Asphalt pavement pit slot repairing capsules, and preparation and construction method thereof

A technology for preparing asphalt pavement and capsules, which is applied to roads, roads, on-site coagulating pavements, etc., can solve the problems of poor storage stability and high energy consumption of hot-mix asphalt mixture, achieve stable properties, improve environmental protection index, The effect of increasing storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

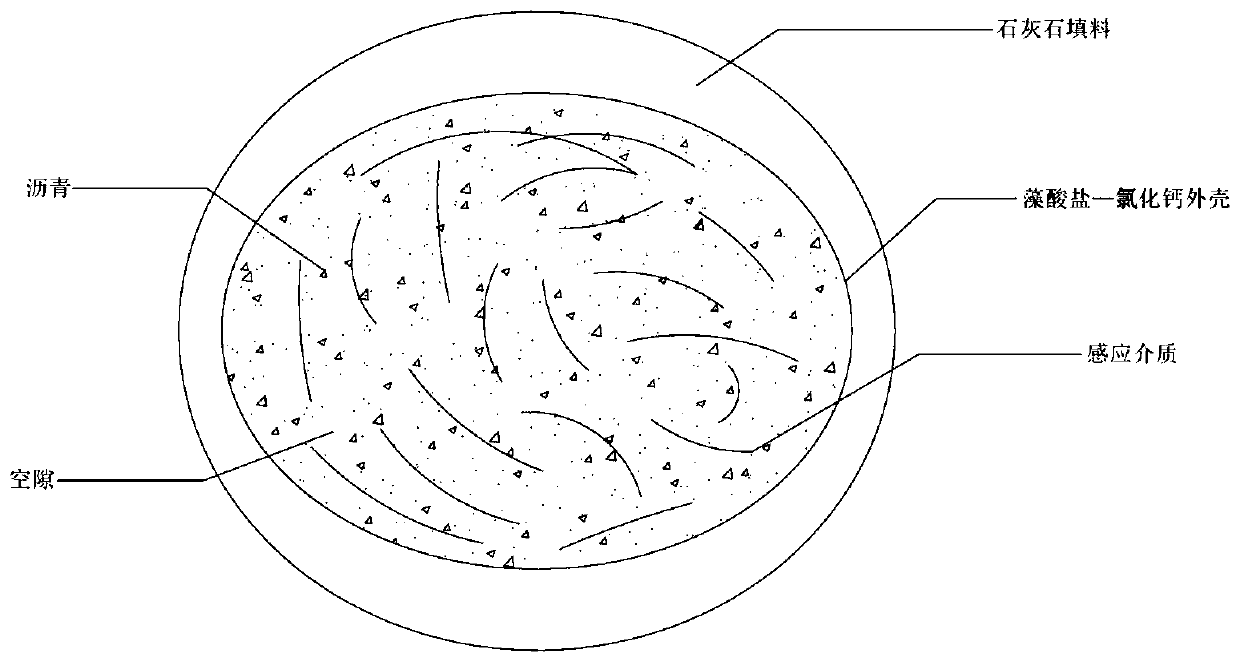

[0040] A method for preparing asphalt pavement pothole repair capsules, characterized in that it comprises the following steps:

[0041] S1: Add the heating medium to the road asphalt and mix at 170°C-180°C for two minutes to ensure uniform mixing;

[0042]S2: Put the mixture obtained in step 1 into a tray and cool it at -15°C--5°C;

[0043] S3: Preliminarily break the cooled mixture in step 2 by hand, and then break it into irregular pieces of different sizes with a hammer, and store them in a container at 2°C-10°C to form the core of the capsule;

[0044] S4: Mix alginate and distilled water, and stir with a stirring device at 400-500 rpm for 10-12 minutes to produce a uniform emulsion; at the same time, mix calcium chloride with distilled water to prepare calcium chloride solution

[0045] S5: The core is first added to the alginate emulsion obtained in step 4, and then added to the calcium chloride solution to generate an ionic gel of alginate on the surface of the core. ...

