Patents

Literature

47 results about "Arsenic trichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arsenic trichloride is an inorganic compound with the formula AsCl₃, also known as arsenous chloride or butter of arsenic. This poisonous oil is colourless, although impure samples may appear yellow. It is an intermediate in the manufacture of organoarsenic compounds.

Method for deep roasting arsenic removal of arsenic-containing material

ActiveCN106222398AHigh removal rateSimple processRotary drum furnacesCrucible furnacesReducing atmosphereArsenic trichloride

The invention discloses a method for deep roasting arsenic removal of an arsenic-containing material, and belongs to the technical field of non-ferrous metallurgy. The fine grinded arsenic-containing material is evenly mixed with a proper quantity of chlorinating agents and water, pelletizing is carried out to obtain pellets, then the pellets are fed into a roasting furnace after being dried, roasting is carried out by controlling the atmosphere in the furnace, and roasted ore with the arsenic content being lower than or equal to 0.1% is obtained. According to the method, chloride such as calcium chloride, sodium chloride and magnesium chloride serves as roasting arsenic removal flux, roasting is carried out in a weak oxidation atmosphere or a weak reduction atmosphere, arsenic is converted into the form of arsenic chloride easy to volatilize so as to be removed from the arsenic -containing material, the process is simple, the arsenic removal rate is high, and the quality of the roasted ore is good.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

