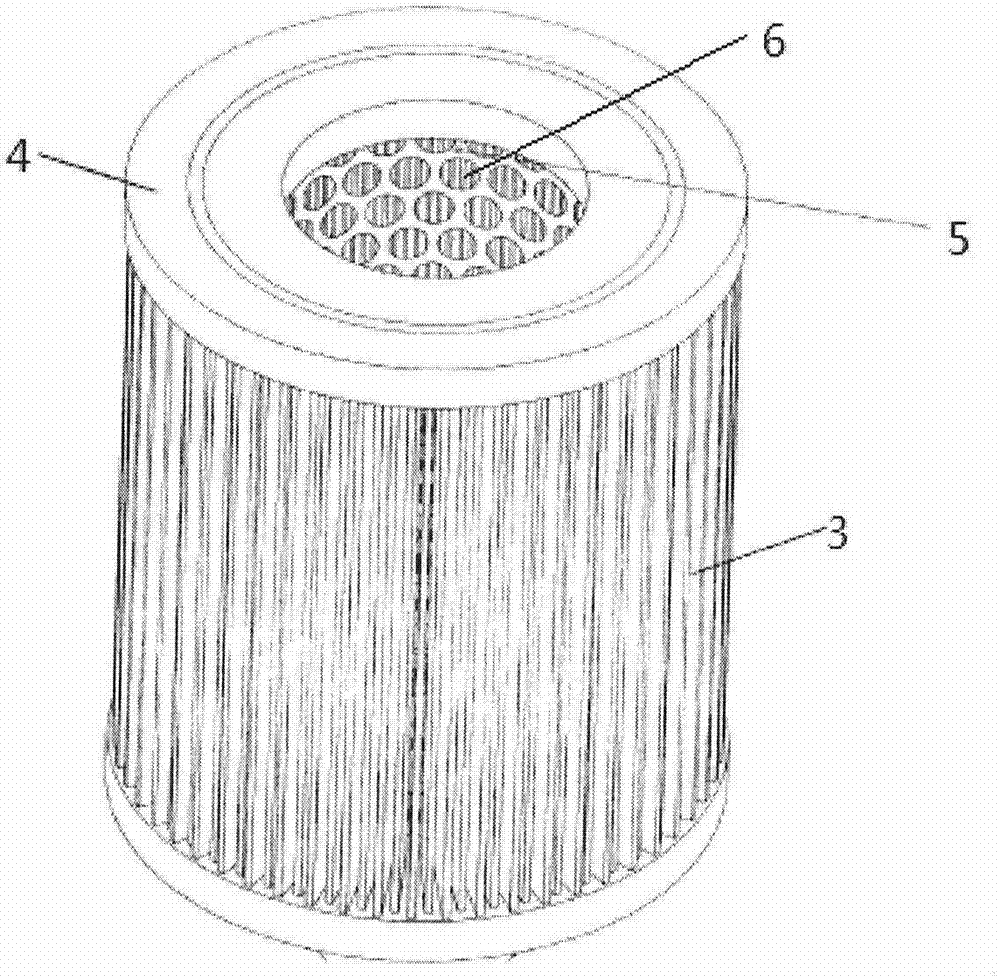

Efficient air filter

InactiveCN104500286AExtend filter timeIncrease humidityCombustion enginesAir cleaners for fuelSuspended particlesWater vapor

The invention discloses an efficient air filter. According to the air filter, when air containing moisture enters cylindrical inclined holes, electrostatic dust removers are adopted to adsorb suspended particles in air by using the electrostatic adsorption principle, and dust collecting plates are driven by motors to clean dust adsorbed by the electrostatic dust removers; a water tank is arranged to further remove dust; a bent pipeline can prolong the filter time of air in water; by pumping of a pressure pump, water in the water tank is atomized through a mesh-shaped atomizing plate for spraying in the manner of multi-layer water mist so as to further filter and purify air. By adopting the air filter, humidity of air purified by water mist is increased, the dew point of water vapor compressed by a lobed rotor compressor is reduced, and moisture is coagulated and separated in a condensing pipe and flows out along the inclined holes; filtered air is dried, reaches the periphery of a filter paper cylinder, and enters a central cylinder after filtering, so that filter paper is prevented from being damped.

Owner:XIJING UNIV

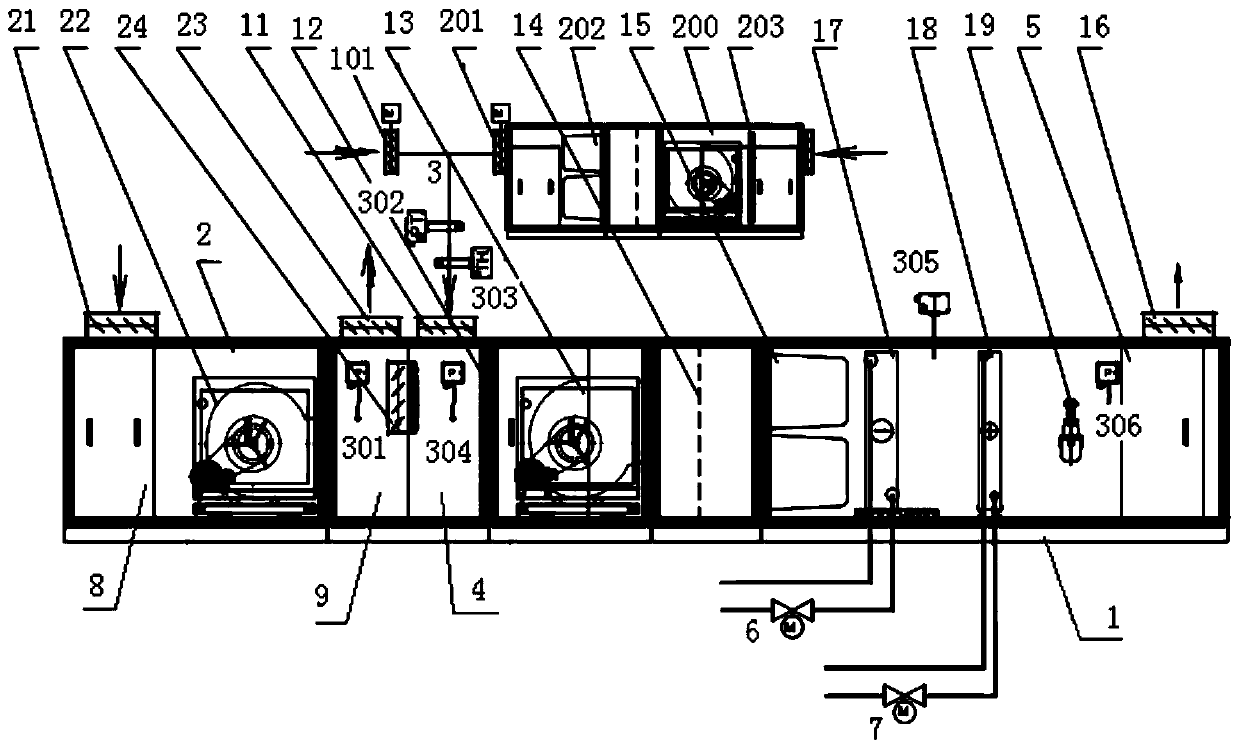

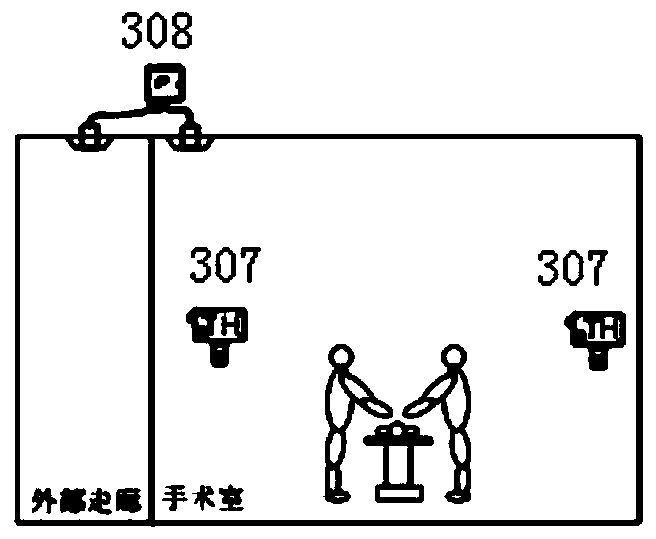

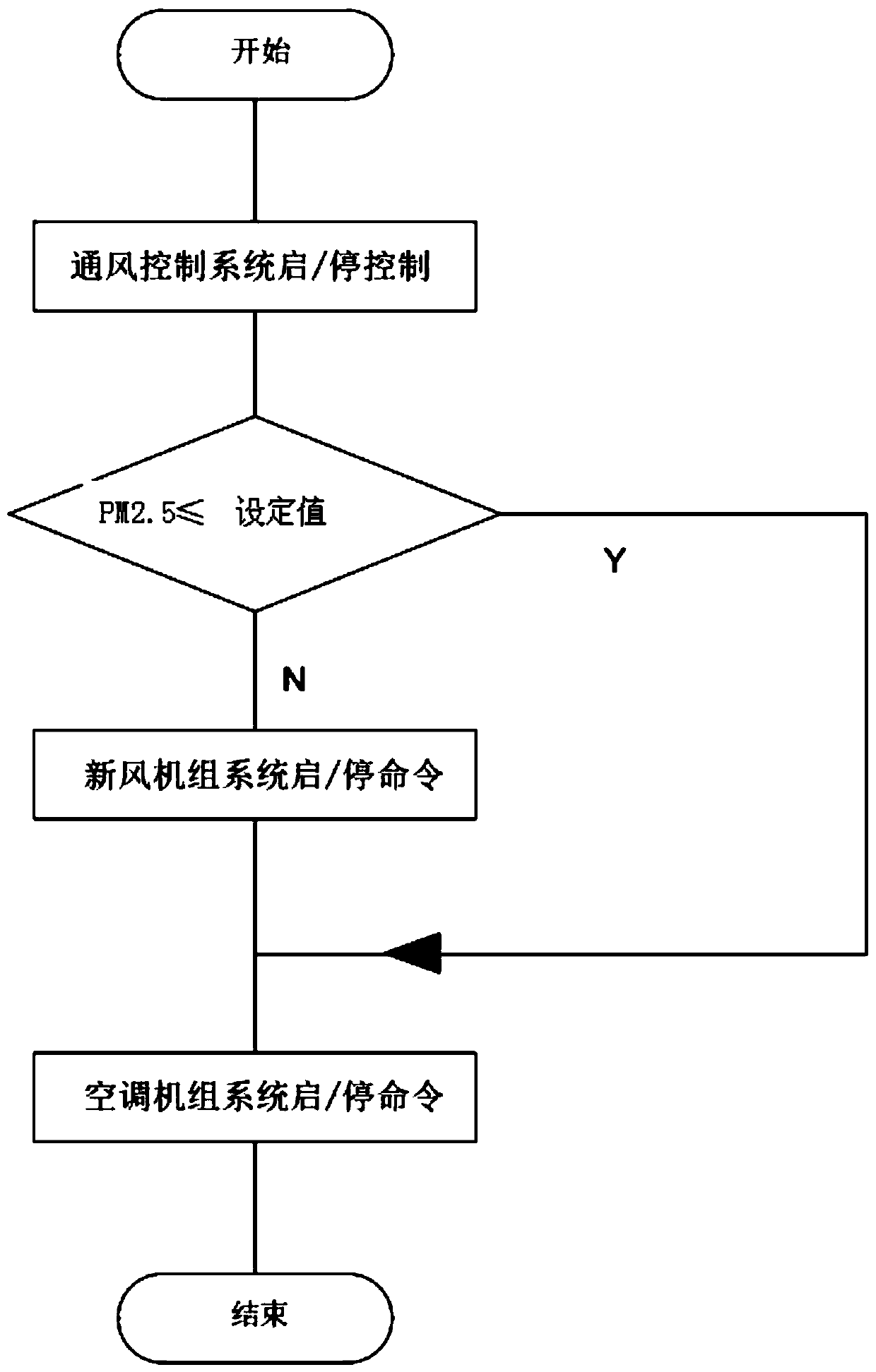

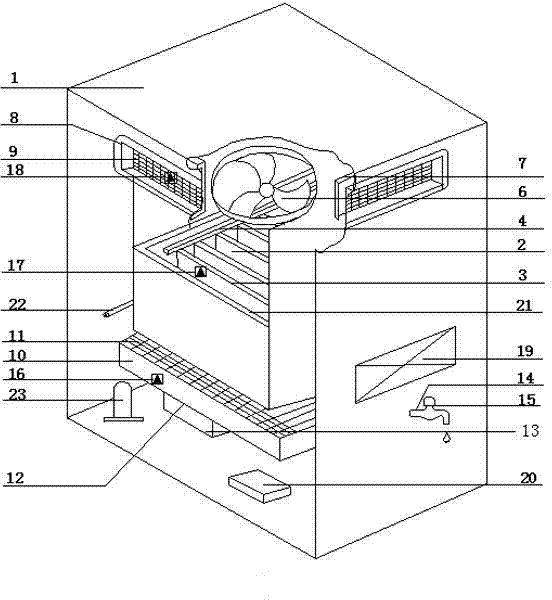

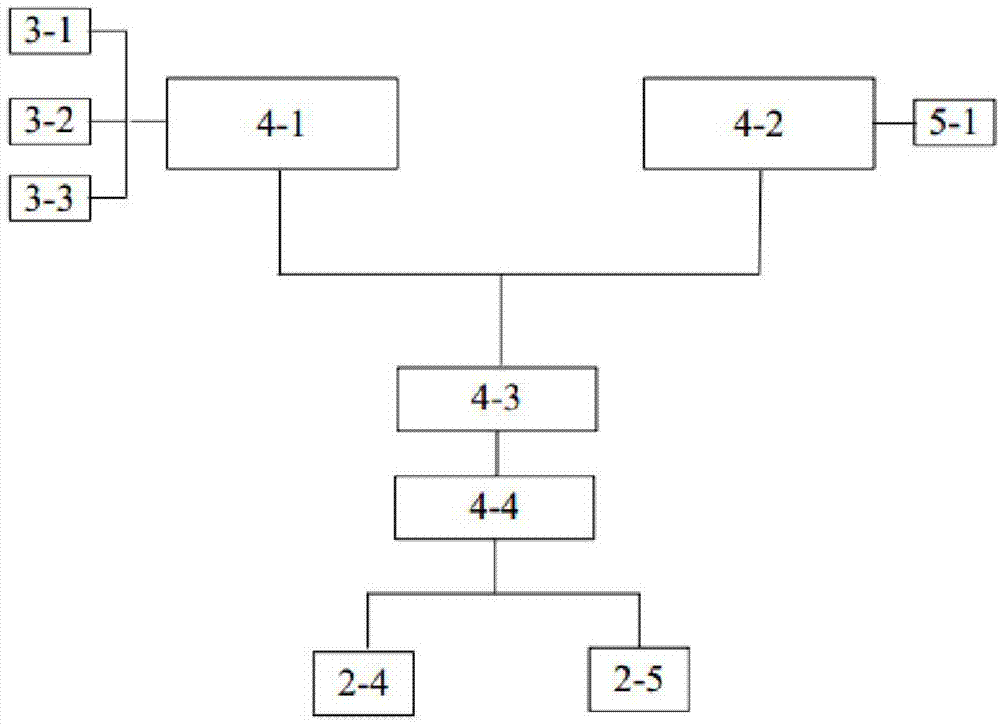

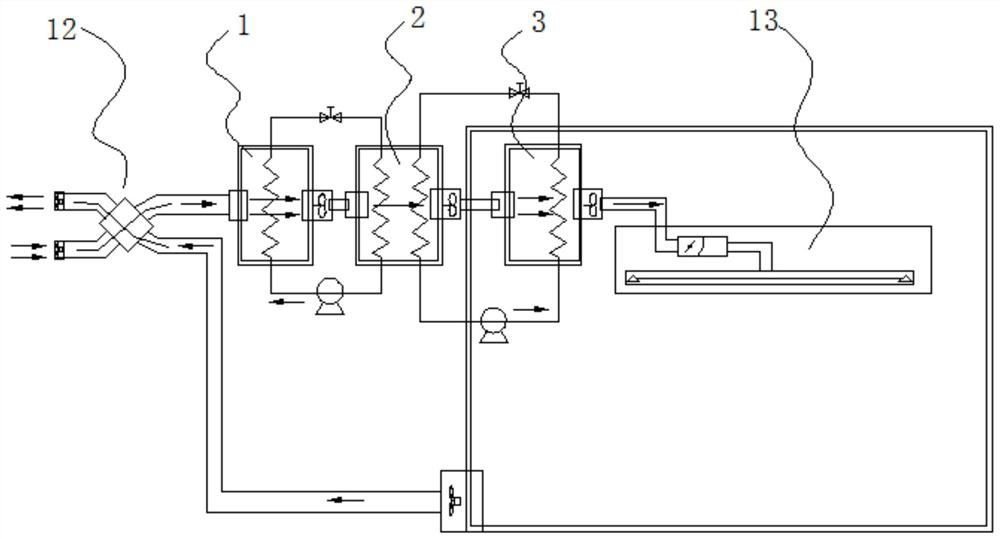

Air conditioning unit for large-bay operating room and control method thereof

ActiveCN110701692AReduce the amount of on-site constructionLower requirementDucting arrangementsMechanical apparatusAir volumeMedicine

