Preparation method of tert-butyl arsenic

A technology of tert-butyl arsenic dichloride and tert-butyl, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, magnesium organic compounds, etc., can solve the problem of high cost and transportation of tert-butyl arsine Difficulty, poor safety and other problems, to achieve the effect of reducing the burden of purification, improving reaction efficiency, and reducing the burden of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

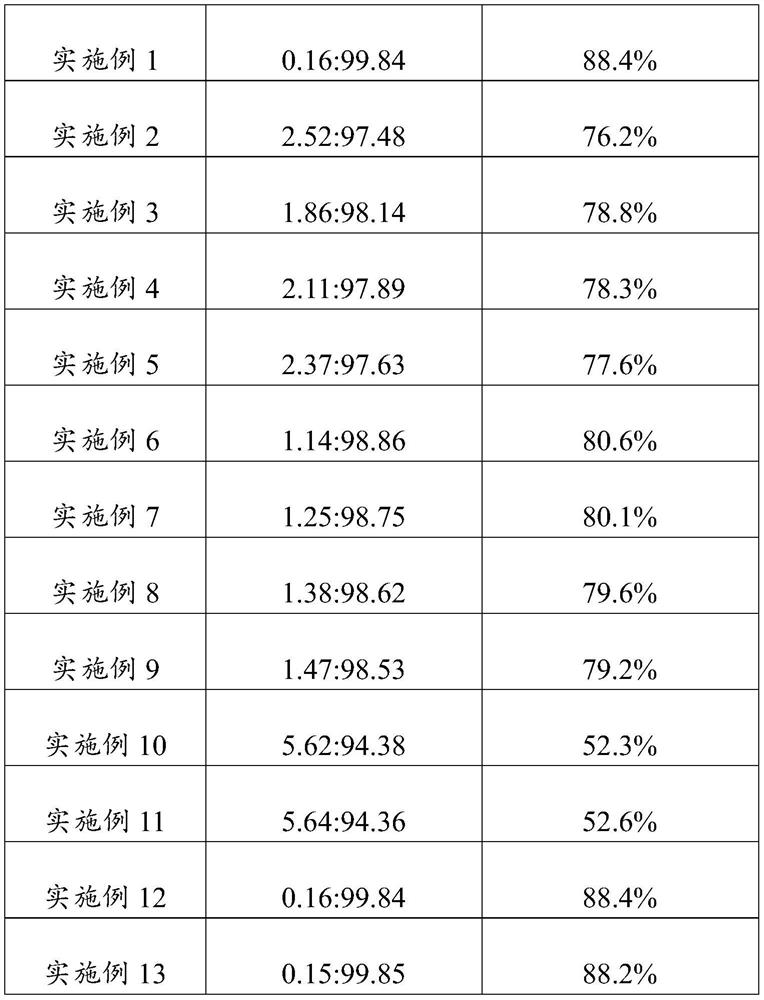

[0030] The present invention provides a kind of preparation method of tert-butyl arsenic, described method comprises the following steps:

[0031] (1) Under the protection of an inert gas, magnesium and tert-butyl chloride react at 60°C to 80°C to generate tert-butylmagnesium chloride, and the reaction between magnesium and tert-butyl chloride is carried out under the condition of an initiator, and the initiator is Organic aluminum or inorganic aluminum, the weight ratio of the initiator to magnesium is (3-7):100, and the mass ratio of magnesium to tert-butyl chloride is 1.02:1-1.05:1;

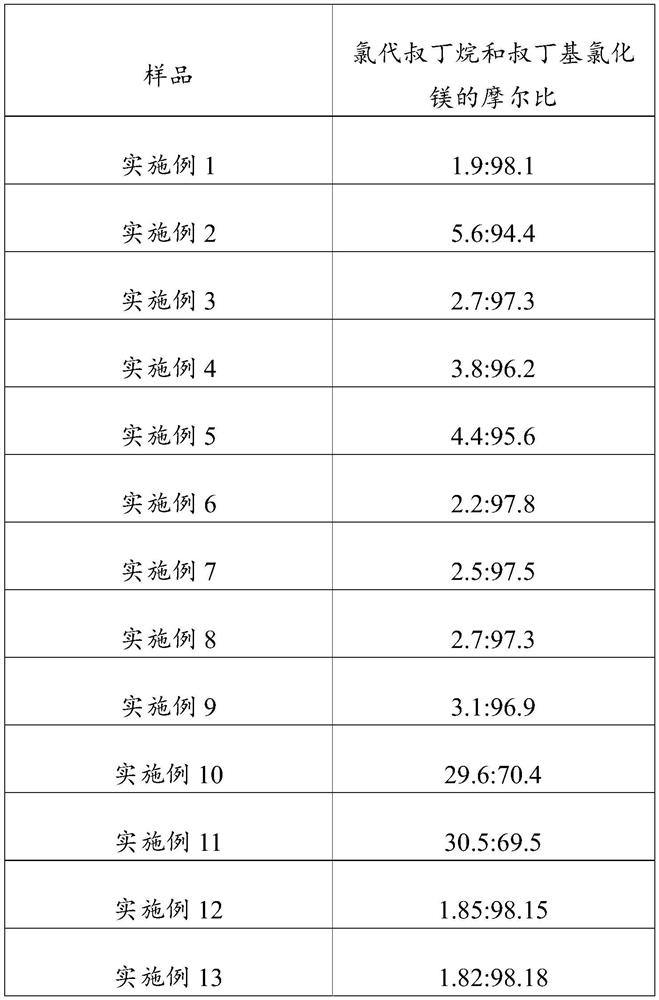

[0032] (2) After arsenic trichloride and the tert-butylmagnesium chloride obtained in step (1) are stirred and reacted below 10°C, tert-butyl arsenic dichloride is obtained; the arsenic trichloride and the tert-butyl magnesium chloride obtained in step (1) The molar ratio of the base magnesium chloride is 0.5:1~0.9:1;

[0033] (3) The tert-butyl arsenic dichloride obtained in step (2) and the...

Embodiment 1

[0036] A kind of preparation method of tert-butyl arsenic as the embodiment of the present invention, described method comprises the following steps:

[0037] (1) Mix 35.1g magnesium bars, 450mL diethylene glycol dibutyl ether, and 1.76g aluminum chloride tetrahydrofuran complex to obtain reaction system B, remove the oxygen in reaction system B, and under nitrogen protection, react system B Heat to 75°C, add tert-chlorobutane solution dropwise to the stirred reaction system B with a constant pressure funnel, the chloro-tert-butane solution consists of 148mL chloro-tert-butane and 150mL diethylene glycol dibutyl Ether composition, insulated and stirred for 1.5 hours to obtain tert-butylmagnesium chloride, cooled to room temperature;

[0038] (2) Dissolve 180g of arsenic trichloride in 150mL of diethylene glycol dibutyl ether to obtain a reaction system C, cool the reaction system C to -10°C, keep the reaction system C in a stirring state, and drop it into the reaction system C...

Embodiment 2

[0042] As a preparation method of tert-butylarsenic in the embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the initiator is anhydrous aluminum trichloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com