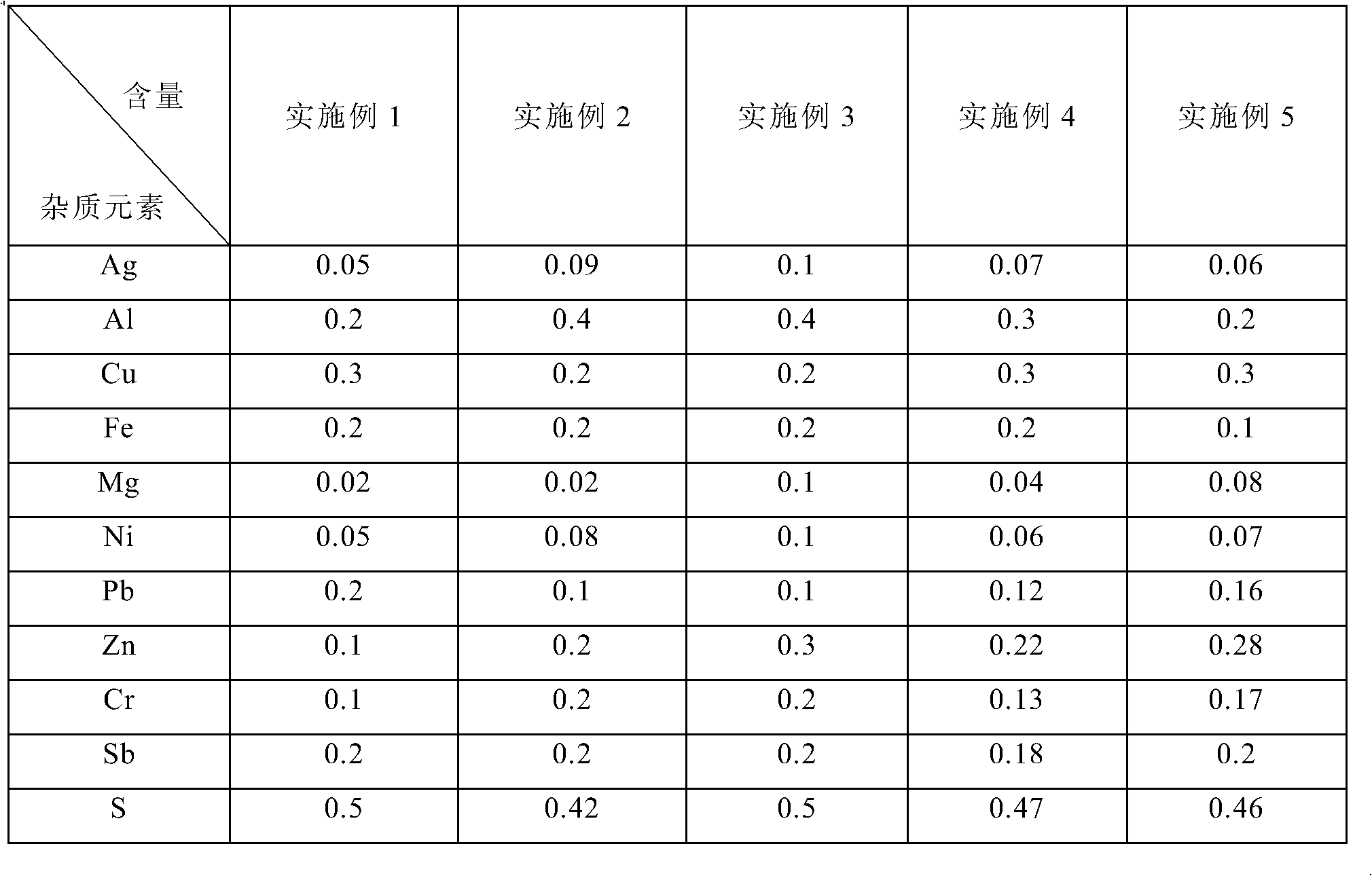

Preparation method of high-purity arsenic

The invention provides a preparation method of high-purity arsenic. The method comprises the steps that: an arsenic raw material is placed in a sublimation furnace; under a certain vacuum degree and a certain sublimation temperature, arsenic is sublimated; the sublimated arsenic vapor is condensed under a condensation temperature, such that purified arsenic is obtained; the purified arsenic is placed into a chlorination furnace; chlorine gas is delivered in, and the temperature is increased; purified arsenic is subjected to a reaction with chlorine gas, such that arsenic trichloride is produced; arsenic trichloride is delivered into a dechlorination tower; the temperature is increased, and arsenic trichloride is evaporated; the evaporated arsenic trichloride passes through a temperature-maintaining section of the dechlorination tower, such that impurity-removed arsenic trichloride is obtained; the impurity-removed arsenic trichloride is delivered into a rectification kettle; the evaporated arsenic trichloride passes through a temperature-maintaining section of the rectification kettle, such that purified arsenic trichloride is obtained; the purified arsenic trichloride is delivered into a reduction furnace; hydrogen is delivered in and the temperature is increased by heating, such that reduced arsenic is obtained; the reduced arsenic is delivered into another sublimation furnace, and is sublimated under a given vacuum degree and a given sublimation temperature, such that reduced arsenic vapor is obtained; and the reduced arsenic vapor is then condensed under a given condensation temperature, such that high-purity arsenic is obtained.

