Flexible automatic loading system and application thereof

A flexible and automatic technology, applied in transportation and packaging, loading/unloading, stacking of objects, etc., which can solve the problems of low degree of automation, lack of automatic scanning and positioning systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

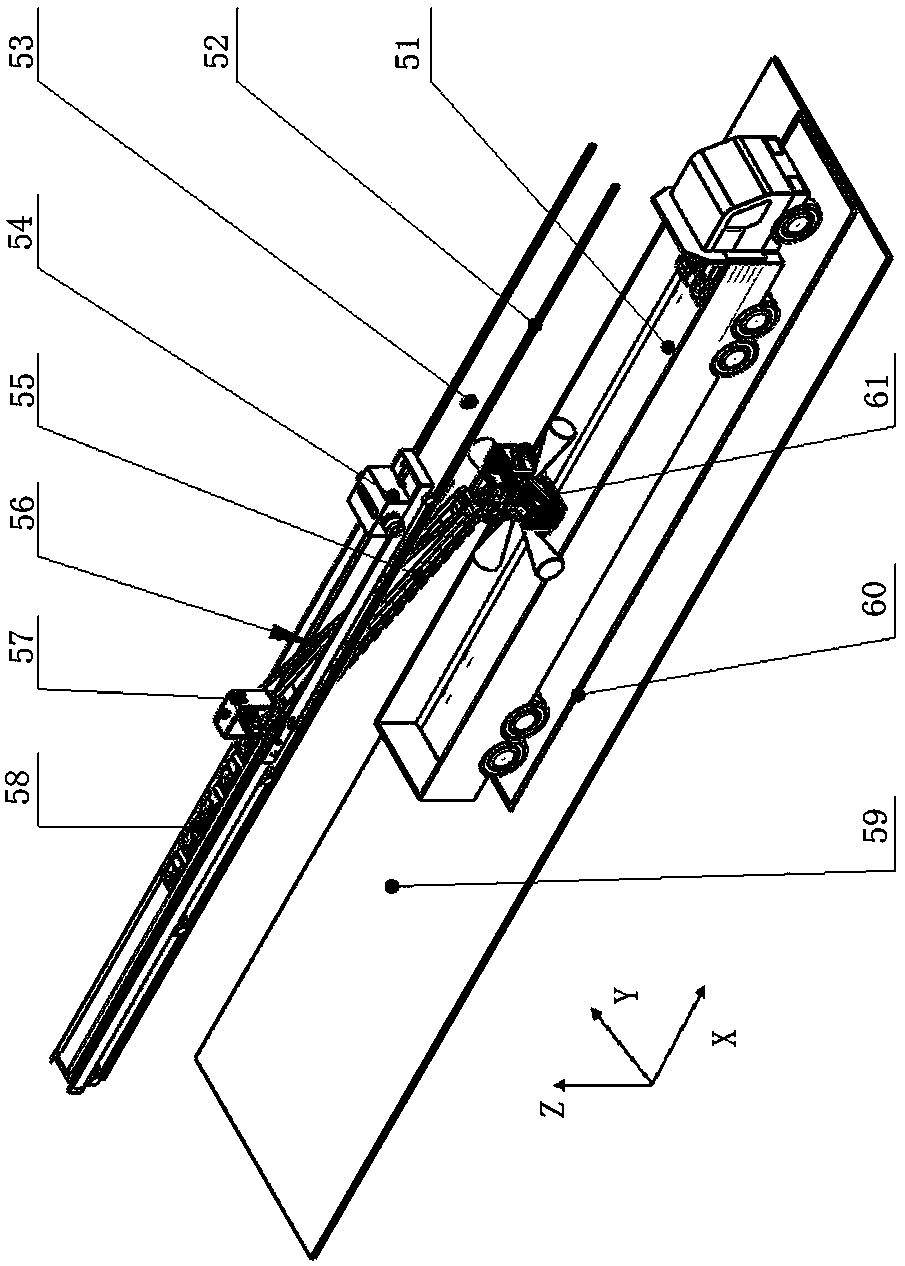

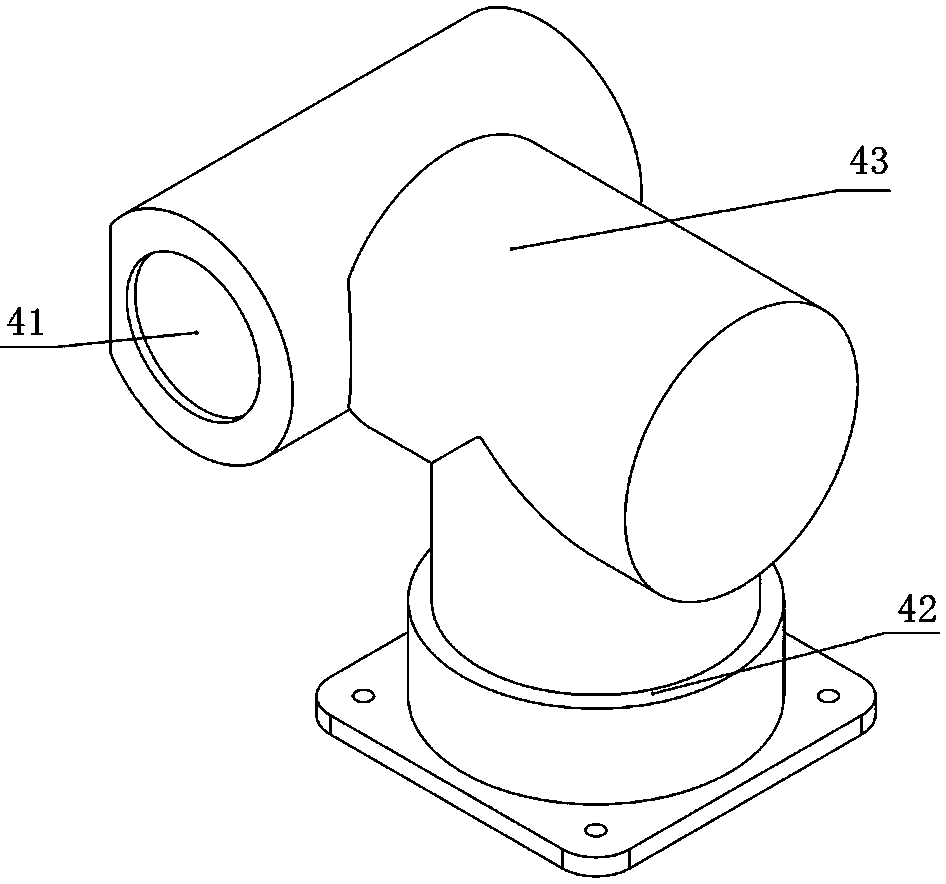

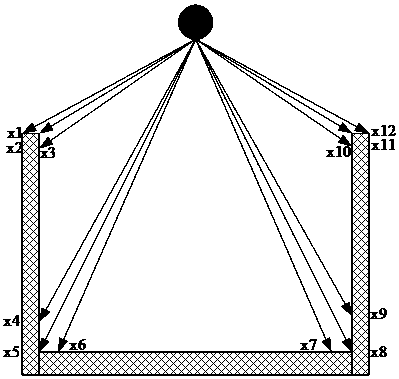

[0085] As shown in the figure, this embodiment provides a flexible automatic loading system, which includes a control system, a laser scanning positioning unit, a feeding unit, a stacking loading unit, a laser scanning positioning unit, a feeding unit, and a stacking loading unit respectively connected with the control system. Among them, the laser scanning positioning unit is mainly used to scan and locate the carriage of the material transporter, and feedback the measurement information to the control system; the feeding unit is mainly used to transport materials to the palletizing and loading unit; the palletizing and loading unit is It is used to stack the material in the carriage of the material transporter to realize the stacking of the material.

[0086] In this embodiment, the feeding unit includes a guide rail, a lifting mechanism arranged on the guide rail, a transmission mechanism, and a parallel link mechanism matched with the palletizing and loading unit. The lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com