Cold/heat source integrated unit

A cold and heat source, integrated technology, applied in the direction of refrigerators, heating and cooling combinations, compressors with multiple condensers, etc., can solve the problems of low energy consumption, difficult building energy consumption, etc., to improve control quality and reduce waste heat Or waste cold discharge, improve the effect of machine dew point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

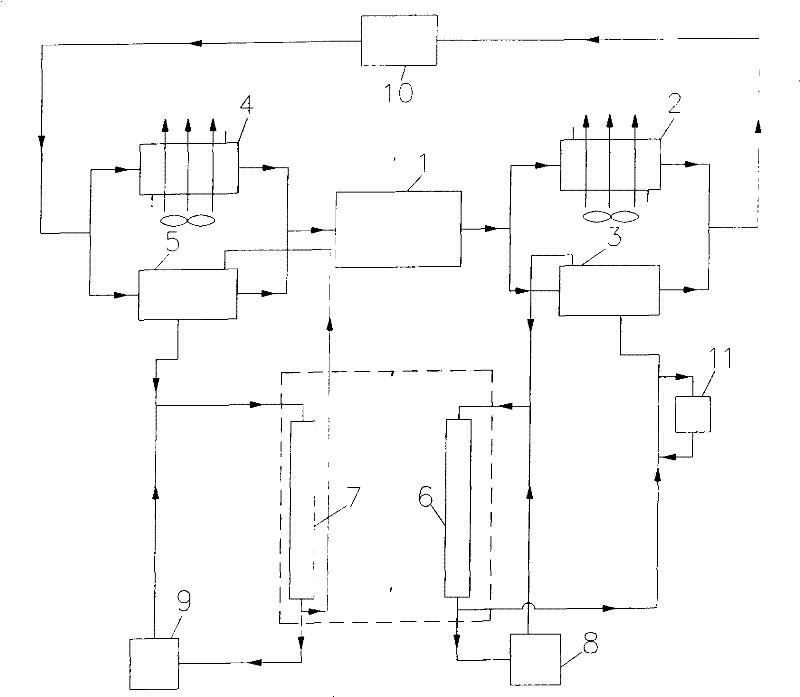

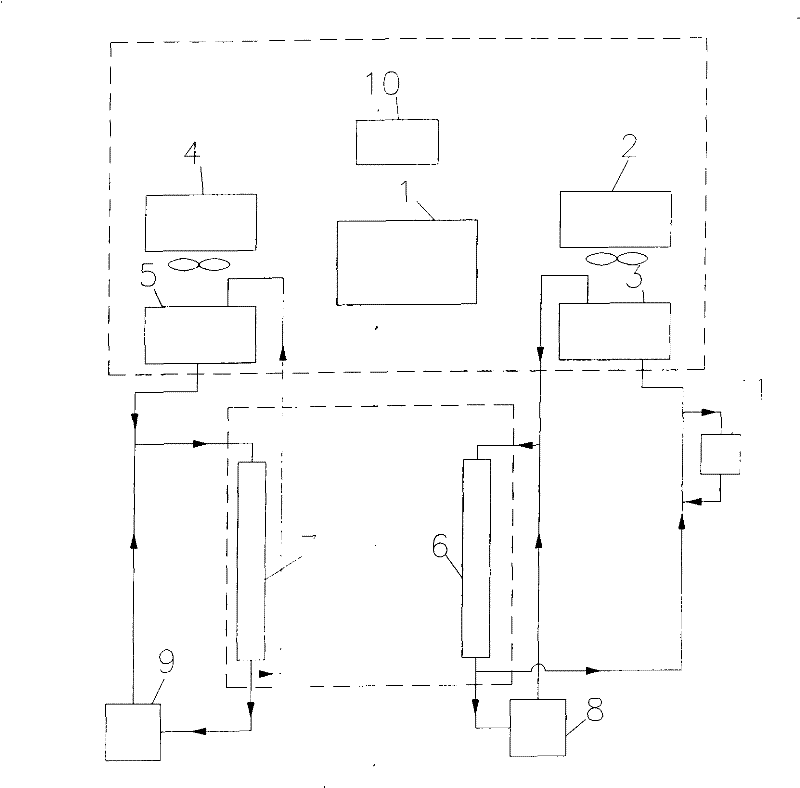

[0036] Example 1: Places of cold and heat sources and their systems in hospital buildings

[0037] The cold and heat source integrated unit of the present invention is particularly suitable for hospital buildings. Modern hospitals require environmental control of the entire building, requiring a large amount of air-conditioned chilled water and hot water. Now, the amount of steam required for sterilization is less and less, and the quality requirements are getting higher and higher. High-quality steam is often supplied by sterilization on site, no longer by the steam system.

[0038] The cold and heat source integrated unit of the present invention replaces the large chiller and the boiler, and becomes the centralized cold and heat source of the hospital, which is installed on the roof. Through the pipeline well, the hot side of the integrated cold and heat source unit is connected to the heating system, and the cold side is connected to the chilled water system, which provi...

Embodiment 2

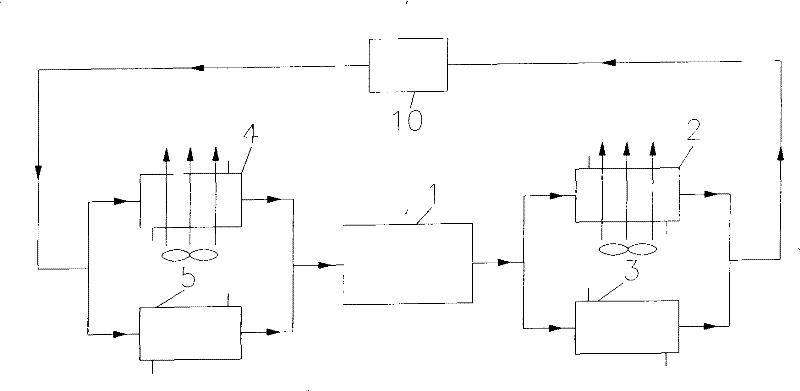

[0041] Example 2: Locations of cold and heat sources and their systems in hotel buildings

[0042] The integrated cooling and heating unit is also suitable for large hotel buildings. The cold and heat source integrated unit replaces the large chiller and boiler, and becomes the centralized cold and heat source of the hotel building, which is installed on the roof. Through the pipeline well, the hot side of the integrated cold and heat source unit is connected to the heating system, and the cold side is connected to the chilled water system, which provides both heating and cooling throughout the year, which is called a four-pipeline system. The cold and heat source integrated unit supplies 7°C chilled water that can meet the needs of air conditioning throughout the year, and can also provide a large amount of 55°C hot water for bathing. In addition to the need for a large amount of hot water for bathing, hotel buildings are becoming larger and larger like modern public buildin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com