Hole-opening method for measuring holes for testing performances of ventilation and air conditioning system

An air-conditioning system and a technology for measuring holes, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increased difficulty in opening measuring holes, achieve flexible use and operation, convenient processing, manufacturing, installation and layout, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

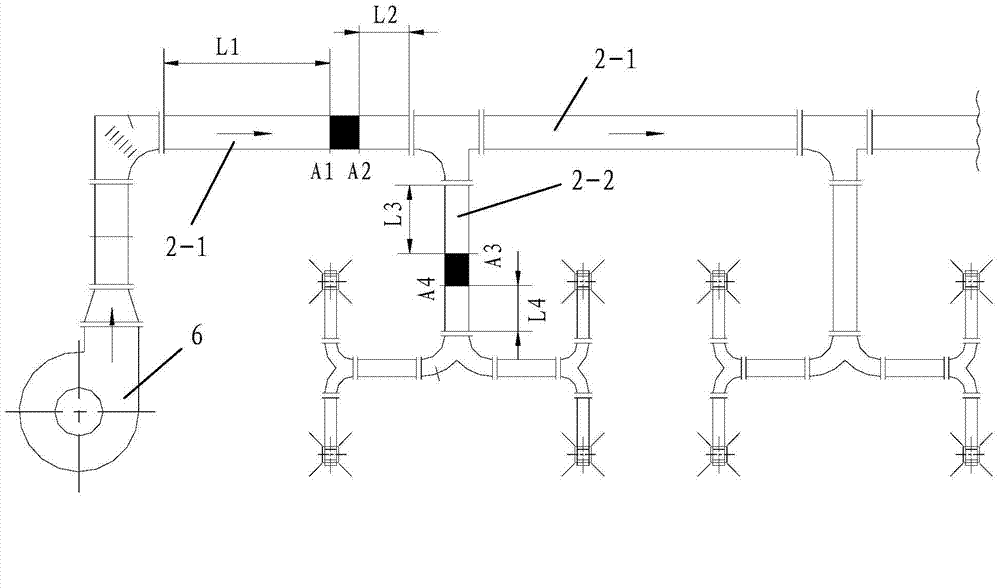

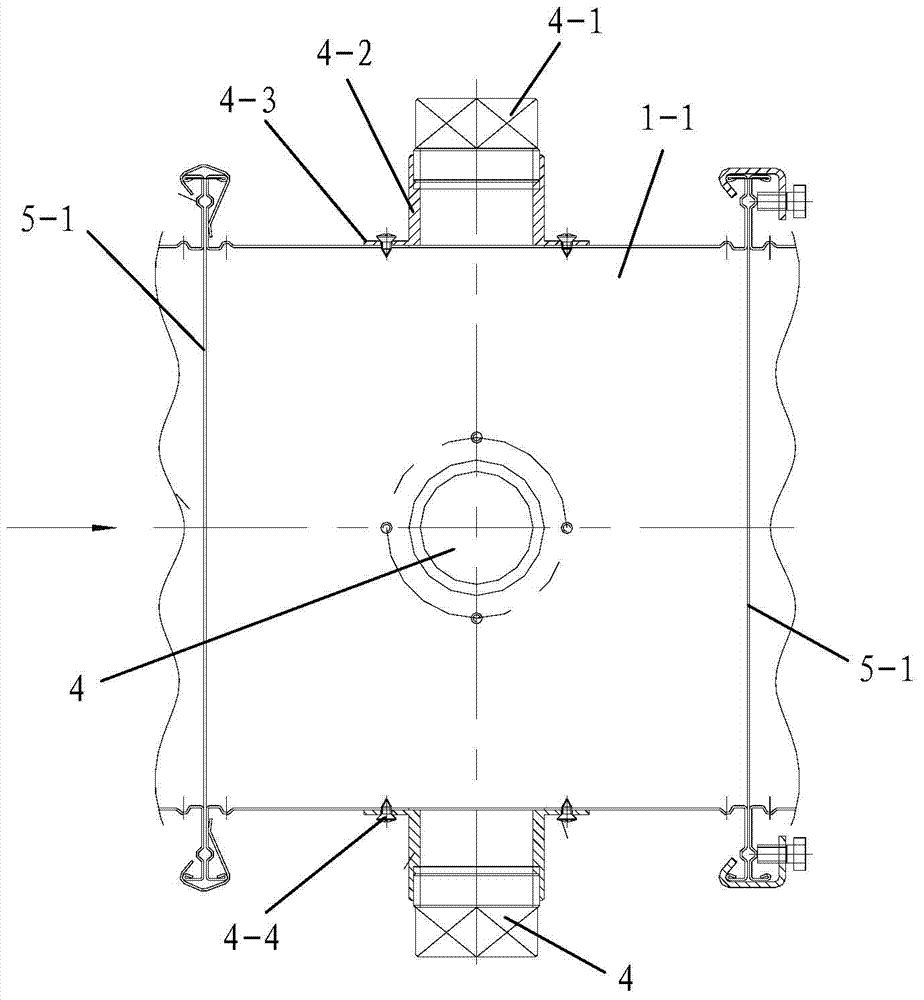

[0065] like figure 1 Shown is a ventilation and air conditioning system performance test with a measuring hole opening method, a ventilation and air conditioning system performance test with a measurement hole opening method, the air duct of the tested ventilation and air conditioning system is the air duct to be tested, and the air duct to be tested is A metal air duct, a non-metallic air duct or a composite material air duct, characterized in that the method comprises the following steps:

[0066] Step 1. Determining the measurement section and the location of the measurement hole: according to the pre-designed test requirements of the ventilation and air conditioning system to be tested, the number of test sections to be tested on the air duct to be tested, the position of each test section and the location of each test section are determined. The number of measuring holes to be opened and the hole positions of each measuring hole shall be determined separately.

[0067] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com