Patents

Literature

97results about How to "Reduce the amount of on-site construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

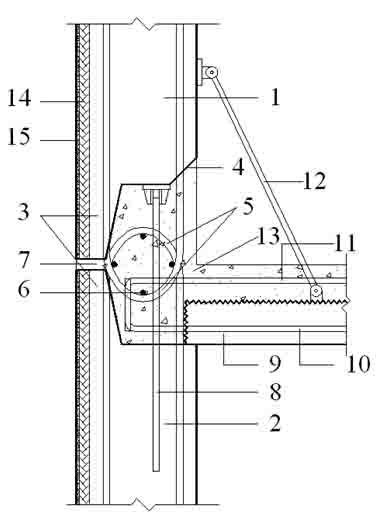

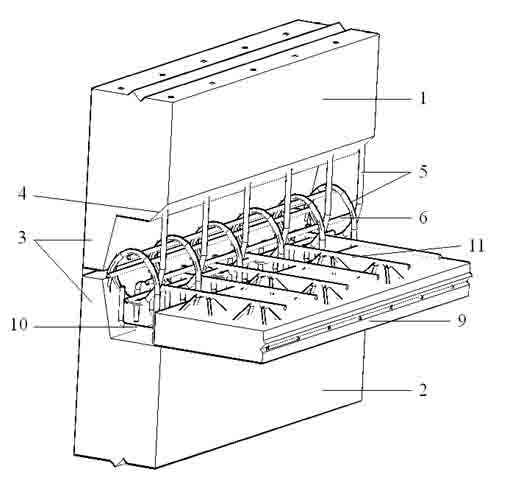

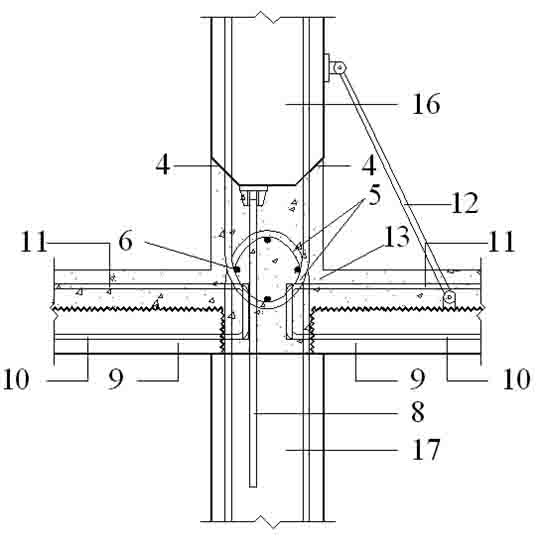

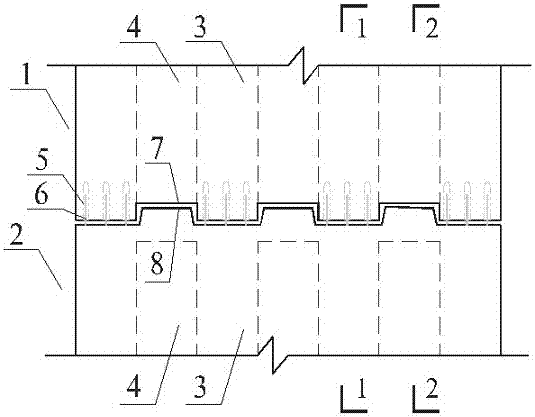

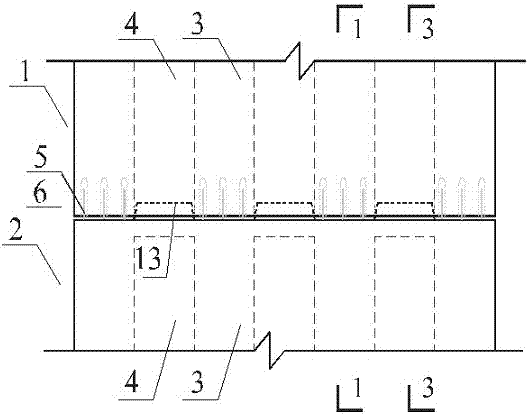

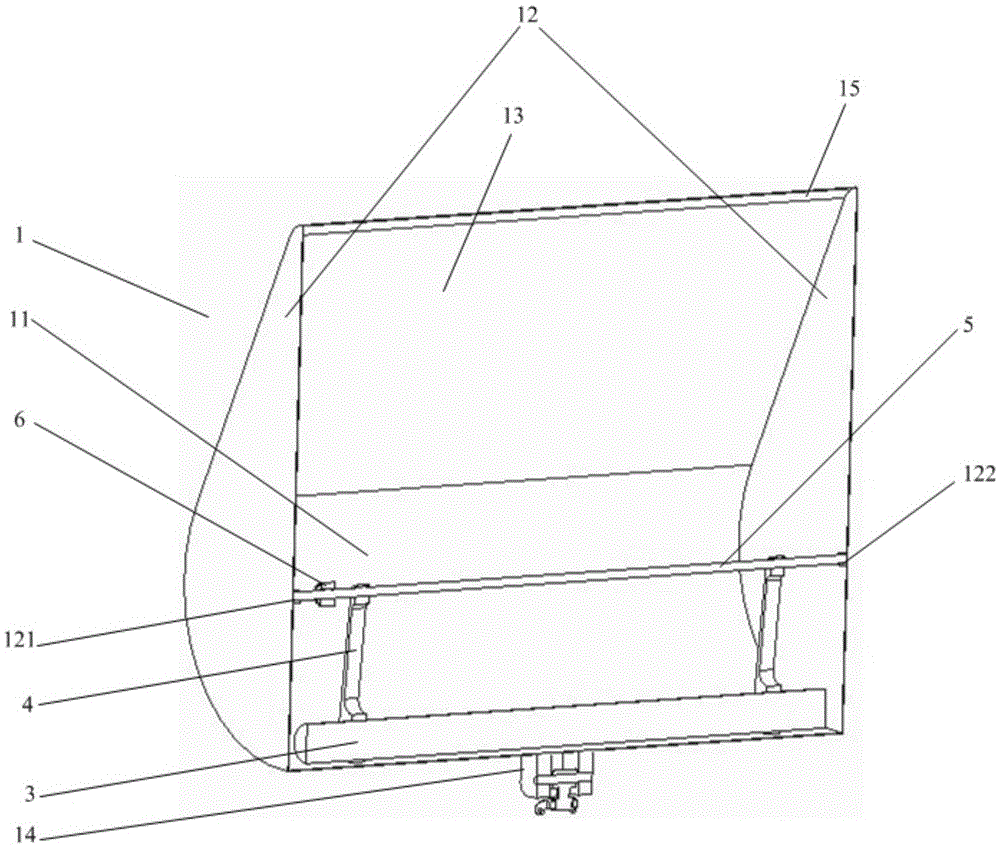

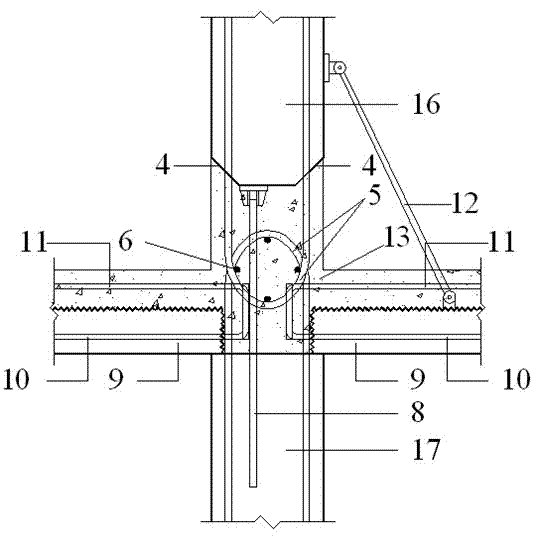

Horizontal seam U-shaped closed rib junction structure of assembled shear wall structure

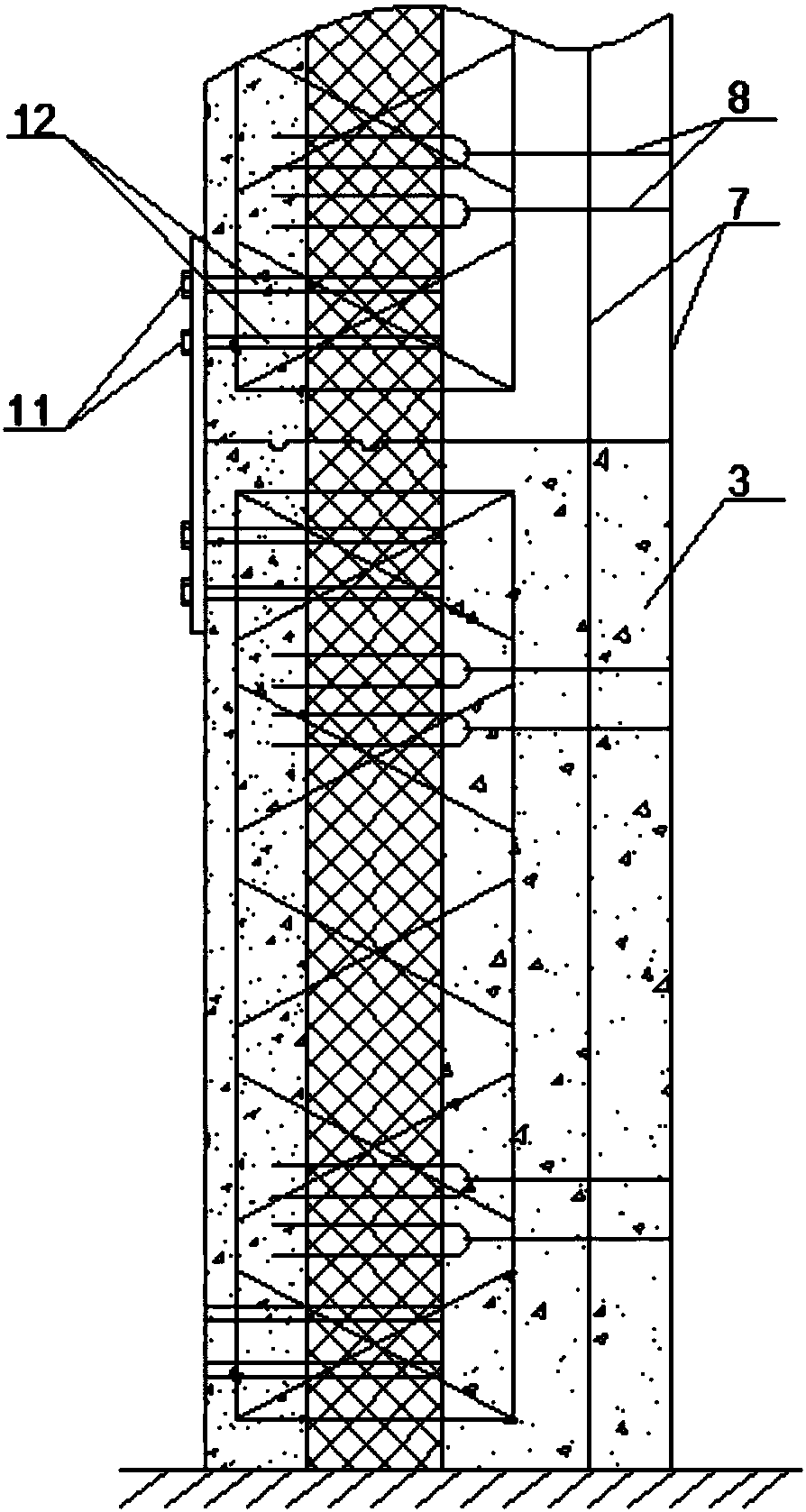

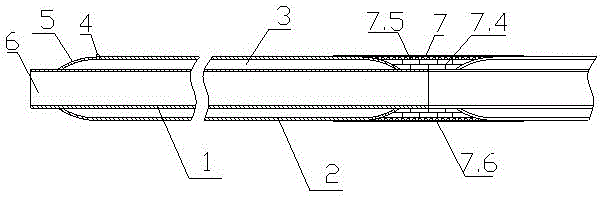

The invention discloses a horizontal seam U-shaped closed rib junction structure of an assembled shear wall structure, comprising an upper-layer outer wall prefabricated shear wallboard (1), a lower-layer outer wall prefabricated shear wallboard (2), an upper-layer inner wall prefabricated shear wallboard (16), a lower-layer inner wall prefabricated shear wallboard (17), U-shaped closed ribs (5), a horizontal reinforcing rib (6) and filled cast-in-place concrete (13), wherein the U-shaped closed ribs adopting the upper-layer outer wall prefabricated shear wallboard, the lower-layer outer wall prefabricated shear wallboard, the upper-layer inner wall prefabricated shear wallboard and the lower-layer inner wall prefabricated shear wallboard are staggered and are in lap joint to form an annular ring; the horizontal reinforcing rib is arranged in the annular ring to reliably connect the vertical reinforcing steel bars of the assembled shear wall; and the filled cast-in-place concrete of a horizontal seam (7) realizes the purpose that the resistance to shear of the horizontal seam is equivalent to the cast-in-place concrete shear wall. The whole prefabricated assembled shear wall can be reliably connected with the shear wall and a floorslab, the whole prefabricated assembled shear wall performance can be ensured, and the horizontal seam U-shaped closed rib junction structure has the advantages of simple form and material conservation and is convenient to construct.

Owner:SOUTHEAST UNIV

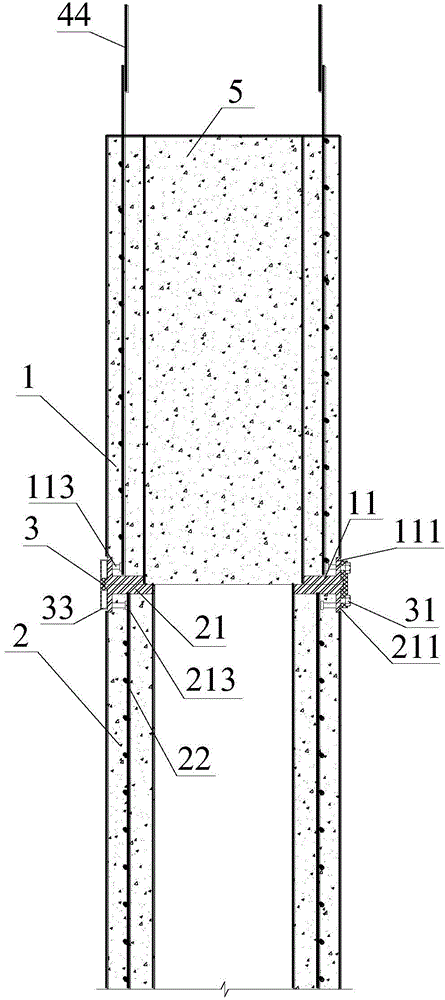

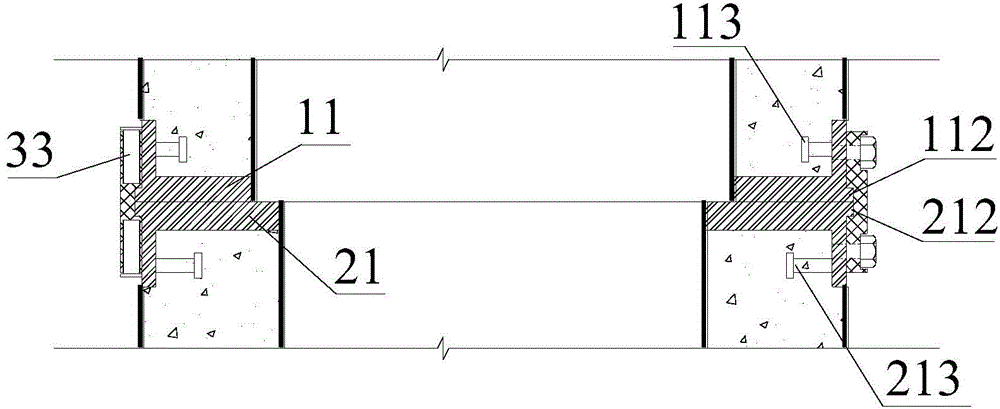

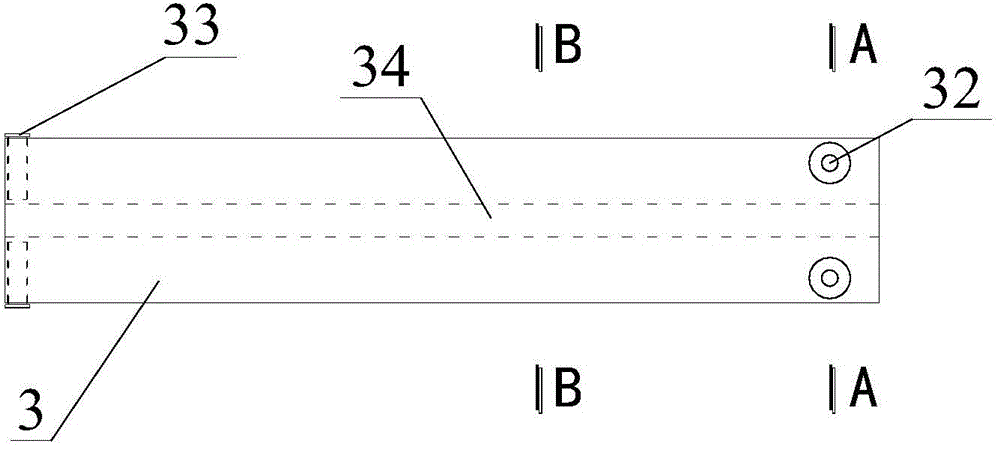

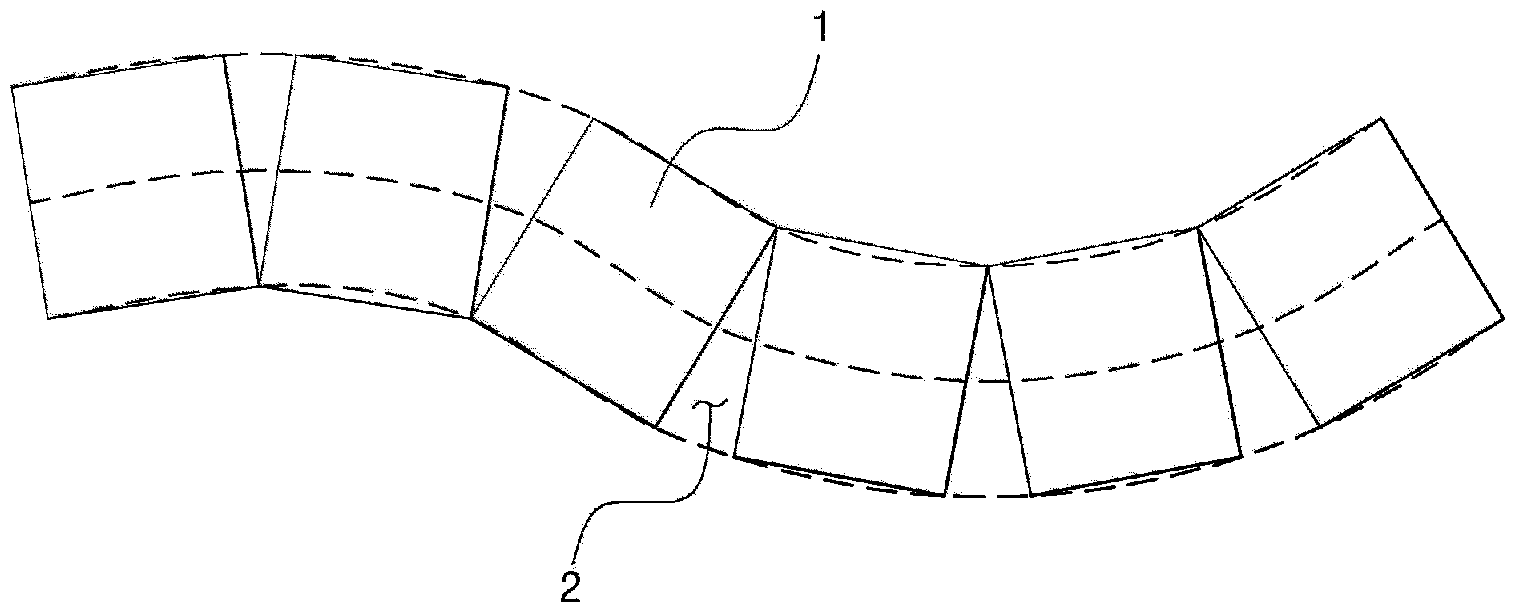

Horizontal joint tooth-groove dry-type connection structure of assembly type cavity shear wall

The invention provides a horizontal joint tooth-groove dry-type connection structure of an assembly type cavity shear wall. The connection structure adapts to the characteristics of easy industrialized production of the assembly type cavity shear wall, and facilitates the industrialized production and on-site quick installation; sleeve connection is adopted for all main stress longitudinal ribs of the wall column sections of the cavity shear wall, distributing ribs of the cavity section are not connected vertically, and the connection form is simplified; the lower part of the cavity section of the upper cavity shear wall is provided with reserved grooves or an empty cavity for use as connecting grooves, and the upper part of the cavity section of the lower cavity shear wall is reserved with convex teeth which are meshed with the grooves, so that the shear-bearing capacity of the horizontal joint of the cavity shear wall is improved; bracket boards are prefabricated at the storey height of the cavity shear wall, the connecting end of a prefabricated floor is prefabricated as an L type, on-site direct bolt connection is made convenient, and the on-site construction quantity is reduced. According to the horizontal joint tooth-groove dry-type connection structure of the assembly type cavity shear wall, wet operation of a construction site is avoided, and industrialized production and green installation and construction are made convenient; the structure can be widely applied to precast assembly type concrete shear wall structures.

