Anti-adhesion polyvinyl alcohol embolization microsphere, and preparation method and application thereof

A technology of polyvinyl alcohol embolization microspheres and polyvinyl alcohol microspheres, which is applied in the directions of application, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. Good control, particle size reduction and other problems, to achieve the effect of good sphericity, low cost, and increased swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

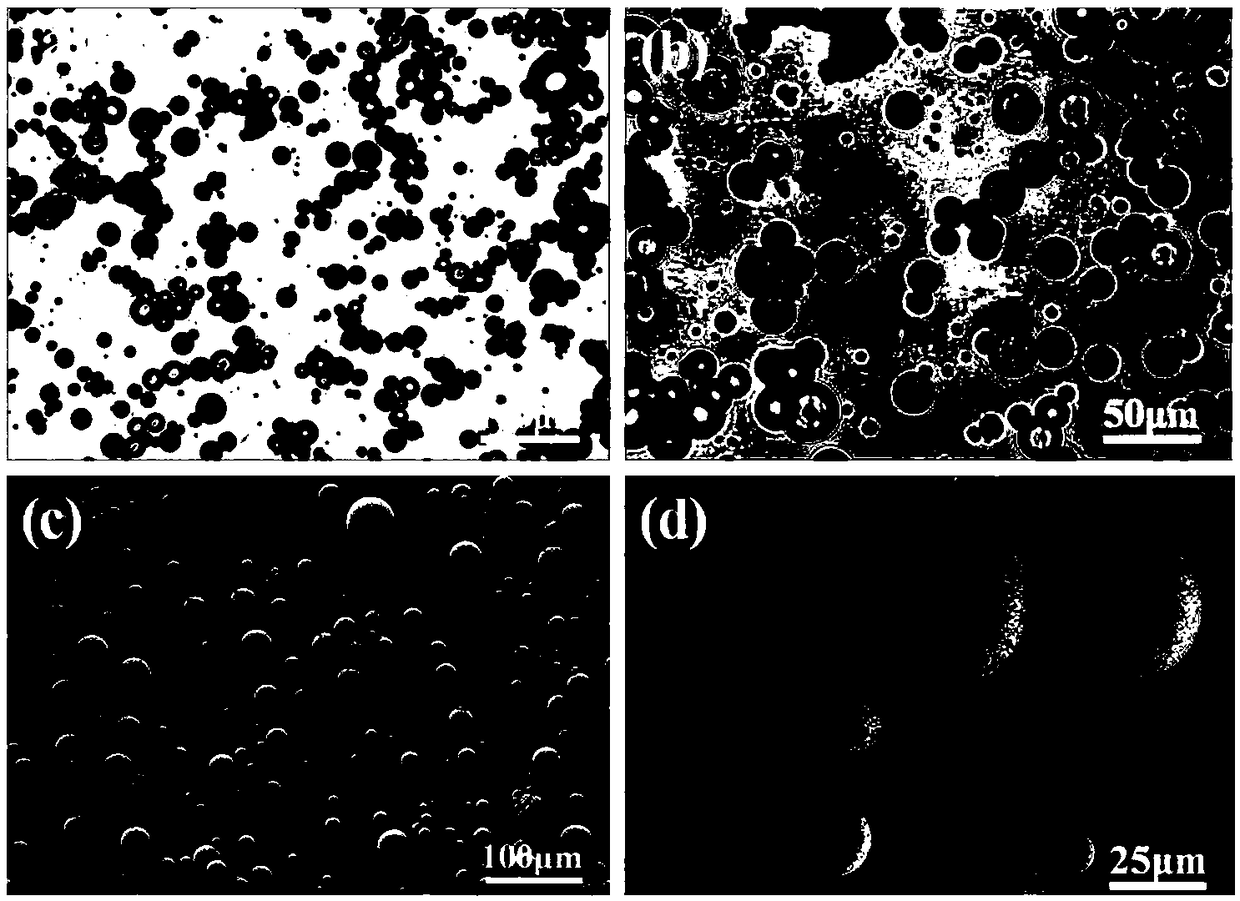

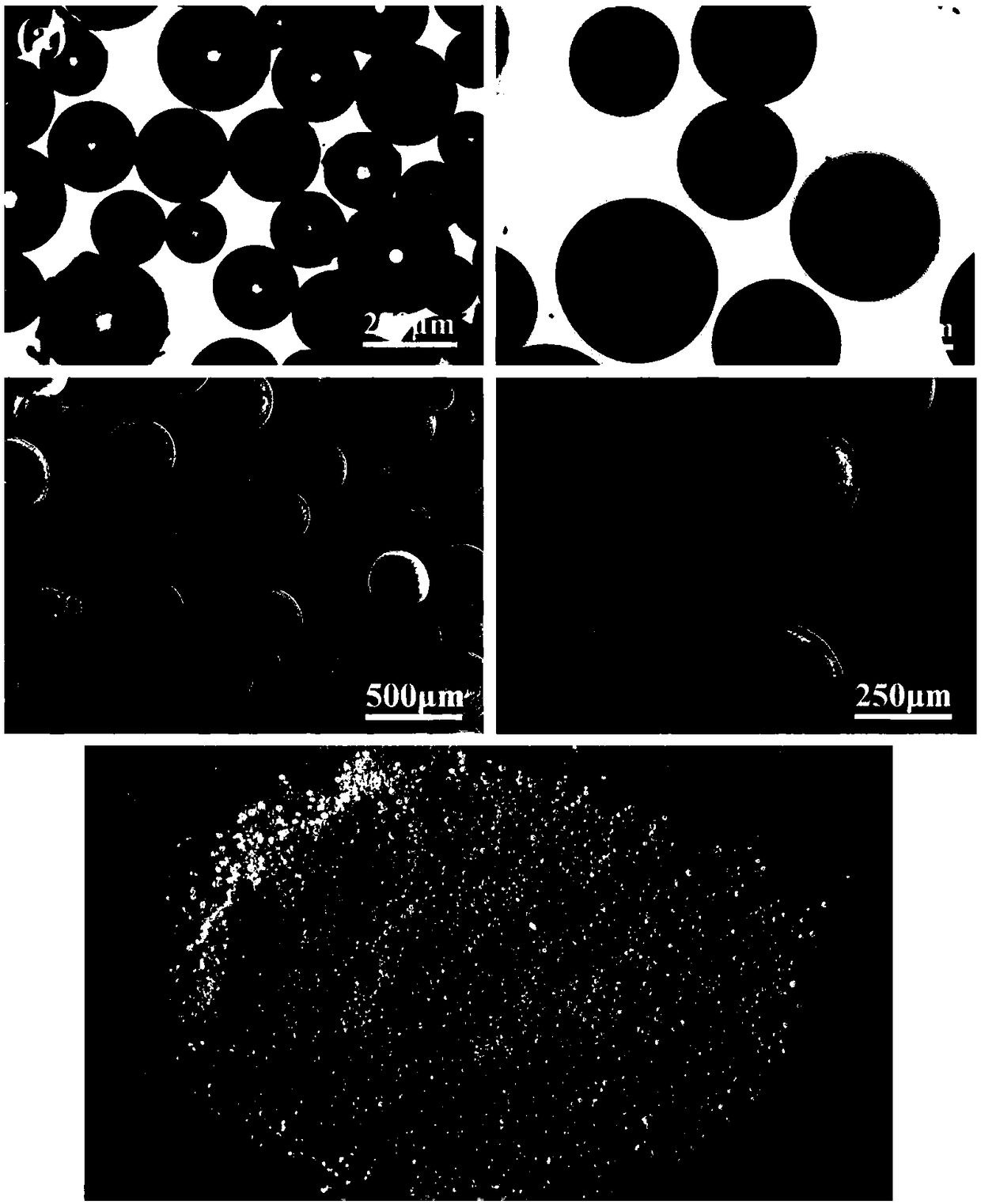

Image

Examples

Embodiment 1

[0030] This embodiment provides a preparation method of anti-adhesion polyvinyl alcohol embolic microspheres, comprising the following steps:

[0031] (1) Preparation of polyvinyl alcohol and chitosan blend solution: heat and dissolve polyvinyl alcohol 124 in a high-temperature water bath or oil bath to obtain an aqueous solution of polyvinyl alcohol with a mass fraction of 10%; Sugar was dissolved in an acetic acid solution with a mass fraction of 1% to obtain a chitosan solution with a mass fraction of 0.84%; polyvinyl alcohol solution and chitosan solution were mixed at a volume ratio of 1:0.64 to prepare a total mass fraction of 6.55%. mixed solution.

[0032] (2) Preparation of anti-adhesion polyvinyl alcohol microspheres: Slowly add the blended solution of the above step a) dropwise to 72 mL of the organic dispersed phase containing 2.43% Span80 by mass fraction, emulsify with magnetic stirring at 350 rpm, and blend The volume ratio of the solution to the organic disper...