The invention discloses an air-conditioning unit for a large-bay operating room and a control method thereof. The air-conditioning unit comprises an air supply unit, an air return unit and an optionalfresh air unit. The installation is convenient, the arrangement is flexible, and a technical interlayer does not need to be used as a machine room; on the premise of keeping the total air supply amount unchanged, the fresh air amount is changed, the pressure difference is maintained, the energy consumption is reduced, and the air quality in the operating room is improved; a PLC control system controls the optimum operation of the air supply unit, the air return unit and the optional fresh air unit in real time aiming at the indoor and outdoor changing hot and wet load to form the air conditioning unit, wherein the project quality of the air conditioning unit is completely controlled by a factory; and a traditional purification air conditioning system combined by fresh air centralized treatment and each operating room circulating unit, and a complex air treatment mode are changed, through variable frequency, the total air supply amount and the total air return amount can be changed, the cleanliness level of operating areas can be changed, or air is only supplied to the operating areas needing to be subjected to surgery, or the emergency conversion is a direct current air supply negative pressure mode, and the control requirements of different surgical environments are achieved with low energy consumption.

Owner:TONGJI UNIV +1

Continuous zinc coating method of high-silicon high-manganese galvanized steel strip

InactiveCN106987790AImprove wettabilityImprove corrosion resistanceHot-dipping/immersion processesFurnace typesCorrosionDew point

The invention discloses a continuous zinc coating method of a high-silicon high-manganese galvanized steel strip. The dew points of all sections in an annealing furnace in a continuous zinc coating production line are controlled as follows: a preheating section: +10-minus 20 DEG C, a heating section: +10-minus 20 DEG C, and a soaking zone: minus 25-minus 50 DEG C. With adoption of the continuous zinc coating method, the dew points in the furnace are raised to oxidize the surface of strip steel, so that oxide of silicon, manganese and other elements is positioned under oxide of iron, and in this way, in the soaking zone and a follow-up balanced section in the annealing furnace, and under high temperature and the protective atmosphere of 5% H2+N2, iron is reduced to pure iron; and under the condition, oxide of silicon and manganese is not reduced but positioned under pure iron, so that the situation that oxide of silicon and manganese is not reduced can be better avoided, and wettability of strip steel is not affected to avoid skip plating defect. According to the method, oxidation of silicon and manganese elements is controlled through controlling the dew points the galvanized wire furnace to improve the wettability between a steel plate and galvanizing zinc and the corrosion resistance of a zinc coating.

Owner:TANGSHAN IRON & STEEL GROUP +1

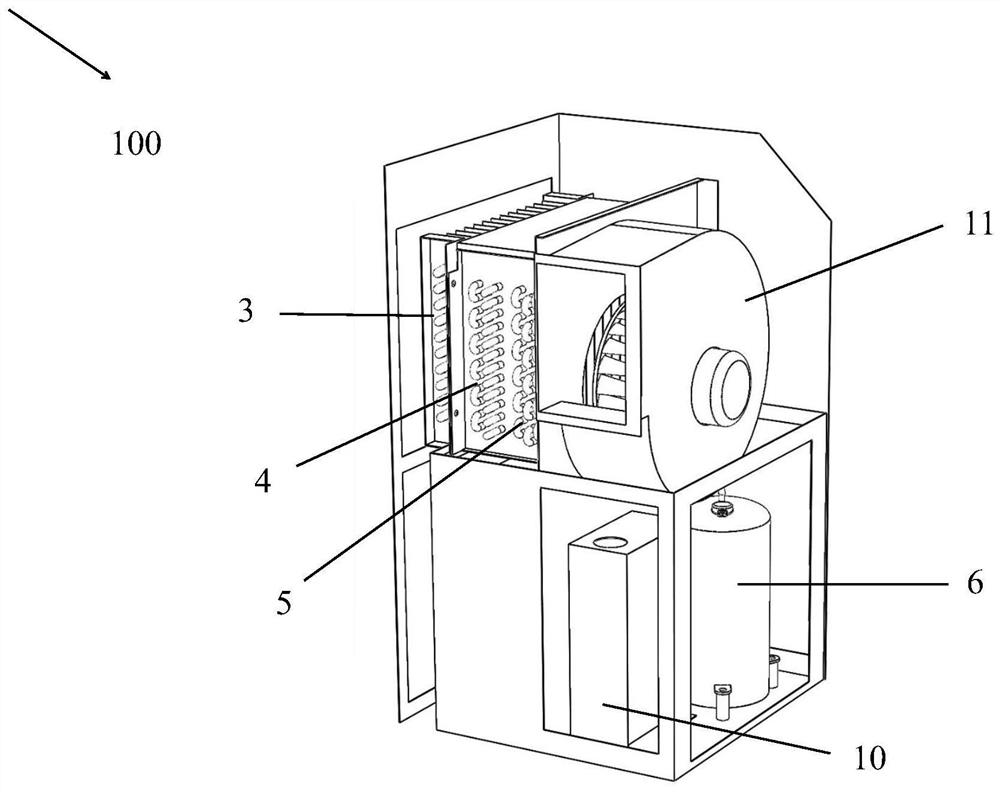

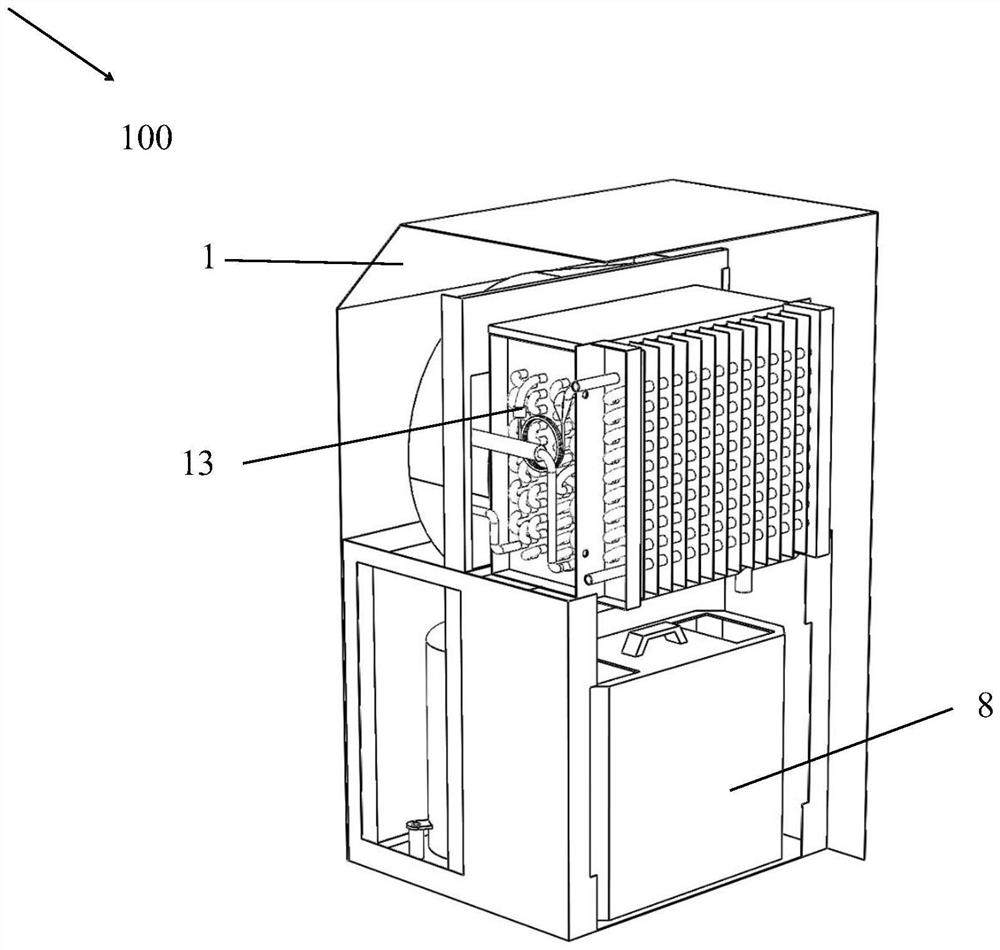

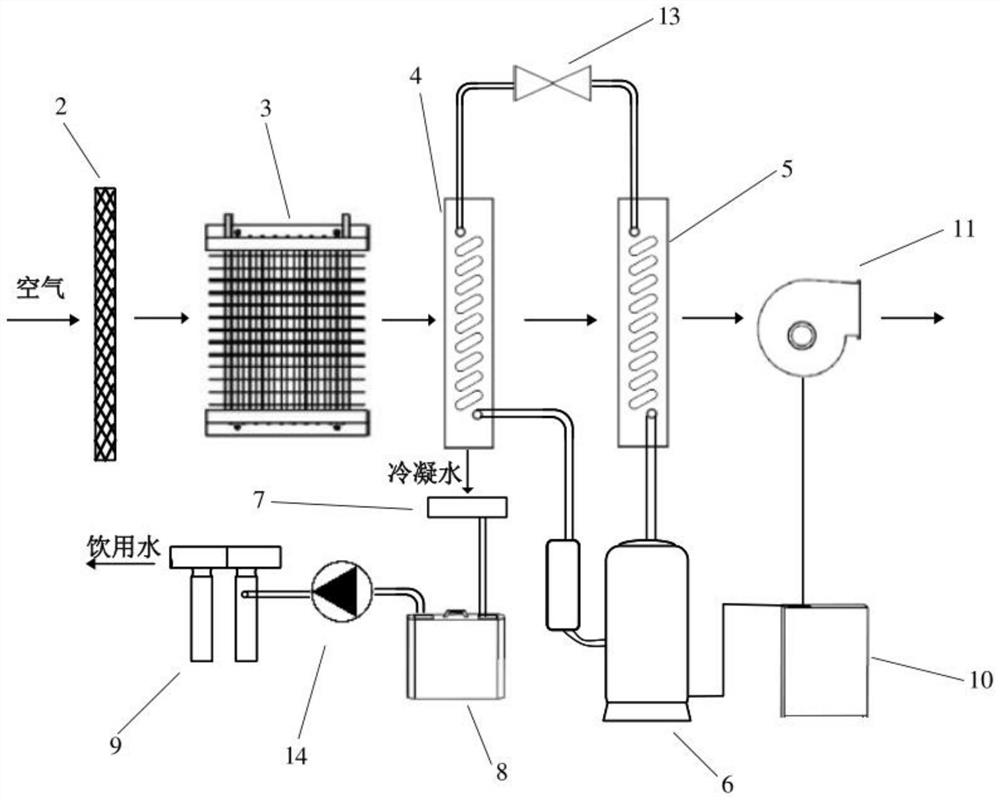

Device for preparing drinking water from air

ActiveCN103790209AHigh yieldImprove water production efficiencyGeneral water supply conservationDrinking water installationRefrigeration compressorWater discharge

