Wall unit used for laminated shear wall and construction method using wall unit

A technology for superimposing shear walls and wall units, applied in the direction of walls, building components, buildings, etc., can solve the problems of connection strength, matching accuracy defects, high construction complexity, long construction period, etc., to reduce the alignment work. The effect of reducing the amount of on-site construction and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

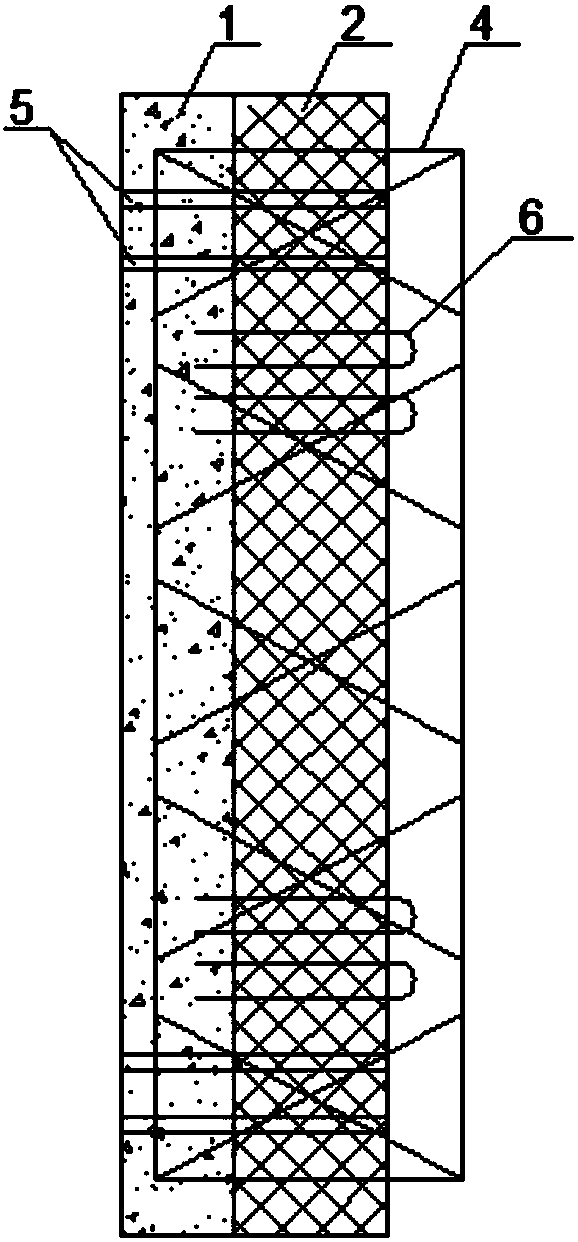

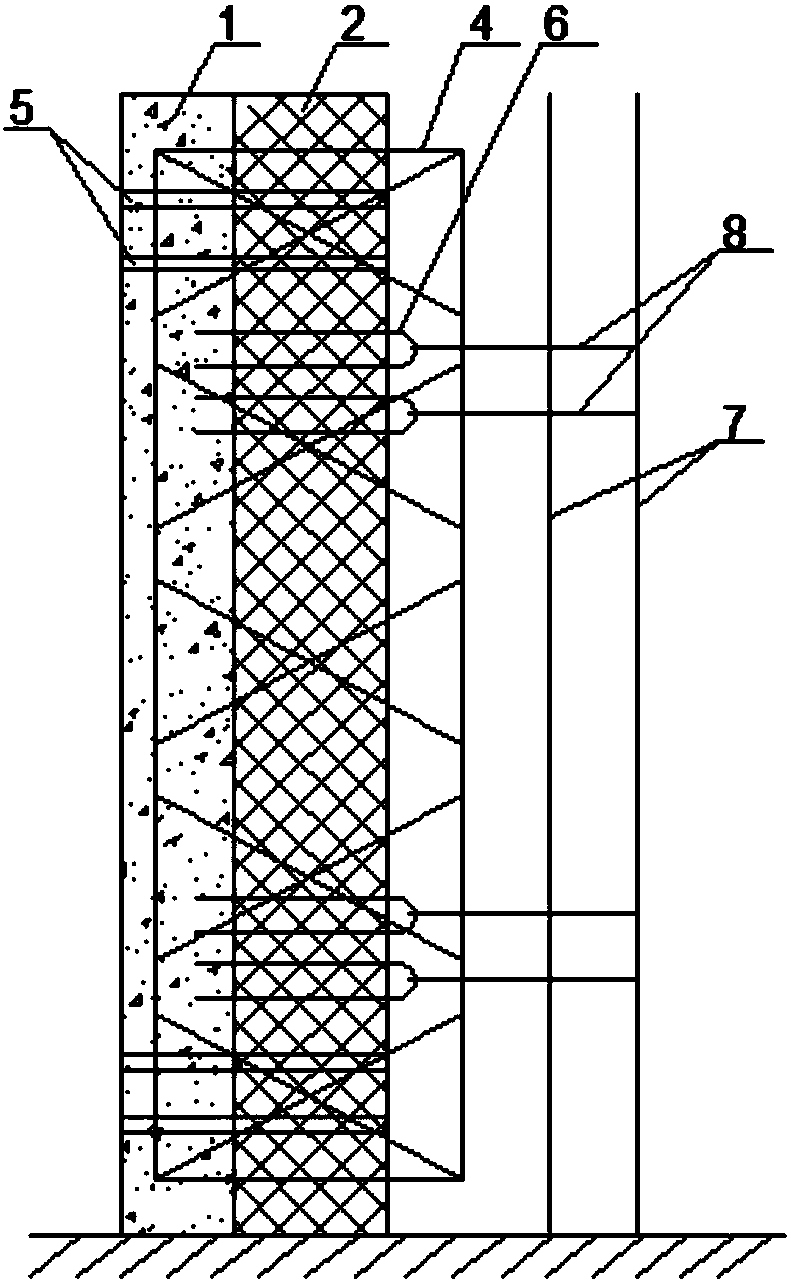

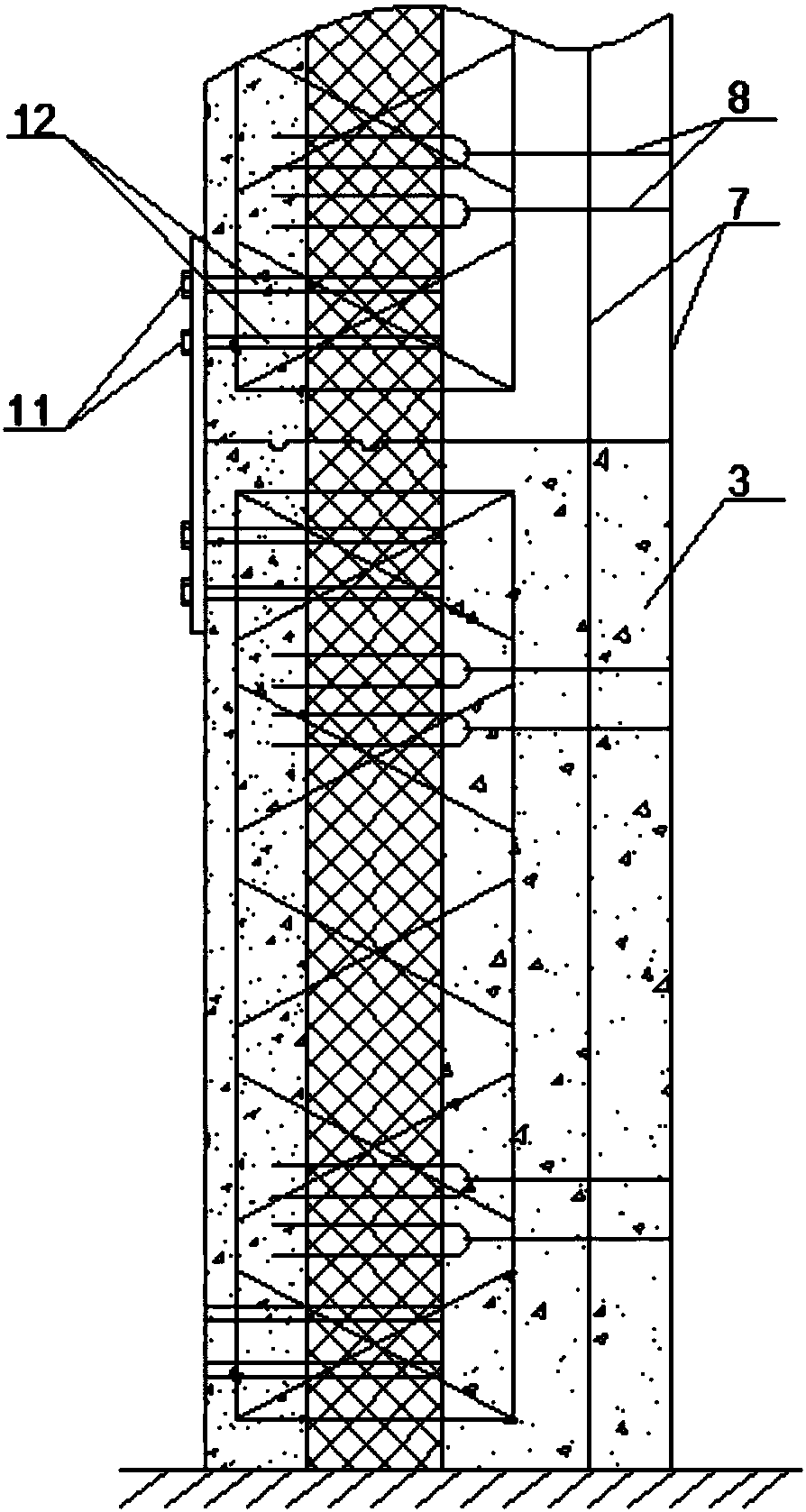

[0022] The present invention relates to a wall unit for a laminated shear wall and a construction method using the same. The wall unit includes a steel wire grid 4 and an insulating layer 2 and a pouring layer filled on the steel wire grid 4. The thermal insulation layer 2 is embedded in the steel wire grid frame 4, the pouring layer is a prefabricated concrete protective layer 1 arranged on one side of the thermal Auxiliary anchors 6 are buried; the wall unit composed of the above structure is prefabricated in the factory, and fixed after being transported to the site, and the inner part of the insulation layer 2 is cast in-situ to form the cast-in-situ concrete layer 3, which is then fixed and poured layer by layer to form a stack Combined with the shear wall structure, the specific process of construction is explained through specific examples.

[0023] Specific examples, such as figure 1 As shown, the steel wire mesh frame 4 is in the form of a truss structure. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com