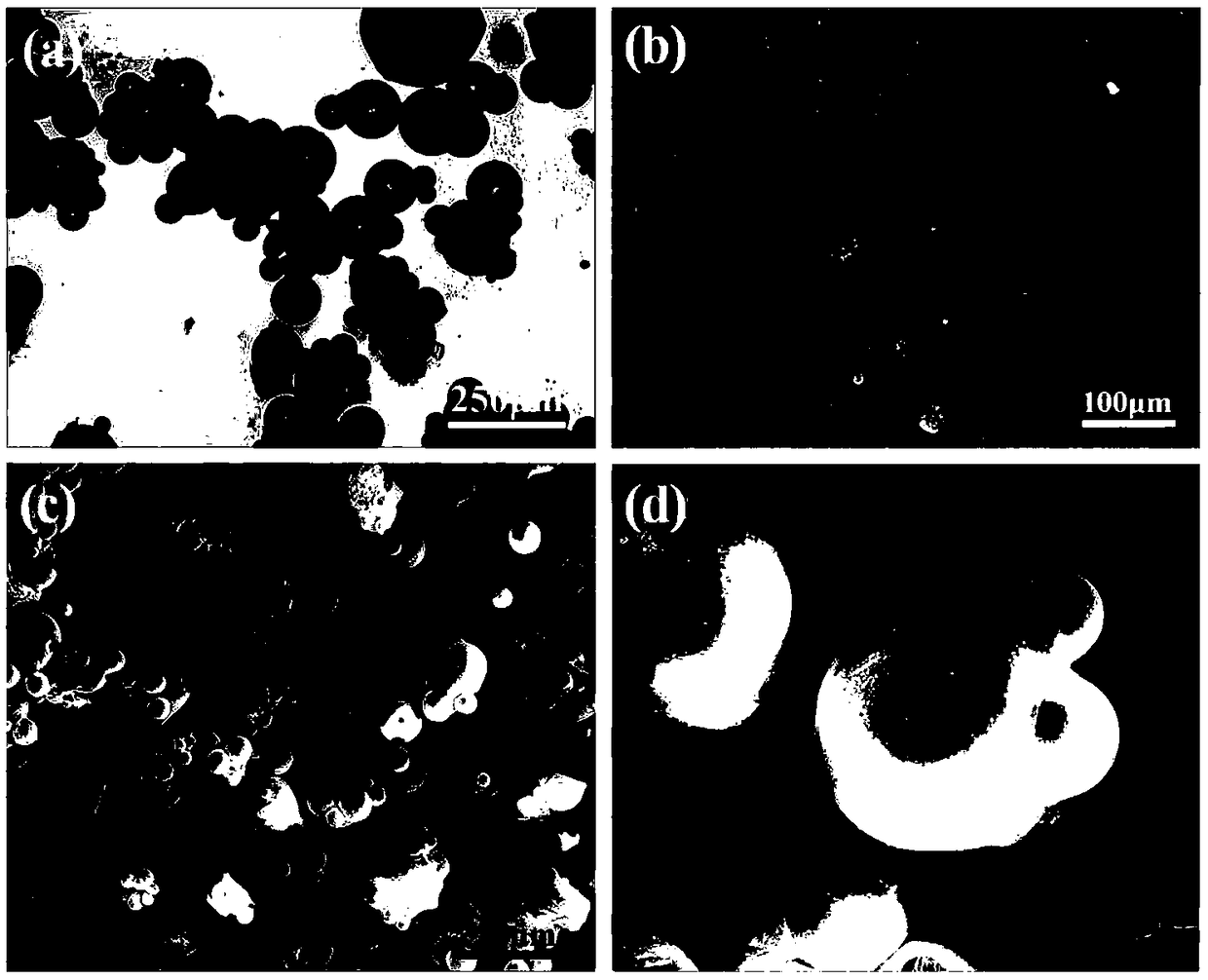

Embodiment 2

[0044] This embodiment provides a preparation method of anti-adhesion polyvinyl alcohol embolic microspheres, comprising the following steps:

[0045] (1) Preparation of polyvinyl alcohol and chitosan blend solution: heat and dissolve polyvinyl alcohol 124 in a high-temperature water bath or oil bath to obtain an aqueous solution of polyvinyl alcohol with a mass fraction of 10%; Sugar was dissolved in an acetic acid solution with a mass fraction of 1% to obtain a chitosan solution with a mass fraction of 0.84%; polyvinyl alcohol solution and chitosan solution were mixed according to a volume ratio of 1:0.64 to prepare a total mass fraction of 6.55%. mixed solution.

[0046] (2) Preparation of anti-adhesion polyvinyl alcohol microspheres: Slowly add the blended solution of the above step a) dropwise into 72 mL of the organic dispersed phase containing 1.8% Span80 by mass fraction, emulsify with magnetic stirring at 300 rpm, and blend The volume ratio of the solution to the org...

Embodiment 3

[0050] This example provides a method for preparing anti-adhesion polyvinyl alcohol embolic microspheres, the steps of which are basically the same as in Example 2, the difference being:

[0051] (1) Preparation of polyvinyl alcohol and xanthan gum blend solution: heat and dissolve polyvinyl alcohol 124 in a high-temperature water bath or oil bath to obtain an aqueous solution of polyvinyl alcohol with a mass fraction of 5%; The gum is dissolved in an acetic acid solution with a mass fraction of 1% to obtain a xanthan gum solution with a mass fraction of 1.5%. The polyvinyl alcohol solution and the xanthan gum solution are mixed at a volume ratio of 1:0.3.

[0052] (2) Preparation of anti-adhesion polyvinyl alcohol microspheres: Slowly add the blended solution of the above step a) dropwise to 72 mL of the organic dispersed phase containing 0.8% Span80 by mass fraction, emulsify with magnetic stirring at 500 rpm, and blend The volume ratio of the solution to the organic dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com