Owner:刘琛

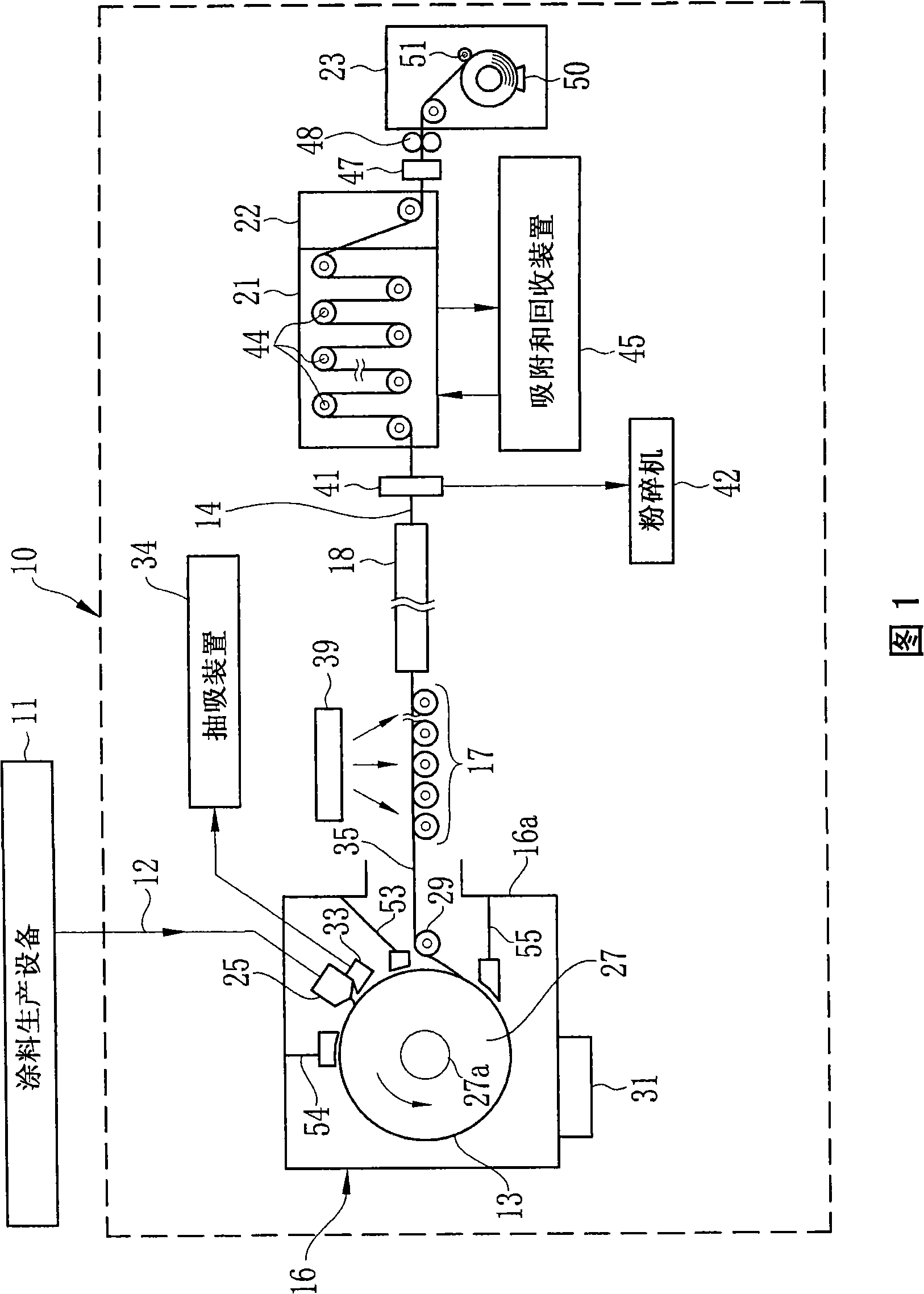

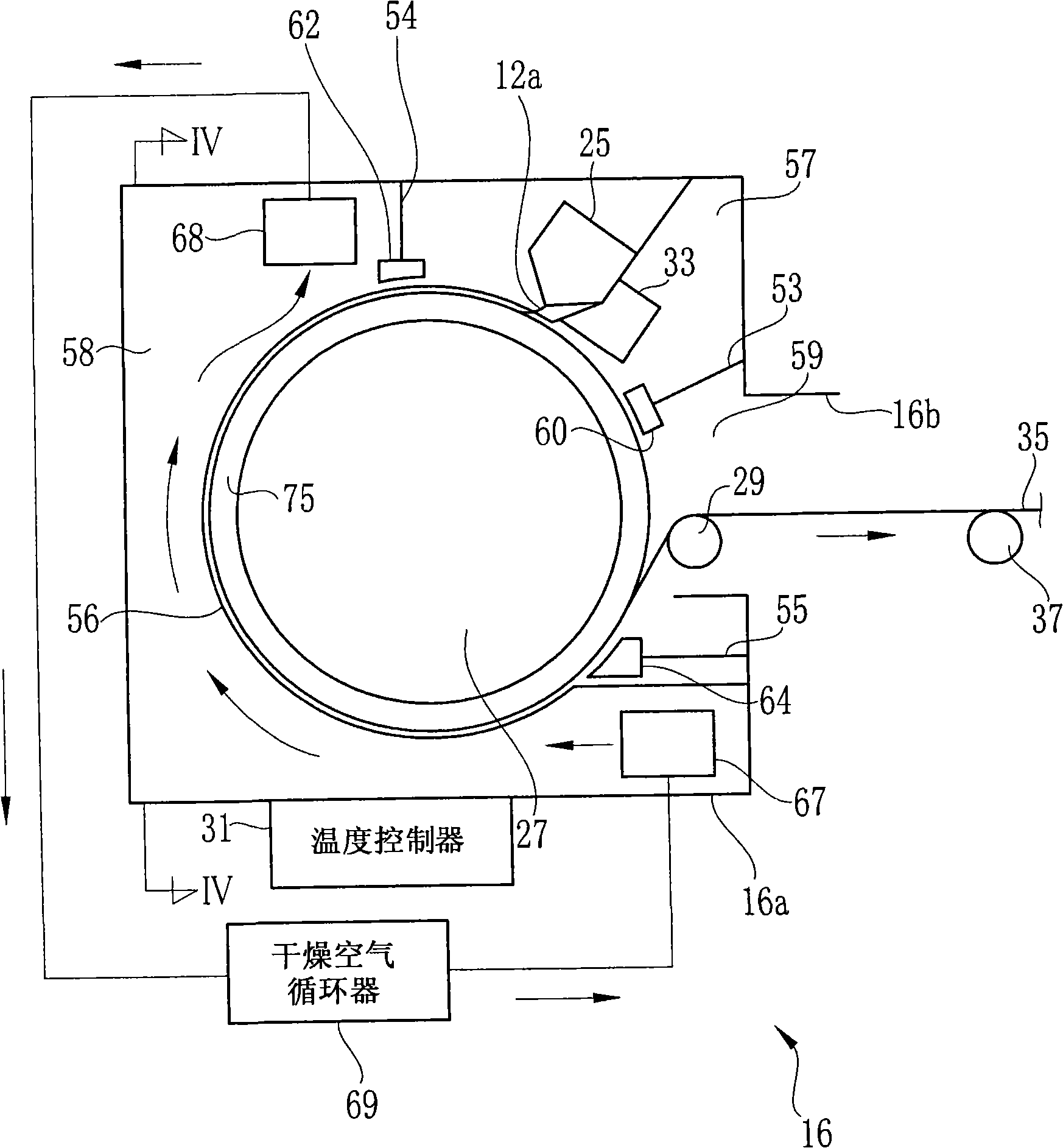

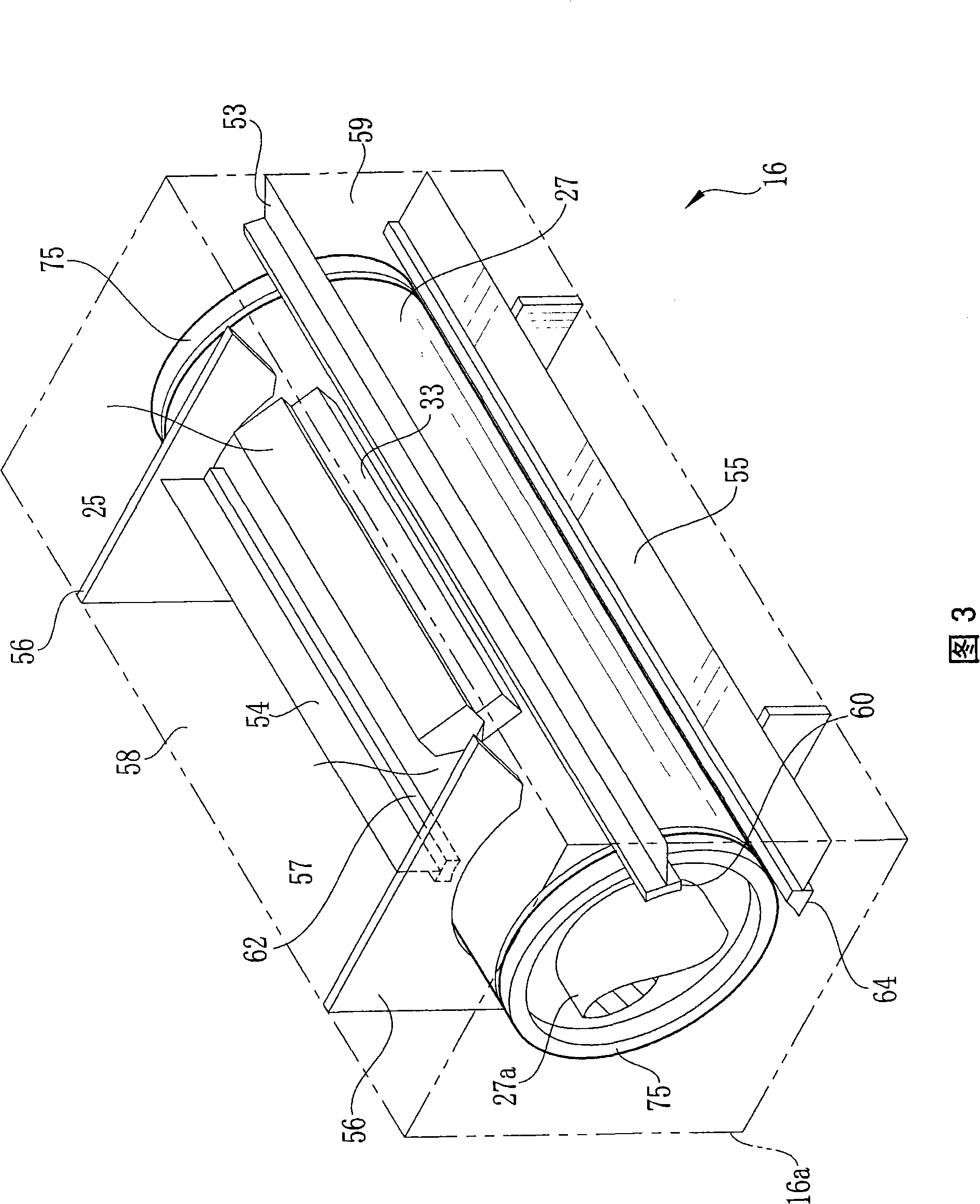

Solution casting apparatus and method

InactiveCN101274470AIncrease the amount of introductionAvoid enteringDrying solid materials with heatDrying machines with progressive movementsSolventCast films

Owner:FUJIFILM CORP

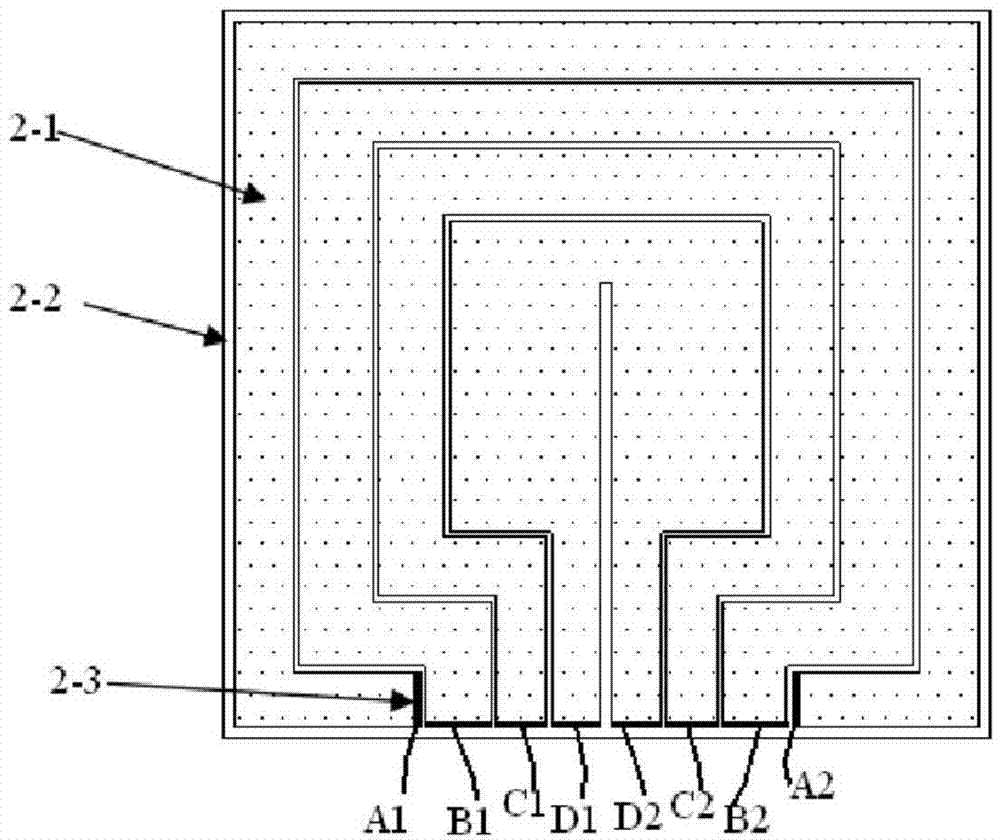

Intelligent anti-condensation and frost-proof glass

ActiveCN103921506AGood light transmissionImprove heating efficiencyGlass/slag layered productsFrostIndium tin oxide

The invention discloses a piece of intelligent anti-condensation and frost-proof glass. The intelligent anti-condensation and frost-proof glass comprises a first glass plate and a second glass plate, wherein one surface of the first glass plate is provided with an ITO (indium tin oxide) membrane; one surface with the ITO membrane of the first glass plate is bonded with the second glass plate through a PVC (polyvinyl chloride) adhesive sheet; the ITO membrane is divided into a plurality of independent open annular areas which are circumferentially nested together. According to the intelligent anti-condensation and frost-proof glass, the heating process is controlled according to an analysis result, and the refrigeration load of a low-temperature exhibition cabinet, a refrigerator and the like can be reduced while the demisting and defrosting can be guaranteed.

Owner:CHINA BUILDING MATERIALS ACAD +1

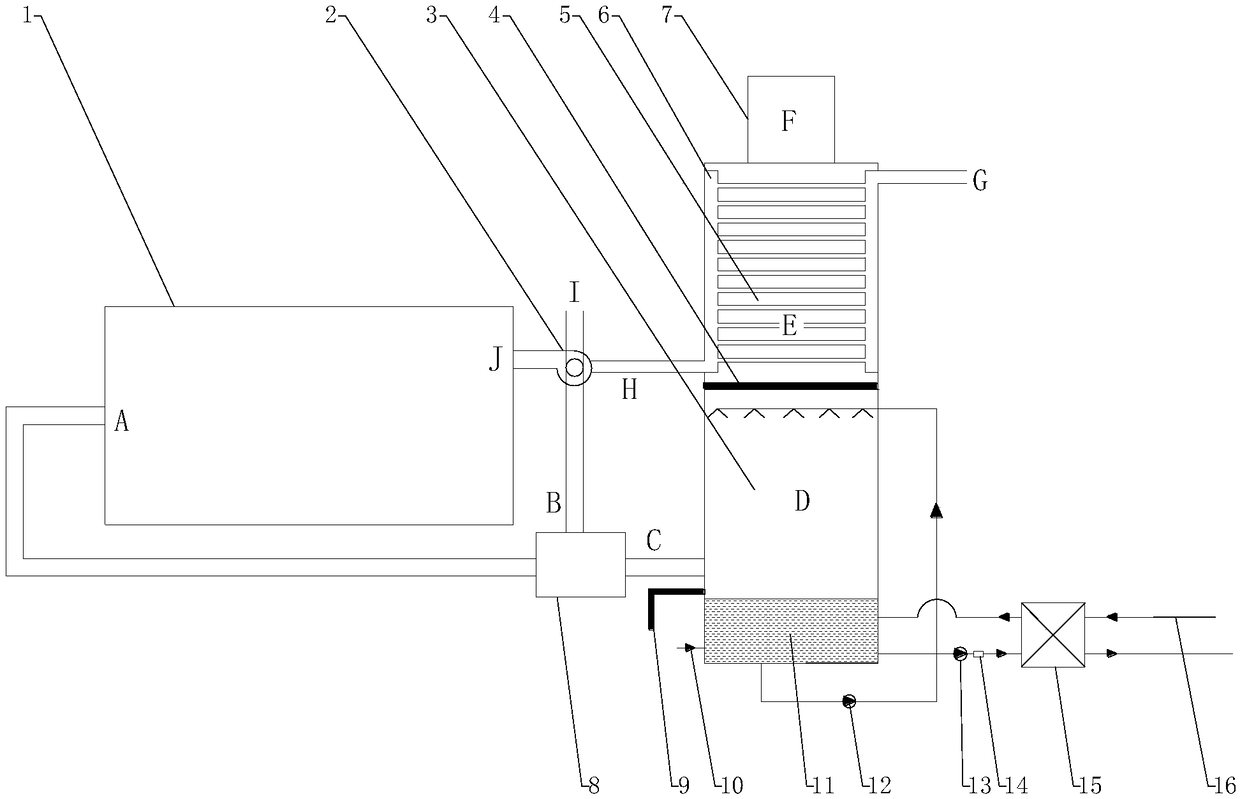

Efficient natural gas boiler with low-nitrogen emission

PendingCN108105796ASmall volumeReduce heat lossCombustion technology mitigationWater heatersLow nitrogenOxygen

The invention discloses an efficient natural gas boiler with low-nitrogen emission. As low-temperature waste heat (sensible heat and latent heat) of smoke is recycled based on an evaporative cooling principle, firstly, the problem that the heat exchange loads of high-humidity smoke and low-humidity combustion-supporting air are not matched is solved by humidifying the combustion-supporting air, meanwhile, the heat exchange coefficient of the high-humidity smoke and the low-humidity combustion-supporting air is effectively improved, low-temperature sensible heat and latent heat of smoke are recycled to the greatest extent, and the problem of white smoke of a natural gas boiler can also be eliminated; secondly, the smoke dew point is increased by humidifying the combustion-supporting air, the grade of the low-temperature latent heat is improved, and the smoke latent heat recycling rate can be improved advantageously; and thirdly, the oxygen concentration is reduced by improving the humidity of the combustion-supporting air, the generation amount of thermal NOx in the natural gas burning process can be reduced, meanwhile, part of NOx can be dissolved through direct contact of smoke and heating medium water, and thus nitrogen oxide emission of the gas boiler can be effectively reduced.