Owner:SOUTHEAST UNIV

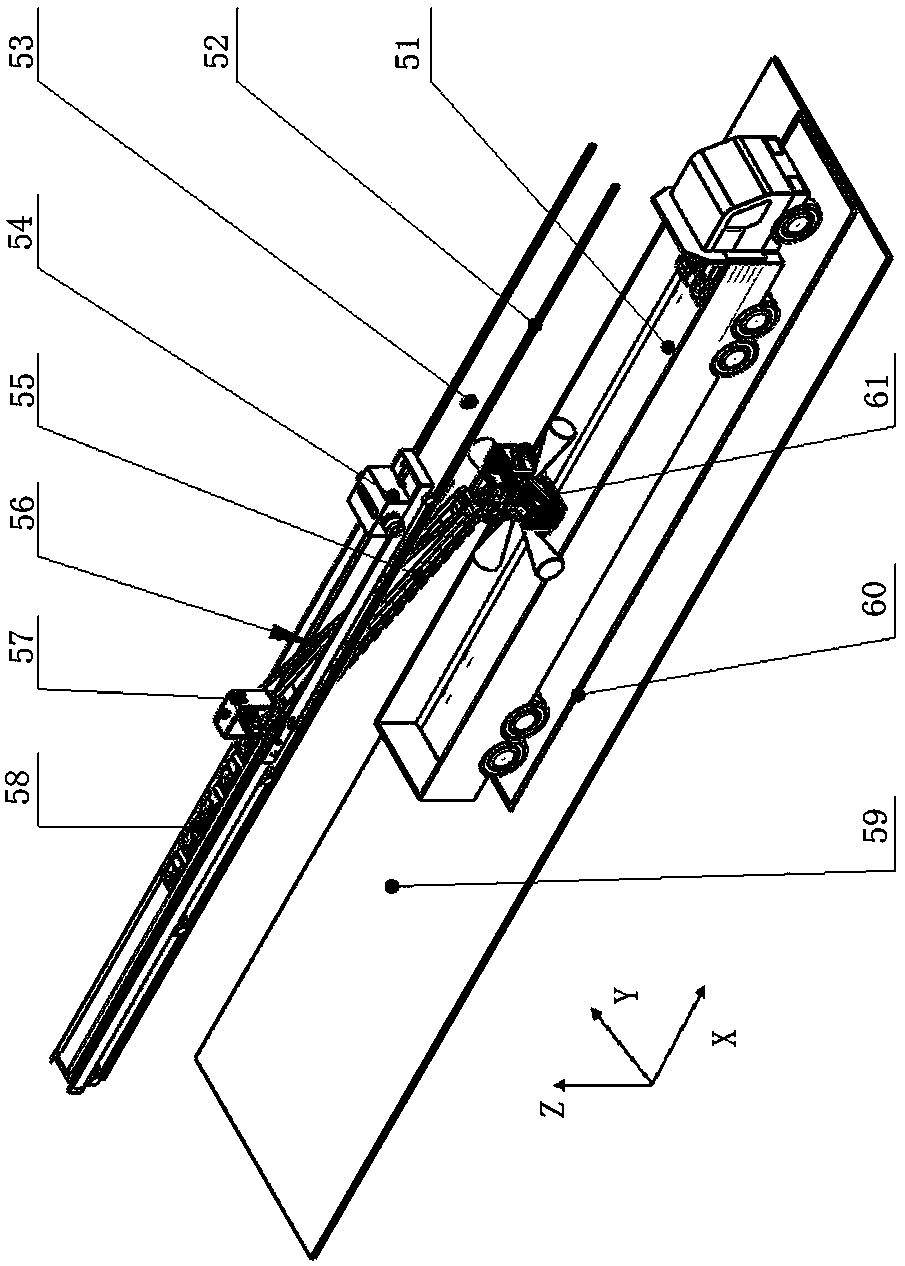

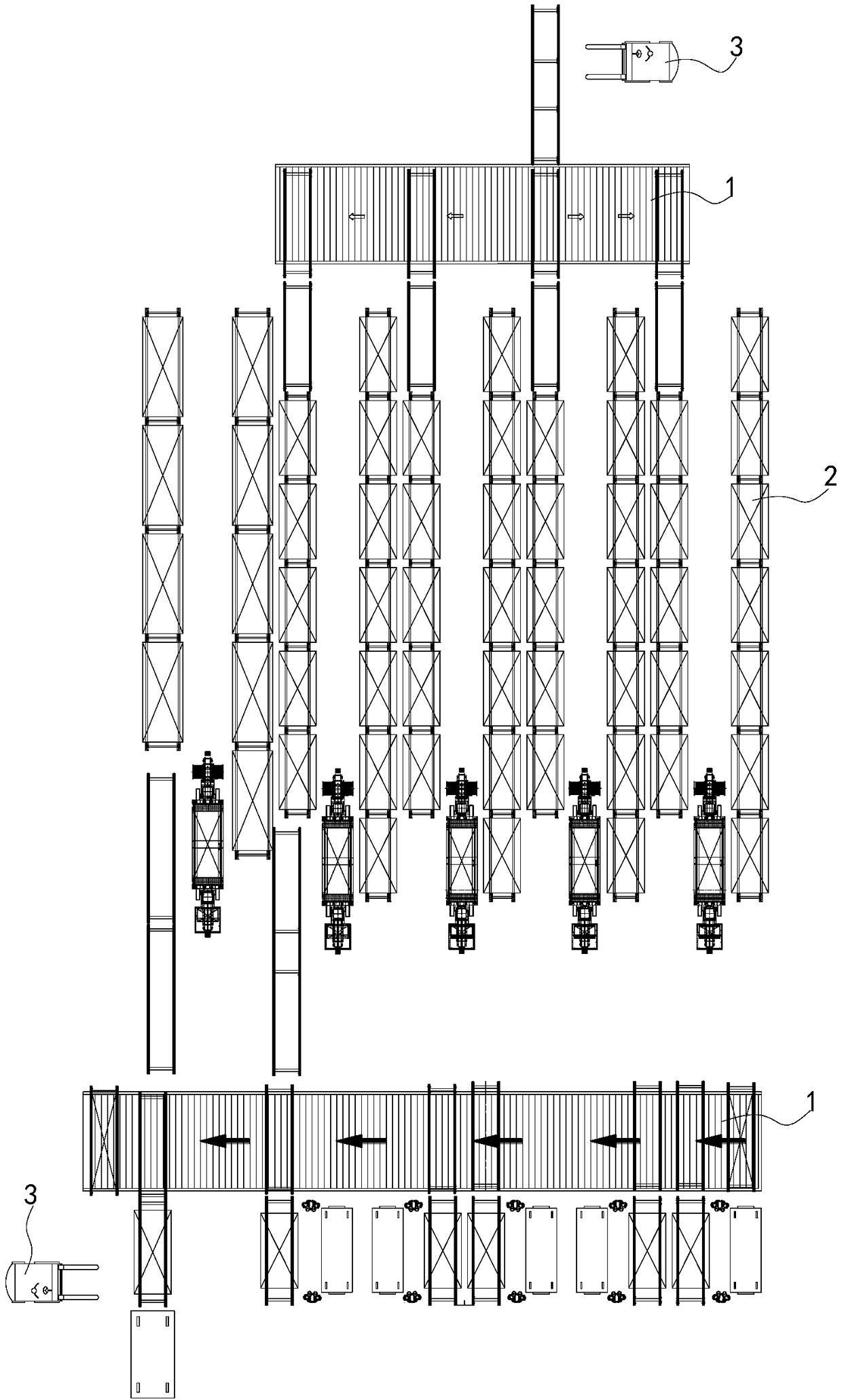

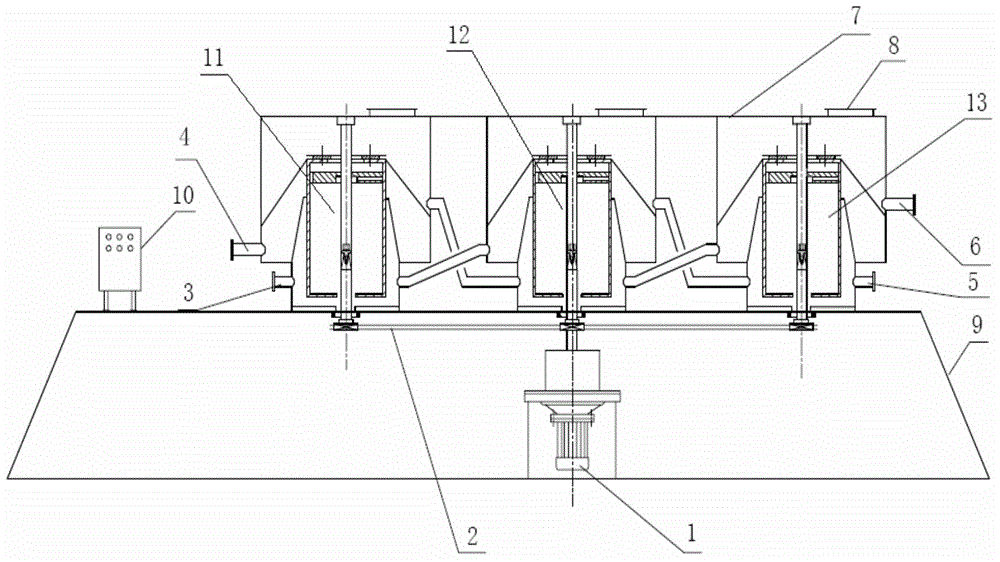

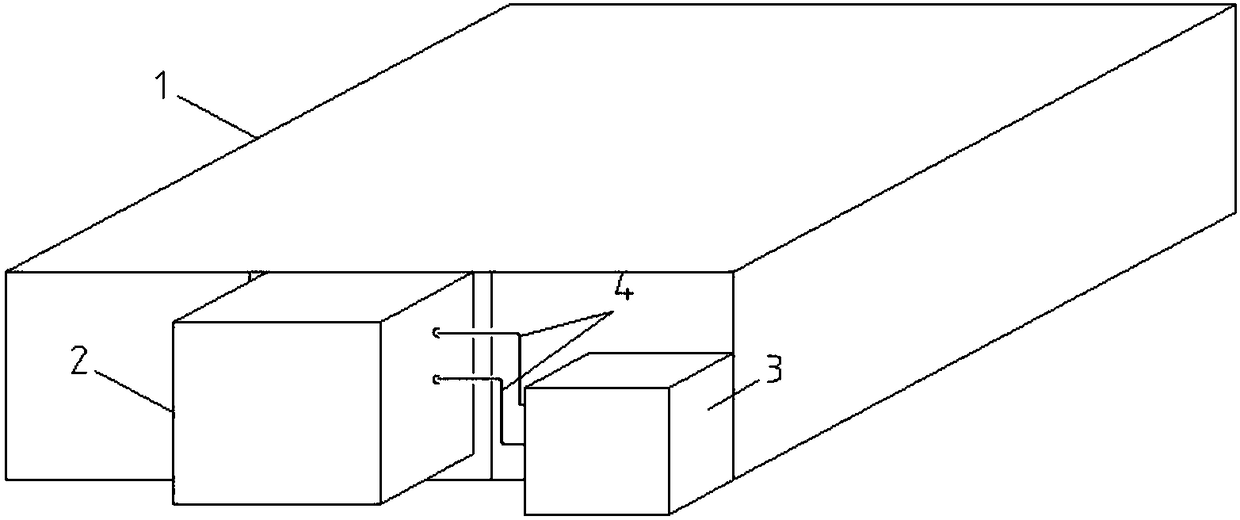

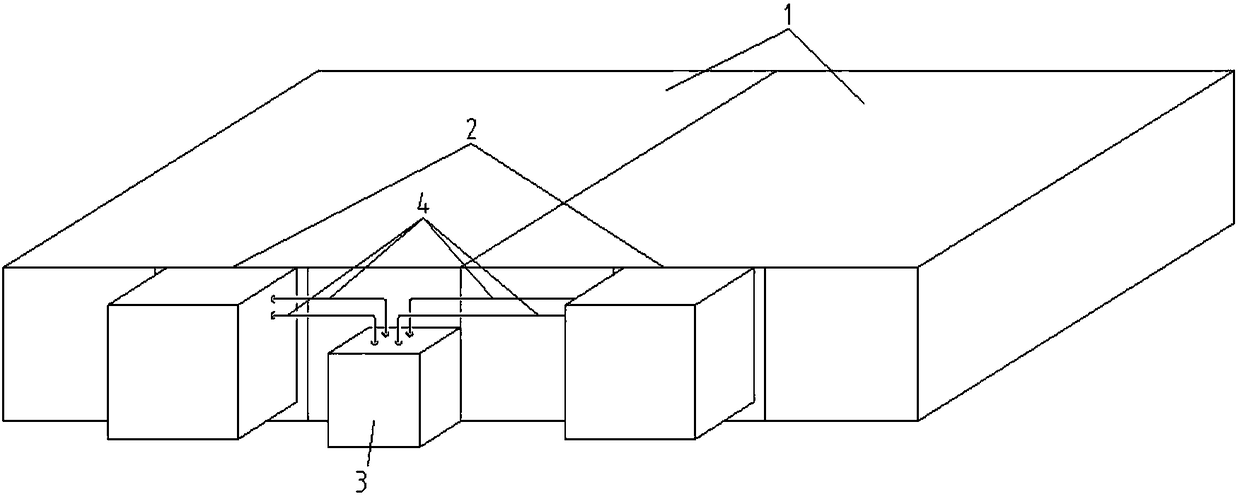

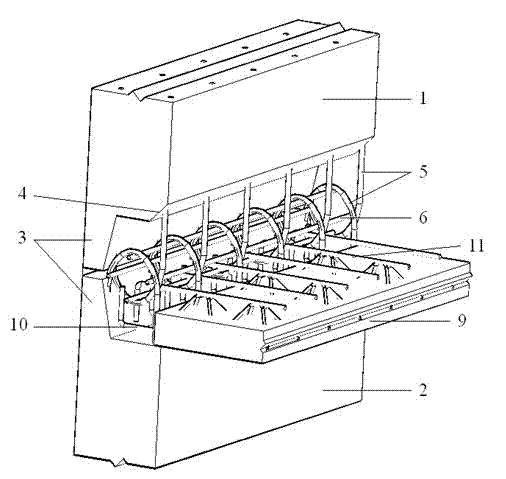

Flexible automatic loading system and application thereof

ActiveCN107618894AMeet the positioning needsSimple structureStacking articlesLoading/unloadingLaser scanningMechanical engineering

The invention discloses a flexible automatic loading system and application thereof. The flexible automatic loading system aims to solve the problems that an existing bagged material loading device lacks a corresponding automatic scanning and positioning system and is low in automatic degree. According to the flexible automatic loading system and the application thereof, mechanisms of the loadingsystem are subjected to completely-new optimization design, a carriage is subjected to automatic scanning positioning through a laser scanning positioning unit, a material is conveyed through a feeding unit, and through a stacking and loading unit, the material is effectively placed on a designated position of the carriage to achieve material automatic loading. The flexible automatic loading system can meet the demands of the sizes and height change of various material conveying vehicles, the loading path can be automatically planned according to the size information and loading tasks of a target vehicle carriage, automatic loading is achieved according to data provided by the laser scanning positioning unit, and in the whole loading process, only loading task manual issuing is needed. According to the flexible automatic loading system, the labor intensity of workers can be effectively reduced, the bad loading environment is avoided, the production efficiency of enterprises is improved, the labor cost of the enterprises is reduced, and the high application value is achieved.

Owner:SICHUAN FUDE ROBOT

Wooden furniture component sorting system and application method thereof

InactiveCN108750508AImprove performanceTake and send smoothlyStorage devicesStack machineAutomated guided vehicle

The invention provides a wooden furniture component sorting system. The wooden furniture component sorting system comprises a stacking machine, goods shelves and automatic guide vehicles. The stackingmachine is connected with the corresponding goods shelves. Wooden furniture components are conveyed to the goods shelves through the stacking machine. The automatic guide vehicles are arranged between the goods shelves and processing equipment. The wooden furniture components on the goods shelves are conveyed to the processing equipment through the automatic guide vehicles. Wheels of the automatic guide vehicles are compact in structure, small in occupied space, high in controllability, reliable in performance and easy to maintain. An inertial navigation mode is adopted. There is no need to lay a continuous induction line on the ground. The site construction capacity is very small. A path can be changed flexibly. The flexibility of the system is higher. During task distribution, an MES transmits tasks to the sorting system. The sorting system receives the tasks, executes the sorting task, transmits a sorting completion instruction to the automatic guide vehicles and transmits the distribution tasks to the starting and ending points, namely the positions where warehouse exits are located and the ending points where the MES distributes the tasks. The automatic guide vehicles go forthe designated warehouse exit and transport material vehicles to the distribution task designated destination points and fed back execution results to the sorting system in real time.

