Method for manufacturing solid three-dimensional concrete block and method for laying concrete tracks using concrete block manufactured using the method

A concrete block and concrete technology, which is applied in the directions of laying track, track, track maintenance, etc., can solve the problems such as the inability of prefabricated blocks to achieve plane and linear consistency, the decrease of track structure stability, and the increase of mortar filling amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

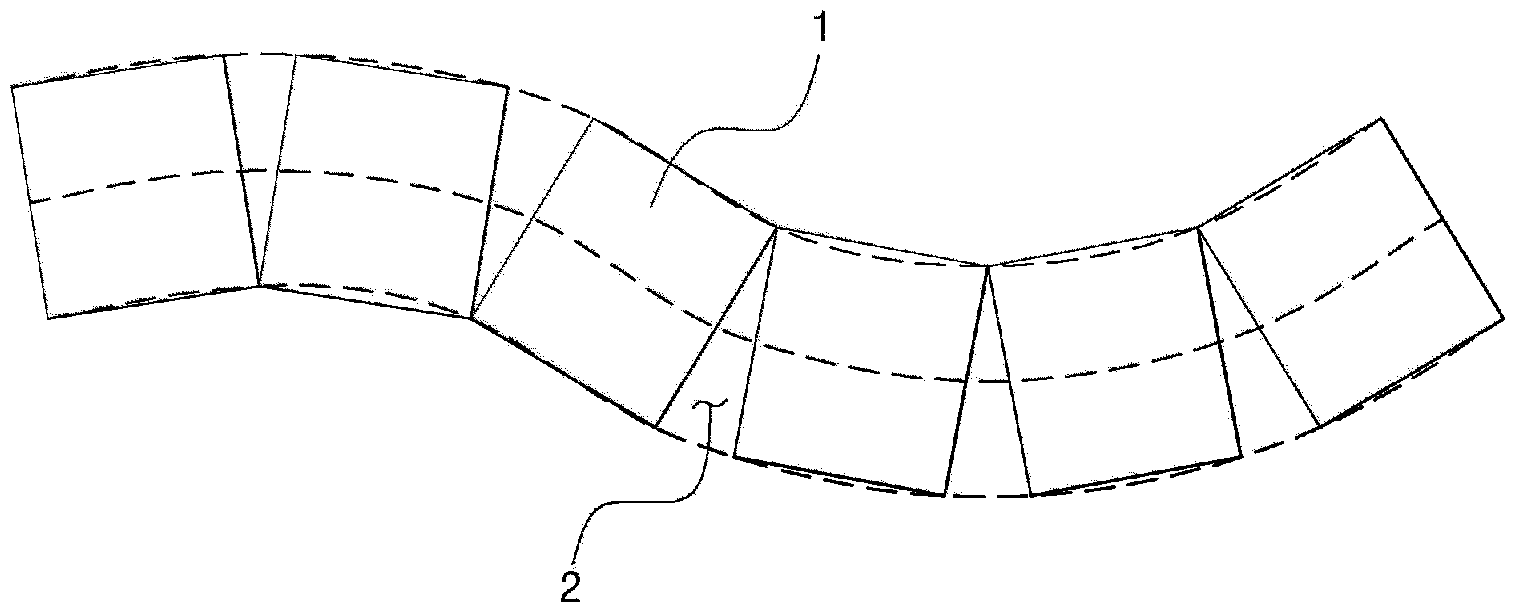

[0049] Exemplary embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. However, the embodiments to be described below are exemplary, and the present invention is described in detail only to the extent that those skilled in the art to which the present invention pertains can easily implement the present invention, and thus, the protection scope of the present invention is not limited thereto. In addition, in the description of several embodiments of the present invention, constituent elements having the same technical features are denoted by the same reference numerals.

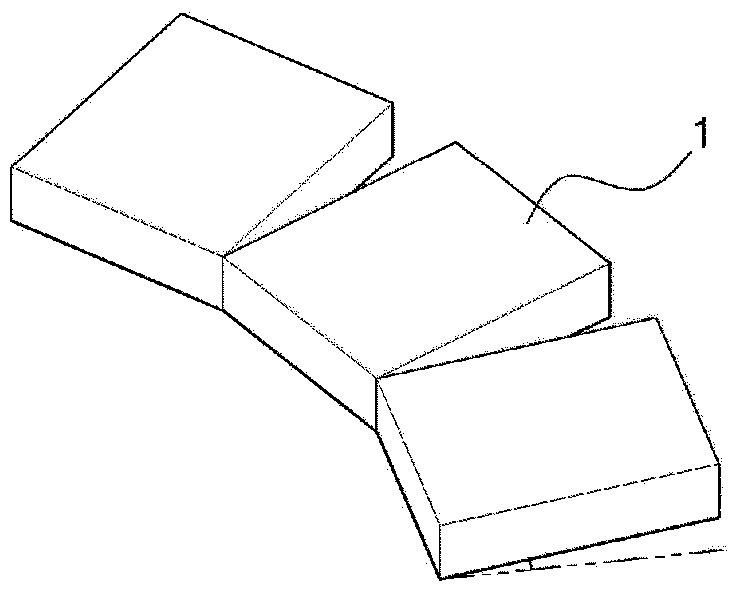

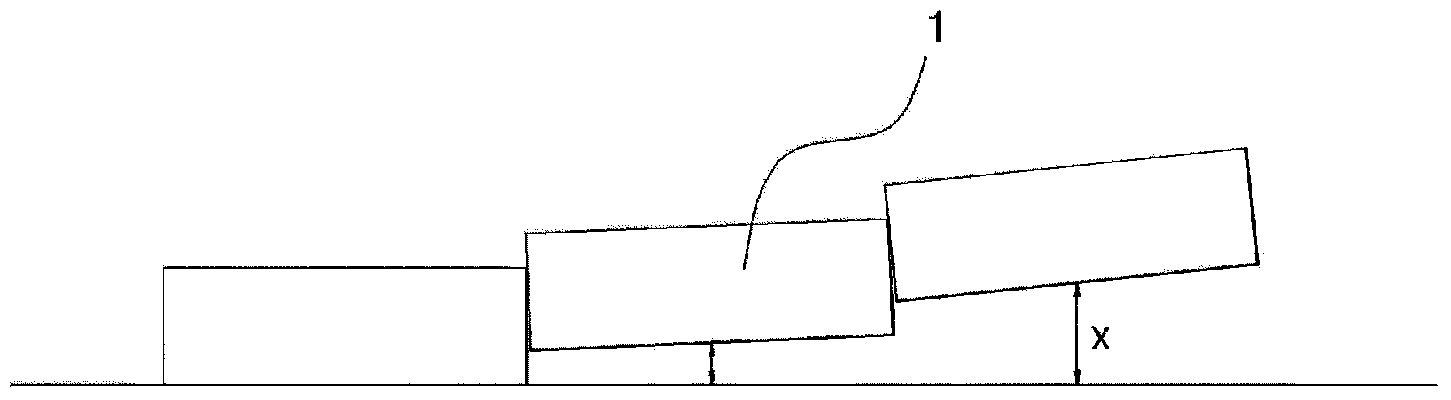

[0050] like figure 2 As shown, the method for manufacturing an integral three-dimensional concrete block according to an exemplary embodiment of the present invention includes the following steps: measuring the site alignment; installing the first temporary assembly support device; installing the first temporary rail; installing the first mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com