Owner:SHANDONG UNIV

Cold/heat source integrated unit

ActiveCN101498499BEmission reductionReduce consumptionEnergy recovery in ventilation and heatingCompression machines with several condensersEngineeringNon-renewable resource

The invention relates to a cold / heat source integrated unit. The outlet of a compressor is respectively connected with an air-cooled condenser and a water-cooled condenser, the air-cooled condenser and the water-cooled condenser are jointed and then connected with a throttle device which is respectively connected with an air-cooled evaporator and a water-cooled evaporator, the air-cooled evaporator and the water-cooled evaporator are jointed and then connected with the inlet of the compressor, the outlet of the water-cooled evaporator is connected with the inlet of a cooling water user terminal, the outlet of the cooling water user terminal is circularly connected with the water-cooled condenser, the outlet of the water-cooled evaporator is connected with the inlet of a hot water user terminal, and the outlet of the hot water user terminal is circularly connected with the water-cooled evaporator. The invention changes the control target which traditionally is a specific space in a building into the control target which is the whole building, comprehensively plans the supply of a cold source and a heat source of the whole building, balances the cold energy and the heat energy, reduces the discharge of waste heat or waste cold, reduces the consumption of unrenewable resources to the minimum and forms a comprehensive energy-saving system.

Owner:SHANGHAI SINKO AIR CONDITIONING EQUIP CO LTD

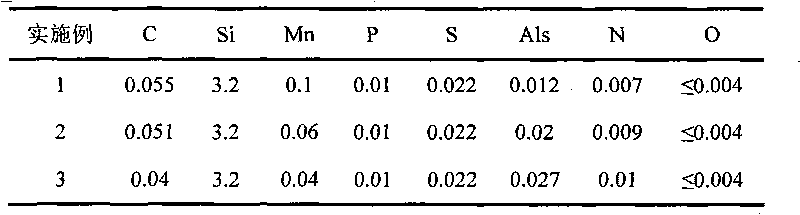

Preparation method of low-temperature GO-oriented silicon steel

ActiveCN101748253ALow heating temperatureReduce energy costsRoll mill control devicesMetal rolling arrangementsHot TemperatureHeating temperature

The invention provides a preparation method of low-temperature GO-oriented silicon steel, mainly comprising the following steps of: smelting, continuous casting, hot-rolling, primary cold-rolling, secondary cold-rolling and high-temperature annealing. The preparation method is characterized in that an intermediate annealing process of a cold-rolled sheet is carried out between the primary cold-rolling and the secondary cold-rolling, wherein the annealing process comprises the following steps of: adopting a rapid heating method, wherein the heating speed is 15 to 35DEG C / s, the annealing temperature is 850 to 1150 DEG C, the heat preservation time is 2.5 to 5.5min, the protection atmosphere is 20%H2+80%N2, and the dew point is 35 to 60 DEG C; firstly coating an Al2O3 separant on the surface of the cold-rolled sheet after the secondary cold-rolling, and then carrying out the high-temperature annealing. The preparation method of the low-temperature GO-oriented silicon steel reduces the heating temperature of a sheet blank and the energy consumption of per ton steel, saves the energy source, omits a decarburizing annealing process by adopting a special process of the intermediate annealing process and using the Al2O3 as the separant of the high-temperature annealing, thereby greatly reducing the energy consumption and the production cost.

Owner:ANGANG STEEL CO LTD

Fuel gas injection type recovery method of sensible heat of convertor coal gas and convertor flue gas

ActiveCN102827993AHigh yieldAvoid Forced ReleaseIncreasing energy efficiencyManufacturing convertersRecovery methodCombustion chamber

The invention relates to a fuel gas injection type recovery method of sensible heat of convertor coal gas and convertor flue gas, and belongs to the technical field of recycling sensible heat of convertor coal gas and convertor flue gas. The main technical problems to be solved are as follows: on one hand, the water waste problem is to be solved, on the other hand, efficient utilization of physical sensible heat in the convertor flue gas is to be realized, and the effects of eliminating the potential safety hazard existing in the traditional system, greatly improving the yield of convertor coal gas and the like are also to be achieved. The method comprises allocation of a flue heat exchange device, a rough dust removing device and a refined dust removing device, an induced draft fan, a pipe network a control system, and is characterized in that a combustion chamber is arranged in a recovery system, fuel gas is injected into the combustion chamber, a heat exchanger is also arranged in the recovery system and the heat exchanger is installed behind the combustion chamber. The method is suitable for the technical field of recycling physical sensible heat in the convertor coal gas and convertor flue gas, and has the effects of saving energy, saving water, being safe, improving yield of convertor coal gas and the like.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Atmospheric Water Harvesting System with Cross-Flow Configuration

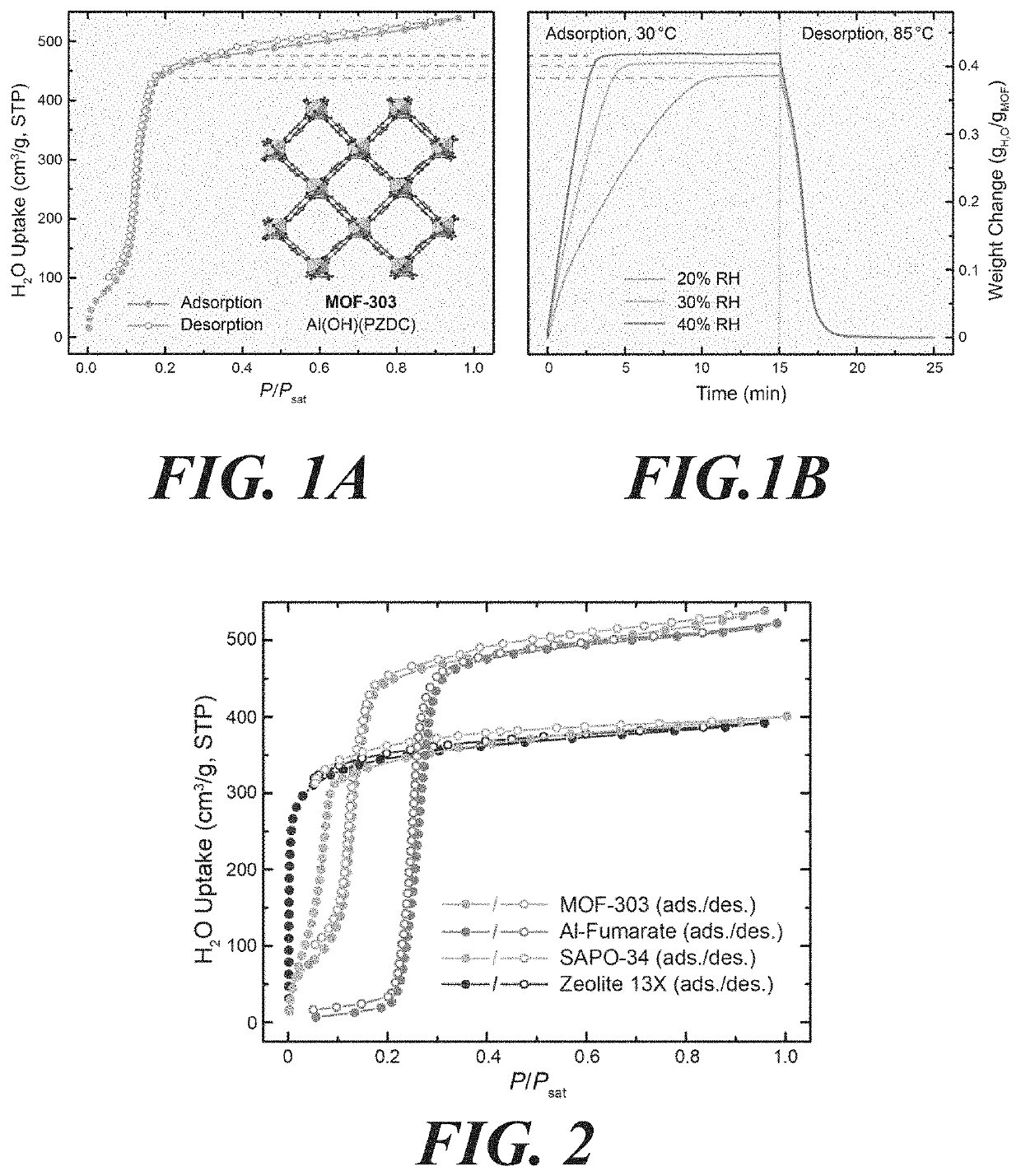

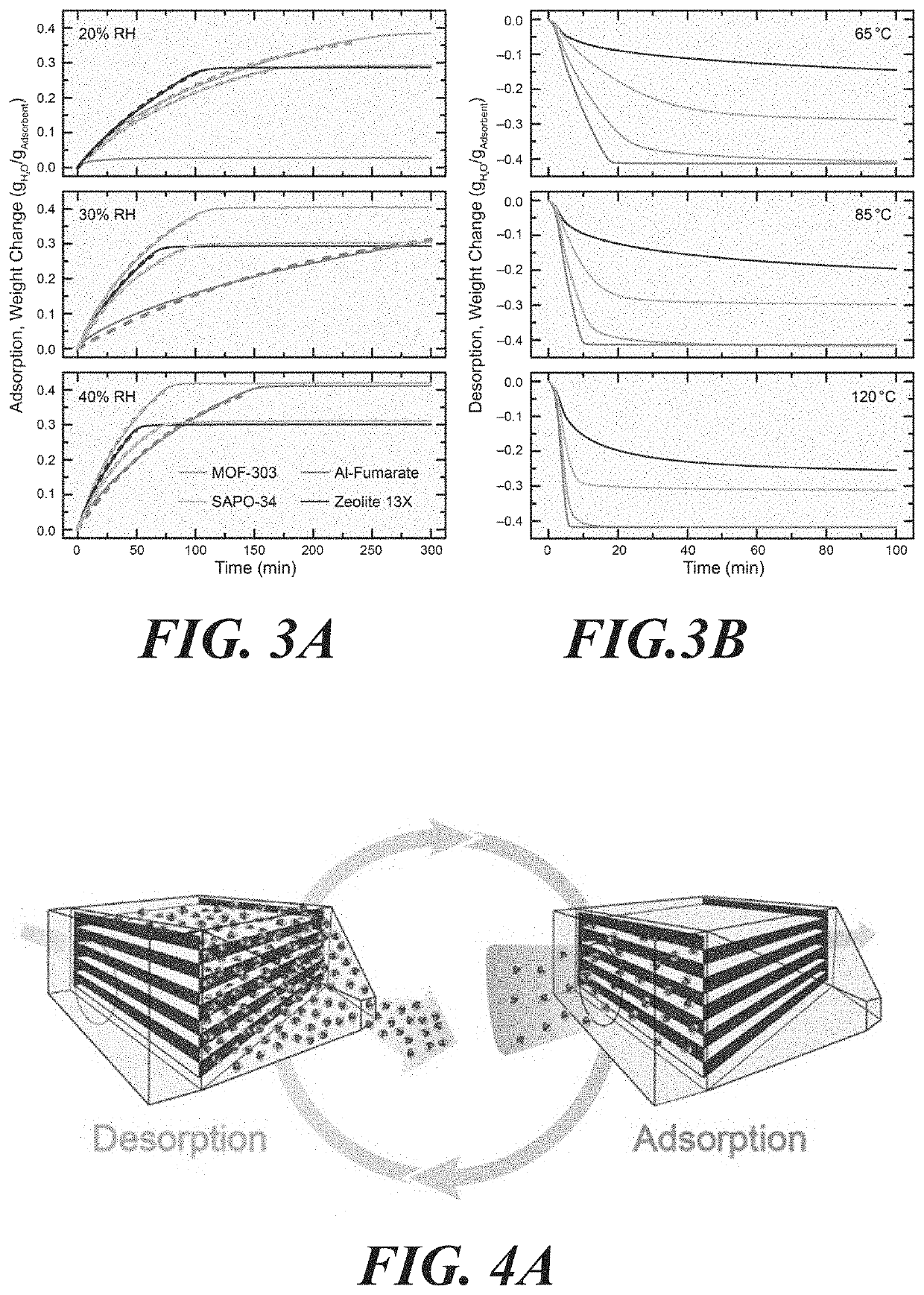

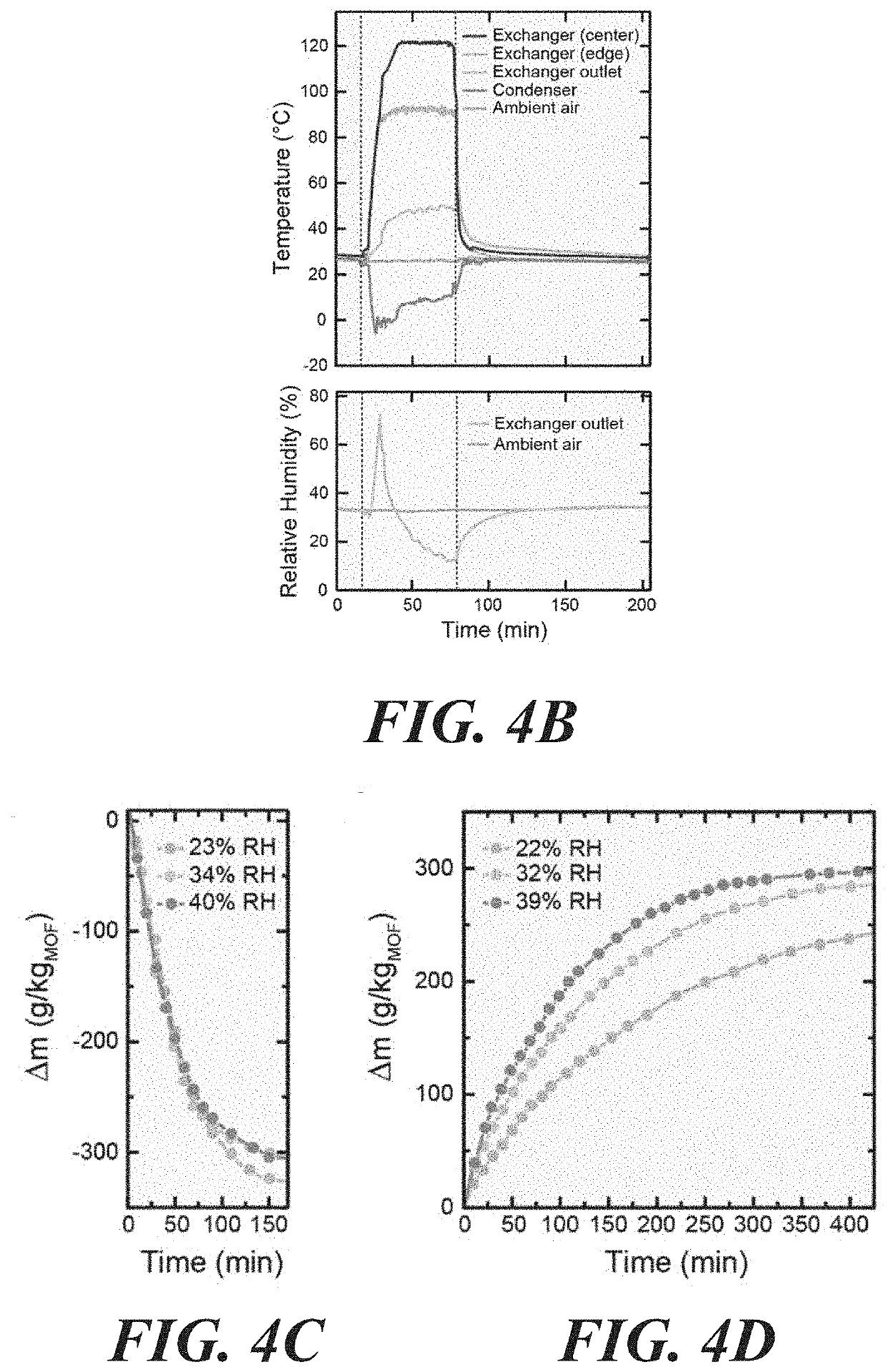

PendingUS20220170247A1Raise the dew pointLower energy requirementsGas treatmentGeneral water supply conservationSorbentEnvironmental engineering

Atmospheric water harvesting systems utilize a sorbent cartridge configured to hold water capture material. The sorbent cartridge is made up of a plurality of permeable trays and a plurality of spacers that are arranged to provide cross-flow for adsorption and desorption airflow pathways. The systems are used for harvesting water from surrounding air.