Owner:MENGTIAN HOUSEHOLD GRP CO LTD

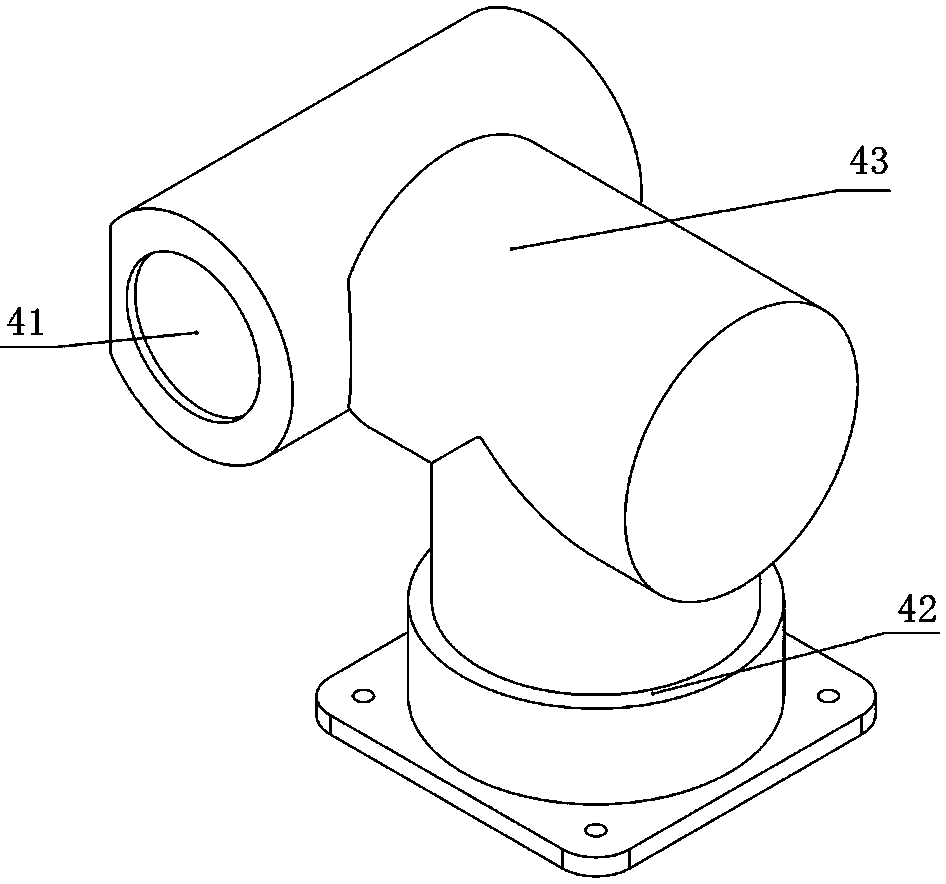

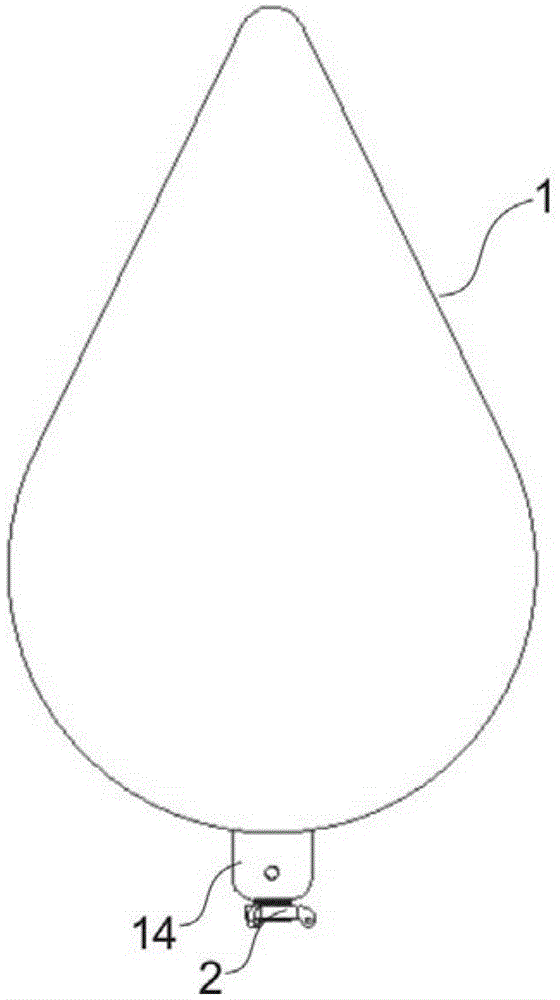

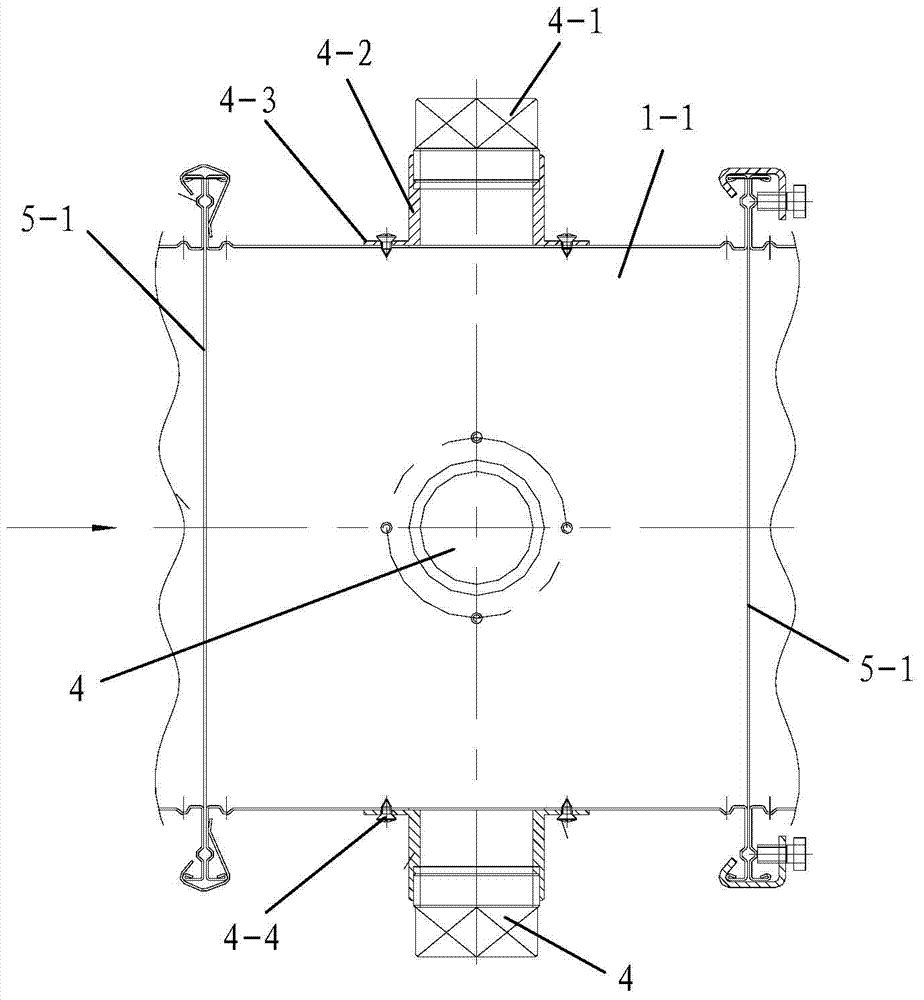

All-closed wave power generation device

InactiveCN105626365ARealize swinging with the wavesAvoid swingingMachines/enginesEngine componentsElectricityWave power generation

The invention provides an all-closed wave power generation device. The all-closed wave power generation device comprises a mooring device and a shell; the shell is a closed box with a hollow internal; the bottom of the box is arched; a counterweight block is arranged at the bottom of the shell, and is suspended on an output shaft for transferring power through a connecting rod; the output shaft is horizontally arranged in the shell; the two ends of the output shaft are respectively connected with two opposite inner walls of the box through bearings; when the shell swings along with waves, the counterweight block relatively moves corresponding to the shell under the effect of gravity, and the connecting rod drives the output shaft to rotate; the output shaft is connected with a gear; and the gear spreads rotation of the output shaft to form relative rotation to a power generation device fixed on the shell so as to generate electricity. The all-closed wave power generation device is high in energy capturing efficiency and convenient for use; moving parts are all located in the closed box without being contacted with seawater; the tightness is excellent; and the reliability is high.

Owner:SHANGHAI MICROPOWERS

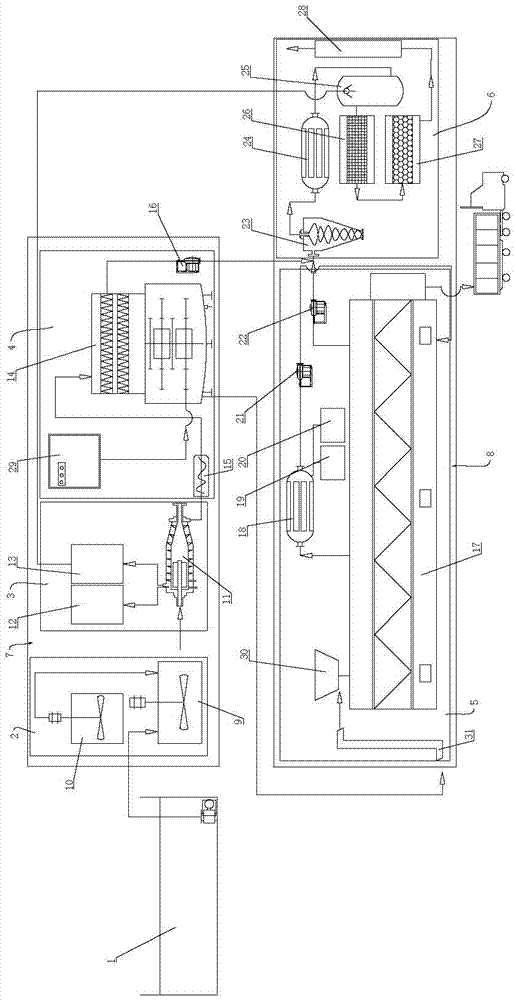

Refinery oily sludge disposal system and method

PendingCN107500501ARealize harmless disposalEliminate hazardsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCentrifugationSludge

The present invention provides a refinery oily sludge disposal system which realizes non-hazardous treatment of oily sludge and effectively solves the problem of resource treatment and utilization of the oily sludge, the refinery oily sludge disposal system has the advantages of skid-mounted design, compact structure and small floor area, the refinery oily sludge disposal system includes an oily sludge reservoir, a quenching and tempering unit, a centrifugal processing unit, a pelletizing and drying unit, a thermal cracking unit and an exhaust gas treatment unit, the quenching and tempering unit, the centrifugal processing unit and the pelletizing and drying unit are respectively arranged on a quenching and tempering centrifugation drying integrated skid body, the exhaust gas treatment unit and the thermal cracking unit are respectively arranged on a thermal cracking exhaust gas integrated skid body, and the invention also provides a refinery oily sludge disposal method.

Owner:无锡雪浪康威环保科技有限公司

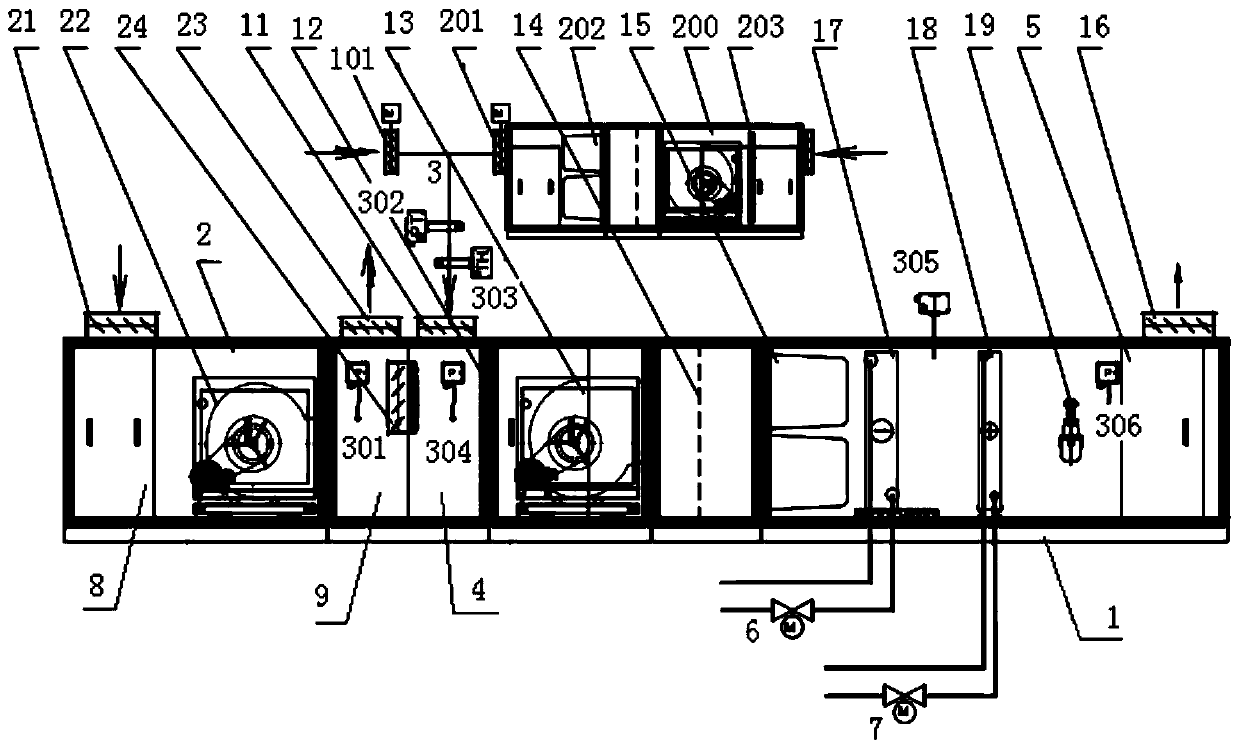

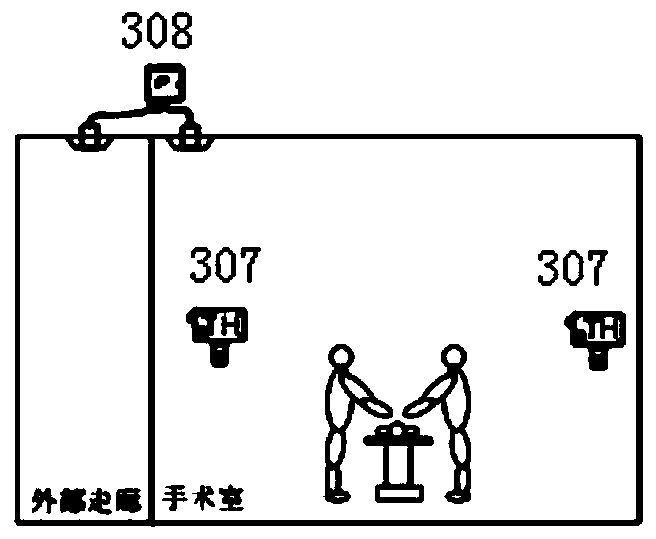

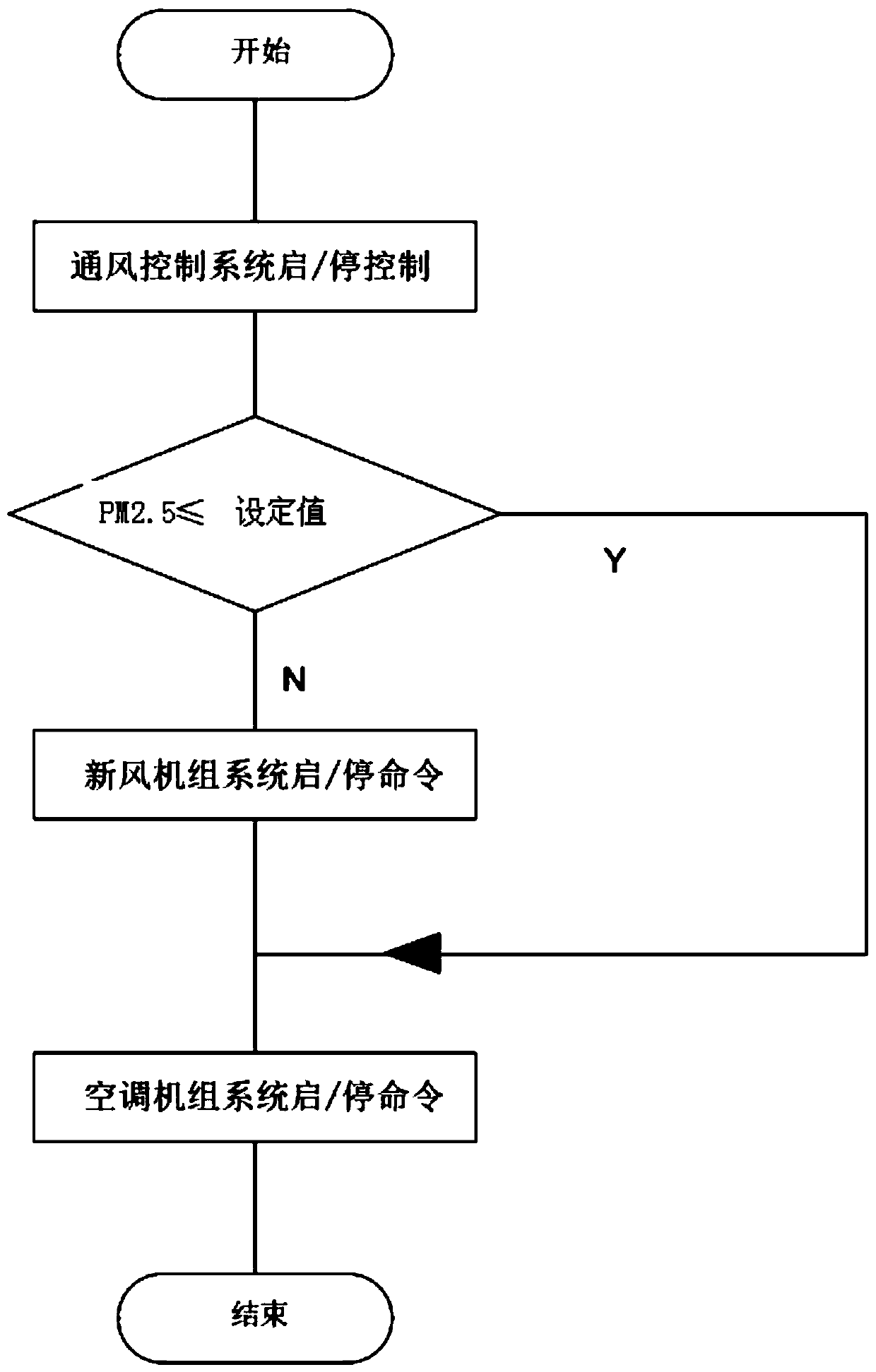

Air conditioning unit for large-bay operating room and control method thereof

ActiveCN110701692AReduce the amount of on-site constructionLower requirementDucting arrangementsMechanical apparatusAir volumeMedicine

The invention discloses an air-conditioning unit for a large-bay operating room and a control method thereof. The air-conditioning unit comprises an air supply unit, an air return unit and an optionalfresh air unit. The installation is convenient, the arrangement is flexible, and a technical interlayer does not need to be used as a machine room; on the premise of keeping the total air supply amount unchanged, the fresh air amount is changed, the pressure difference is maintained, the energy consumption is reduced, and the air quality in the operating room is improved; a PLC control system controls the optimum operation of the air supply unit, the air return unit and the optional fresh air unit in real time aiming at the indoor and outdoor changing hot and wet load to form the air conditioning unit, wherein the project quality of the air conditioning unit is completely controlled by a factory; and a traditional purification air conditioning system combined by fresh air centralized treatment and each operating room circulating unit, and a complex air treatment mode are changed, through variable frequency, the total air supply amount and the total air return amount can be changed, the cleanliness level of operating areas can be changed, or air is only supplied to the operating areas needing to be subjected to surgery, or the emergency conversion is a direct current air supply negative pressure mode, and the control requirements of different surgical environments are achieved with low energy consumption.

