Steel structure unit room connecting system based on wedge-shaped blocks and integral connecting plates

A technology of wedge-shaped block and connecting plate, applied in the direction of building structure and construction, can solve the problems of poor joint mechanical performance, high construction precision requirements, complex joint structure, etc., to achieve good integrity, improve integrity, and meet assembly requirements. The effect of type construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

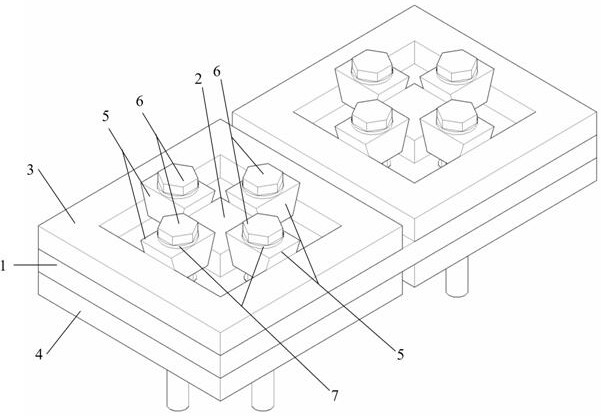

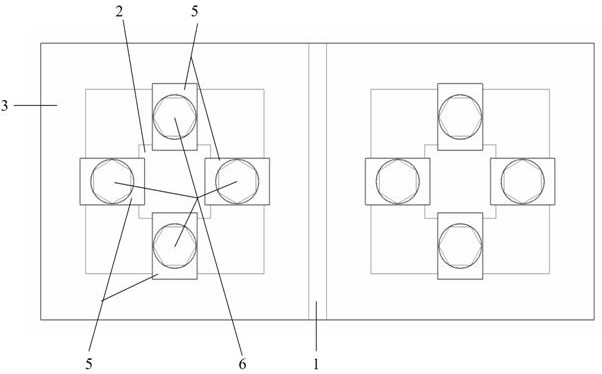

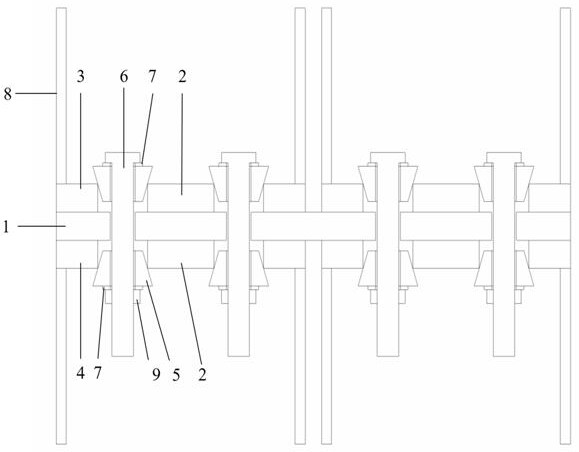

[0029] refer to Figure 1-Figure 6 , a steel structure unit room connection system based on wedge-shaped blocks and integral connecting plates, including connecting plate 1, upper column corner bottom plate 3, lower column corner top plate 4, wedge-shaped block 5, long bolts 6 and nuts 9; the The upper and lower sides of the connecting plate 1 are respectively provided with anti-shear keys 2, and the wedge-shaped block 5 is placed between the bottom plate 3 of the upper column corner piece and the anti-shear key 2 on the top of the connecting plate, and between the top plate 4 of the lower column corner piece and the anti-shear key below the connecting plate. Between the shear keys 2 , the connecting plate 1 is provided with an oblong hole 10 , the wedge block 5 is provided with a vertical through hole 11 , and the long bolt 6 passes through the upper and lower wedge blocks 5 and the middle connecting plate 1 . The bottom plate 3 of the upper column corner piece and the top pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com