Embodiment 1

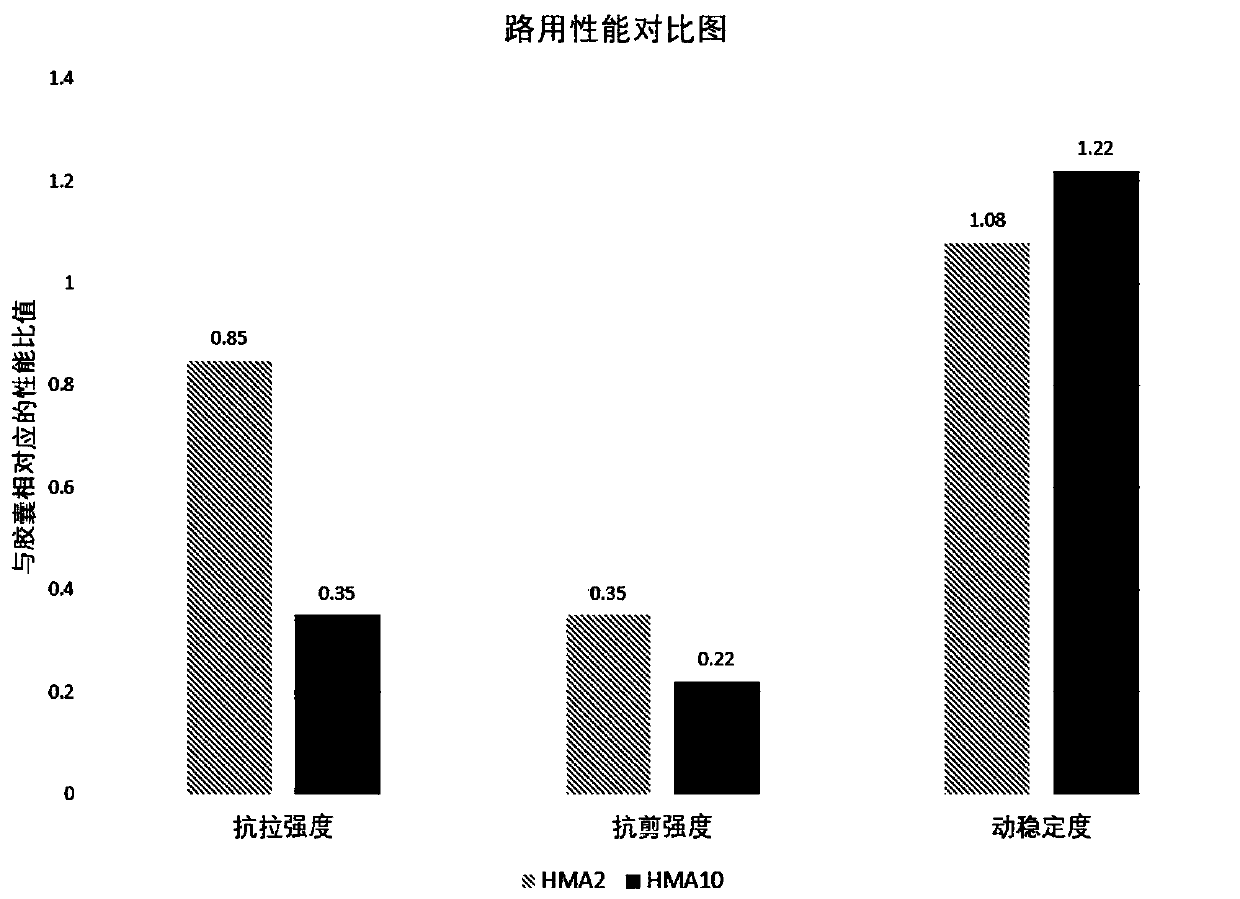

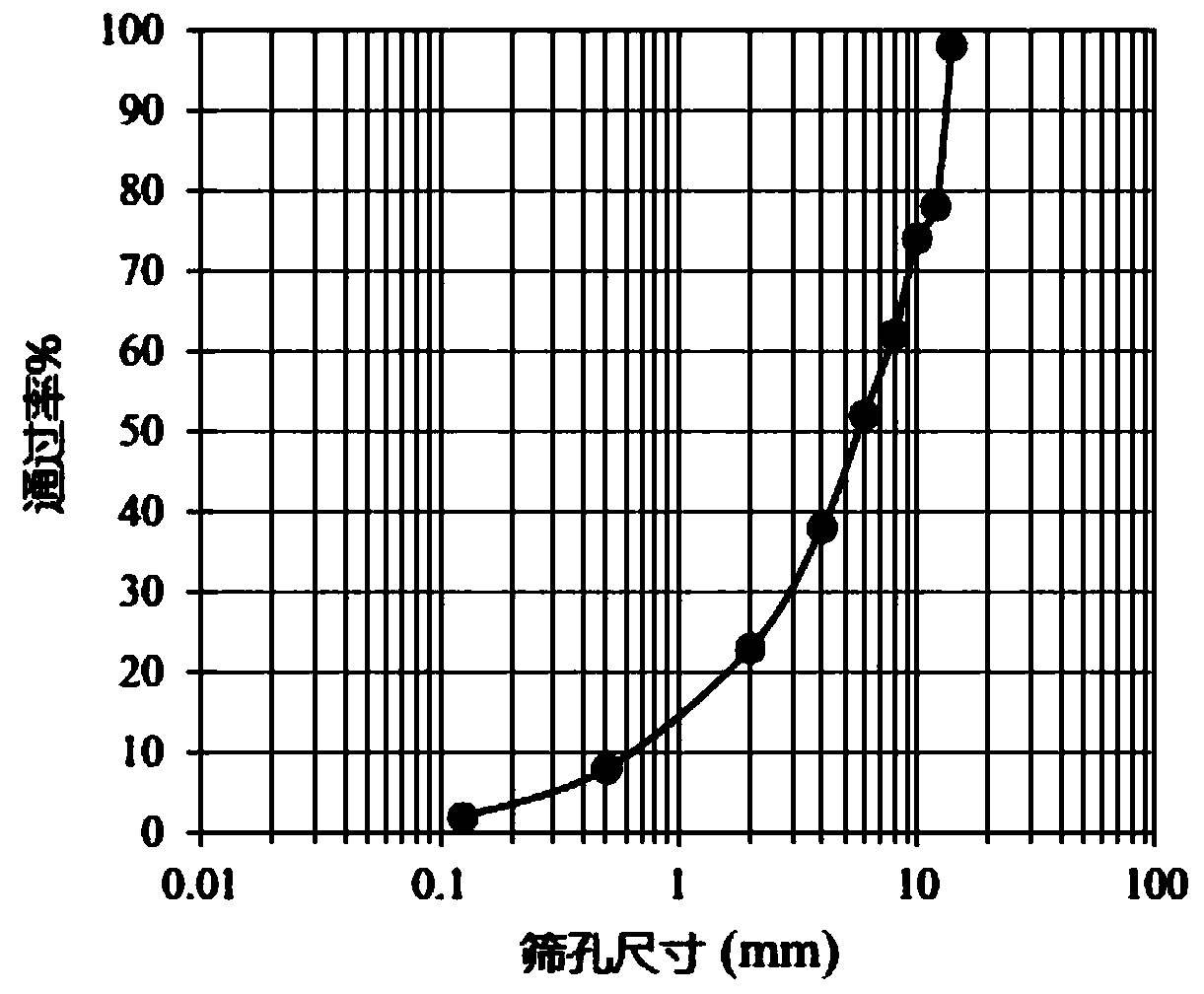

[0061] In order to compare the pavement and mechanical properties of asphalt pavement pothole repair capsules and ordinary asphalt mixtures for pothole repair. A comparative test was carried out on three kinds of asphalt mixtures. The test contents are tensile test, shear test and high temperature rutting test. Among the three groups of experiments, the first group is a test piece made of asphalt pavement pothole repair capsule; the second group is a HMA2 type test piece, the raw material is asphalt content of 8%, and the maximum nominal particle size of the aggregate used is 2mm; The three groups are HMA10 specimens, the raw material is asphalt content of 5%, and the maximum nominal particle size of the aggregate used is 10mm. The test pieces are all made in accordance with JTGE20-2011 "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", and the rest of the experimental conditions are the same. image 3 A schematic diagram of a typical gradation of a ...

Embodiment 2

[0066] The materials and related tests of this embodiment are the same as those in Example 1.

[0067] 10% road petroleum asphalt, 10% steel wool, 35% alginate-calcium chloride polymer, 45% aggregate.

[0068] The pit repair capsule prepared by the method can be used for repairing pits of general size.

[0069] The asphalt pavement pothole repair capsules prepared by this method were used to make corresponding test pieces, and relevant evaluation tests were carried out. The test showed that although the high temperature rutting resistance of the test pieces prepared by the asphalt pavement pothole repair capsules was slightly worse than that of HMA2 and HMA10 type test pieces, But its tensile strength and shear strength are significantly better than HMA2 and HMA10 type specimens. It shows that the pothole repair capsule has good road use and mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com