Light steel structure wall body module

A light steel structure and wall technology, applied in the direction of building components, building structure, thermal insulation, etc., can solve problems such as complex process, low efficiency, and difficult to solve the problem of firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with examples in conjunction with the accompanying drawings.

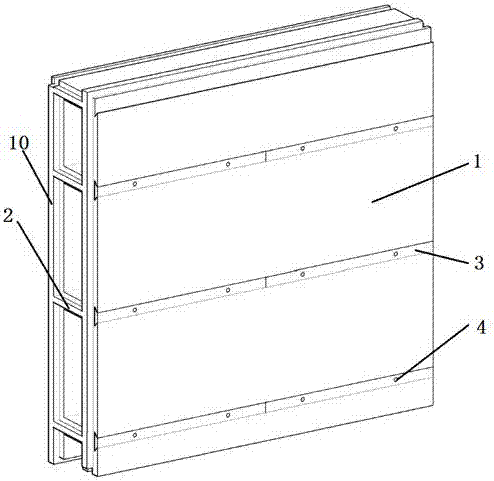

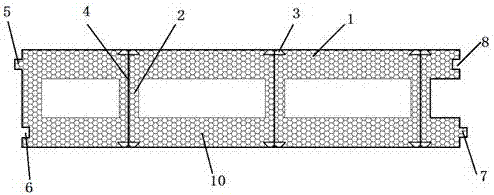

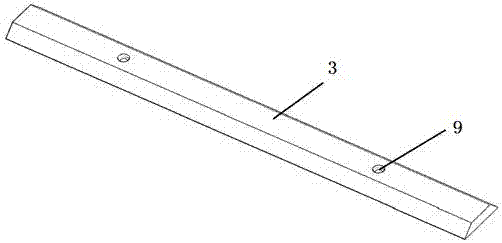

[0017] combine Figure 1-Figure 4 , the first embodiment of the present invention includes an EPS formwork. The EPS formwork is a cavity formwork formed by connecting the core ribs 2 at equal intervals between the inner plate 10 and the outer plate 1. Inserts are arranged on the surfaces of the inner plate and the outer plate. groove, the shape of the slot can be a dovetail groove or a stepped groove, the slots on the inner plate and the outer plate correspond to each other, and also include a connecting plate 3 and a connecting bolt 4 with a through hole 9, and there are at least two connecting plates on one connecting plate. The shape of the connecting plate is the same as that of the slot, the connecting plate is inserted in the slot, and the connecting bolt passes through the through hole of the connecting plate on the inner and outer plates and the E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com