Aeronautical container/tray article examination system

A cargo inspection and container technology, applied in the field of radiation detection, can solve the problems of large area of civil engineering, low container inspection efficiency, and high cost of system engineering, so as to increase structural strength and rigidity, improve inspection speed and resolution, and improve wear resistance. The effect of enhanced penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

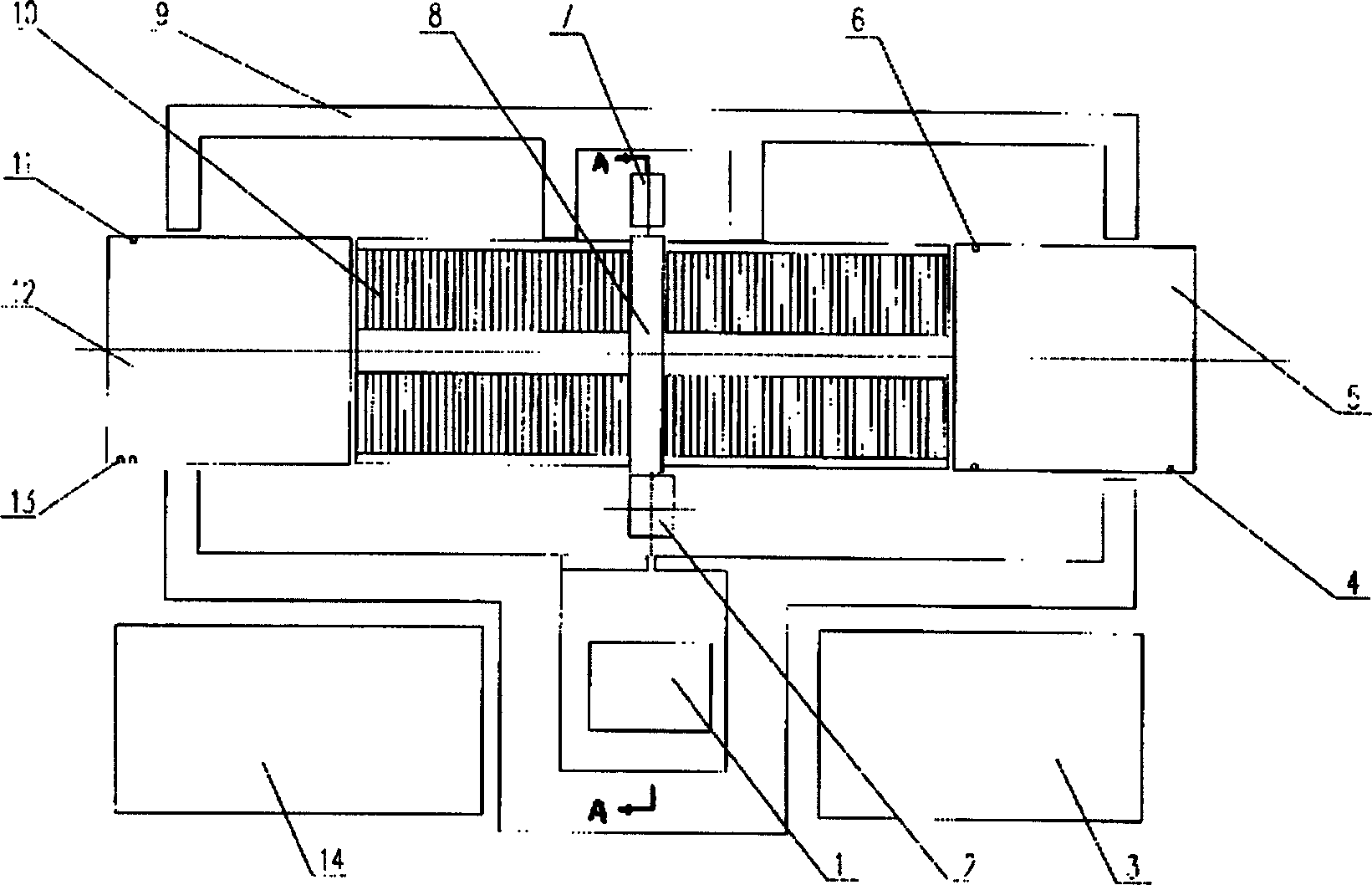

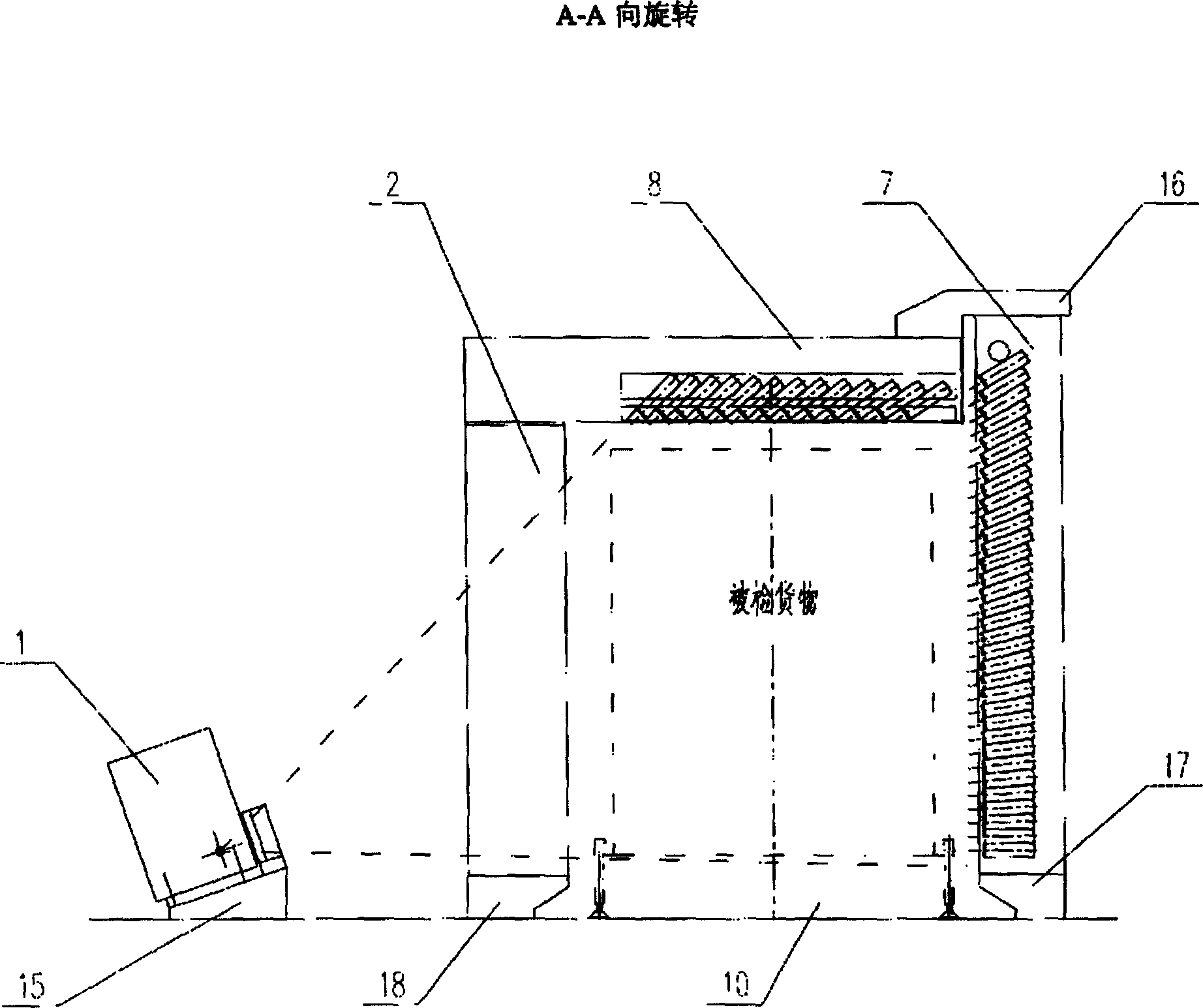

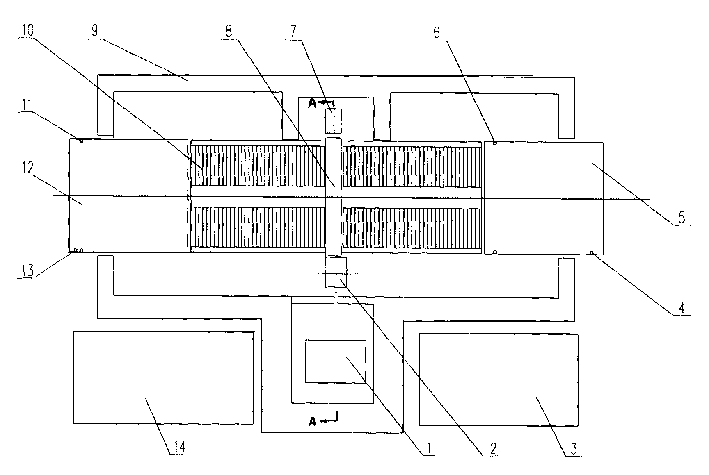

[0016] see figure 1 , 2 , an air container / pallet cargo inspection system using an accelerator as a radiation source, mainly including an electron linear accelerator 1, a collimator 2, a horizontal detector arm 8, a vertical detector arm 7, and conveyed by a plate conveyor 10 and an upper roller. Machine 5, composite transmission device consisting of roller conveyor 12, radiation shielding wall 9, equipment cabin 14, and operating room 3. The accelerator 1, the collimator 2, and the vertical detector arm 7 are respectively installed on the accelerator base 15, the collimator base 18, and the vertical detector arm base 17. The collimator 2 is located between the conveying device and the accelerator 1 , the upper end of the collimator 2 supports a horizontal detector arm 8 , and the vertical detector arm 7 is installed on the other side of the conveying device opposite to the accelerator 1 . The horizontal detector arm 8 is located directly above the transmission device, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com