White smoke plume elimination system based on upper spraying and upper air inlet spray tower

A technology of elimination system and spray tower, which is applied in the direction of gaseous effluent wastewater treatment, water/sludge/sewage treatment, and the use of liquid separating agent, etc. It can solve problems such as limited dehumidification and whitening effect, equipment corrosion, and flue gas leakage. , to achieve significant water and energy saving effects, reduce anti-corrosion requirements, and enhance heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

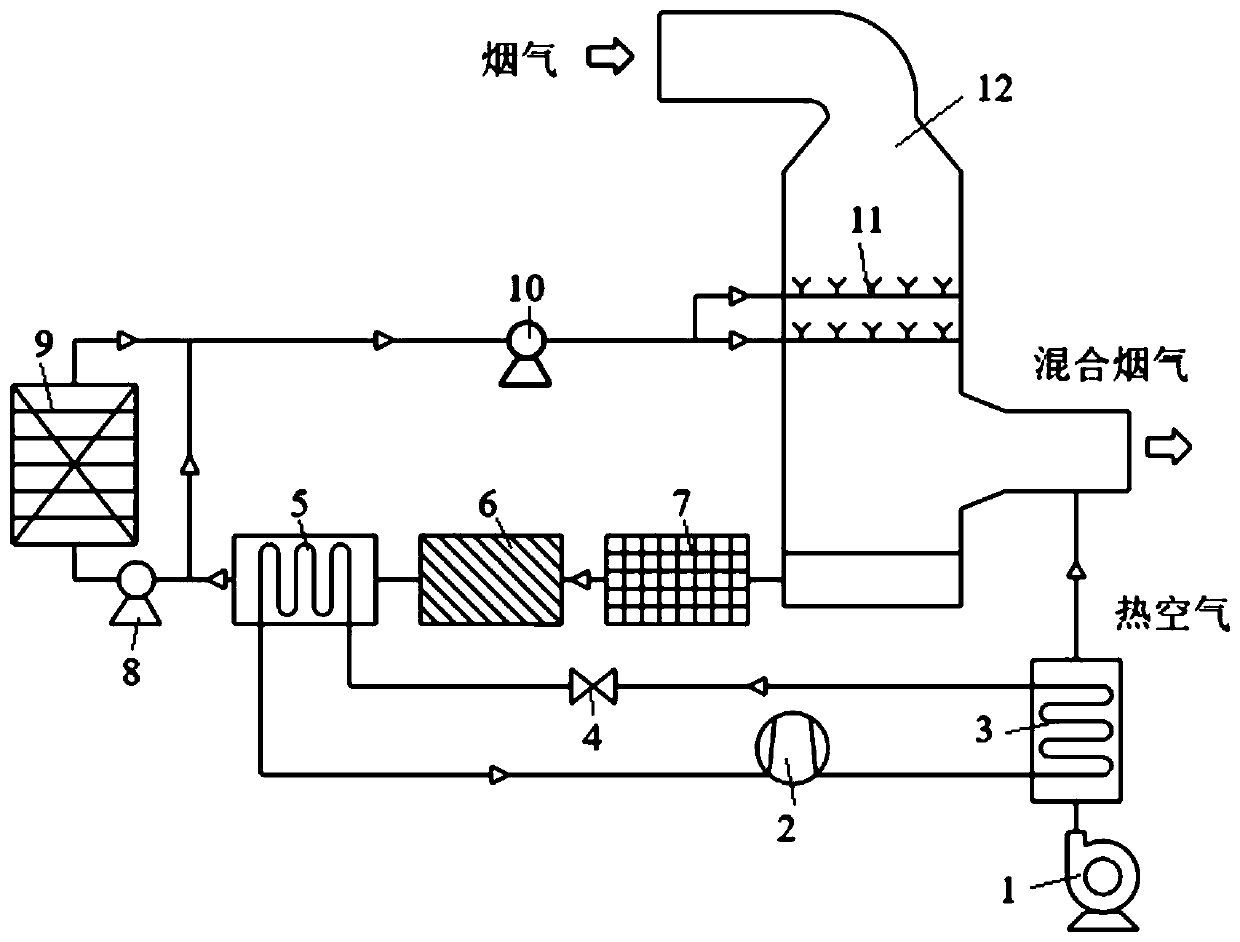

[0015] Such as figure 1 As shown, the white smoke plume elimination system based on upper spraying and upper intake spray tower of the present invention mainly includes fan 1, compressor 2, condenser 3, throttle valve 4, evaporator 5, dosing pool 6, filter Pool 7, first water pump 8, water storage tank 9, second water pump 10, nozzle 11, spray tower 12 and other components, as well as corresponding connecting pipes and control components.

[0016] A spray layer composed of a plurality of nozzles (11) and a second water pump 10 form a water spray subsystem; a filter pool 7 and a dosing pool 6 are connected to form a water treatment subsystem; a compressor 2, an evaporator 5, a throttle valve 4, The condensers 3 are connected in series to form a heat pump subsystem; the water storage tank 9, the first water pump 8 and connecting pipes form a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com