Owner:RGT UNIV OF CALIFORNIA

Convertor coal gas recovery method

ActiveCN102827991AAvoid consumptionStable generationDispersed particle filtrationChemical industryRecovery methodCombustion chamber

The invention relates to a convertor coal gas recovery method, and belongs to the technical field of recycling physical sensible heat in convertor flue gas. The main technical problems to be solved are as follows: on one hand, the water waste problem is to be solved, on the other hand, efficient utilization of physical sensible heat in the convertor flue gas is to be realized, and the problems of sensibility increase of confined explosion caused by due to cancel of an evaporation cooling process and the like are also to be solved. The method comprises allocation of a flue heat exchange device, a rough dust removing device and a refined dust removing device, an induced draft fan, a pipe network a control system, and is characterized in that a combustion chamber is arranged in the method, a heat exchanger is also arranged in the method and the heat exchanger is installed behind the combustion chamber. The method is suitable for the technical field of recycling physical sensible heat in the convertor flue gas, and has the characteristics of saving water, saving energy, improving system safety, improving recovery rate of convertor coal gas and the like.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

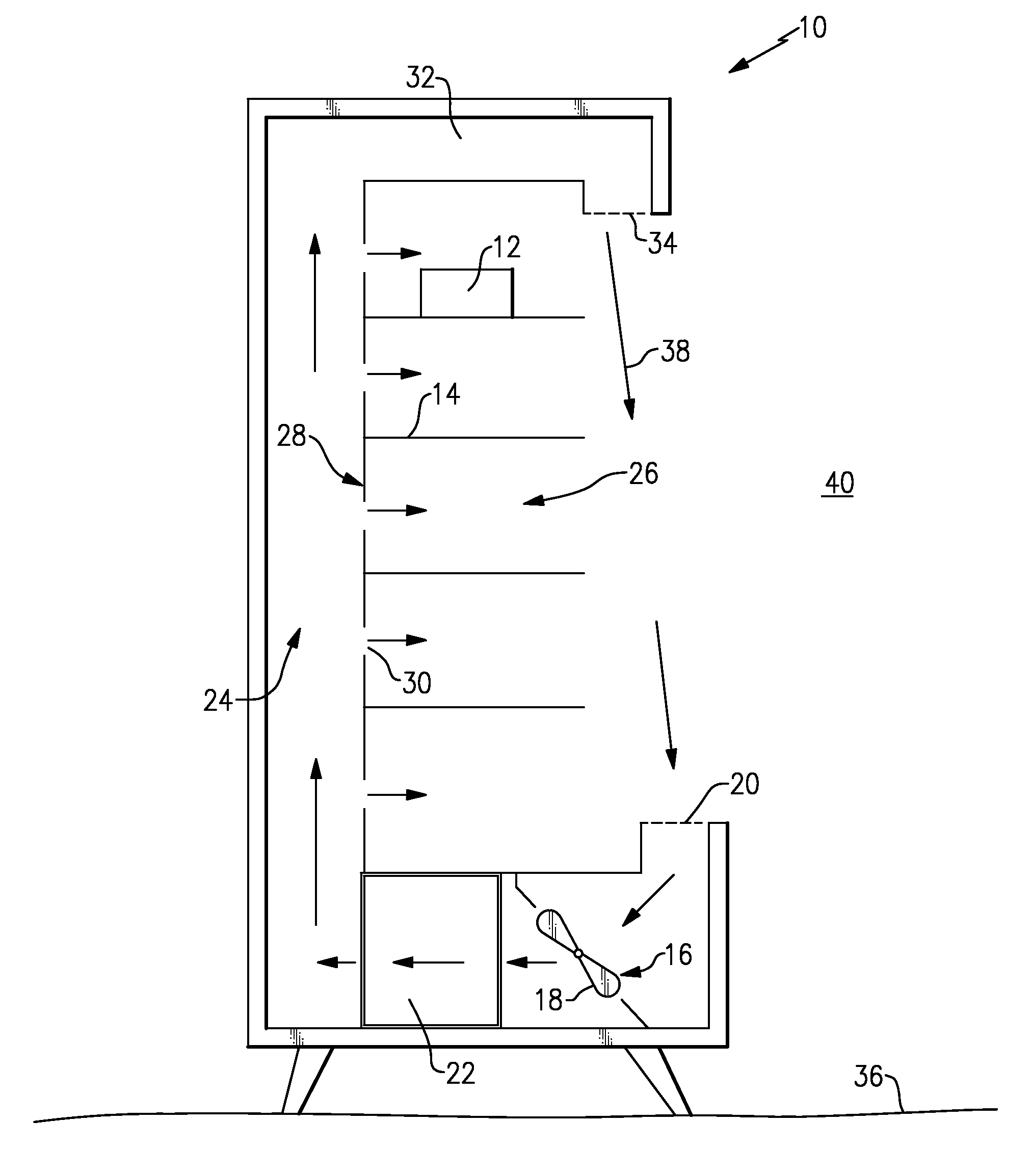

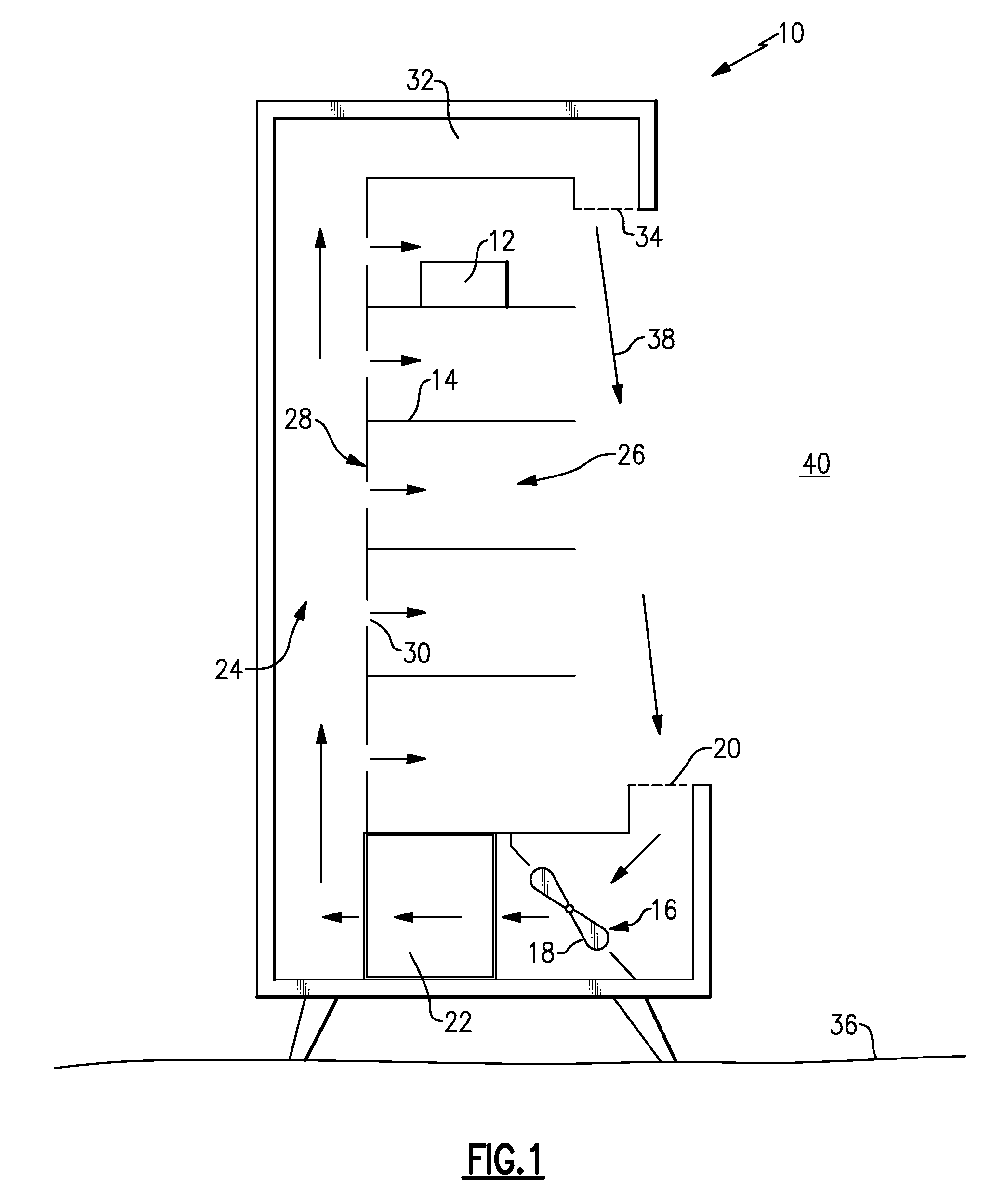

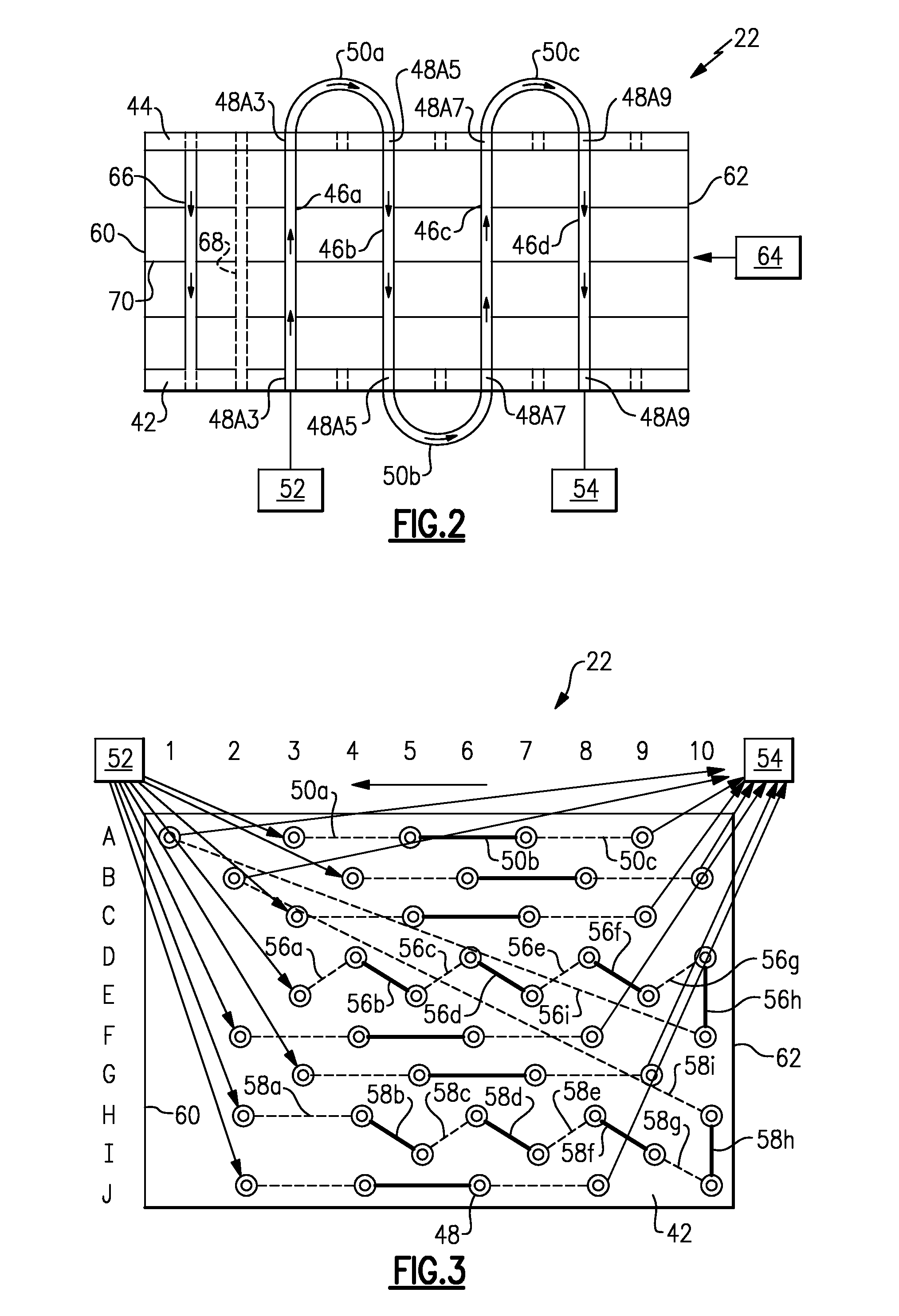

Display case including heat exchanger for reducing relative humidity

ActiveUS8910488B2Raise the dew pointReduce humidityShow cabinetsDomestic refrigeratorsEngineeringRefrigerant

