Precise centring die device for prefabricated concrete structure grouting sleeve

A technology for concrete structures and grouting sleeves, applied in the directions of mold auxiliary parts, manufacturing tools, ceramic molding machines, etc., can solve the problems of low assembly quality of components, difficult to implement, difficult to accurately control relative positions, etc. Constitute the effect of simple and effective, simplifying the positioning procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

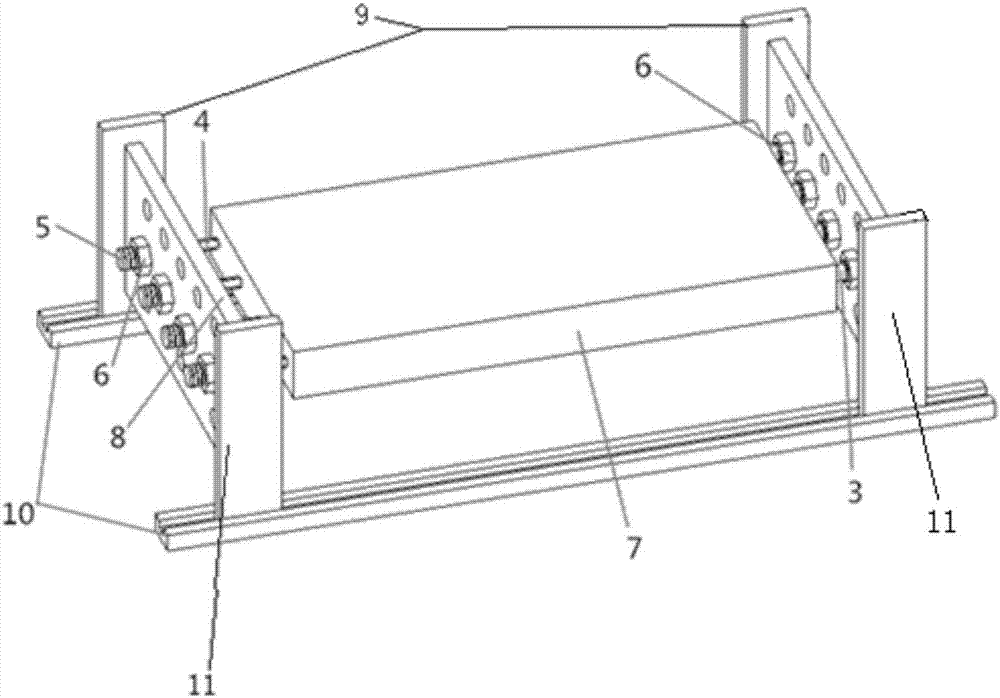

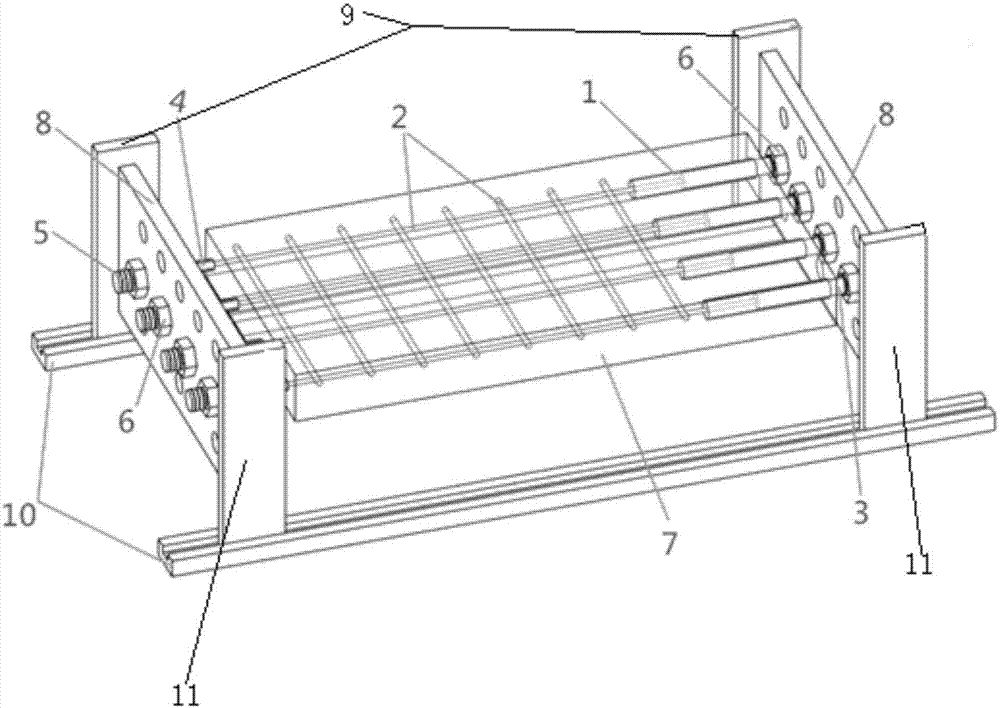

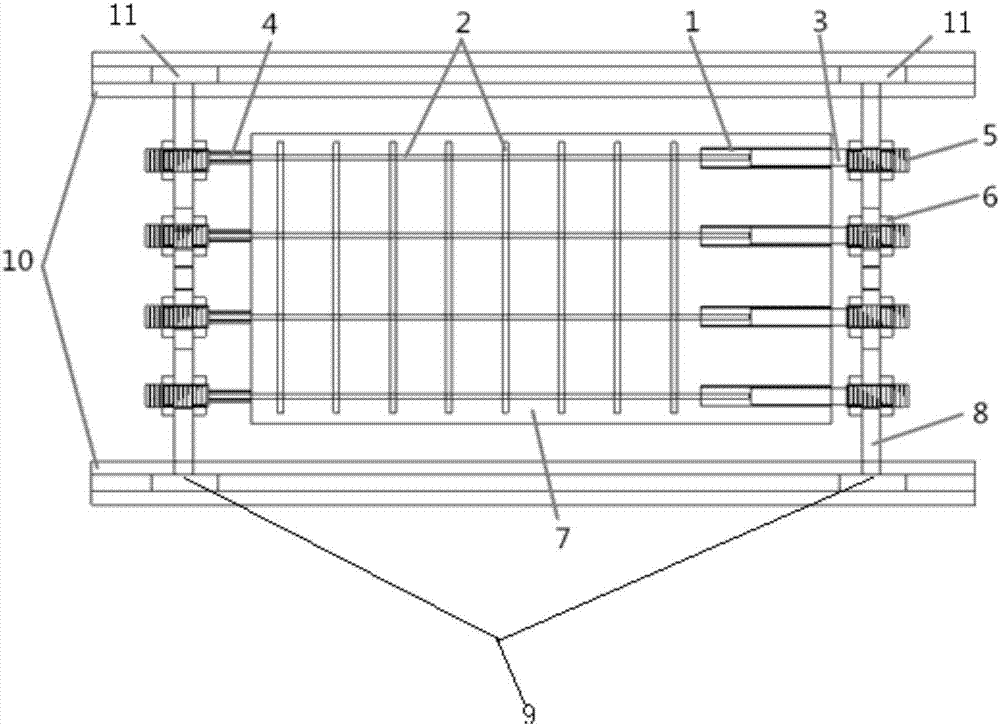

[0024] Example: such as figure 1 , 2 , 3, a prefabricated concrete structure grouting sleeve accurate centering mold device, including slideway 10, two groups of steel frames 9, sleeve positioning shaft rod 3, extended steel bar positioning shaft rod 4, fixed nut 6; Two sets of steel frames 9 are arranged in parallel on the slideway 10 of the production line of the precast concrete component 7, and the two sets of steel frames slide through the slideway 10 to realize docking and separation with the two ends of the casting mold of the precast concrete component 7. Each set of steel frames 9 includes Two side steel plates 11 and one horizontal steel plate 8, the horizontal steel plate 8 is arranged between the two side steel plates 11, multiple rows of small holes with different spacings are arranged on the horizontal steel plate 8, and one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com