Horizontal seam U-shaped closed rib junction structure of assembled shear wall structure

A technology of horizontal joints and closed ribs, applied in building structures, building components, building insulation materials, etc., can solve problems such as difficulty in realizing integrated construction of external wall insulation, weak connection between floor slabs and prefabricated wall panels, and affecting the overall performance of the structure. , to achieve the effect of ensuring shear resistance, small construction amount on site, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

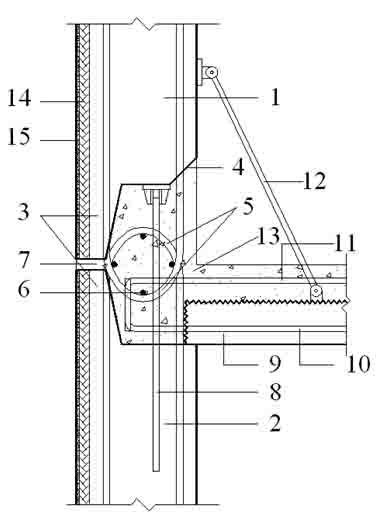

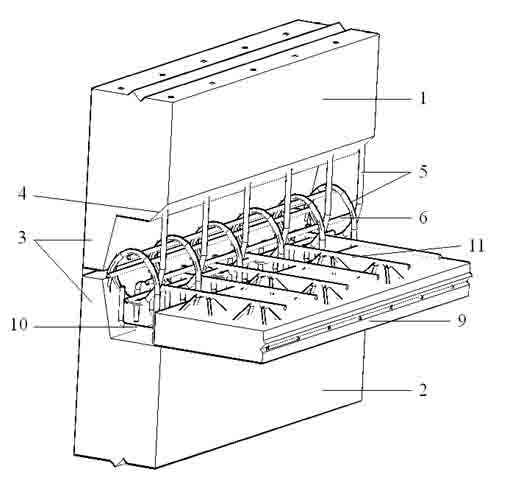

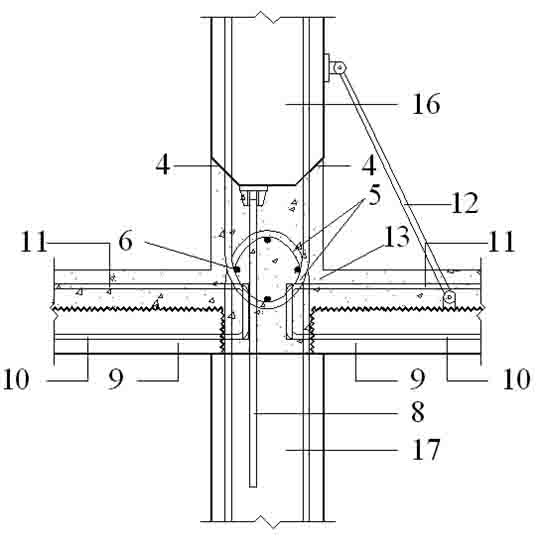

[0023] In the horizontal joints of the assembled shear wall structure of the present invention, the wall panel units are prefabricated in layers, the longitudinal reinforcement of the prefabricated wall panels on the upper and lower layers is dislocated, and the longitudinal reinforcement protruding from the end is bent into a U-shaped closed reinforcement. The U-shaped closed ribs protruding from the ends of the upper and lower prefabricated wall panels at the joints are staggered and overlapped to form a circular ring. A number of horizontal reinforcing steel bars are arranged in the circular ring, and the cast-in-place concrete is filled through the horizontal joints to make the upper and lower prefabricated. The wall panels are integrated to increase the shear resistance of the horizontal joints; the prefabricated concrete thin slabs of the laminated floor are placed on the bearing surface of the thickness of the concrete protective layer outside the longitudinal reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com