Fabricated pile and construction method thereof

A construction method and prefabricated technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficulty in ensuring the quality of pile body concrete, small horizontal bearing capacity of pipe piles, and small transverse bending moment, and achieve quality Easy to guarantee, high bearing capacity, and avoid the effect of poor ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

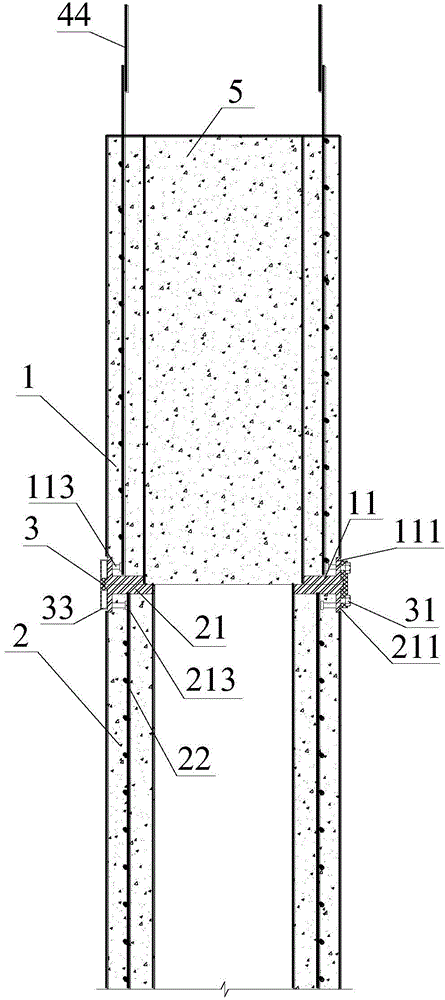

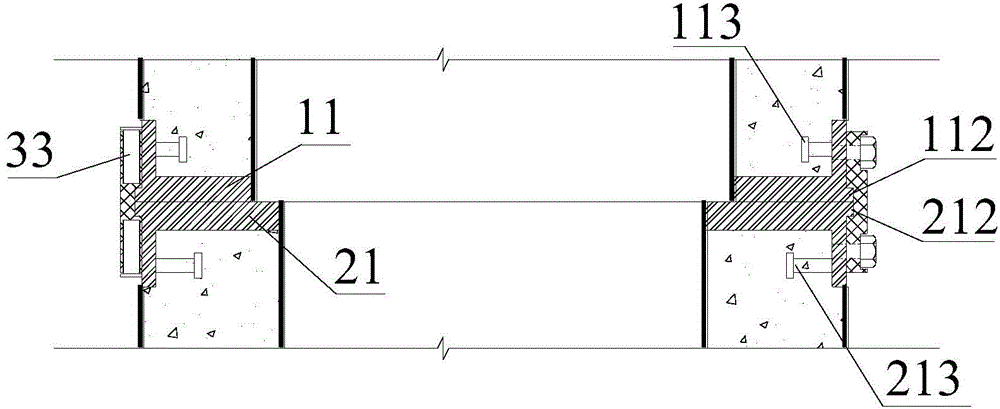

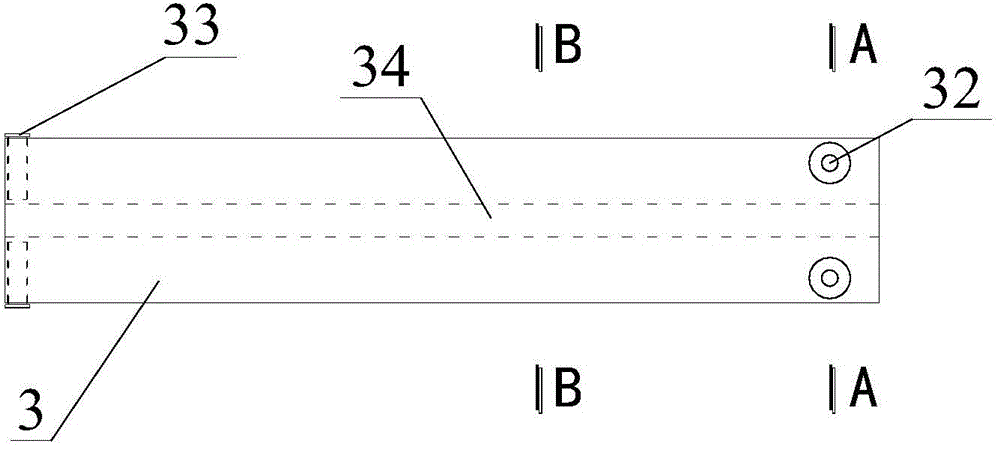

[0030] Please refer to the accompanying drawings, a kind of assembled pile, including the lower tubular pile 2, the lower tubular pile 2 is provided with the steel cage of the lower tubular pile, and the upper end of the lower tubular pile 2 is provided with an upper end plate 21. The upper end of the lower pipe pile 2 is equipped with a top pipe pile 1, and the lower end of the top pipe pile 1 is provided with a lower end plate 11 pressed on the upper end plate 21, and the lower end plate 11 is connected with the upper end plate 21. , the top pipe pile 1 is provided with a top pipe pile reinforcement cage 4, a well-shaped composite stirrup 43 is arranged every 200-400mm on the reinforcement cage 4 of the top pipe pile, and a well-shaped compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com