Owner:TONGJI UNIV +1

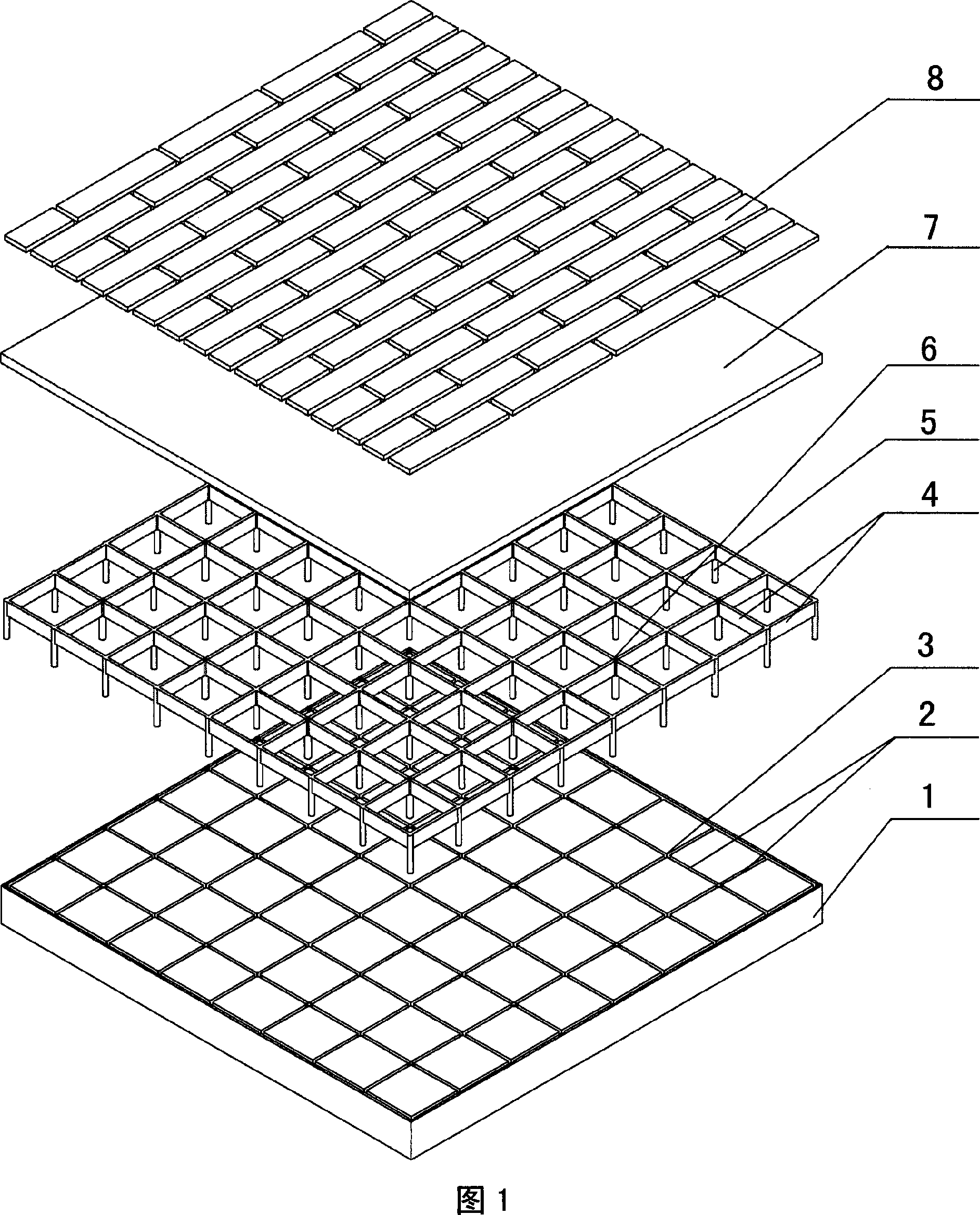

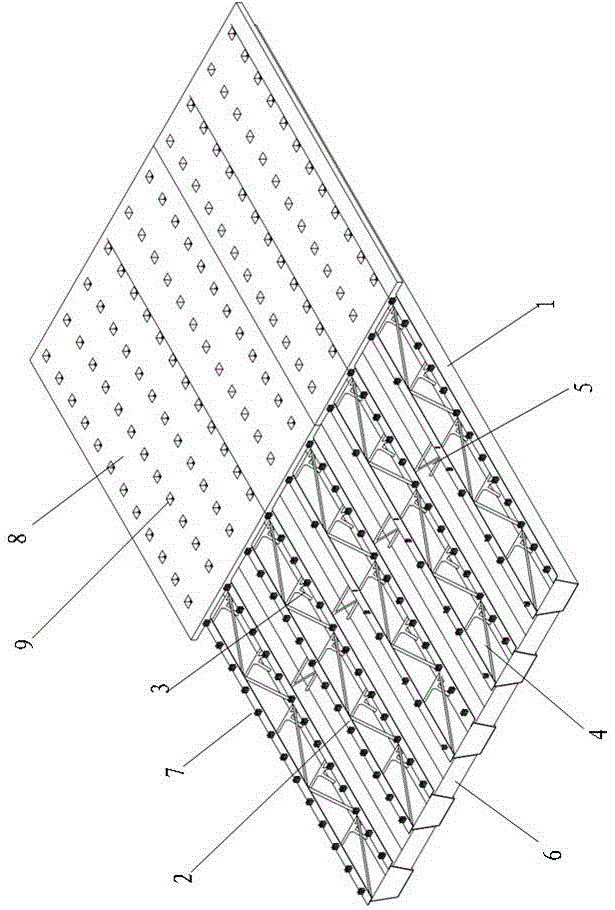

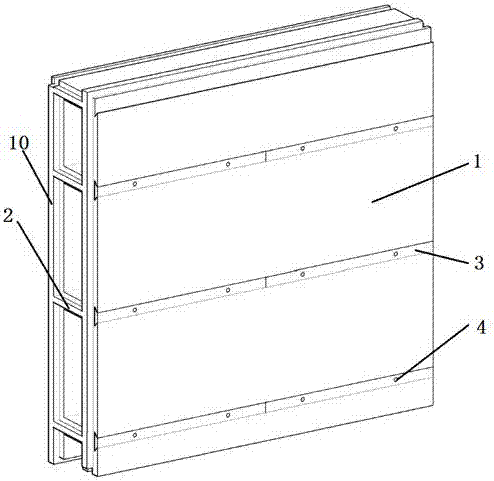

Composite thermal insulation energy-saving board

InactiveCN101100895AReduce the amount of on-site constructionImprove integrityCovering/liningsHeat proofingFloor slabThermal insulation

A multiplex heat-preserve plate is composed by supporting frame and heat-preserve layer. The supporting frame mainly includes base layer and supporter. The heat-preserve layer is made by heat insulation material with holes on the top matching to the frame supporter. Filling the holes forms an integrated part by base, enforcing rib and supporter. Force to the plate is evenly spread to enforcing ribs and supporters then to the base wall.

Owner:赵明桥

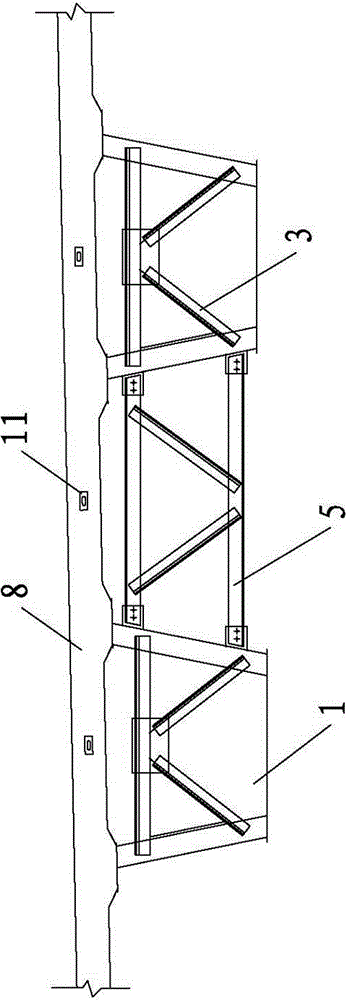

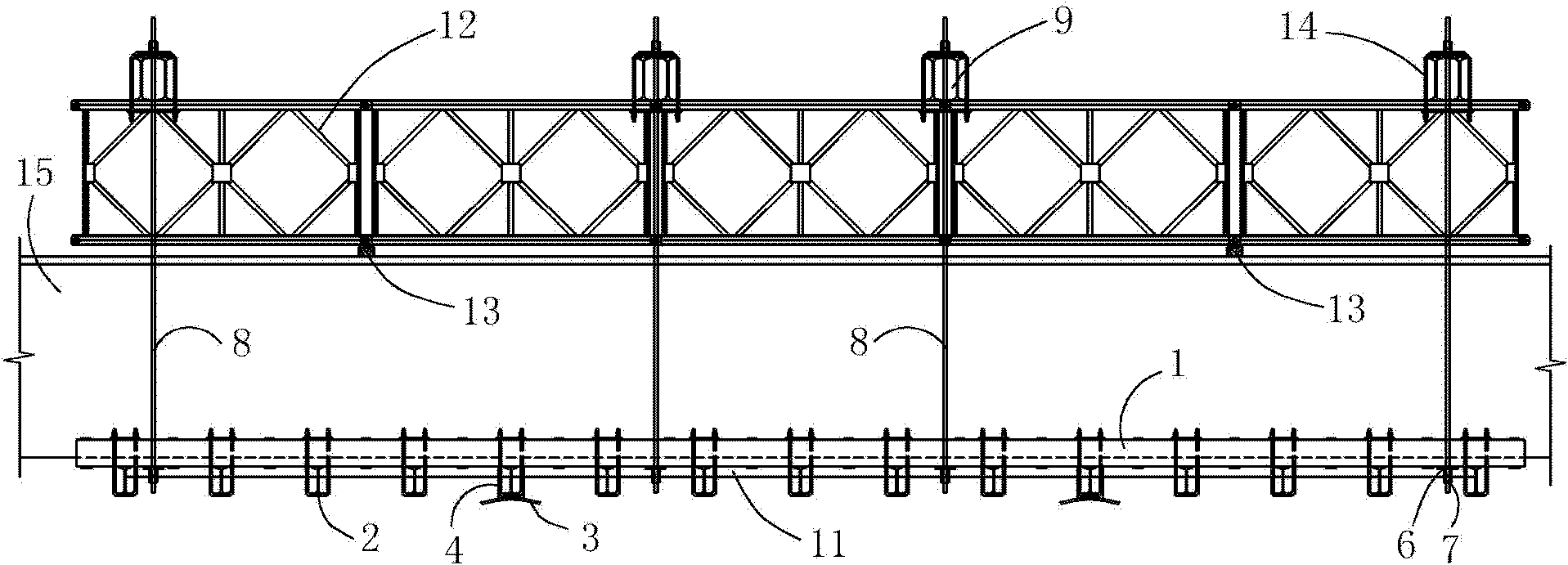

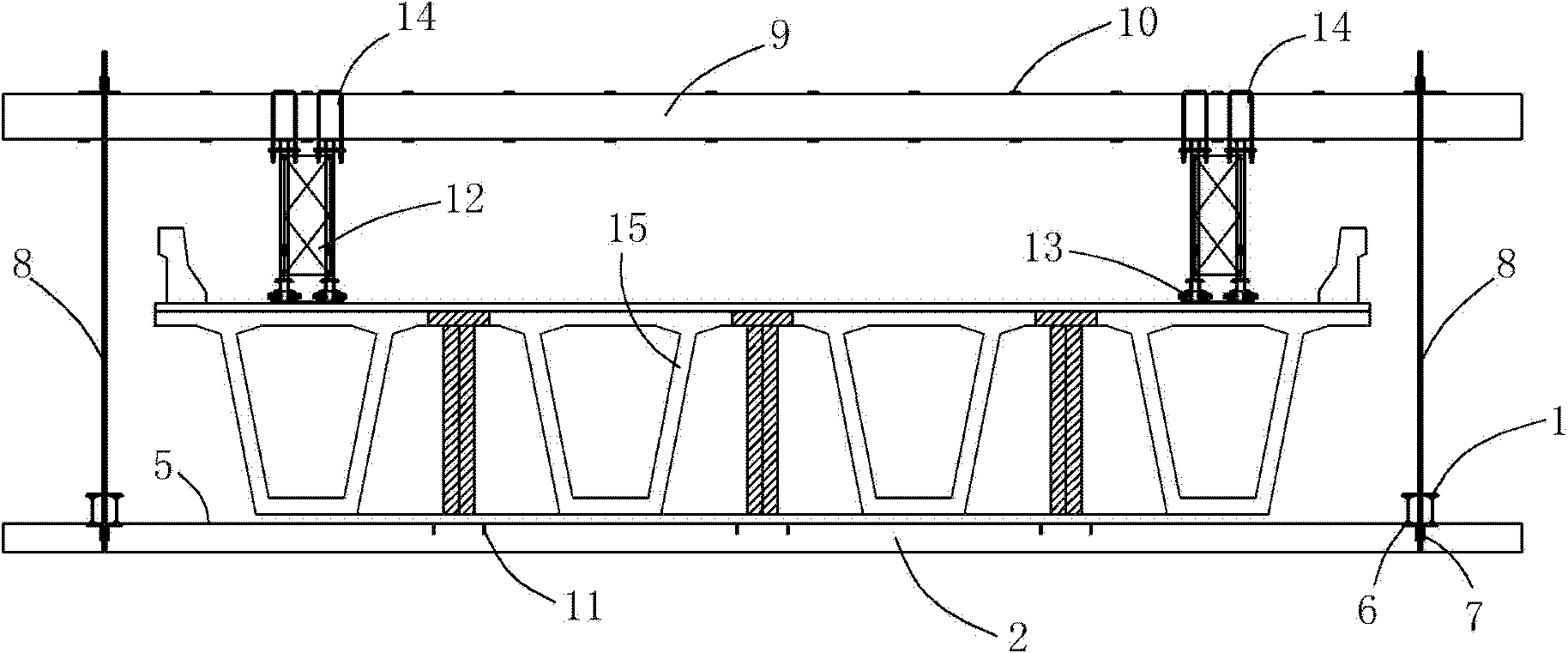

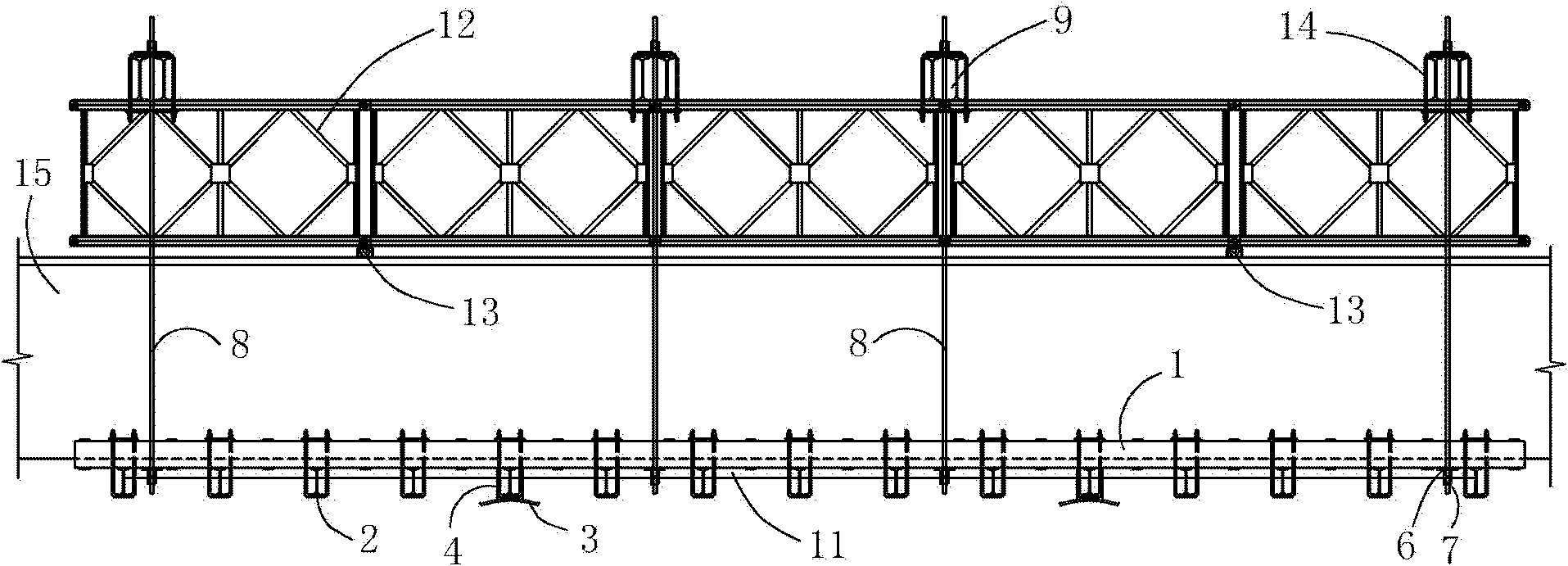

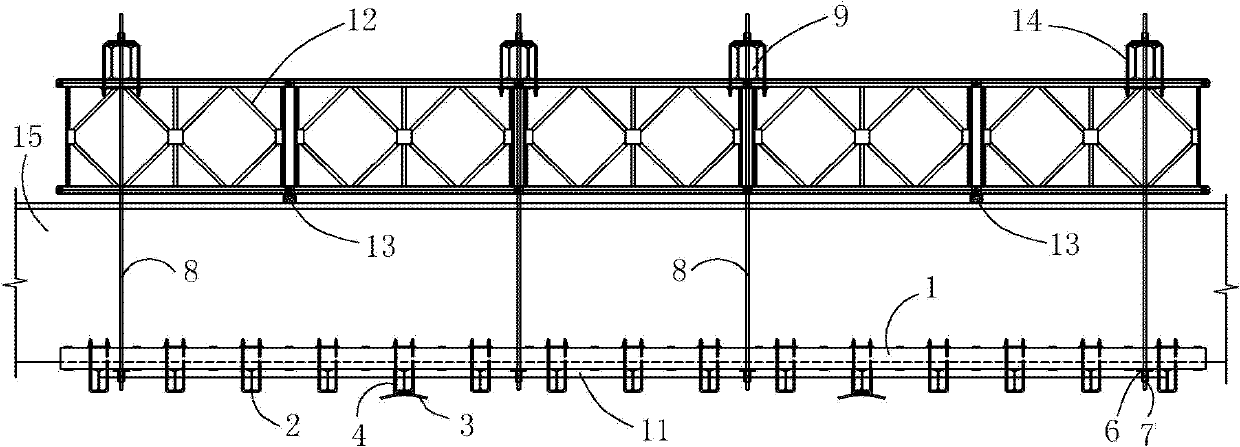

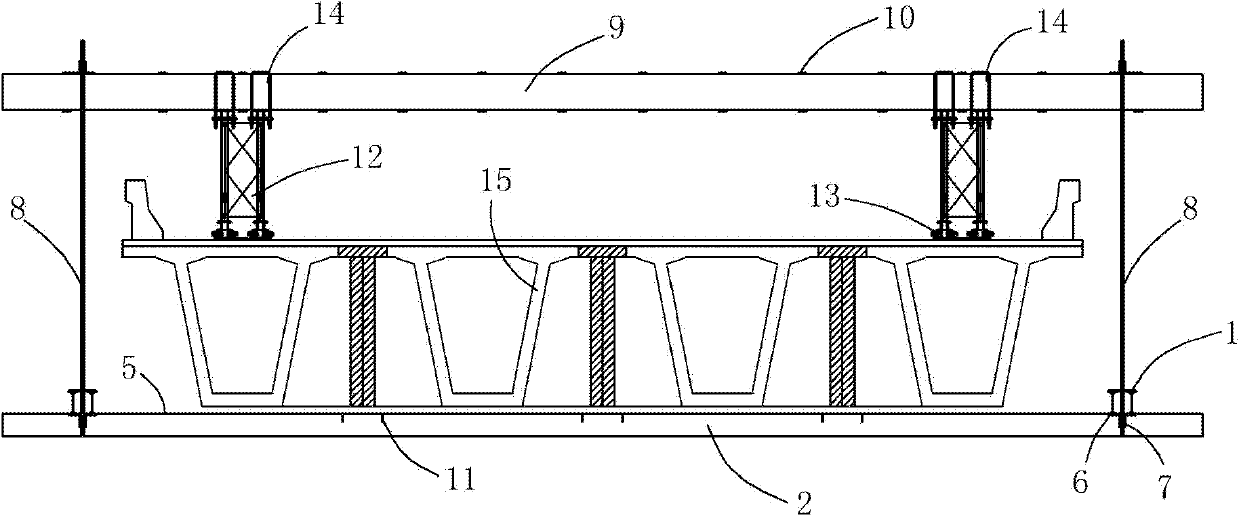

Rapid assembling type steel box-precast concrete plank bridge structure and construction method thereof

InactiveCN105421210AFast constructionConstruction quality is easy to controlBridge structural detailsBridge erection/assemblyEngineeringPrecast concrete

The invention relates to a rapid assembling type steel box-precast concrete plank bridge structure and a construction method thereof. The structure comprises a plurality of steel box beams, a precast concrete deck panel and a shear transfer device, wherein the steel box beams are arranged at equal intervals, and every two adjacent steel box beams are connected through a truss type horizontal connector and a solid-web horizontal connector; an upper flange is arranged on the upper portion of each steel box beam, and horizontal connectors are welded between the upper flanges; the precast concrete deck panel is arranged on top of the steel box beams, and the shear transfer device is vertically welded to the upper flanges and inserted into the precast concrete deck panel. According to the structure, the industrial precast degree is high, construction quality is reliable, site assembly is quick, and interference with under-bridge traffic in the construction period is reduced due to the fact that the support-free construction technique is adopted.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

Combined centrifugal extractor

InactiveCN104874201AClosely connectedReduce resistanceLiquid solutions solvent extractionCentrifugesEngineeringCentrifugal extractor

The present invention relates to the technical field of liquid-liquid separation, and specifically discloses a combined centrifugal extractor, which comprises a driving device, a synchronous transmission mechanism, and a plurality of centrifugal extractors connected in series, wherein the driving device is connected with the plurality of the centrifugal extractors through the synchronous transmission mechanism so that the plurality of the centrifugal extractors can perform synchronized operation. According to the present invention, the plurality of the centrifugal extractors are combined to form the integration, and the synchronized operation of the plurality of the centrifugal extractors is achieved by the synchronous transmission mechanism so as to achieve the simultaneous control on the plurality of the centrifugal extractors and effectively improve the extraction effect and the extraction efficiency; and the assembled, modular and skid-mounted design is used and the extractors are compactly connected so as to provide the strong integrity, reduce the occupation area, shorten the length of the connection pipeline, simplify the pipeline structure, reduce the pipeline resistance, reduce the flow loss inside the pipeline, reduce the energy consumption, save the production cost, substantially reduce the on-site construction amount, and rapidly and conveniently install and disassemble.

