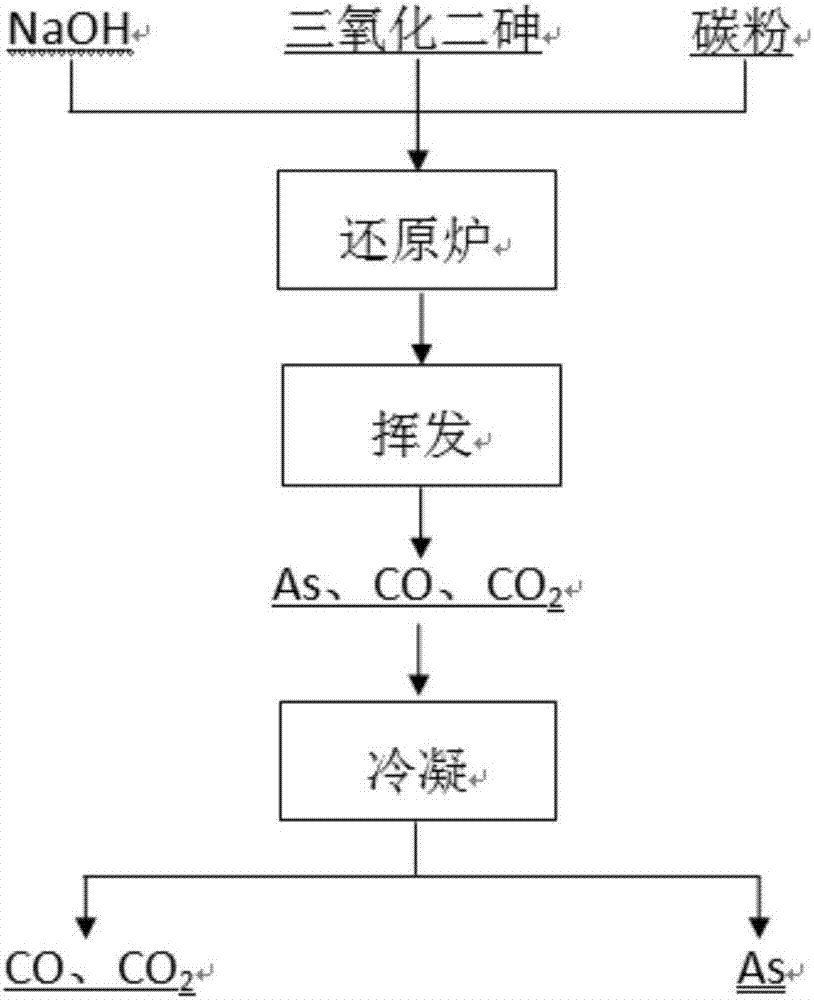

Method for preparing metallic arsenic through As2O3 reduction

A metal arsenic and as2o3 technology, applied in the field of non-ferrous metal metallurgy, can solve the problems of potential safety hazards, low product purity, easy oxidation of arsenic vapor, etc., and achieve the effect of simple steps, strong operability, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 50kgAs 2 o 3 Mix the powder with carbon powder (the amount of carbon powder added is 20% of the mass of the raw material) and NaOH powder (1.5 times the theoretical amount of carbon dioxide generated) and put it into a closed reaction furnace, heat up to 700°C and maintain a reducing environment for 4 hours Finally, stop heating, and after the reduction, open the outlet valve to volatilize the arsenic vapor and condense it in the condenser to obtain metallic arsenic, the purity of which is >99% after testing, and the yield of arsenic reaches 95.62%.

Embodiment 2

[0023] Take 50kgAs 2 o 3 Mix the powder with carbon powder (the addition of wood carbon powder is 15% of the raw material mass) and NaOH powder (2 times the theoretical amount of carbon dioxide generated) and put it into a closed reaction furnace, heat up to 1000 ° C and maintain a reducing environment 2 Stop heating after 1 hour, and after the reduction, open the outlet valve to volatilize the arsenic vapor and condense it in the condenser to obtain metallic arsenic. The purity is >99% after testing, and the yield of arsenic reaches 96.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com