Owner:HILL PHOENIX

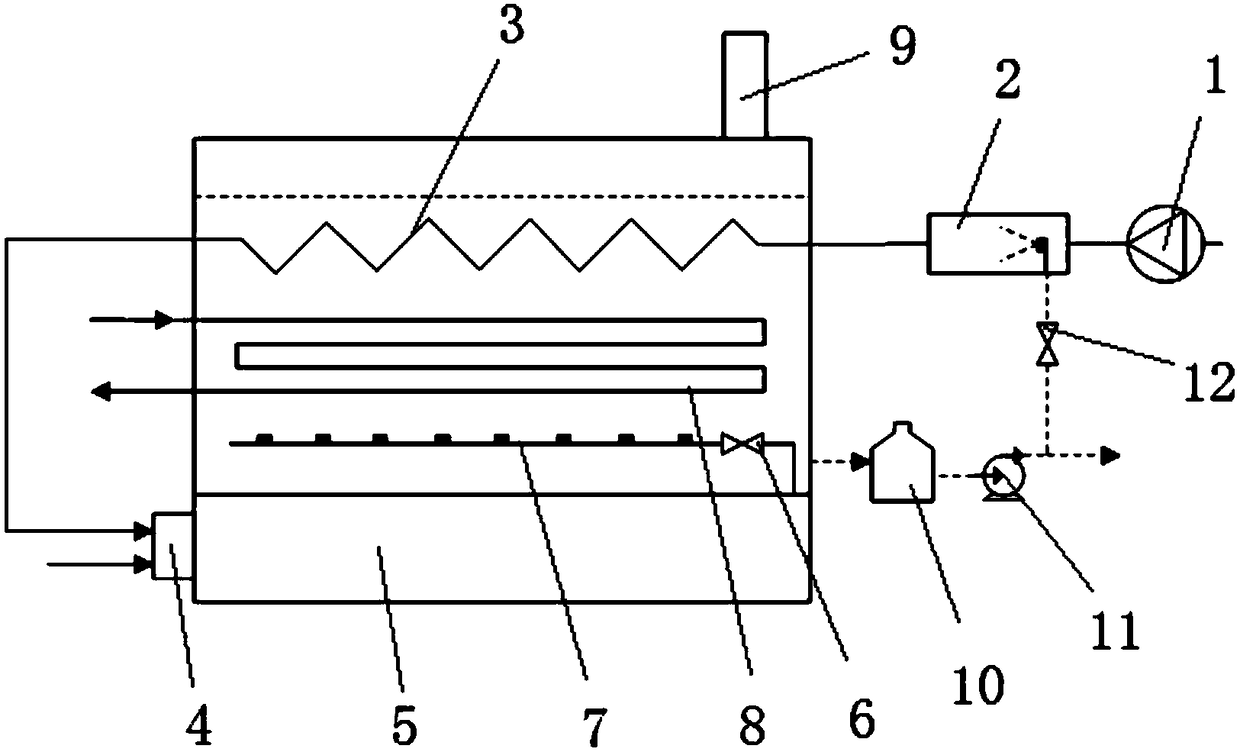

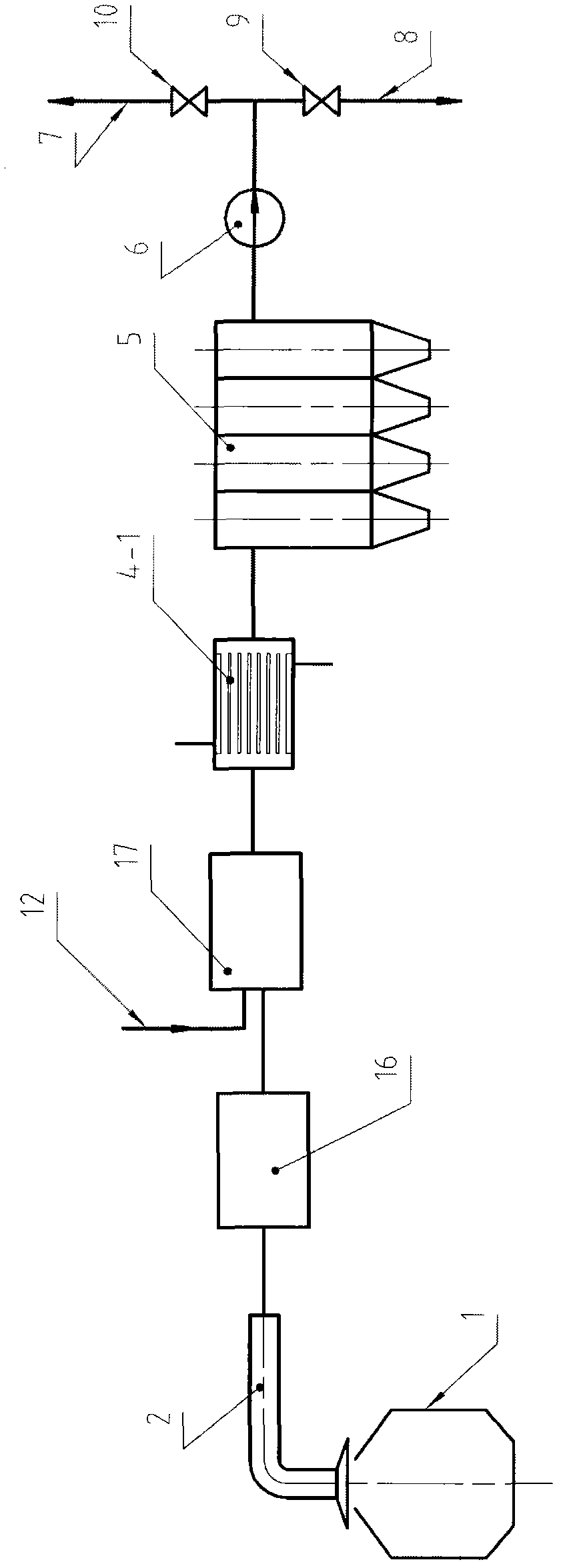

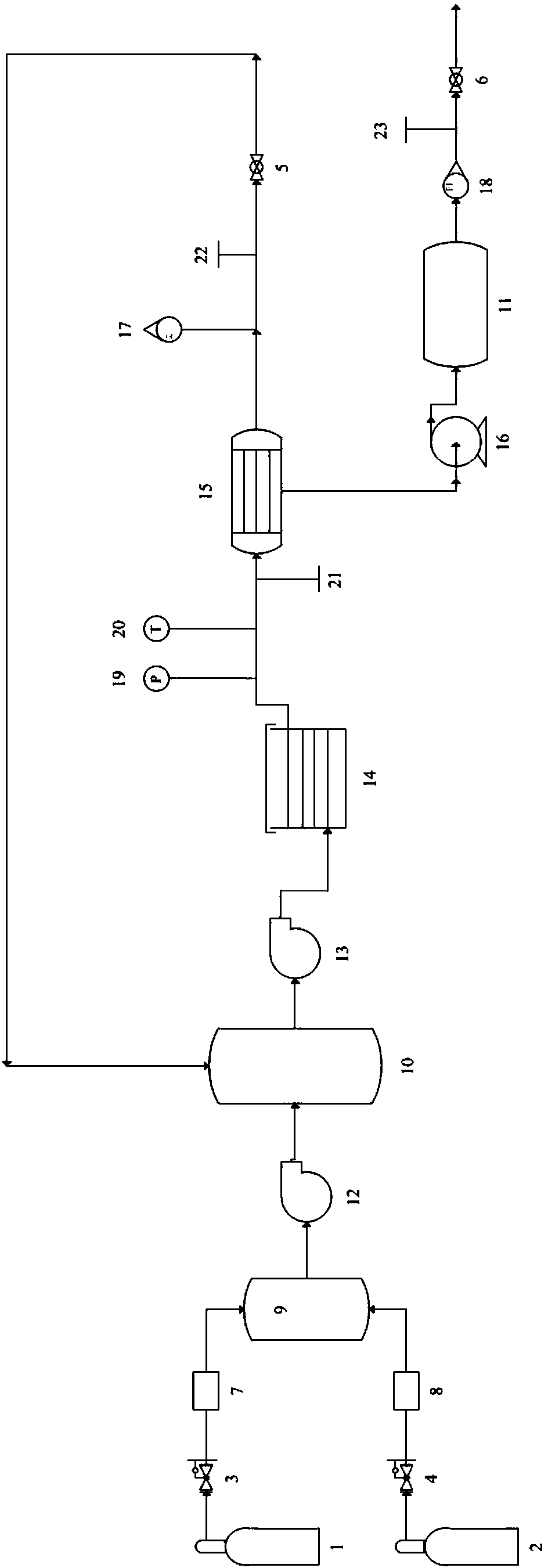

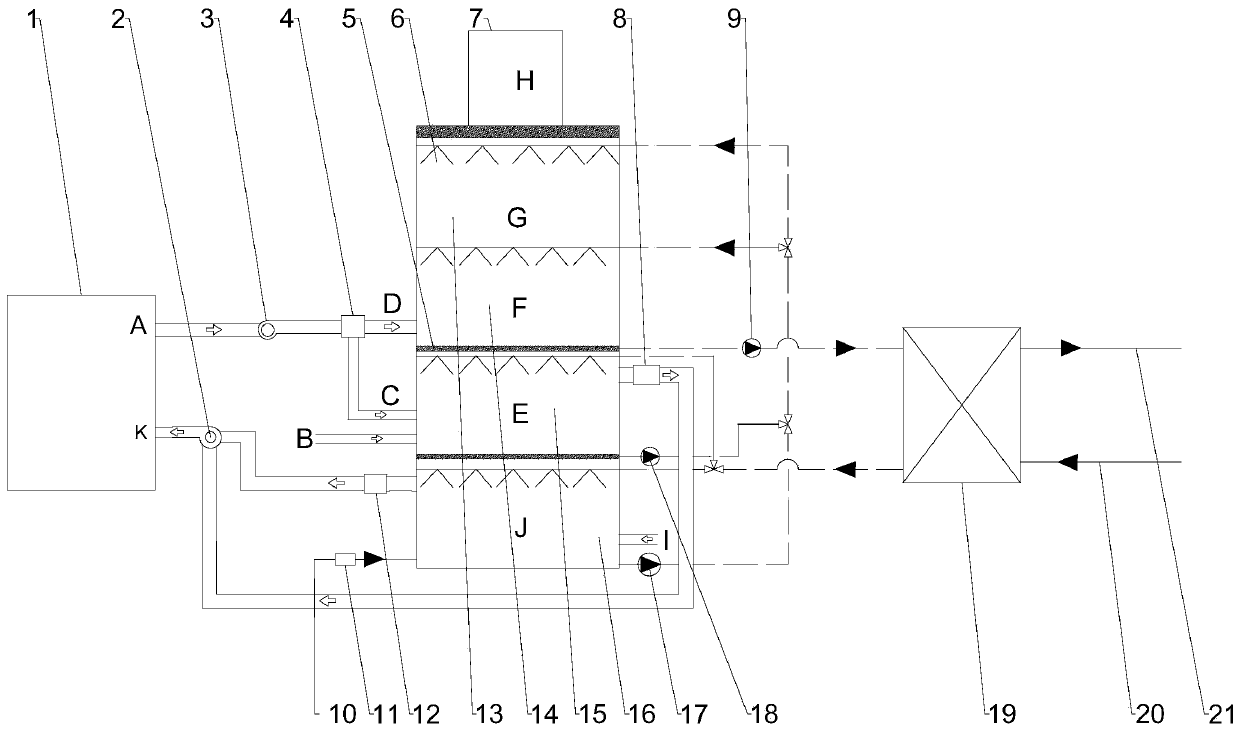

Gas boiler waste heat recovery and purification system based on membrane humidification

ActiveCN109268821ALower combustion temperatureAchieve depthIndirect carbon-dioxide mitigationCombustion apparatusLiquid storage tankHeat transfer

The invention discloses a gas boiler waste heat recovery and purification system based on membrane humidification, which belongs to the technical field of flue gas waste heat recovery and purification. The system comprises a membrane type spray heat and mass transfer tower 7 and a flue gas recirculation device 2. The flue gas recirculation device 2 is respectively connected with a boiler 1 and themembrane type spray heat and mass transfer tower 7, after flue gas A passes through a fan 8, recirculation flue gas B is supplied to a draught fan, the recirculation flue gas B, and fuel gas I and high-temperature high-humidity combustion air H are introduced into the boiler 1 after mixed to supply gas J for the boiler so as to reduce NOx; the membrane type spray heat and mass transfer tower 7 isvertically divided into a liquid storage tank 11, a flue gas-medium circulating water heat transfer segment 3 and a flue gas-air heat and mass transfer segment 5 from bottom to top so as to be used for recycling the total heat of the flue gas. The system realizes the recycle of the total heat of flue gas waste heat, improves the heat efficiency of the boiler, and reduces the NOx emission of the boiler through the humidification of combustion air and the recirculation of the flue gas.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

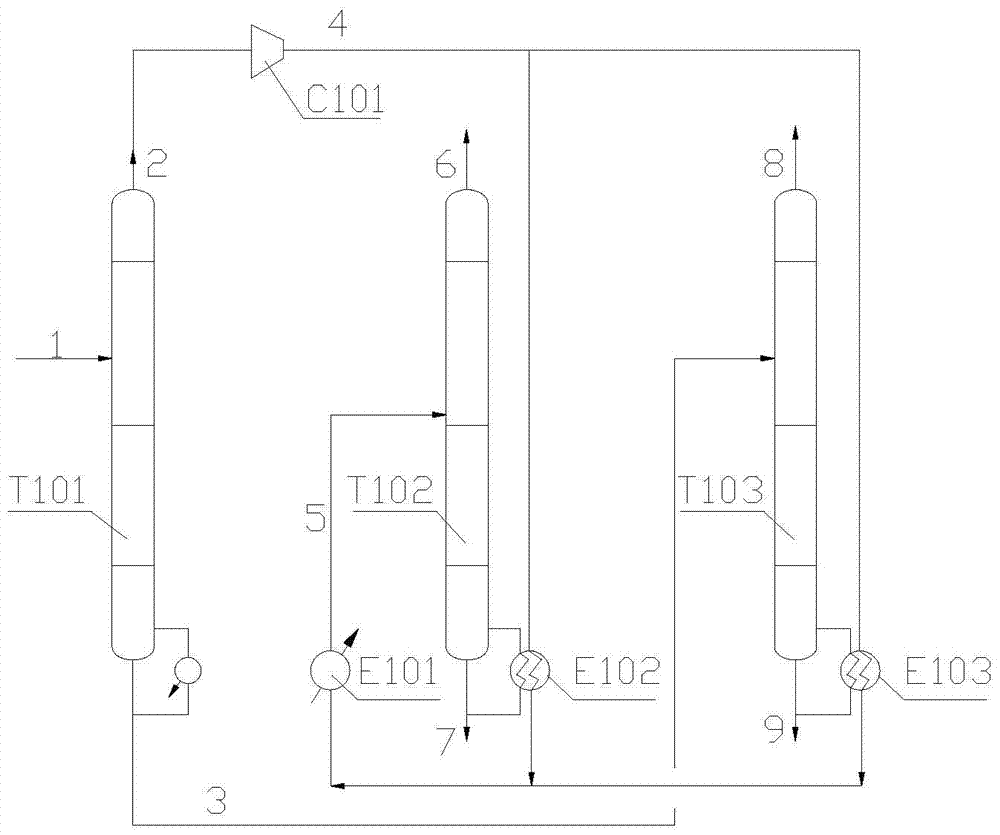

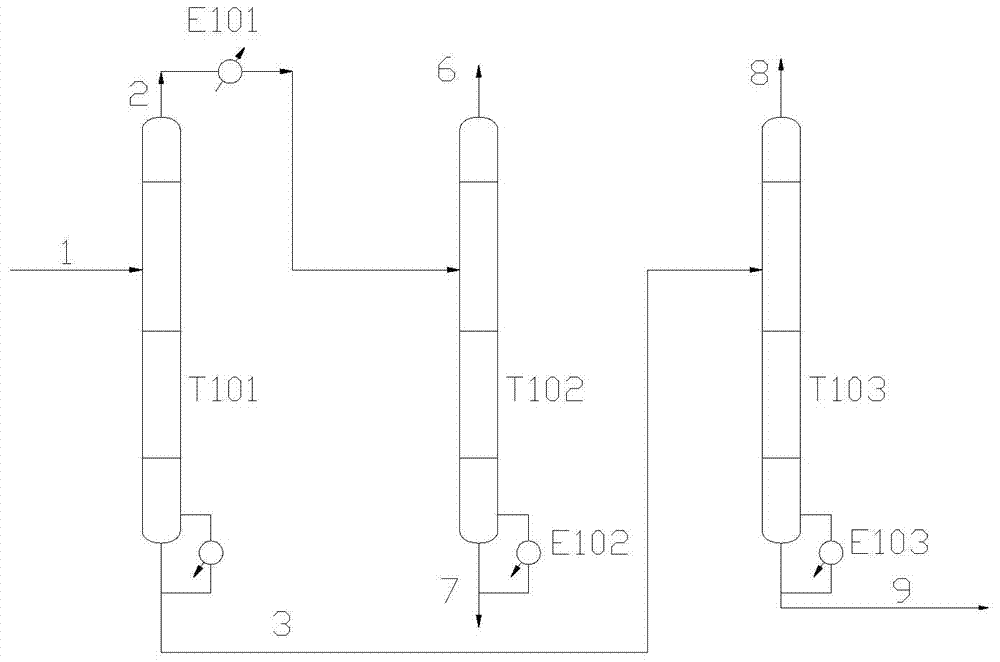

Method for separating ethylbenzene dehydrogenation reaction products

ActiveCN105669354BReduce polymerization lossRaise the dew pointDistillation purification/separationReboilerHigh energy

The present invention relates to an ethylbenzene dehydrogenation reaction product separation method, and mainly solves the problems of high energy consumption and large styrene polymerization loss of conventional ethylbenzene dehydrogenation reaction product separation devices. The ethylbenzene dehydrogenation reaction product separation method well solves the problems, the ethylbenzene dehydrogenation reaction product separation method comprises the following steps: a first light component removal process is used in an ethylbenzene / styrene separation system, to be more specific, a dehydrogenation liquid first enters a crude styrene tower T101 for separation, an overhead material stream I mainly comprising benzene, toluene and ethylbenzene is obtained, the material stream I is compressed by a C101 compressor to obtain a material stream III, after heat exchange, the material stream III enters an ethylbenzene tower T102, benzene and toluene are obtained on top of the T102, a tower bottom liquid is circulating ethylbenzene, a T101 tower bottom material stream II mainly comprises styrene and high-boiling materials, the T101 tower bottom material stream II enters a styrene refining tower T103, a styrene product is obtained on top of the T103, high-boiling materials are obtained at the bottom of the tower, wherein the material stream III is used as a T102 or T103 reboiler heat source, or is divided into two flows used as respectively the T101 reboiler heat source and the T103 reboiler heat source, and the ethylbenzene dehydrogenation reaction product separation method can be used for industrial production of ethylbenzene / styrene separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Detecting device and detecting method for penetrating quality of gas separation membrane for preferably penetrating organic substances

PendingCN107789991ARaise the dew pointNot easy to condenseSemi-permeable membranesBuffer tankProcess engineering