Owner:THUNIP CORP LTD

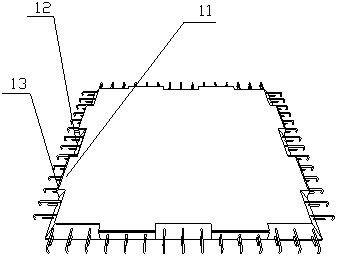

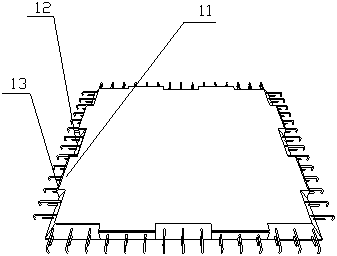

Combined type protection shed frame and construction method thereof

ActiveCN102425123AReduce the amount of on-site constructionReduce distractionsBuilding repairsTrack maintainenceBridge deckCross over

The invention discloses a combined type protection shed frame and a construction method thereof. The combined type protection shed frame is characterized in that a bearing structure located on the top surface of a bridge is arranged; the top surface of the bridge is taken as a bearing foundation by bearing longitudinal girders in the bearing structure; bearing cross girders crossing over the bridge are supported by the bearing longitudinal girders; a steel-structure frame located at the bottom part of the bridge is arranged; frame longitudinal girders in the steel-structure frame are suspended below the bearing cross girders through suspenders, and are located at both sides of the bridge; and frame cross girders in the steel-structure frame are suspended at the bottom parts of the frame longitudinal girders. The combined structure of the combined type protection shed frame disclosed by the invention is entirely borne on a bridge deck, and foundations do not need to be constructed at both sides of the existing railroad line, thereby, the on-site construction quantity of the existing railroad line is greatly reduced, the construction risk is lowered, the potential safety hazards areeliminated, and the interference on the normal operation of the existing railroad line is effectively reduced.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

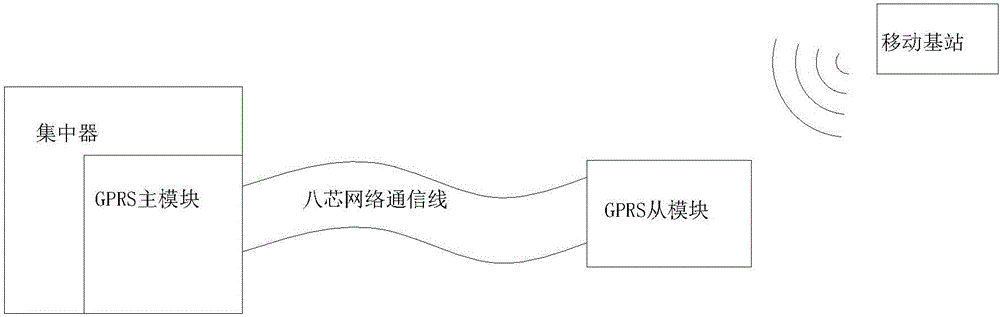

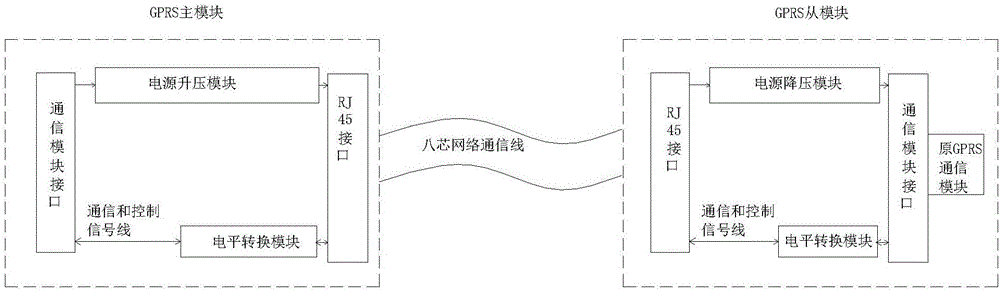

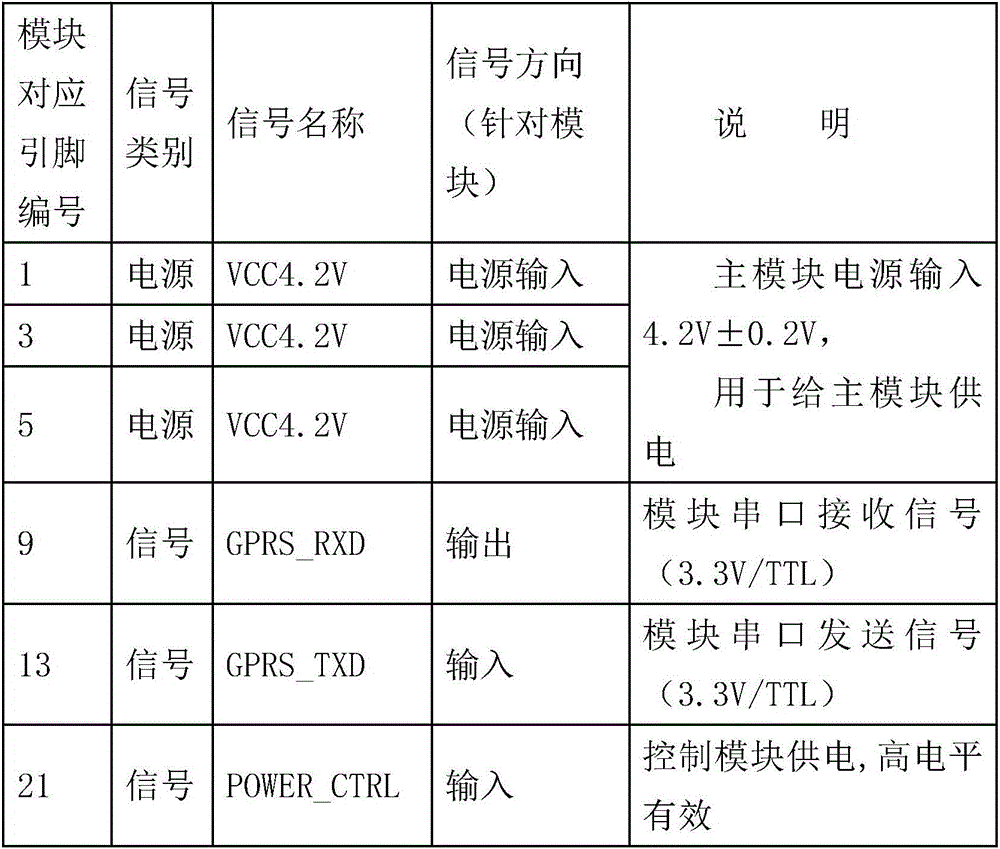

Multifunctional remote wireless communication relay equipment based on remote wireless communication relay technology

InactiveCN106504500ASolve online difficultiesGuaranteed progressTransmission systemsComputer terminalEngineering

The invention provides multifunctional remote wireless communication relay equipment based on a remote wireless communication relay technology. A communication module of an original acquisition terminal is divided into two parts, namely a main module and a slave module; the slave module is arranged at a position with a good wireless signal; the received wireless signal is transmitted through a cable to pass through sections with bad signals and then is transmitted to the main module; the main module is used for replacing the position of an original module; and the received signal is sent back to a concentrator and the main module supplies power to the slave module. The problem that a basement terminal located in a wireless signal dead zone is offline can be solved; an effective communication distance between the two modules can reach 600m; a signal receiving end has a gaining effect so that the terminal can be online normally under a weak signal; the selection of placement positions of the receiving end is more so that the wiring distance of the cable is greatly educed; and State Grid Formal Specifications are considered and an original communication module can be freely replaced on terminals of a plurality of factories.

Owner:ANHUI ELECTRIC POWER FUYANG POWER SUPPLY

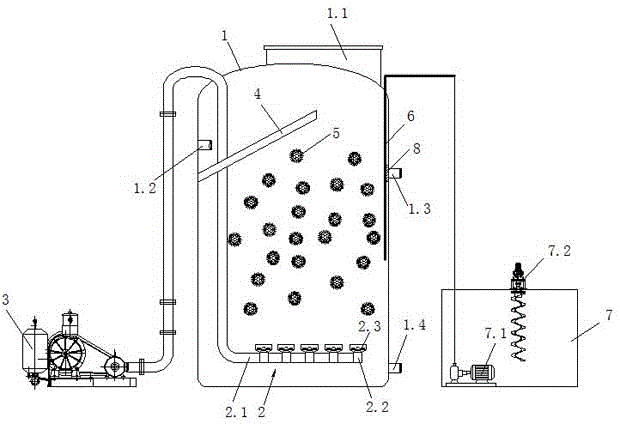

Novel sewage tank

ActiveCN105565485AImprove metabolic efficiencyWell mixedBiological treatment apparatusSustainable biological treatmentMicro bubbleApposition

The invention discloses a novel sewage tank. Enough oxygen is provided for a microorganism through generating continuous micro-bubbles at the bottom of a tank body; a carrier for apposition growth is provided for the microorganism through a biological active filling; the metabolic efficiency of the microorganism is enhanced; meanwhile, sewage forms up-and-down convection in the tank body under the actions of a gravity current and the micro-bubbles to generate agitation; dirt cannot precipitate; the suspended carrier is also enabled to migrate and spread all over in the tank along with a water current; an agent is uniformly mixed; the purpose of purification treatment is effectively achieved.

Owner:YIXING INNOVATION ENVIRONMENTAL PROTECTION

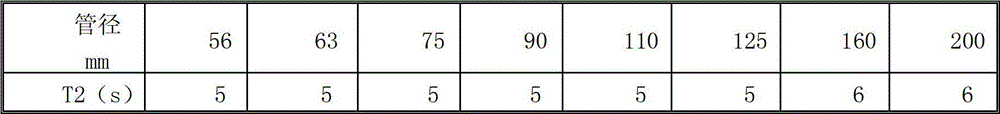

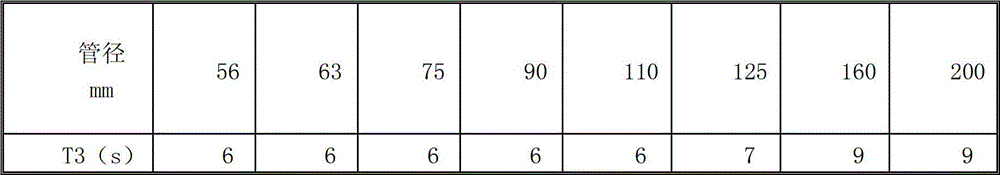

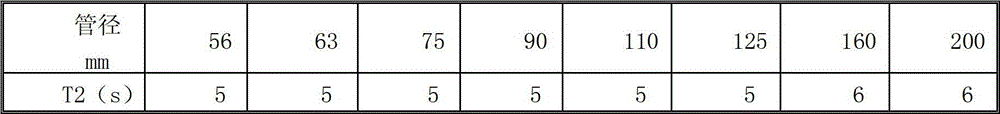

Construction method for siphon rainwater drainage system

The invention discloses a construction method for a siphon rainwater drainage system. The construction method includes the steps of construction preparation, installation of a rainwater drain, installation of a suspension fixing system, fusion welding of a high-density polyethylene (HDPE) pipe and the like. The method is convenient to construct and good in construction quality.

Owner:成张佳宁

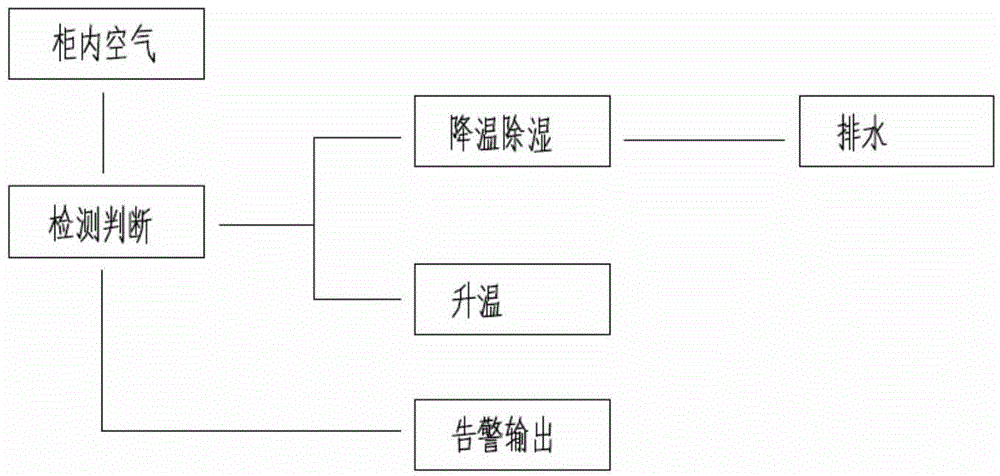

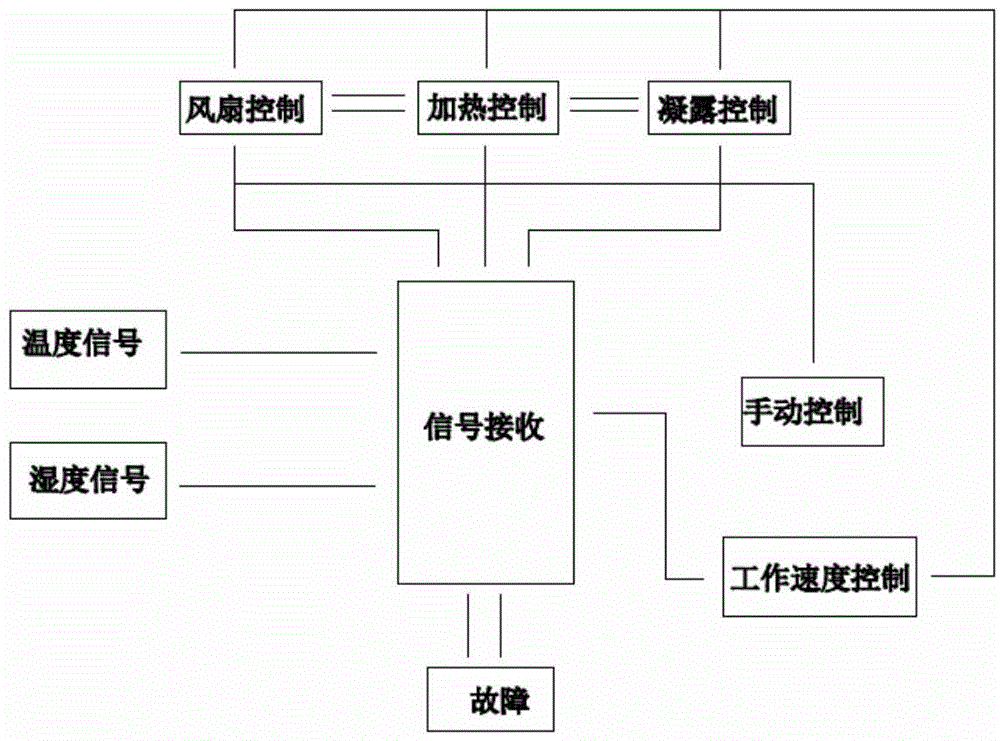

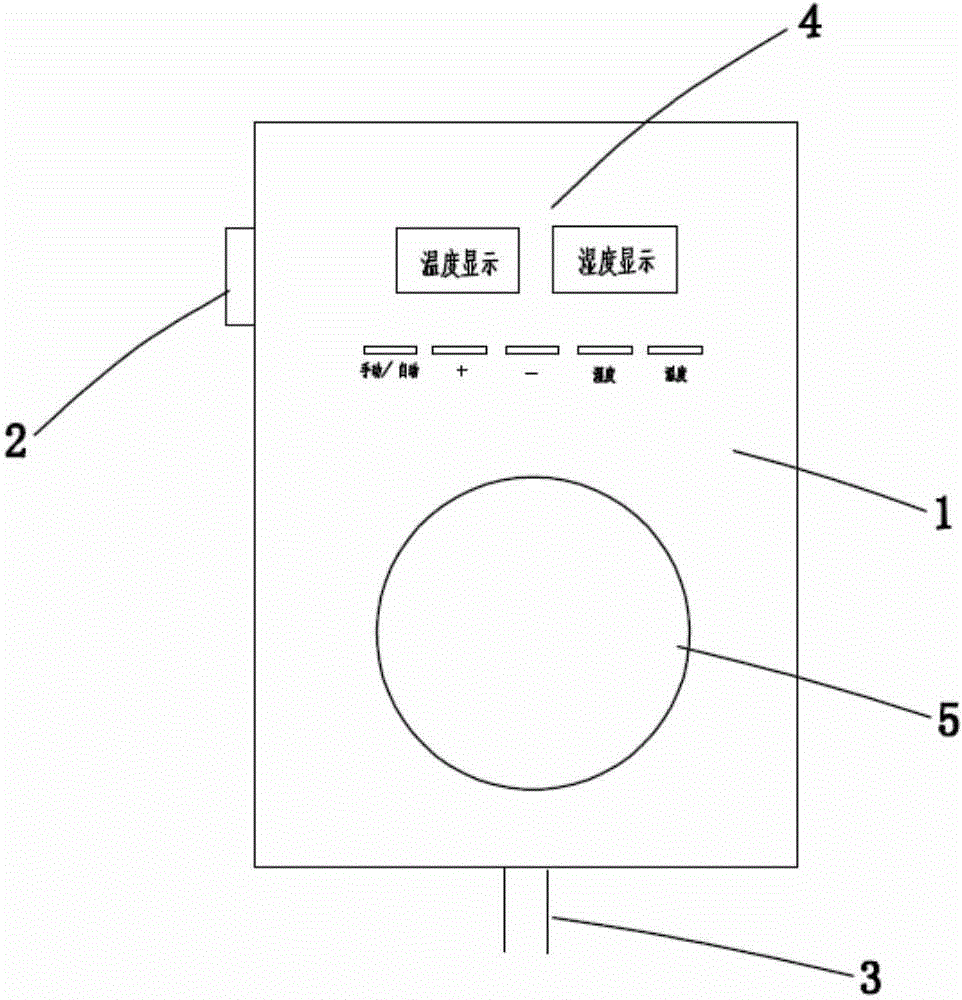

Dehumidification and condensation-prevention device for five boxes of substation

InactiveCN103606828AReduce moisture contentReduce humiditySubstation/switching arrangement cooling/ventilationSimultaneous control of multiple variablesDisplay deviceEngineering

The invention discloses a dehumidification and condensation-prevention device for five boxes of a substation. The dehumidification and condensation-prevention device for the five boxes of the substation comprises a shell, a power interface, a drainage port and a display, wherein the power interface and the drainage port are formed in the side portion and the bottom of the shell respectively, the display is arranged on a panel of the shell, a control device, a temperature sensor, a humidity sensor, a fan and a heater are arranged in the shell, the temperature sensor and the humidity sensor are connected with the control device, the fan and the heater are connected with the power interface and are controlled by the control device, and the display is connected with the control device. The dehumidification and condensation-prevention device for the five boxes of the substation is installed inside the five boxes; due to the fact that condensation conditions are created locally, damp air in each box can condense into water, the water can be directly discharged out of a cabinet, the humidity of the interior of the five boxes can be rapidly and effectively reduced, and the condensation phenomenon can be prevented from happening.

