Rapid assembling type steel box-precast concrete plank bridge structure and construction method thereof

A prefabricated concrete slab and prefabricated concrete technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve problems such as difficult to guarantee construction quality, large construction load, cracking of bridge decks, etc., and achieve rapid prefabricated assembly and on-site construction volume The effect of less and faster construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

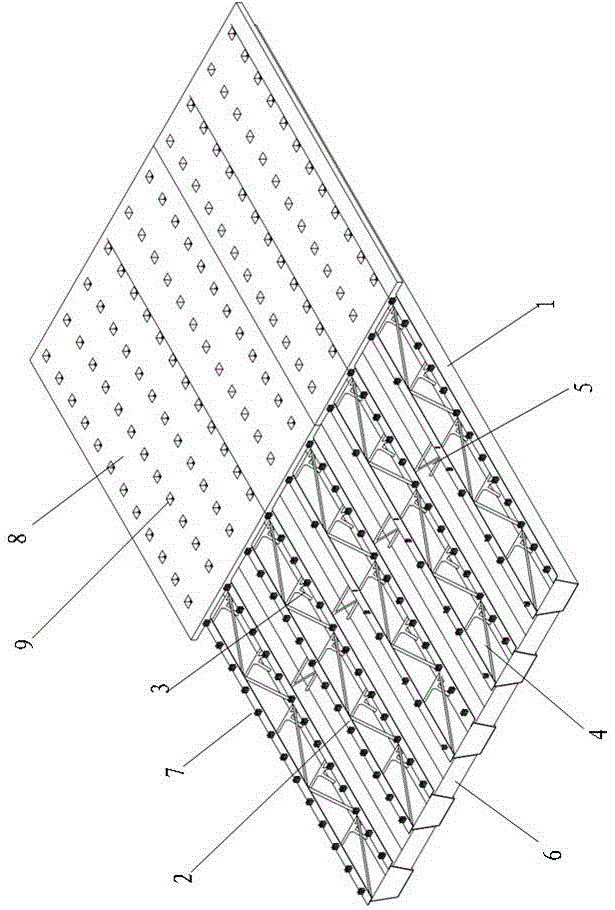

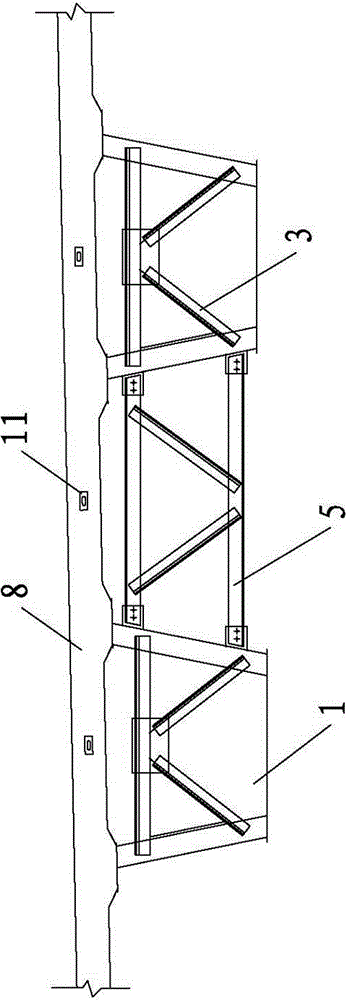

[0028] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a rapidly assembled steel box-prefabricated concrete slab bridge structure, which is composed of several steel box girders 1, prefabricated concrete bridge decks 8, and shear force transfer devices 7.

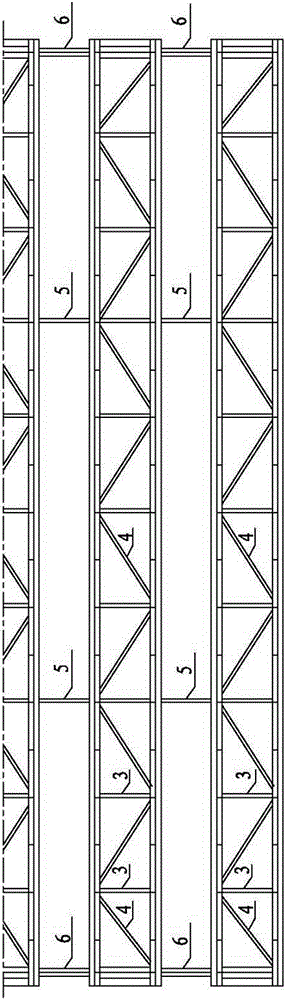

[0029] Wherein, the plurality of steel box girders 1 are arranged at equal intervals, and adjacent steel box girders 1 are connected by truss-type horizontal connections 5 and solid-web type horizontal connections 6 . The solid-belly horizontal connection 6 is located at both ends of the steel box girder 1; the truss-type horizontal connection 5 is located between the solid-web horizontal connection 6; the distance between two adjacent solid-web horizontal connections 6 is 6m; the The truss type horizontal connection 5 and the solid web type horizontal connection 6 are connected with the steel box girder 1 by high-strength bolts.

[0030] Further, upper flanges 2 are arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com