The invention discloses a detecting device and a detecting method for penetrating quality of a gas separation membrane for preferably penetrating organic substances. A first buffer tank of the detecting device communicates with a gas source through a pipeline; an outlet communicates with a membrane assembly through a first compressor; a raw gas sampling hole is formed in an inlet of the membrane assembly; a residual gas outlet of the membrane assembly is connected with the first buffer tank through a reflux pipeline; the residual gas sampling hole and a residual gas flow meter are arranged onthe reflux pipeline; a penetrating gas outlet of the membrane assembly is connected with a second buffer tank through a vacuum pump; and a penetrating gas sampling hole and a penetrating gas flow meter are arranged at an outlet of the second buffer tank. The residual gas of the device is returned into raw gas for being recycled, so that gas sources are saved, and large capacity of raw gas can be obtained. The detecting method adopts carbon dioxide-nitrogen gas as raw material gas, and test permeability performance of carbon dioxide to membrane to represent permeability performance of the gas,the detecting method is simple to operate, safe and environmentally friendly, and strong in applicability.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

Adsorption-condensation type air water taking device

PendingCN114016570ARaise the dew pointLarge adsorption capacityGeneral water supply conservationDrinking water installationAir filtrationCondensation process

The invention provides an adsorption-condensation type air water taking device which is used for continuously taking water. The device comprises a shell, an air filter screen, a separation type adsorption bed, an evaporator, a condenser, a compressor, a water pan, a water storage device, a water filter, a fan and a motor. The separation type adsorbent bed used in the invention combines the hydrogel and a heat exchanger, heat and mass transfer performance of the hydrogel in the adsorption and desorption processes is enhanced, heat and moisture transfer efficiency of air-materials is improved, adsorption-condensation circulation based on a separated adsorption bed is further used, a dew point of air is improved by adopting adsorption circulation, and unit water taking energy consumption in the condensation process is reduced. Besides, the dew point of the air flowing through the adsorption bed can be improved through adsorption-condensation circulation based on the separation type adsorption bed, so energy consumption is reduced, efficiency is improved, and a water taking unit based on the separation type adsorption bed is relatively small, convenient and particularly suitable for flexible water supply in desert arid areas.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Automatic heating anti-fogging door and window used in winter

InactiveCN111425117AAvoid erosionExtended service lifeCombination devicesDispersed particle filtrationPhysicsAir transport

The invention provides an automatic heating anti-fogging door and window used in winter and relates to the field of anti-fogging technologies. The automatic heating anti-fogging door and window used in winter comprises a window frame, outer-side glass, middle-layer glass, a seal gasket, inner-side glass, an air filtering mechanism, a cleaning mechanism, an air transport mechanism, a control device, a temperature sensing device, a cover plate, connecting rods, fixing rods, a circular channel, a guide pipe, a water outlet and heating sheets, wherein the outer-side glass is arranged in the middleof the window frame; the middle-layer glass is arranged behind the outer-side glass and fixedly connected to outer-layer glass by the seal gasket; the air filtering mechanism is arranged at the top end of the interior of the window frame; the air transport mechanism is arranged on the left side and the right side of the interior of the window frame; the cleaning mechanism is arranged in the middle close to the upper end of the window frame; and the water outlet is formed in the bottom end of the front side of the window frame. By heating the glass, and discharging external air that is dried and filtered, the saturability of moisture in air around the door and window is reduced. By cleaning the outer surface of the outer-side glass by the cleaning mechanism, the problem that the vision ofpeople is adversely affected by the fogged door and window in winter is effectively solved.

Owner:周能

Secondary refining method for improving molten steel cleanliness

The invention discloses a secondary refining method for improving molten steel cleanliness. After molten steel obtained through converter tapping enters a ladle, the molten steel is subjected to gas blowing stirring with the gas blowing amount being 1-5 NL / min.t; firstly, the moisture content of gas is detected, and then the gas is humidified to enable the moisture content of the gas to be 10%-50%; the gas blowing time is 15-50 min, the hydrogen content of the molten steel is detected after gas blowing, and it is guaranteed that the hydrogen content of the molten steel is 0.0005%-0.0025%; and the molten steel is subjected to vacuum treatment for 15-30 min, and then temperature measurement, oxygen determination, hydrogen determination and tapping are conducted.

Owner:ANGANG STEEL CO LTD

RH deep decarbonization and clean steel smelting method

ActiveCN106282490ARaise the dew pointFast decarburizationProcess efficiency improvementWater contentLifting gas

The invention discloses a RH deep decarbonization and clean steel smelting method. The RH deep decarbonization and clean steel smelting method comprises following steps: oxygen blowing is finished in 5min of refining; when molten steel carbon content is 0.0030% or lower, water content of a lifting gas is detected, and the lifting gas is subjected to humidification treatment so as to control the water content of the lifting gas to be 10 to 50%, and hydrogen content of molten steel to be 0.0005 to 0.0025%, and then molten steel is subjected to circulation for 15 to 30min; when molten steel carbon content is 0.0010% or lower, humidification treatment of the lifting gas is stopped, a deoxidizing agent is added for deoxidizing of molten steel, and molten steel is subjected to circulation for another 10 to 30min; temperature measuring is carried out; oxygen determination is carried out; hydrogen determination is carried out; and steel tapping is carried out.

Owner:ANGANG STEEL CO LTD

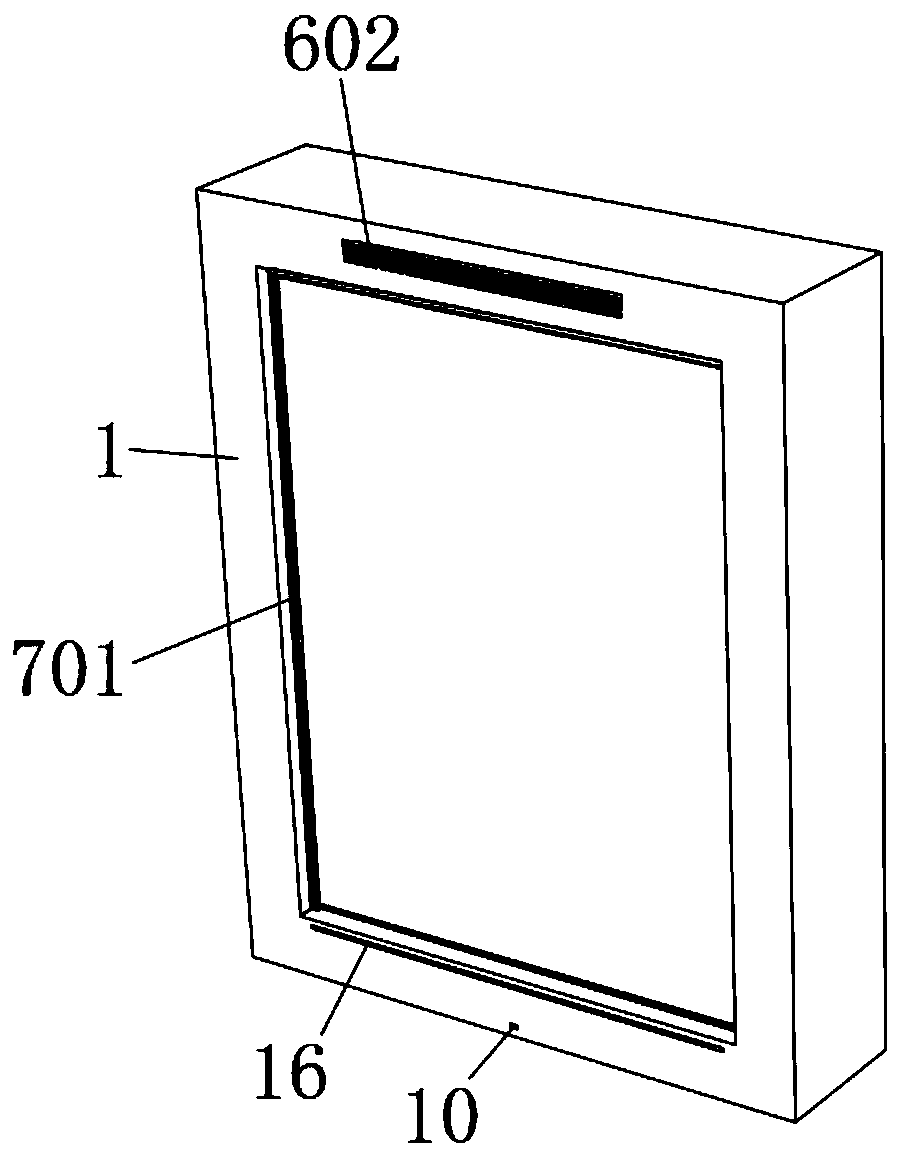

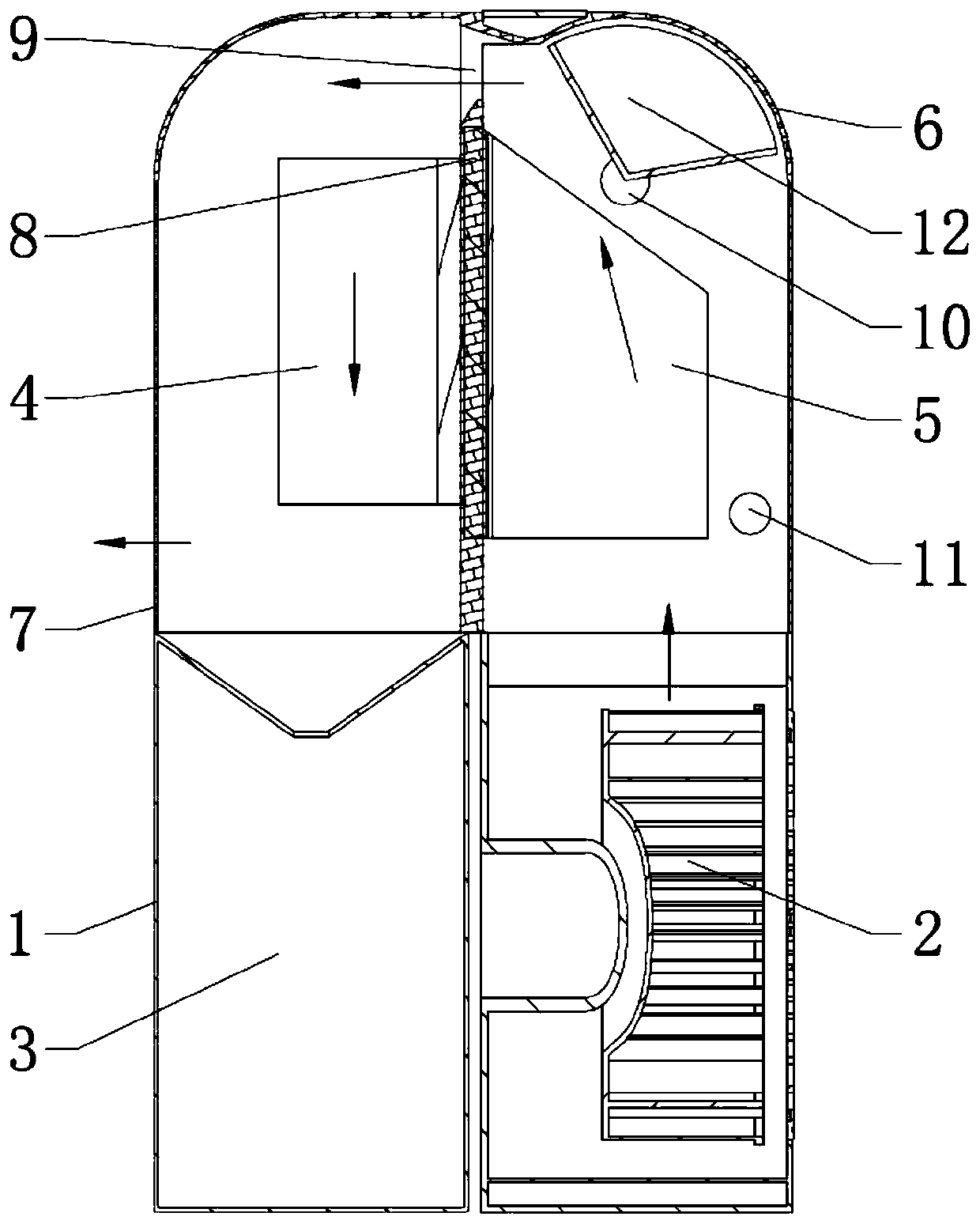

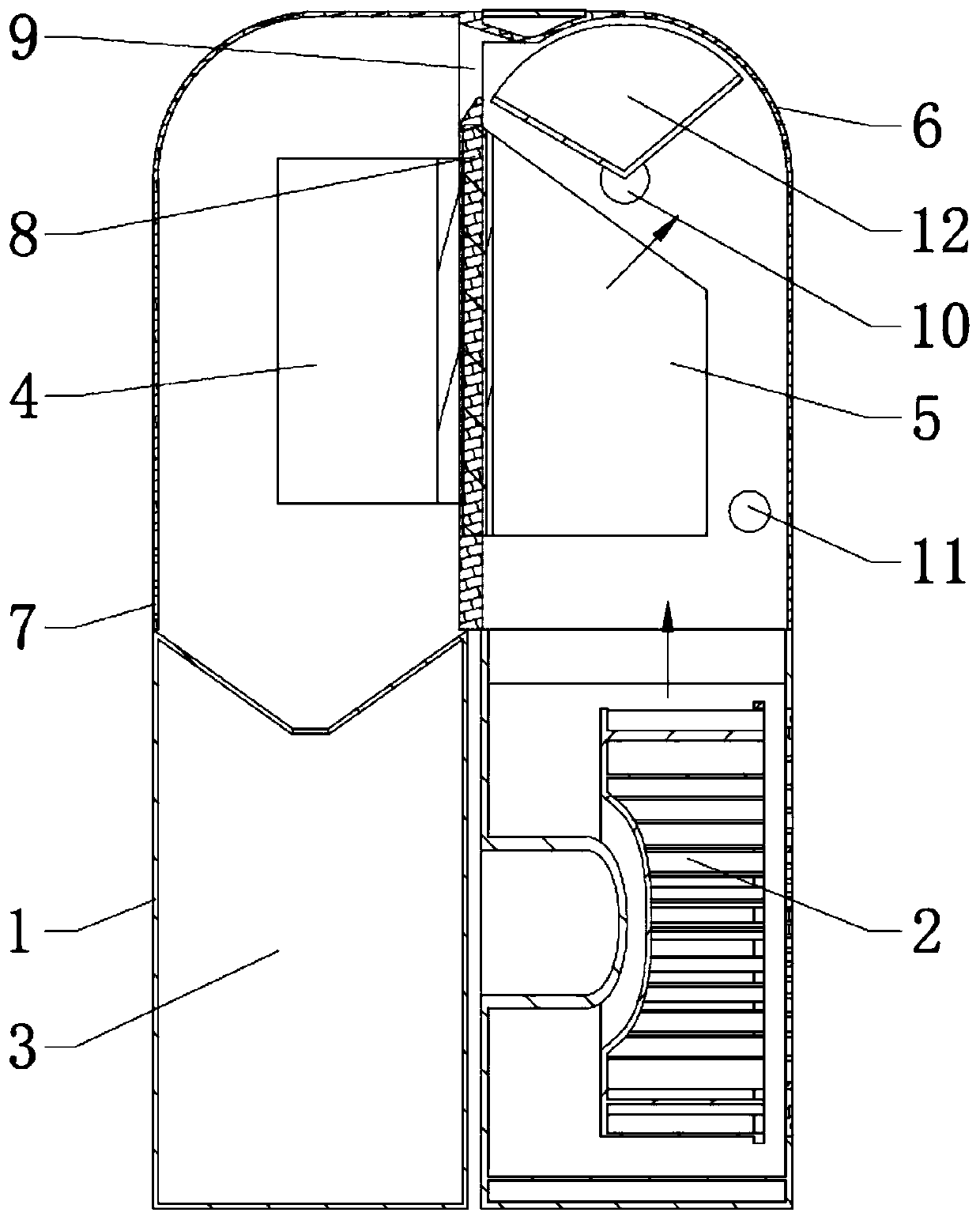

Dehumidifier

PendingCN110094809AReasonable layout of wind pathReduce the temperatureMechanical apparatusMachines using electric/magnetic effectsCold airWater storage tank

The invention provides a dehumidifier comprising a machine shell, a centrifugal air bellow and a water storage tank. The machine shell is internally provided with a heating chamber and a condensationchamber, the heating chamber is internally provided with heat dissipating fins, and the condensation chamber is internally provided with condensation fins; the water storage tank is located below thecondensation chamber and communicates with the bottom of the condensation chamber, the centrifugal air bellow is located below the heating chamber, an air outlet is in communication with the bottom ofthe heating chamber, the machine shell is provided with a hot air outlet communicating with the heating chamber and a cold air outlet communicating with the condensation chamber, an internal air opening is formed between the upper end of a partition and the machine shell, and opening degree adjustment devices are arranged on the hot air outlet and the internal air opening; a dehumidification channel is formed from the centrifugal air bellow to the heating chamber to the internal air opening to the condensation chamber to the cold air outlet; and a hot air channel is formed from the centrifugal air bellow to the heating chamber to the hot air outlet, and the opening degree adjusting devices control the air volume of the dehumidification channel and the hot air channel. A semiconductor refrigerating chip replaces a compressor, the condensation efficiency is improved, the size and weight of the whole machine are reduced, and the cost is reduced.

