Phosphate preparation equipment and preparation method thereof

A phosphate ester and equipment technology, which is applied in the field of phosphate ester preparation equipment and its preparation, can solve the problems of affecting the reaction conversion rate, increasing the cost of neutralization alkali, and unfavorable phosphate ester production, so as to reduce the generation of side reactions and improve the recovery rate , to meet the effect of large-scale continuous industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

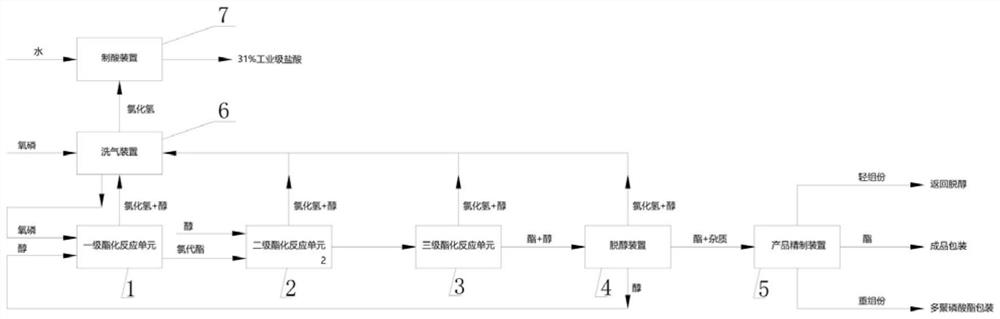

[0061] Utilize the method for preparing the tributyl phosphate preparation equipment of the present embodiment of claim 1, comprising the following steps:

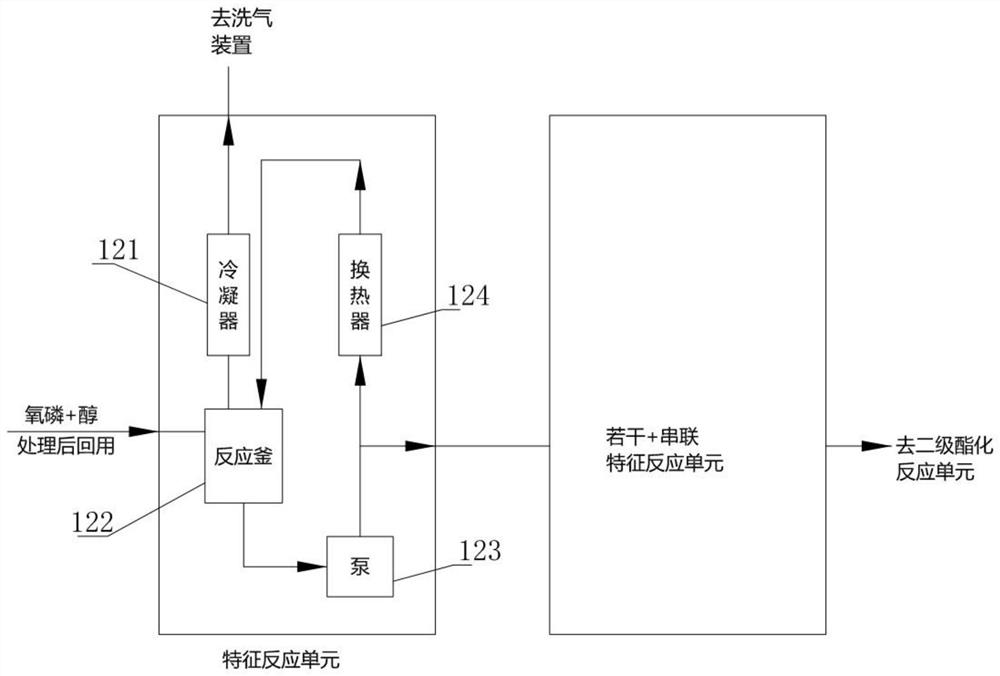

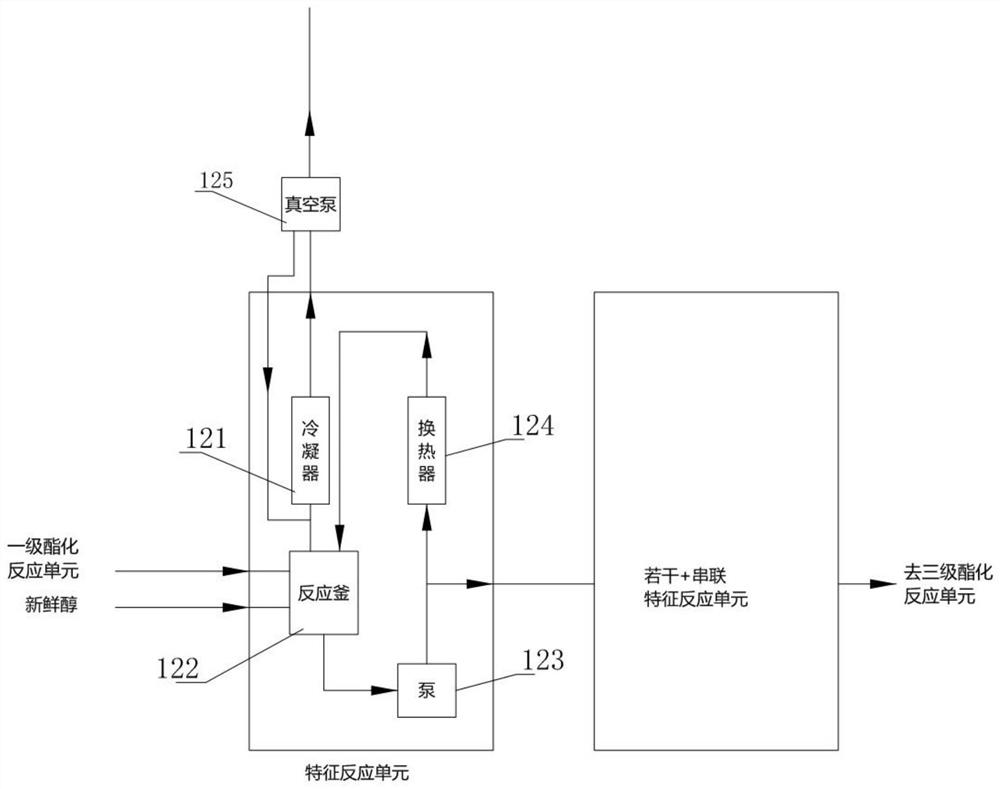

[0062] Such as figure 2 As shown, the first step: primary esterification: the content of phosphorus trichloride is 0.5% phosphorus oxychloride with a flow rate of 0.23m 3 / h of butanol with a moisture content of 0.3% by weight at a flow rate of 0.45m 3 / h is added in the reactor 122 of primary esterification unit together, and this reactor 122 can be made up of a two-party reactor, two five-party reactors in series and make above-mentioned phosphorus oxychloride and butanol continuous reaction, pump 123 Use any one of the multi-stage series transfer pump or the potential difference to realize the continuous delivery of the esterification reactant, and each of the above-mentioned reactors is equipped with a first condenser 121 (in the figure, only the reactor 122 is equipped for illustration) The first condenser 121), un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com