Composite bolting shear key structure

A shear key and composite technology, which is applied in building construction, construction, bridge construction, etc., to achieve the effects of improving construction efficiency, reducing the number of studs, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

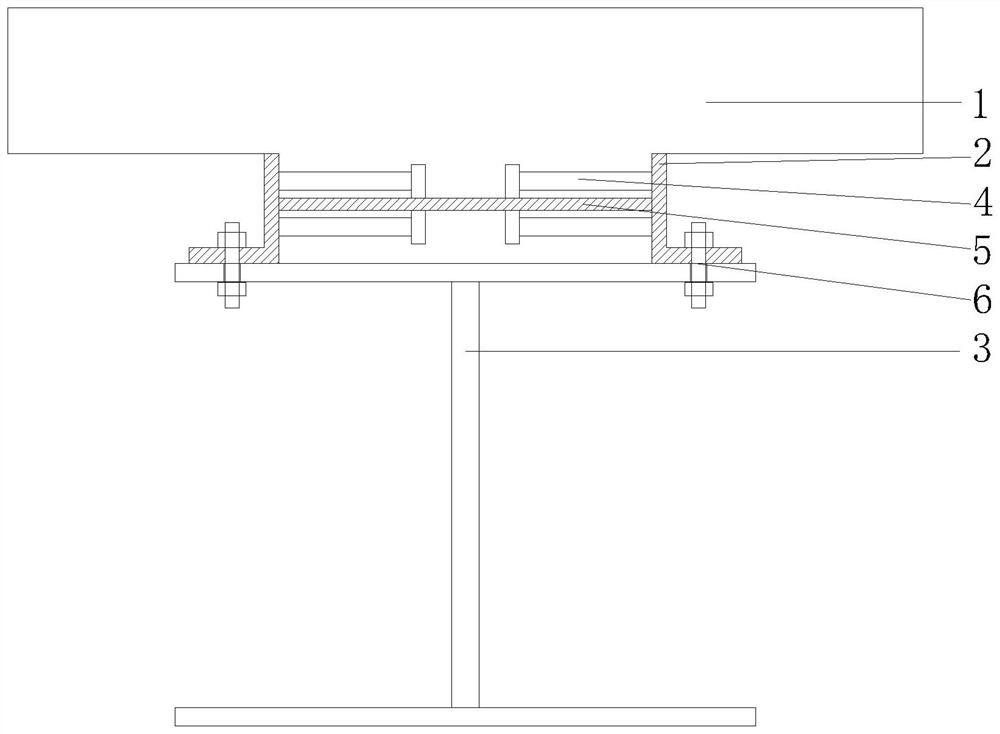

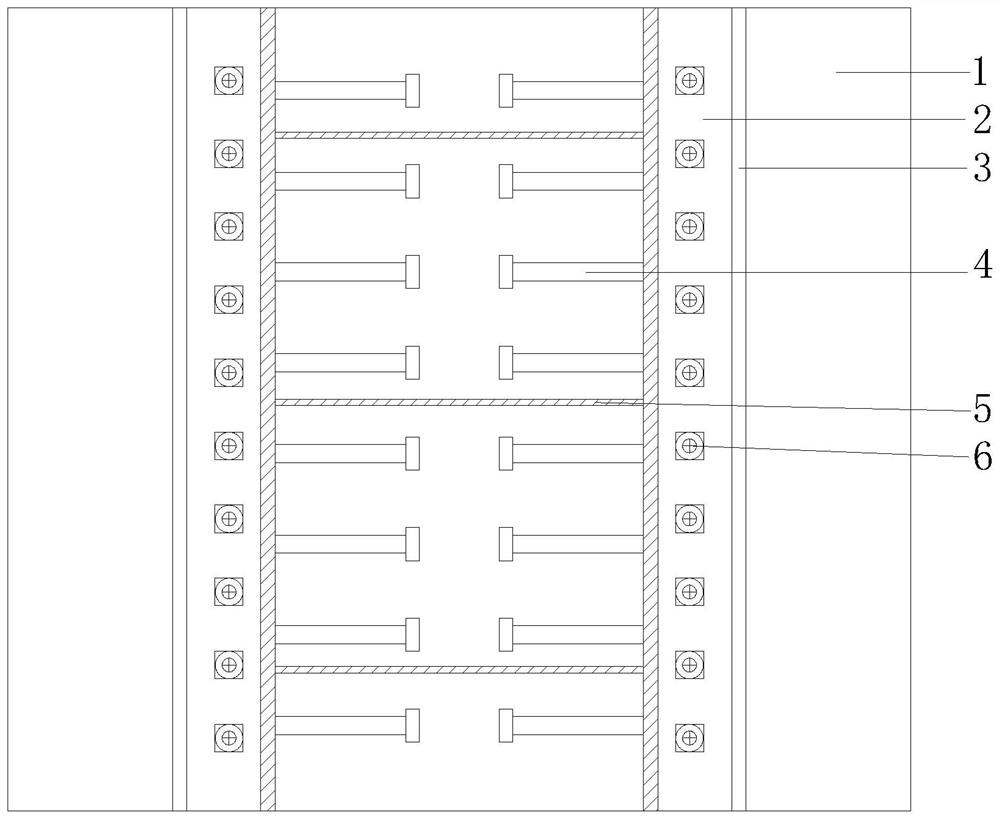

[0023] figure 1 It is a structural schematic diagram of the present invention,

[0024] As shown in the figure, the longitudinal direction in this scheme is the extension direction of the precast concrete bearing plate 1, the horizontal direction is the width direction of the precast concrete bearing plate 1, and the horizontal direction and the vertical direction correspond to figure 1 Horizontal and vertical when placed in the middle, no more details here, the composite bolted shear key structure in this embodiment includes a prefabricated concrete bearing plate 1, a steel transition piece 2 and a steel support piece 3, the steel transition piece The piece 2 is pre-embedded in the precast concrete bearing plate 1 and forms an integral body with the precast concrete bearing plate 1, and the steel transition piece 2 has a connecting part protruding from the precast concrete bearing plate 1 for bolting with the steel support piece 3; it also includes The shear assembly embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com