Owner:BEIJING SMARTMI TECH

Heat exchanger, heat exchange system and method for deep recovery of flue gas waste heat of gas boiler

ActiveCN111256159ASmall footprintHigh recovery rate of latent heatHeat storage plantsStationary conduit assembliesFlue gasMechanical engineering

The invention discloses a heat exchanger, heat exchange system and method for deep recovery of flue gas waste heat of a gas boiler. The heat exchanger includes a cylindrical shell, a first fixing plate, a second fixing plate, a plurality of heat exchange tubes and liquid distribution tubes; both ends of the cylindrical shell are each of a necking-down opening structure, and a flue gas inlet and aflue gas outlet are formed; the first fixing plate and the second fixing plate are separately arranged on the cross-sections of both ends of the cylindrical shell, and are sealed with the inner wall of the cylindrical shell; an air inlet and an air outlet are formed in the positions, between the first fixing plate and the second fixing plate, on the side wall of the cylindrical shell, and a baffleplate is arranged between the air inlet and the air outlet; both ends of the heat exchange tubes are separately nested in the first fixing plate and the second fixing plate and are arranged coaxiallywith the cylindrical shell, one ends of the heat exchange tubes communicate with the flue gas inlet, and the other ends of the heat exchange tubes communicate with the flue gas outlet; and the liquiddistribution tubes are arranged directly above the heat exchange tubes and are arranged coaxially with the heat exchange tubes to enable sprayed liquid to fall on the heat exchange tubes to form a film on each heat exchange tube.

Owner:SHANDONG UNIV

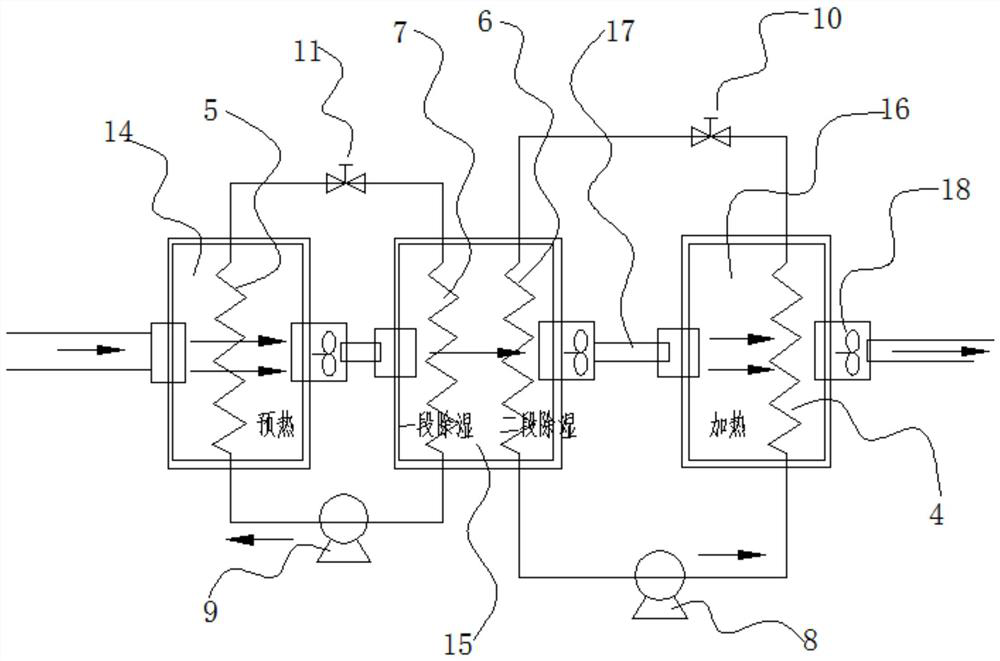

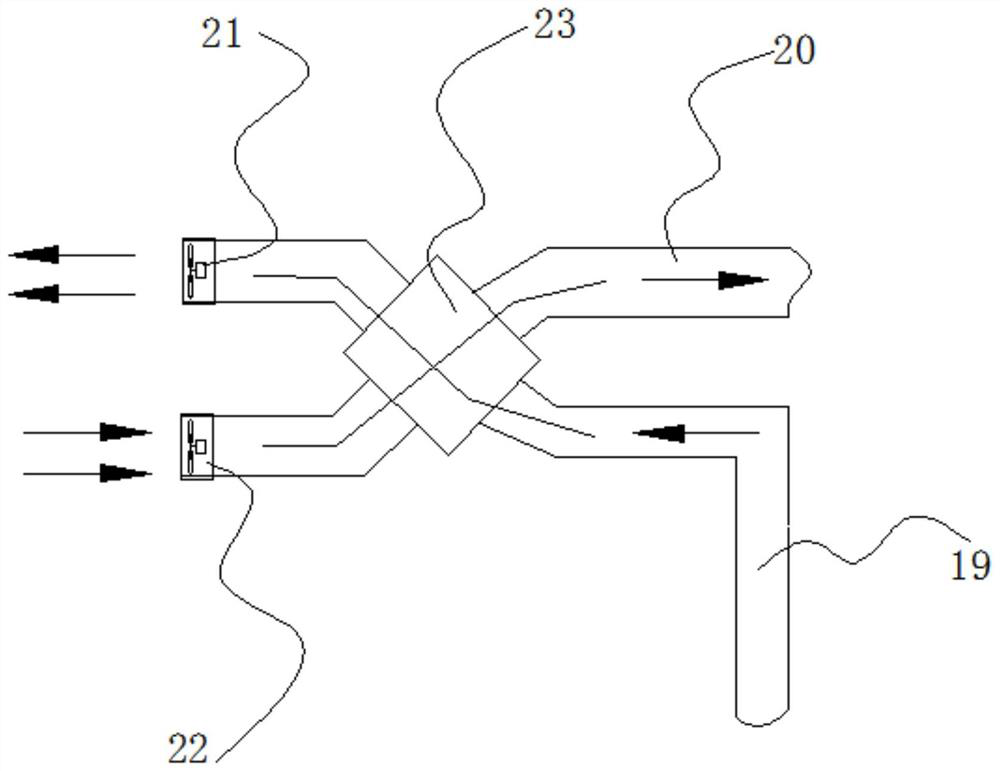

A closed-loop double-pump preheating and dehumidification indoor heating supply system

ActiveCN109899920BImprove dehumidification effectIncrease temperatureMechanical apparatusLighting and heating apparatusCold airWaste heat

The invention discloses a closed ring double-pump type preheating dehumidifying indoor hot air supply system. The closed ring double-pump type preheating dehumidifying indoor hot air supply system comprises a preheating outer machine case, a dehumidifying outer machine case, a heating inner machine case, a primary condenser, a secondary condenser, a primary evaporator, a secondary evaporator, a primary compressor, a secondary compressor, a primary one-way valve, a secondary one-way valve, an inlet and outlet air waste heat recycling device and an air amount variable terminal heat supply device. A here-case body double-pump double-refrigerant loop structure is adopted, outdoor wet and cold air is preheated by the preheating outer machine case first so that a dew point is increased; then, dehumidifying is performed through the dehumidifying outer machine case, so that very good dehumidifying and drying effects can be achieved; and moreover, a relatively high temperature can be retained,so that the heating of the heating inner machine case is facilitated, and the efficiency and the heat utilization rate are improved.

Owner:광동웜하우스테크놀로지컴퍼니리미티드

Double-tower high-efficiency energy-saving rectification process

PendingCN113680087ALow costHigh product contentDistillation regulation/controlDistillation in boilers/stillsFluid phaseDistillation

The invention belongs to the technical field of separation of chemical substances, and discloses a double-tower high-efficiency energy-saving rectification process which comprises the following steps: step 1, feeding a liquid to be purified into a crude distillation tower, and heating the liquid in a tower kettle by using a heating medium to form mixture steam at the tower top; step 2, condensing the mixture steam at the top of the crude distillation tower to form a vapor phase and a liquid phase, and backflowing the liquid phase to the crude distillation tower, wherein the product content of the extracted product in the mixture steam is 80-95%; and step 3, introducing the vapor phase formed in the step 2 into the rectification tower for rectification, and condensing tower top vapor in the rectification tower to obtain a high-purity product. The problems that in the prior art, due to the fact that the purity of a product led out from a single rectifying tower is high, the bubble point of a chemical product is low, the temperature of a cooling medium needed for cooling is low, the preparation cost of the low-temperature cooling medium is high, and the rectifying cost is high are solved.

Owner:CHONGQING SHANJU CHEM MACHINERY

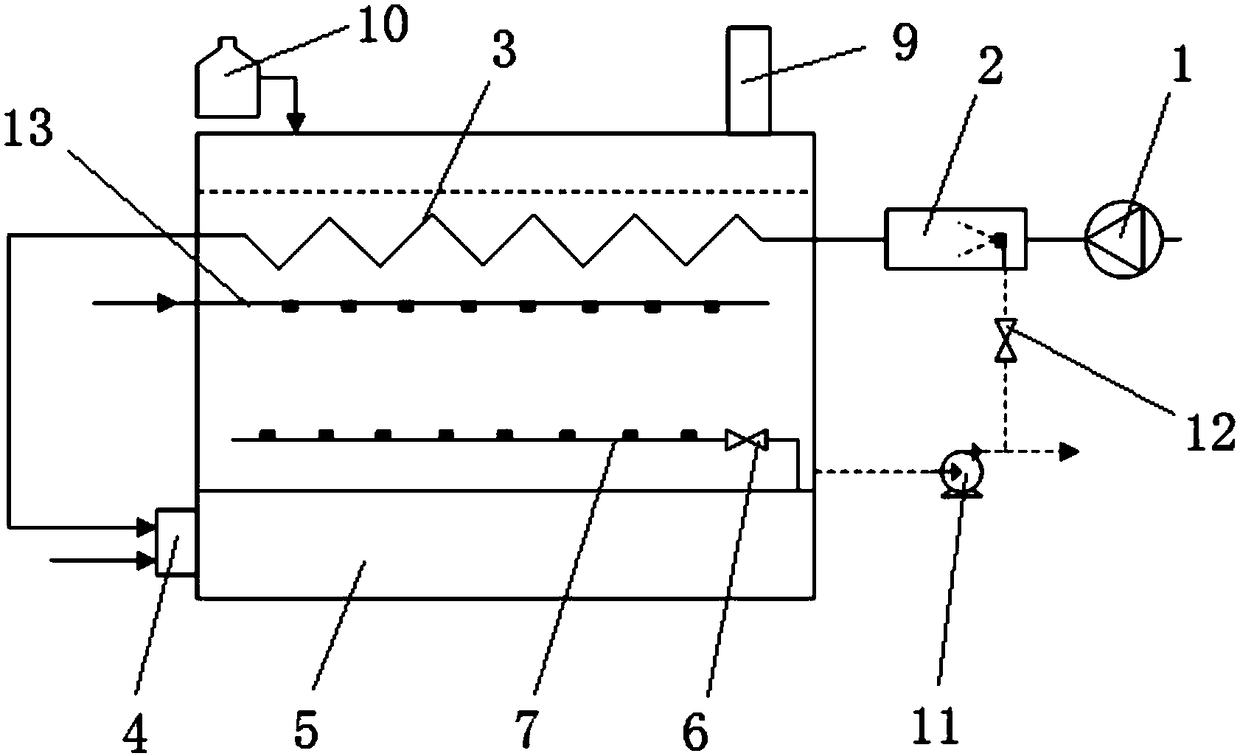

Gas Boiler Flue Gas Waste Heat Recovery and Purification System for Combustion Air and Gas Humidification

ActiveCN109268820BRaise the dew pointIncrease temperature differenceIndirect carbon-dioxide mitigationCombustion apparatusThermodynamicsFlue gas

The invention provides a gas-fired boiler flue gas waste heat recovery and purification system with a function of humidifying combustion air and gas. The system comprises a spray type heat exchange tower, an intermediate circulating water system, a flue gas circulation device and a gas mixing device, wherein the combustion air, the gas and boiler flue gas are subjected to water-heat exchange withthe intermediate circulating water system in the spray heat exchange tower and are humidified; the humidified gas returns to a boiler through the gas mixing device to continue burning. The invention uses the intermediate circulating water as a medium to realize the humidification and recirculation of the flue gas as well as recovery of the latent heat of the flue gas under the high intermediate circulating water temperature condition; furthermore, the latent heat of the high temperature flue gas and sensible heat are utilized to heat the humidified gas and combustion air; after being subjectedto recirculation, the humidified flue gas, combustion air and gas are mixed and introduced into the gas boiler, so that NOx emission can be reduced, and the dew point of the flue gas is increased; therefore, the purposes of reducing pollutant emission from the gas boiler and improving the heating effect of the boiler are achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Method for controlling arsenic in clean smelting of arsenic-containing gold-copper concentrate

ActiveCN113403485BReduce contentRaise the dew pointGas treatmentArsenic oxides/hydroxides/oxyacidsChemical industryEngineering

The invention relates to a method for controlling arsenic in clean smelting of arsenic-containing gold-copper concentrate, which belongs to the field of chemical industry. Including: side blowing smelting system, side blowing arsenic collection system and steel belt furnace refining system; side blowing smelting system is used to process arsenic-containing gold and copper concentrate; side blowing furnace ascending flue is sprayed with pyrite powder to reduce oxygen in flue gas content, thereby reducing the content of sulfur trioxide; increasing the height of the quenching tower is conducive to the full contact between the absorbent and the flue gas to cool down; the absorbent uses water to improve the grade of arsenic trioxide, and the purity of arsenic trioxide reaches more than 95%; 95% Arsenic trioxide is treated in a steel belt furnace to obtain more than 99.5% refined arsenic trioxide.

Owner:CENT SOUTH UNIV +1

Recovery method of converter gas

ActiveCN102827991BAvoid consumptionStable generationDispersed particle filtrationChemical industryRecovery methodCombustion chamber

The invention relates to a convertor coal gas recovery method, and belongs to the technical field of recycling physical sensible heat in convertor flue gas. The main technical problems to be solved are as follows: on one hand, the water waste problem is to be solved, on the other hand, efficient utilization of physical sensible heat in the convertor flue gas is to be realized, and the problems of sensibility increase of confined explosion caused by due to cancel of an evaporation cooling process and the like are also to be solved. The method comprises allocation of a flue heat exchange device, a rough dust removing device and a refined dust removing device, an induced draft fan, a pipe network a control system, and is characterized in that a combustion chamber is arranged in the method, a heat exchanger is also arranged in the method and the heat exchanger is installed behind the combustion chamber. The method is suitable for the technical field of recycling physical sensible heat in the convertor flue gas, and has the characteristics of saving water, saving energy, improving system safety, improving recovery rate of convertor coal gas and the like.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com