Owner:STATE GRID CORP OF CHINA +1

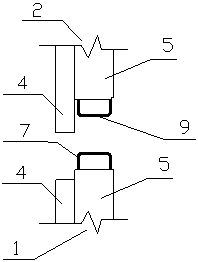

Assembly method of upper and lower interior walls and floors

The invention provides an assembly method of upper and lower interior walls and floors, including the following steps: S1, prefabricating interior wall shear walls and floors; S2, hoisting and installing: a first interior wall shear wall is hoisted and positioned, a first floor and a second floor are respectively hoisted on the two end faces of the top side of the first interior wall shear wall, asecond interior wall shear wall is hoisted on the top side of the first interior wall shear wall, and the two ends of the bottom side of the second interior wall shear wall are respectively pressed on the supporting ribs on the top sides of the first floor and the second floor; a cavity is formed between the floors and the first and second interior wall shear walls, and longitudinal steel bars, lacing wires and anchoring parts are ingeniously arranged in different ways; and S3, casting connection: concrete is poured into the cavity to form a double-overlapping post-poured connecting beam or adouble-anchorage horizontal post-poured strip which connects the floors and the interior wall shear walls together. The on-site construction work for the connection joint is less. The construction cost is lowered, and the construction period is shortened. The integrality and seismic strength of the building are greatly improved.

Owner:绿建科技集团新型建材高技术有限公司

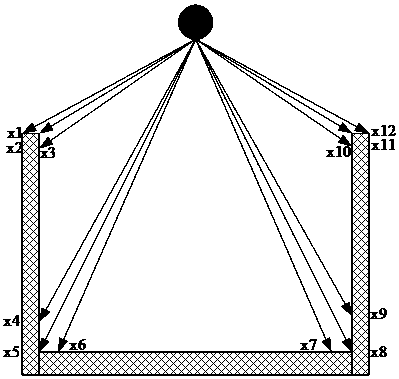

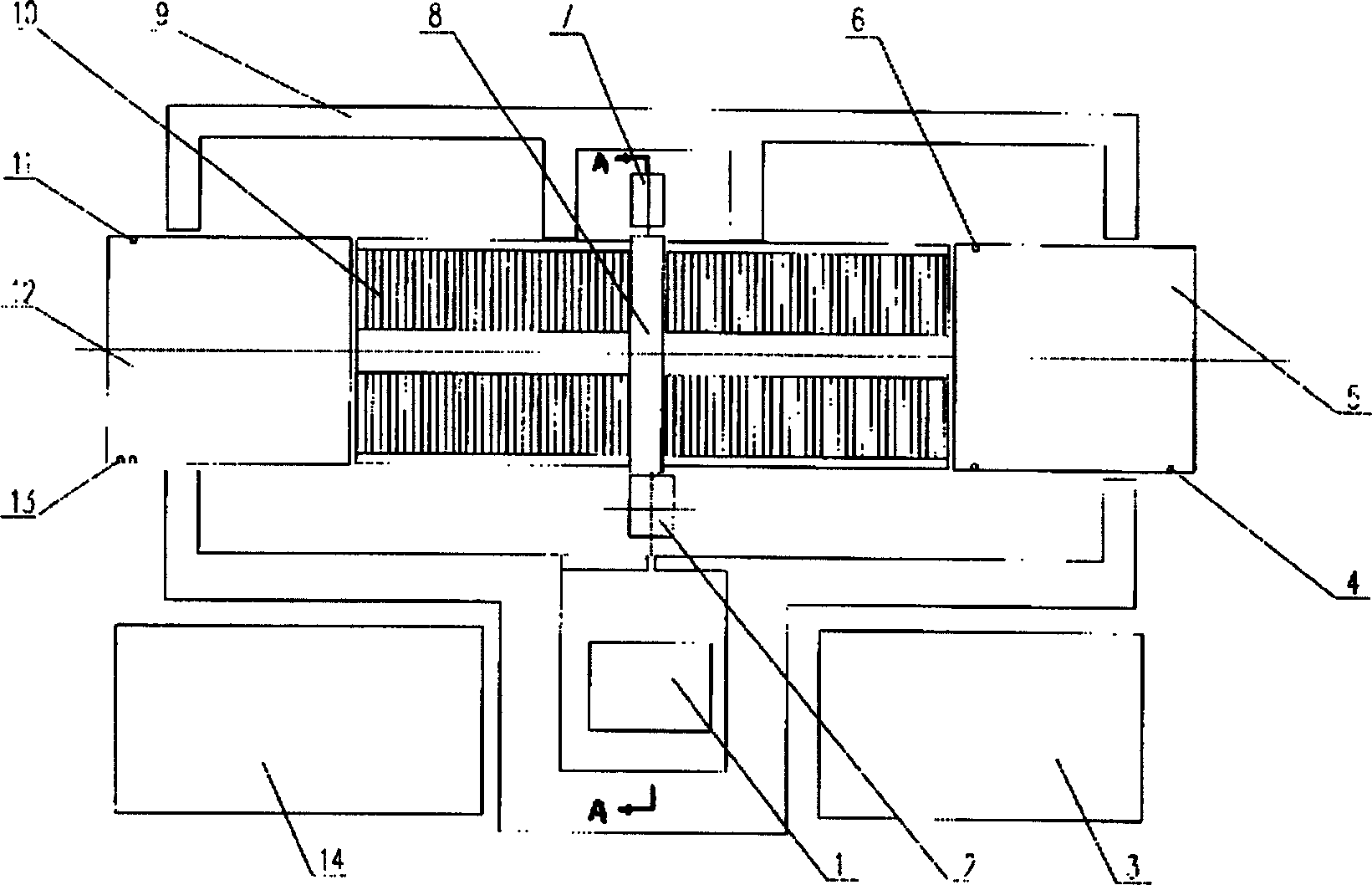

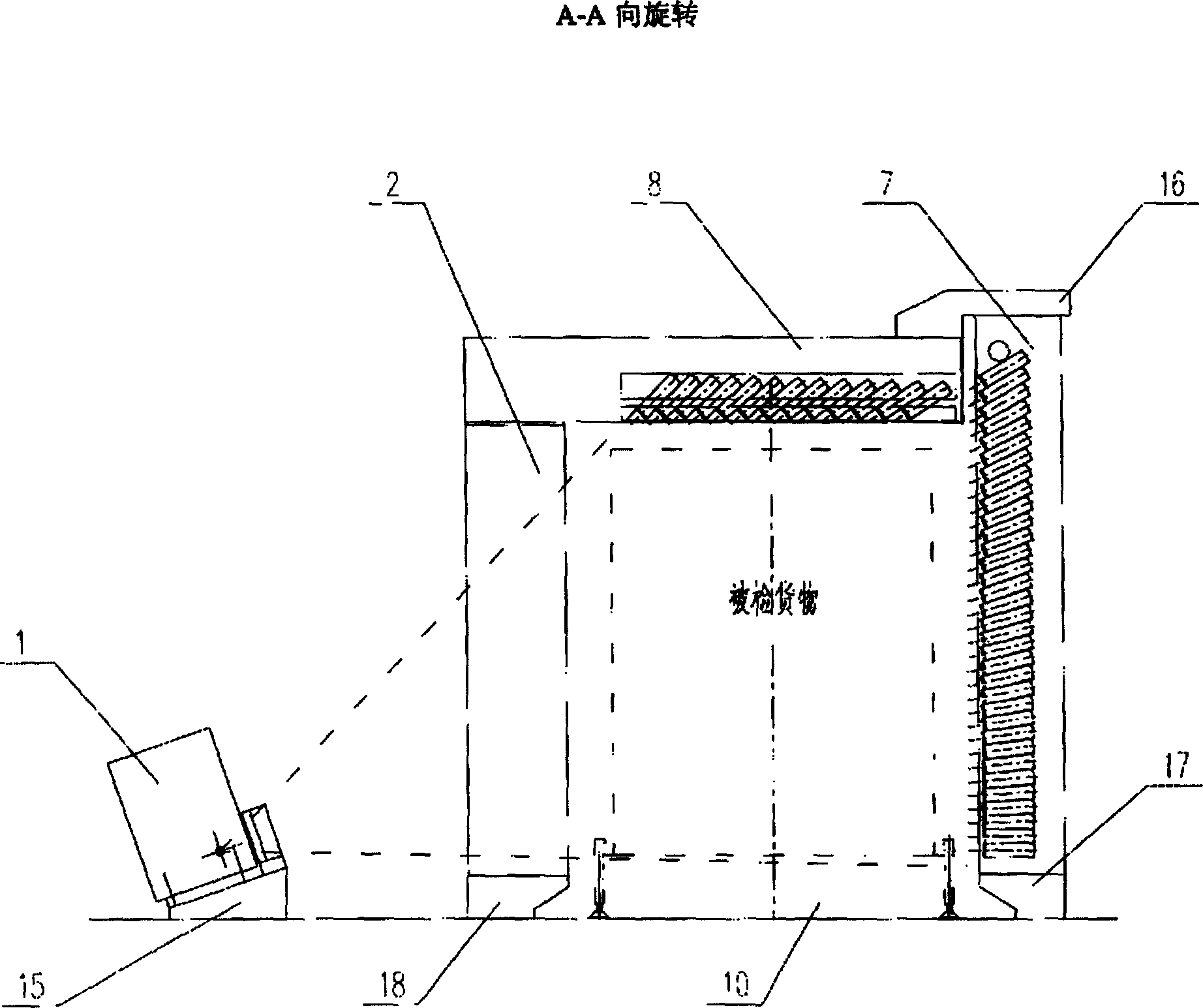

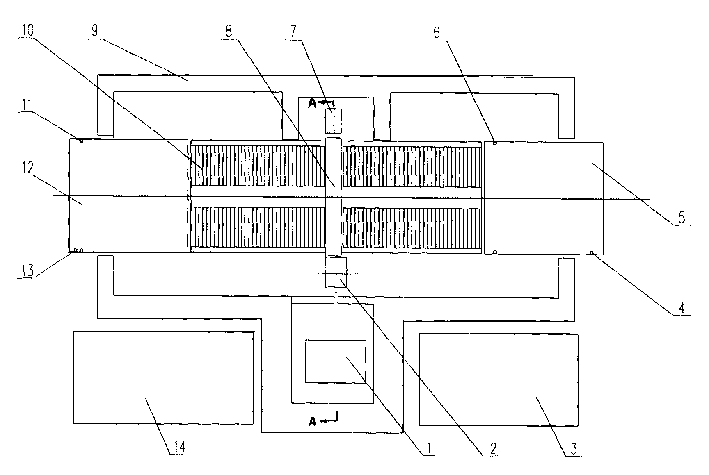

Aeronautical container/tray article examination system

InactiveCN1185482CStrong penetrating powerInspection speed is fastSamplingMaterial analysis by transmitting radiationPhase detectorAviation

This invention relates to system for examining aviation container / tray cargoes, which comprises electronic linear accelerator, gas detector, a collimator, lateral detector beam, vertical detector beam, transfer device, radiation shielding wall, equipment module and a operation room in which the gas detectors are mounded on the said two beams separately which are on the same surface with the accelerator and collimator forming a stable portable frame with the two beams and the collimator is in between the accelerator and the transferring device which comprises a roller way and apron conveyers. The portal frame and transferring device make up the scan channel set with radiation module and operation room with a table inside.

Owner:TSINGHUA UNIV +1

Multi-functional modular combined cold box

PendingCN108438566ASimple structureReasonable designLarge containersTank wagonsModular compositionManufacturing technology

The invention relates to the technical field of manufacturing of refrigeration equipment and particularly relates to a multi-functional modular combined cold box. The multi-functional modular combinedcold box provided by the invention comprises a box body module, tail end modules and a cold source module; the box body module is connected with at least one tail end module; each tail end module isconnected with the cold source module; the box body module is used for providing a low-temperature storage space or a low-temperature operation space; each tail end module comprises a plurality of secondary functional modules and is used for providing heat exchange conditions for a low-temperature environment; the cold source module is used for providing cold source supply for each tail end module; and a control module is used for harmonizing the secondary functional modules of all tail end modules so as to provide one or a plurality of functions including temperature regulation, humidity regulation and air regulation. The cold box formed by adopting the three modules realizes standard production, is low in manufacturing cost and short in installation period, can guarantee the quality, andis also beneficial for realizing flexible switching between different functions such as quick freezing, quick precooling, cooling, cold storage of cooled materials, cold storage of frozen materials,air-regulated cold storage and low-temperature production environment.

Owner:青岛中集冷方科技有限公司

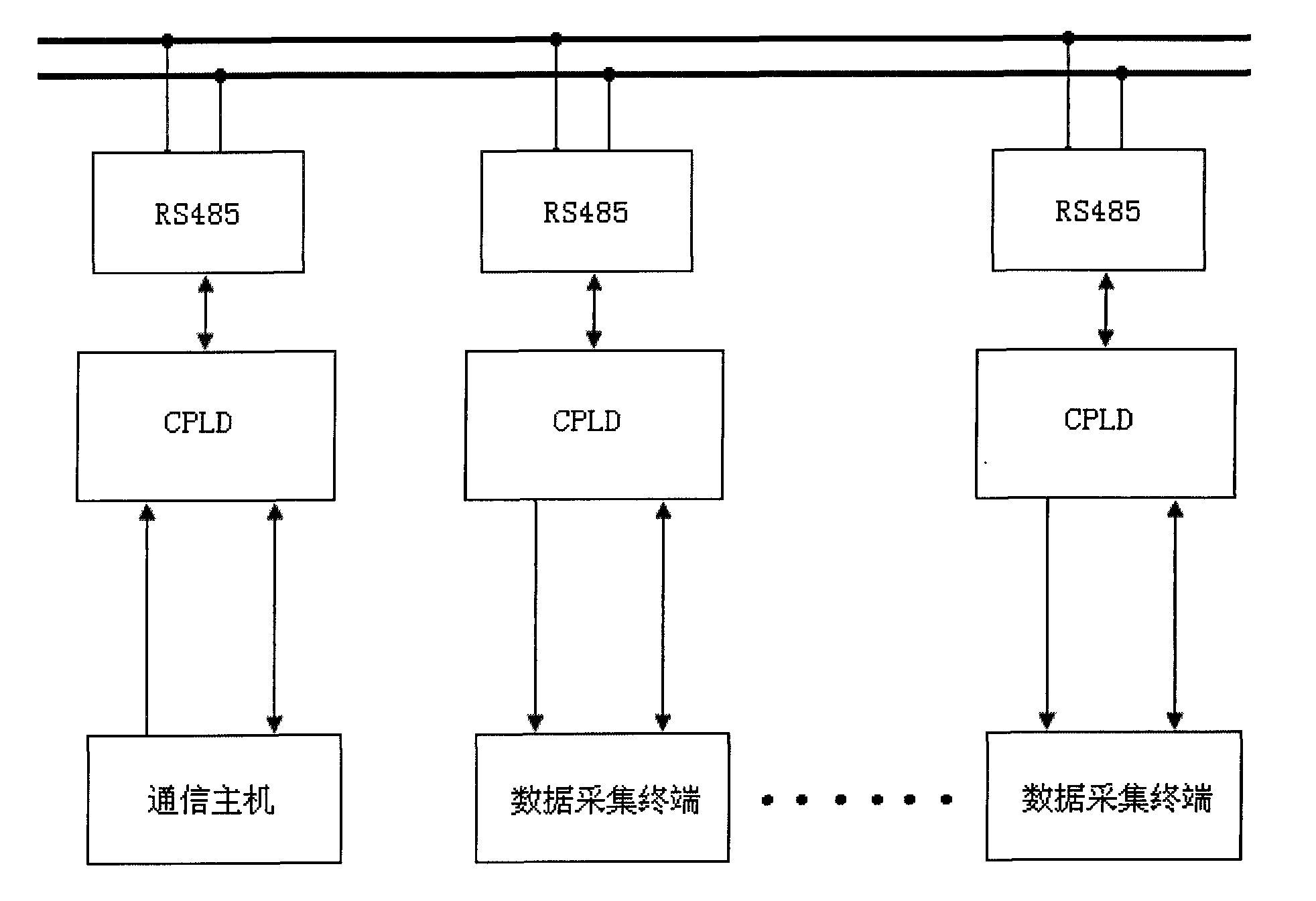

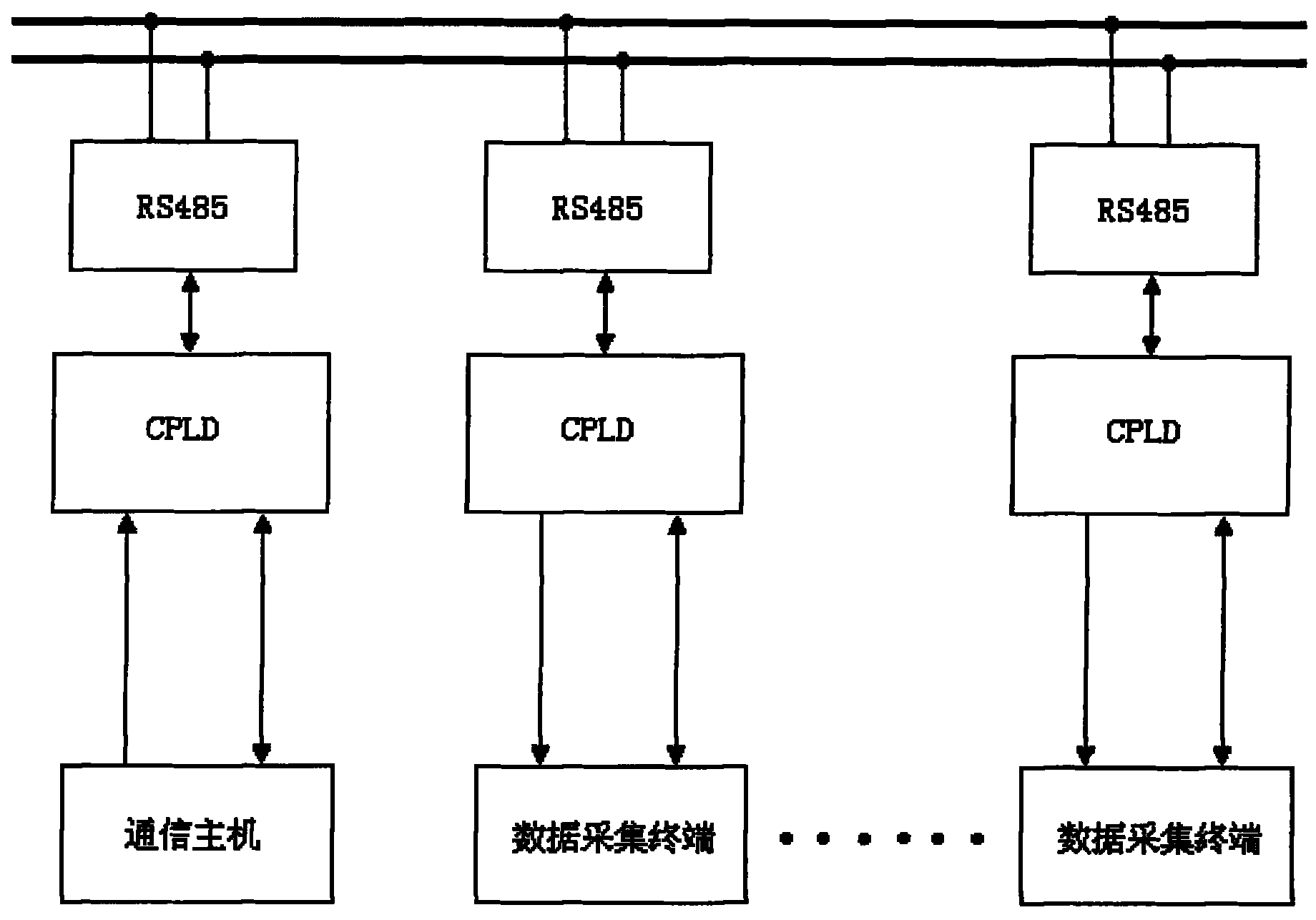

Synchronous data acquisition device of transformer substation and method

InactiveCN101820337ALow costReduce the amount of on-site constructionSynchronising arrangementData synchronizationData stream

The invention relates to a synchronous data acquisition device of a transformer substation and a sampling method thereof, relating to the technical field of transformer substation data sampling and aiming at solving the technical problem on how to reduce the site construction volume and the hardware cost. The device is characterized in that a communication host and various data acquisition terminals in the transformer substation are connected to a standard serial bus respectively through a programmable logic unit, wherein the programmable logic unit connected with the communication host is internally provided with a synchronous code pattern generating module, and the programmable logic units connected with various data acquisition terminals are internally provided with synchronous code pattern decoding modules; the communication host controls the programmable logic unit connected with the communication host to send synchronous code patterns to the standard serial bus at regular time; and all the programmable logic units connected with the data acquisition terminals are used for detecting the synchronous code patterns in a communication data stream in real time and controlling the data acquisition terminals to carry out synchronous data sampling after catching the synchronous code patterns. The device can reduce the site construction volume and the hardware cost.

