Combined extraction method for arsenic in high-arsenic manganese ore tailings

A high-arsenic manganese ore and combined extraction technology, which is applied in the direction of improving process efficiency, can solve the problems of not finding open documents, etc., and achieve good economic benefits, saving and protecting the environment, and saving production water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

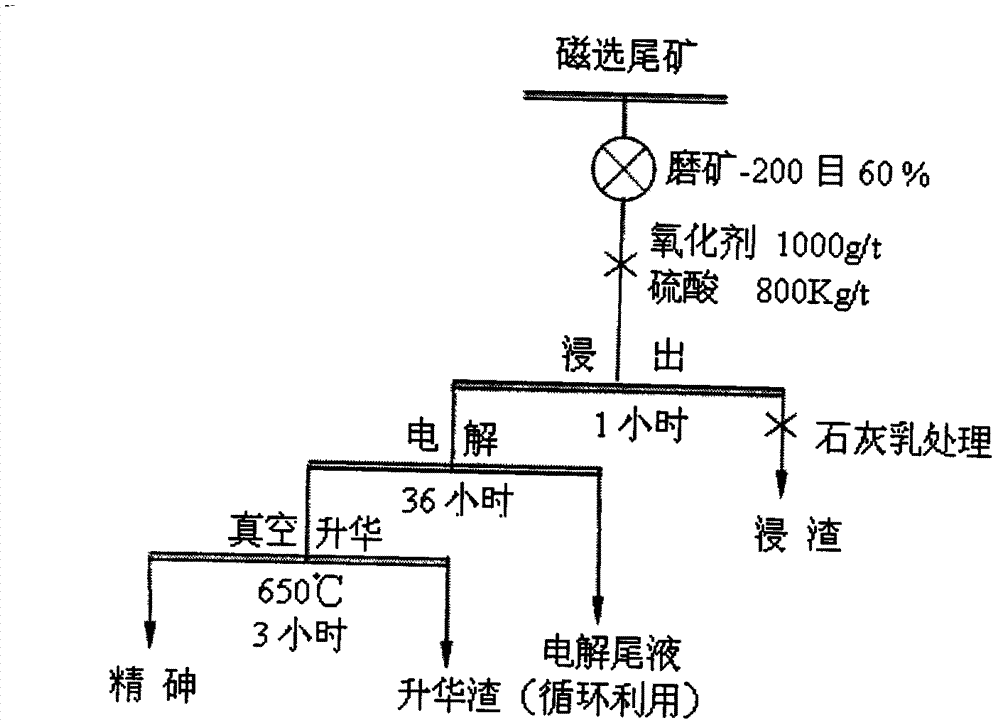

Image

Examples

Embodiment 1

[0026] The Algerian high-arsenic manganese ore tailings raw material with a grade weight of 10.2% was ground with a ball mill, and the particle size of 60% of the weight was controlled to be -200 mesh, and put into the leaching equipment. Sulfuric acid weight 0.8t / t, oxidant H 2 o 2 The dosage weight is 1Kg / t, the leaching time is 1 hour, and the arsenic grade weight in the leaching residue is controlled to be ≤0.5%. The arsenic leaching solution is used for electrolysis, and the leaching residue is treated and discharged with milk of lime. The arsenic leaching solution is put into the electrolysis equipment for electrolytic reduction. The electrolysis uses a graphite plate anode and a titanium plate cathode. The electrolysis time is 36 hours and the plate area is 15m2. 2 / m 3 , the distance between the plates is 15mm, and the current density is 500A / m 2 , control the weight of arsenic in the electrolytic crude arsenic product to 25.8%, and the electrolytic recovery rate r...

Embodiment 2

[0028] Grind the high-arsenic manganese ore tailings raw material with a grade weight of 9.6% with a ball mill to control the particle size of 60% of the weight to -200 mesh, put it into the leaching equipment, prepare the pulp with a weight concentration of 60%, and use sulfuric acid with a weight concentration of 98% Weight 0.8t / t, oxidant H 2 o 2 The dosage weight is 0.95Kg / t, the leaching time is 1.2 hours, and the weight of arsenic grade in the leaching residue is controlled to be ≤0.5%. The arsenic leaching solution is used for electrolysis, and the leaching residue is treated and discharged with milk of lime. The arsenic leaching solution is put into the electrolytic equipment for electrolytic reduction. The electrolysis uses graphite plate anode, titanium plate cathode, and the plate area is 15m 2 / m 3 , the distance between the plates is 15mm, and the current density is 480A / m 2 , The electrolysis time is 35 hours, the weight of arsenic in the electrolytic crude a...

Embodiment 3

[0030] Grind the Algerian high-arsenic manganese ore tailings raw material with a grade weight of 10.5% with a ball mill, and control the particle size of 60% of the weight to be -200 mesh, and put it into the anti-corrosion leaching equipment. The weight concentration of the prepared pulp is 40%, and the weight concentration is 98%. The sulfuric acid is 0.8t / t, the oxidant H 2 o 2 The dosage weight is 1.1Kg / t, the leaching time is 1.5 hours, and the arsenic grade weight in the leaching residue is controlled to be ≤0.5%. The arsenic leaching solution is used for electrolysis, and the leaching residue is treated and discharged with milk of lime. Put the arsenic leaching solution into the electrolytic cell equipment for electrolytic reduction. The electrolysis uses graphite plate anode, titanium plate cathode, and the plate area is 15m 2 / m 3 , the distance between the plates is 15mm, and the current density is 525A / m 2 , The electrolysis time is 35 hours, the arsenic conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com