Owner:上海申瑞电力科技股份有限公司

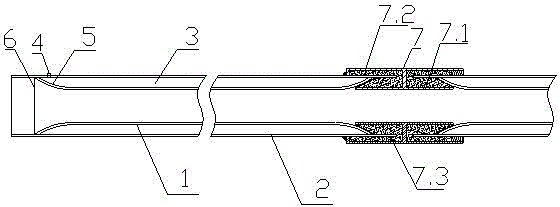

Fabricated pile and construction method thereof

The invention discloses a fabricated pile which comprises a lower pipe pile. A lower pipe pile reinforcing cage is arranged in the lower pipe pile, and an upper end plate is arranged at the upper end of the lower pipe pile. A top pipe pile is arranged at the upper end of the lower pipe pile, a lower end plate which is pressed on the upper end plate is arranged at the lower end of the top pipe pile, and the lower end plate and the upper end plate are connected. A top pipe pile reinforcing cage is arranged in the top pipe pile, composite stirrups shaped like a Chinese character 'jing' are arranged on the top pipe pile reinforcing cage every other 200-400 mm, and a post-poured concrete grouting core is arranged in the top pipe pile. The invention further discloses a construction method of the fabricated pile. According to the fabricated pile and the construction method of the fabricated pile, the upper fabricated pipe pile and the lower fabricated pipe pile are assembled together, and the advantages of the pipe piles and the advantages of cast-in-situ bored piles are fused together in the mode that the post-poured concrete grouting core is poured in the top pipe pile. The fabricated pile has the advantages that pile connection is simple, convenient and fast, the construction cost is low, construction is quick, the quality can be guaranteed easily, and the bearing capacity is high.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +2

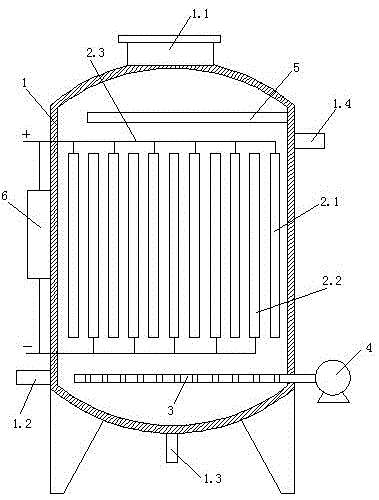

Novel photoelectron-catalysis sewage purification tank

InactiveCN105668691AImprove mass transfer efficiencyReduce CODWater/sewage treatment by irradiationWater treatment compoundsLight energyOxygen

The invention discloses a novel photoelectron-catalysis sewage purification tank. The purification tank mainly utilizes a nano material and a photoelectron-catalysis technology. A titanium dioxide thin film electrode, which has good photoelectron-catalysis efficiency and is commonly doped with nitrogen and platinum, is mainly utilized; the thin film electrode can be used for degrading organic matters in water with light energy under the working of a weak electric field. A micro-pore aeration device is arranged at the bottom of a tank body and provides sufficient oxygen for a photoelectron-catalysis process, and a mass transferring speed is improved. The equipment is provided with a control cabinet and can be automatically operated for a long time; the equipment is simple and easy, is green and environmental friendly, and has a good application prospect.

Owner:YIXING INNOVATION ENVIRONMENTAL PROTECTION

Method for manufacturing solid three-dimensional concrete block and method for laying concrete tracks using concrete block manufactured using the method

InactiveCN103429819AFilled tightlyShorten construction timeBallastwayMouldsVertical alignmentSubgrade

Owner:姜南勋

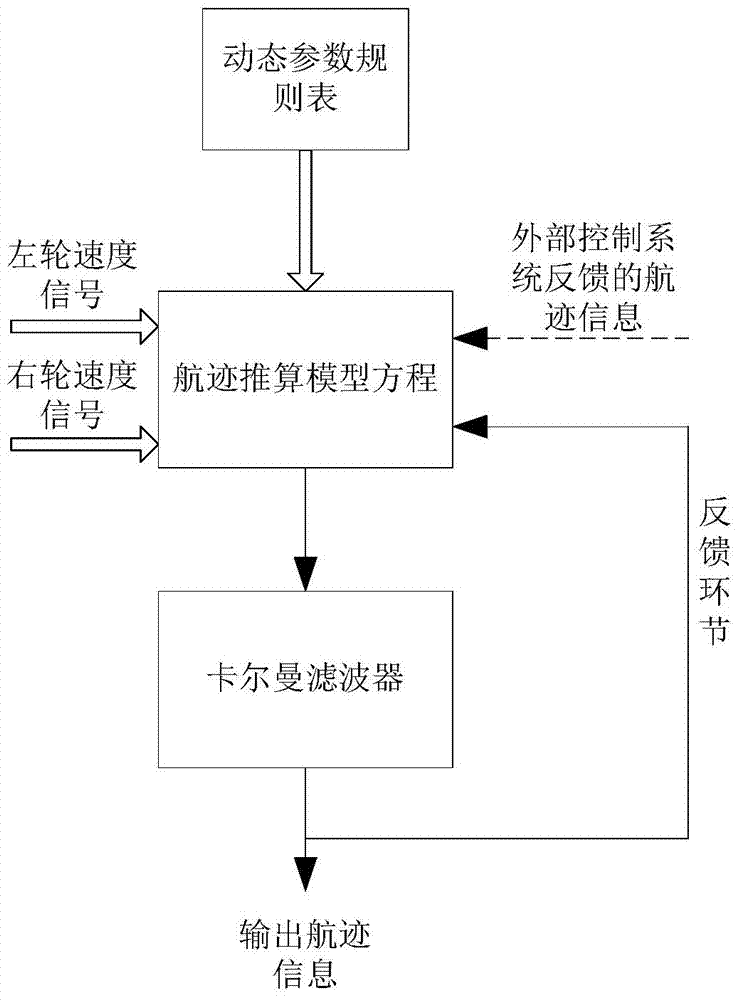

Transformer substation inspection robot track calculation method and device based on inter-wheel differential

ActiveCN104848856AImprove adaptabilitySolve the incompatibilityNavigation by speed/acceleration measurementsTransformerSimulation

The invention discloses a transformer substation inspection robot track calculation method and device based on inter-wheel differential. A feedback link is added in the track calculation method, track data treated by virtue of Kalman filtering is fed back to a track calculation equation, the self-correction of the equation is realized, and the influence of interference on the track calculation can be effectively alleviated. The track calculation precision is relatively high in a local part, the circuit is simple, the parameter is simple to debug, and the algorithm is easy to realize. The transformer substation inspection robot track calculation method is combined with a magnetic track navigation technology, a magnetic track can be buried in a segmenting manner, the in-situ construction can be effectively reduced, and the cost is reduced; the transformer substation inspection robot track calculation method also can be combined with a GPS global navigation system, in a failure area of the GPS, the track information with high local precision can be outputted, and the weaknesses of the GPS global navigation system can be effectively compensated.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

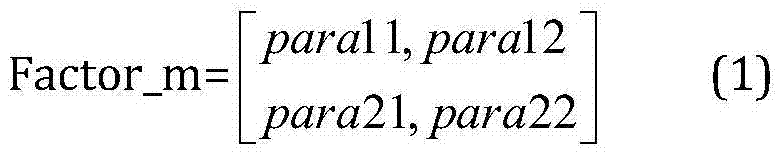

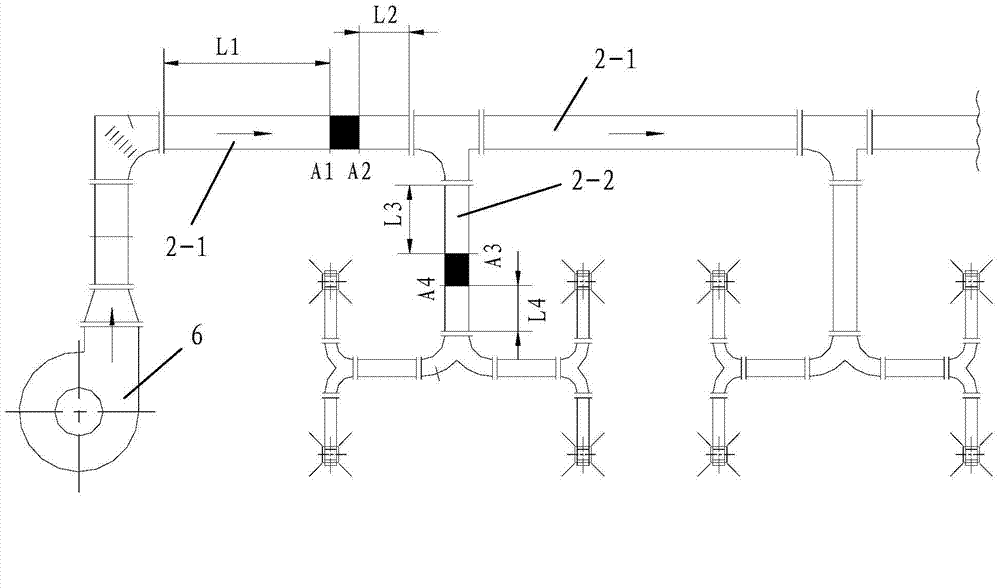

Hole-opening method for measuring holes for testing performances of ventilation and air conditioning system

ActiveCN104772497ASimple stepsReasonable designMetal working apparatusTest performanceTest requirements

The invention discloses a hole-opening method for measuring holes for testing performances of a ventilation and air conditioning system. The hole-opening method comprises the following steps: I, determining positions of measuring sections and the measuring holes: according to pre-designed test requirements of the ventilation and air conditioning system, determining quantity of to-be-tested test sections on a to-be-tested flue, the position of each test section as well as quantity of to-be-opened measuring holes in each test section and hole position of each measuring hole; II, opening and sealing measuring holes: respectively opening all measuring holes in the to-be-tested flue, and sealing each measuring hole as follows: 201, opening holes: drilling by adopting drilling equipment; 202, sealing the measuring holes: sealing processed and formed measuring holes by adopting a sealing part. The hole-opening method disclosed by the invention is simple in step, reasonable in design, convenient to realize, high in working efficiency, good in using effect and capable of simply, conveniently and quickly completing a hole-opening process of measuring holes of an air hose, and guaranteeing the performance test effects of the ventilation and air conditioning system.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

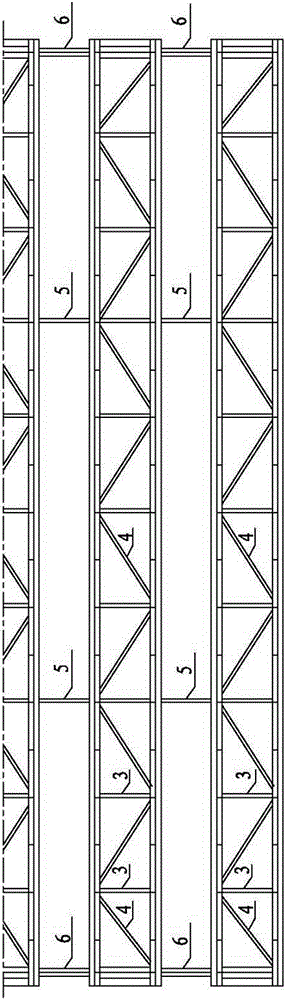

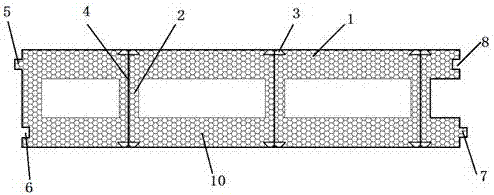

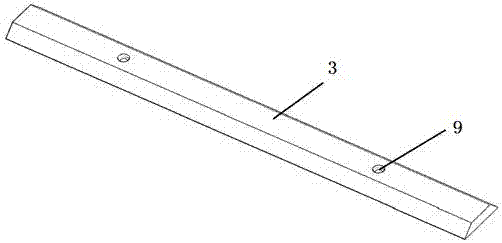

Light steel structure wall body module

The invention provides a light steel structure wall body module. The light steel structure wall body module comprises an EPS template, the EPS template is a cavity template composed of an inner side plate, an outer side plate and connecting core ribs which are connected between the inner side plate and the outer side plate and are distributed at equal intervals, the surfaces of the inner side plate and the outer side plate are provided with inserting grooves, the inserting groove in the inner side plate and the inserting groove in the outer side plate correspond to each other, the light steel structure wall body module further comprises connecting plates provided with through holes and connecting bolts, the shape of the connecting plates is the same as that of the inserting grooves, the connecting plates are installed in the inserting grooves in an inserted mode, and the connecting bolts penetrate through the through holes in the connecting plates of the inner side plate and the outer side plate and the EPS template to connect the ESP module and the connecting plates at the two sides into one. The light steel structure wall body module is simple in process, high in efficiency and convenient in industrialized production, and can drastically lower field construction amount, and improve the overall construction procedure of a building. Outer wall plates of cement plates and the like can be adopted to be directly fixed on the connecting plates, and an outer wall protective layer is formed, so that the outer wall construction of the building is not influenced by weather or climate.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT +1

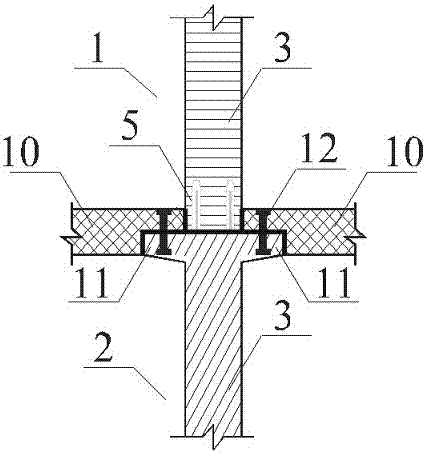

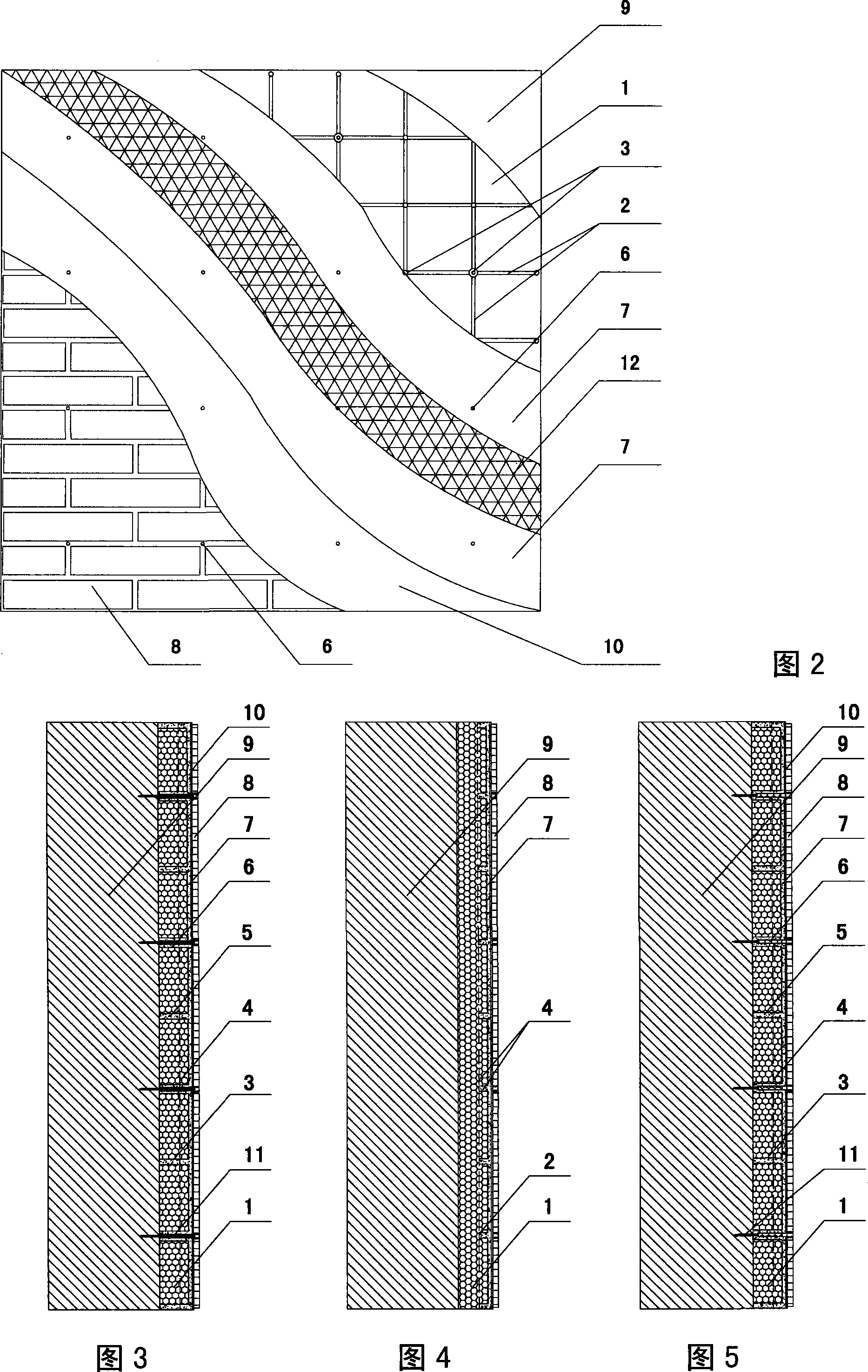

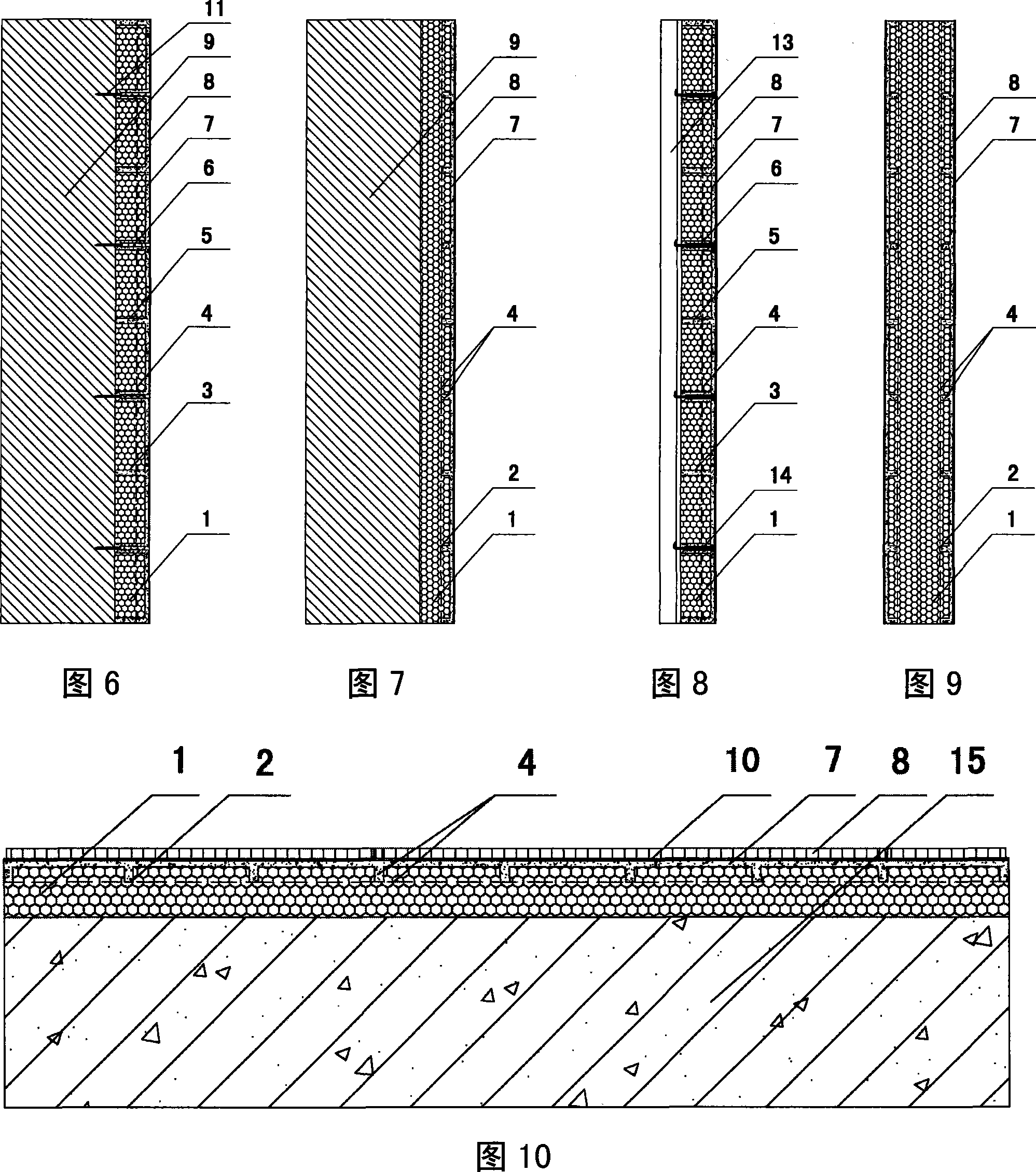

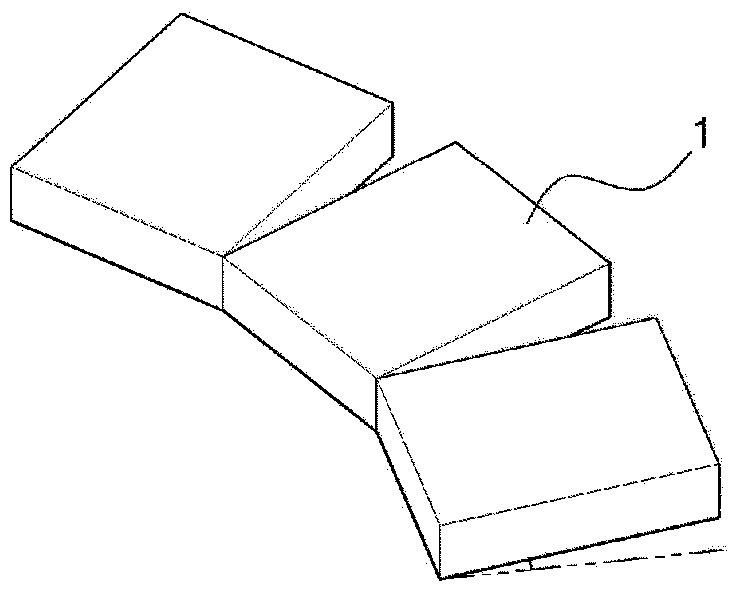

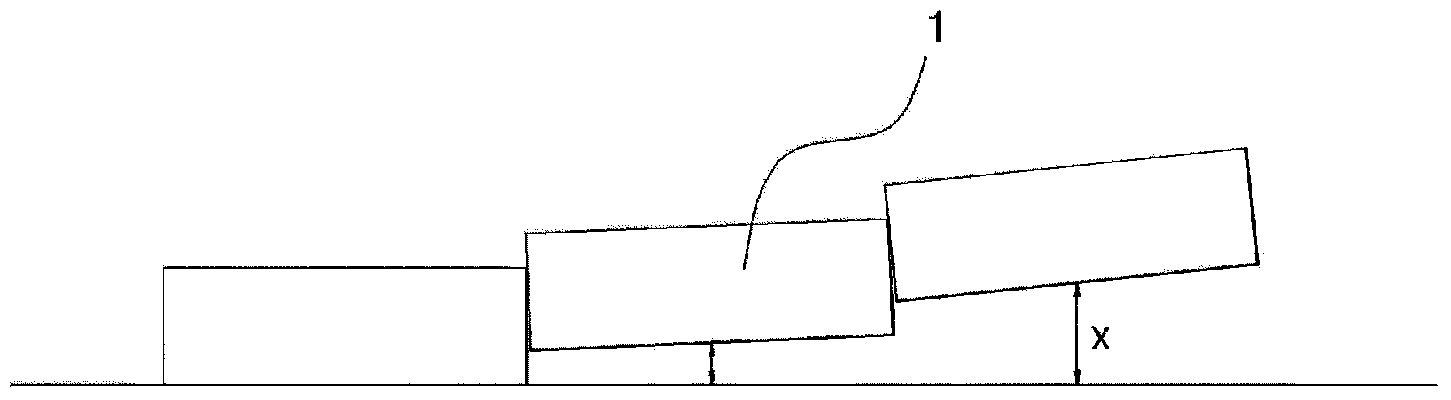

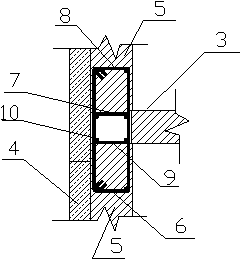

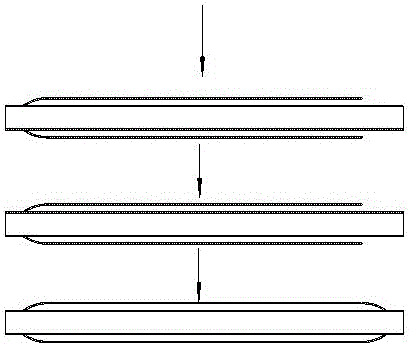

Fabricating method of upper and lower self-insulation outer walls and floor slab

The invention provides a fabricating method of upper and lower self-insulation outer walls and a floor slab. The fabricating method comprises the following steps that S1, shear walls and the floor slab are prefabricated; S2, hoisting and installing are carried out, specifically, a first shear wall is hoisted and positioned, the floor slab is hoisted and is arranged at one end of the top side the first shear wall, a second shear wall is hoisted and is arranged on the top side of the first shear wall, the inner face of the bottom side of a heat preservation layer of the second shear wall is tightly attached to the upper wall of a load-bearing layer of the first shear wall, the bottom side of a load-bearing layer of the second shear wall is arranged on the top side of the floor slab, a cavityis formed by the floor slab, the load-bearing layer of the fist shear wall, the load-bearing layer of the second shear wall and the bottom side of the heat preservation layer of the second shear wall, and longitudinal steel bars, tie bars and anchoring parts are ingeniously arranged in different modes; and S3, pouring and connecting are carried out, specifically, concrete is poured in the cavityto form a self-insulation double-overlapping post-pouring connecting beam or a double-anchoring horizontal post-pouring strip, and the floor slab, the first shear wall and the second shear wall are connected into a whole. On-site construction quantity of the fabricated joint is little, the manufacturing cost is low, the construction period is saved, and integrality and anti-shock strength of a building are improved.

Owner:绿建科技集团新型建材高技术有限公司

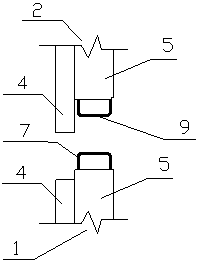

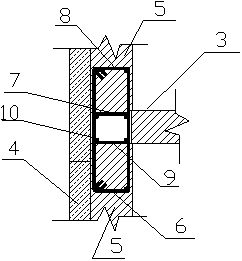

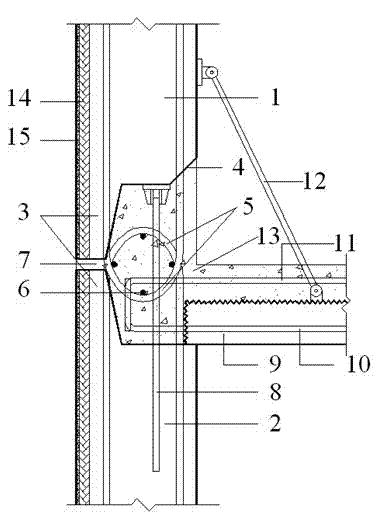

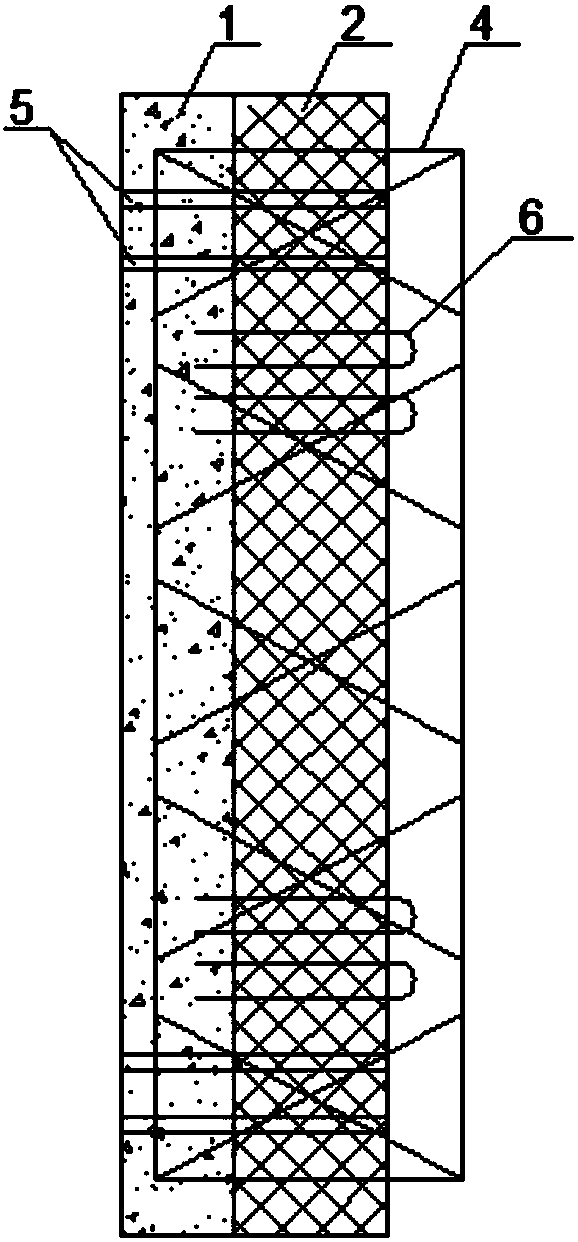

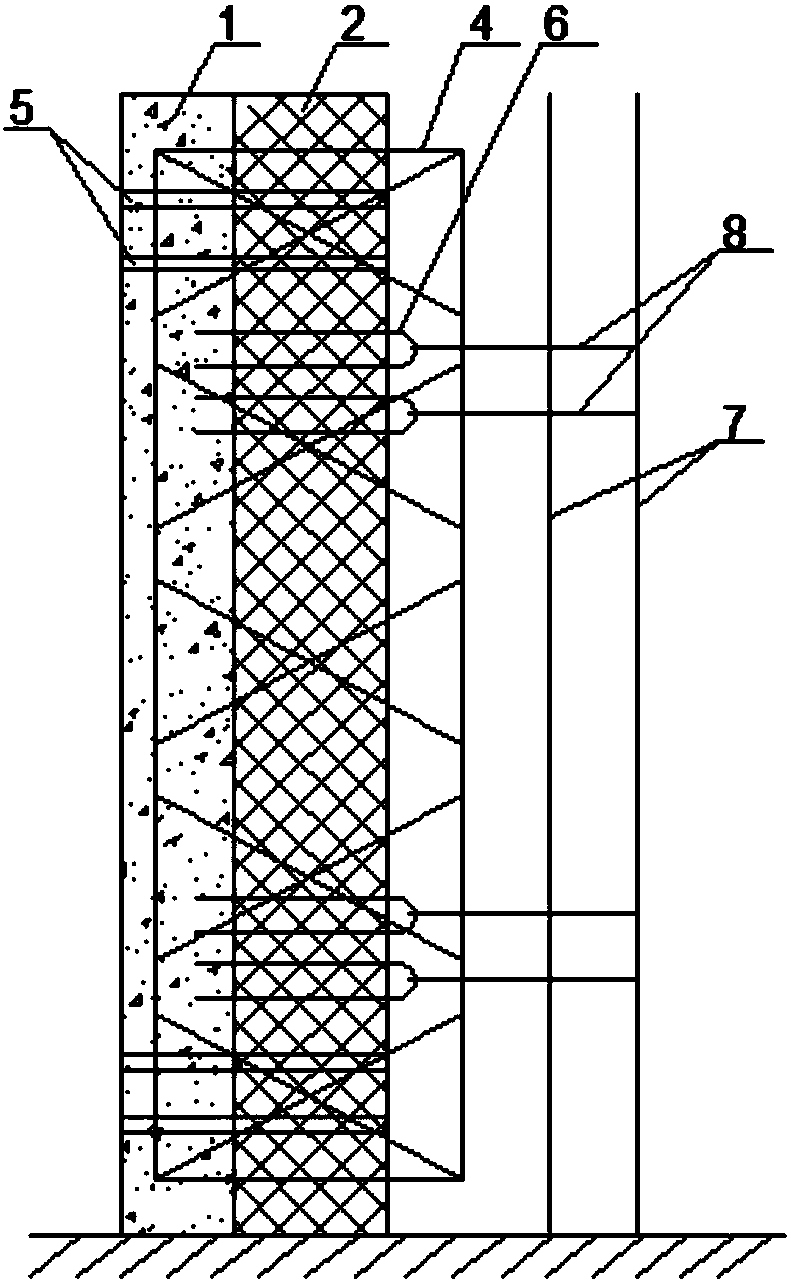

Horizontal seam U-shaped closed rib junction structure of assembled shear wall structure

InactiveCN102168455BGuaranteed shear resistanceGuaranteed bending capacityBuilding insulationsFloor slabClassical mechanics

The invention discloses a horizontal seam U-shaped closed rib junction structure of an assembled shear wall structure, comprising an upper-layer outer wall prefabricated shear wallboard (1), a lower-layer outer wall prefabricated shear wallboard (2), an upper-layer inner wall prefabricated shear wallboard (16), a lower-layer inner wall prefabricated shear wallboard (17), U-shaped closed ribs (5),a horizontal reinforcing rib (6) and filled cast-in-place concrete (13), wherein the U-shaped closed ribs adopting the upper-layer outer wall prefabricated shear wallboard, the lower-layer outer wallprefabricated shear wallboard, the upper-layer inner wall prefabricated shear wallboard and the lower-layer inner wall prefabricated shear wallboard are staggered and are in lap joint to form an annular ring; the horizontal reinforcing rib is arranged in the annular ring to reliably connect the vertical reinforcing steel bars of the assembled shear wall; and the filled cast-in-place concrete of ahorizontal seam (7) realizes the purpose that the resistance to shear of the horizontal seam is equivalent to the cast-in-place concrete shear wall. The whole prefabricated assembled shear wall can be reliably connected with the shear wall and a floorslab, the whole prefabricated assembled shear wall performance can be ensured, and the horizontal seam U-shaped closed rib junction structure has the advantages of simple form and material conservation and is convenient to construct.

Owner:SOUTHEAST UNIV

Wall unit used for laminated shear wall and construction method using wall unit

The invention relates to a wall unit used for a laminated shear wall and a construction method using the wall unit. The wall unit comprises a steel wire frame, and an insulating layer and a casting layer filled on the steel wire frame, wherein the insulating layer is embedded into the steel wire frame; the casting layer is a prefabricated concrete protective layer arranged on one side of the insulating layer; mounting fixing holes are formed in the outer end face of the prefabricated concrete protective layer; auxiliary pulling fasteners are preburied inside the prefabricated concrete protective layer, and are mounted layer by layer during construction; vertical load-bearing bars are arranged on the inner side of an insulating board, and are connected with the auxiliary pulling fasteners in virtue of pulling fasteners used for anchoring; a casting template is arranged outside the vertical load-bearing bars, and then casting is performed on a cavity between the insulating layer and thetemplate, to form a cast-in-place concrete layer. The vertically adjacent wall units are fixedly connected through fixed parts and bolts, and then setting and casting operations of the template are carried out, the shear wall constructed by using the construction method can greatly simplify the construction process and also has the strength of an integral casting wall, and the requirement of the shear wall is highly met.

Owner:河北晶达建筑科技股份有限公司

Combined type protection shed frame and construction method thereof

ActiveCN102425123BReduce the amount of on-site constructionReduce distractionsBuilding repairsTrack maintainenceBridge deckCross over

The invention discloses a combined type protection shed frame and a construction method thereof. The combined type protection shed frame is characterized in that a bearing structure located on the top surface of a bridge is arranged; the top surface of the bridge is taken as a bearing foundation by bearing longitudinal girders in the bearing structure; bearing cross girders crossing over the bridge are supported by the bearing longitudinal girders; a steel-structure frame located at the bottom part of the bridge is arranged; frame longitudinal girders in the steel-structure frame are suspended below the bearing cross girders through suspenders, and are located at both sides of the bridge; and frame cross girders in the steel-structure frame are suspended at the bottom parts of the frame longitudinal girders. The combined structure of the combined type protection shed frame disclosed by the invention is entirely borne on a bridge deck, and foundations do not need to be constructed at both sides of the existing railroad line, thereby, the on-site construction quantity of the existing railroad line is greatly reduced, the construction risk is lowered, the potential safety hazards areeliminated, and the interference on the normal operation of the existing railroad line is effectively reduced.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

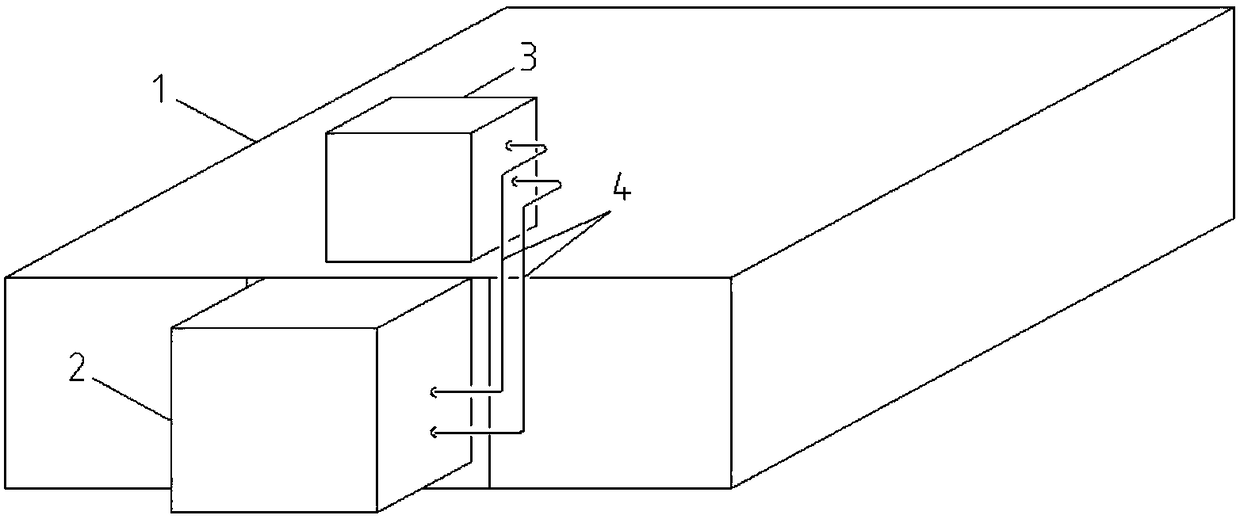

Vacuum insulating pipe

InactiveCN106195531AImprove insulation effectReduce heat transferThermal insulationCorrosion preventionVacuum pumpingEngineering

The invention discloses a vacuum insulating pipe. The vacuum insulating pipe comprises a pipe body. The pipe body comprises an inner pipe body (1) and an outer pipe body (2). The inner pipe body (1) is arranged in the outer pipe body (2). A vacuum cavity (3) is formed between the inner pipe body (1) and the outer pipe body (2) under the situation that the inner pipe body (1) is wrapped by the outer pipe body (2). A vacuum pumping connector (4) is arranged on the outer pipe body (2). Different-diameter sections (5) are arranged at the two ends of the inner pipe body (1). The caliber of the outer side of each different-diameter section (5) is larger than that of the inner side of the different-diameter section (5). The end portions of the different-diameter sections (5) are connected to the inner wall of the outer pipe body (2). A connecting looping opening (6) used for being connected with an adjacent pipe body is formed by the end portion of the outer pipe body (2) and the inner wall of each different-diameter section (5). A vacuum manner is adopted in the vacuum insulating pipe, the heat isolation and preservation performance of the vacuum insulating pipe is superior to that of a heat isolation and preservation material, the heat conduction coefficient is greatly reduced, and meanwhile the field construction amount is reduced.

Owner:宁波万里管道有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com