Owner:FIRST RARE MATERIALS CO LTD

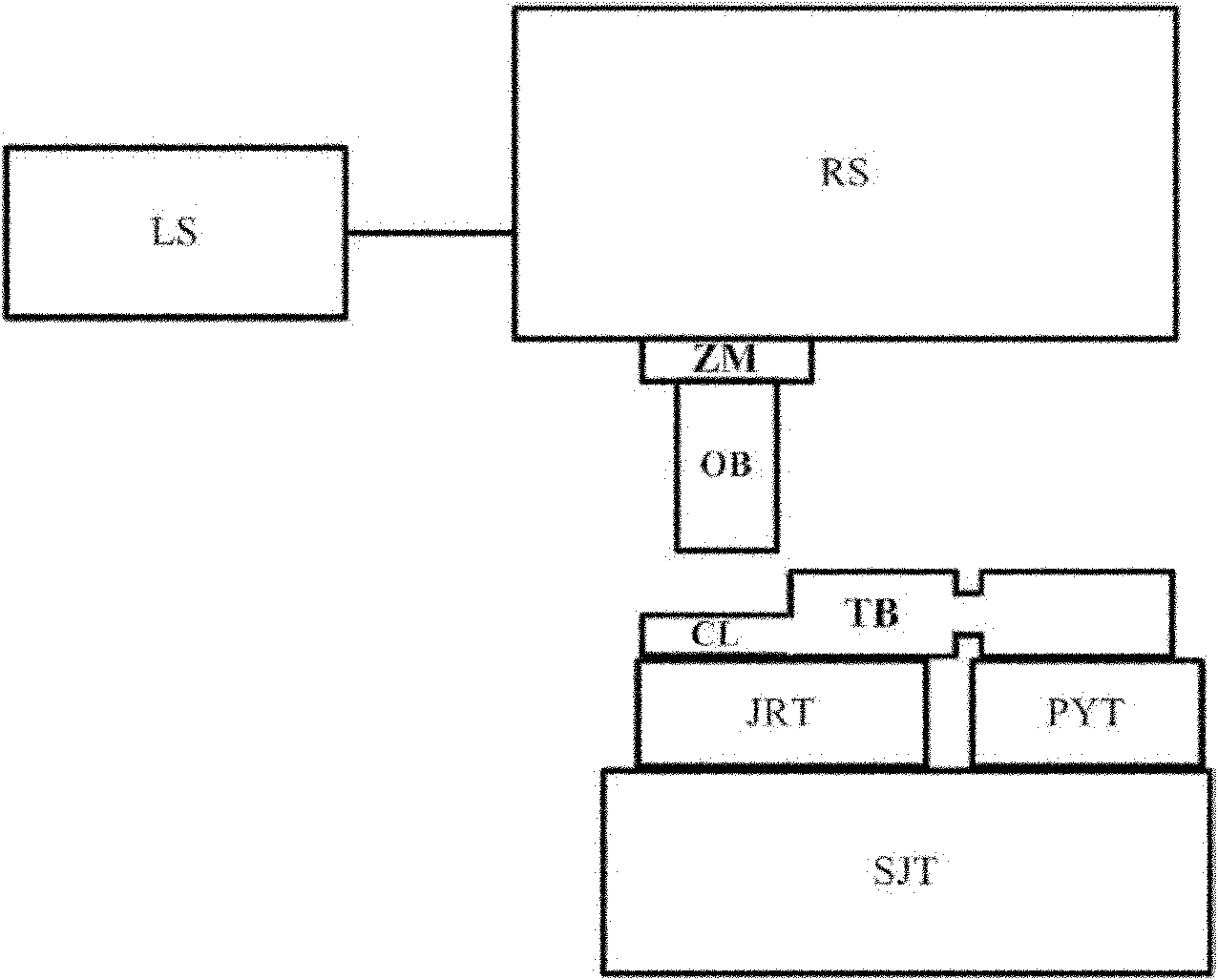

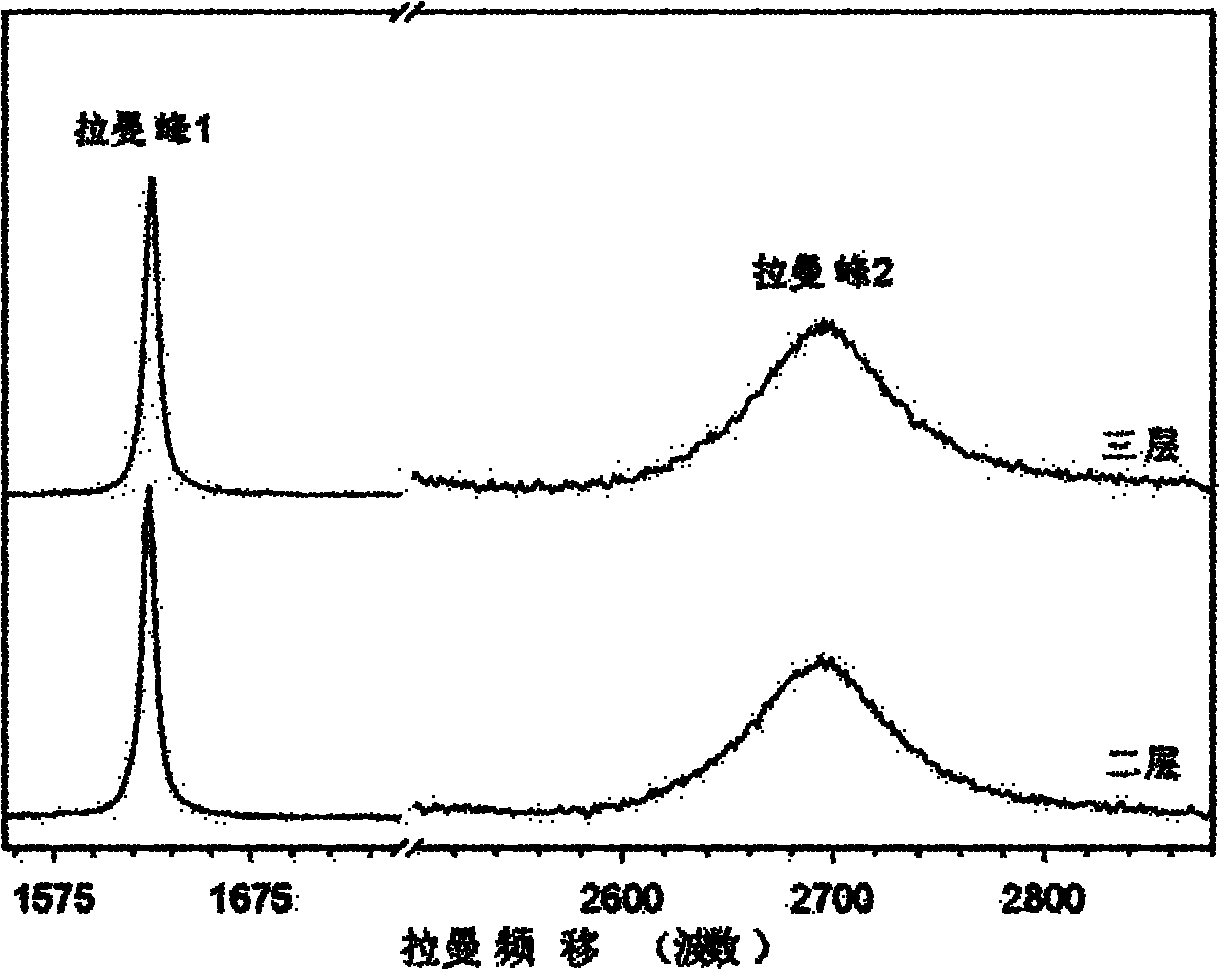

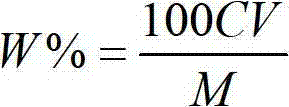

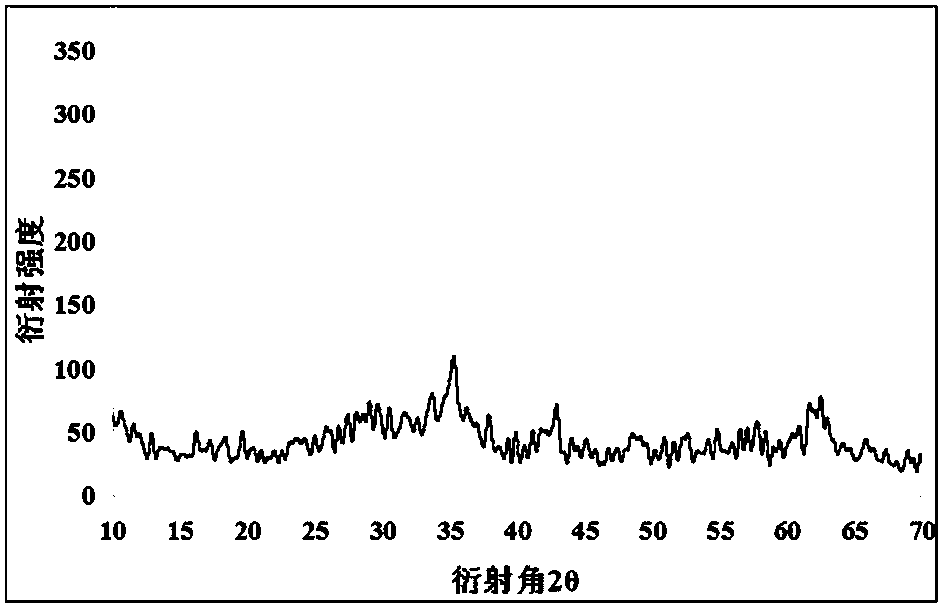

Graphene sheet intercalation compound preparation method and in situ microRaman representation system

InactiveCN102156116AEasy to manufactureCreate pollutionPreparing sample for investigationRaman scatteringCuvetteAlcohol

The invention discloses a graphene sheet intercalation compound preparation method and an in situ micro-Raman representation system. The preparation method comprises the following steps: respectively placing the graphene sheet and ferric trichloride into a glass tube and a cuvette which are connected ang communicated with each other; vacuumizing the glass tube and the cuvette by a molecular pump; sealing the vacuumized glass tube and cuvette by an alcohol lamp; heating to 340 DEG C and keeping the temperature for 6 to 24 hours; and cooling to the normal temperature. The in situ micro-Raman representation system comprises the glass tube and the cuvette which contain the graphene sheet and the ferric trichloride and sealed from the outside and communicated with each other, a laser, a Raman spectrometer, a heating platform, a lifting platform, a translational platform and two scanners. The graphene sheet / ferric trichloride intercalation compound preparation method is simple and practical; and the in situ micro-Raman representation system can be used for in situ representing the micro-Raman spectrum of a graphene / ferric trichloride intercalation compound, and in situ monitoring the formation condition of the graphene / ferric trichloride intercalation compound.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

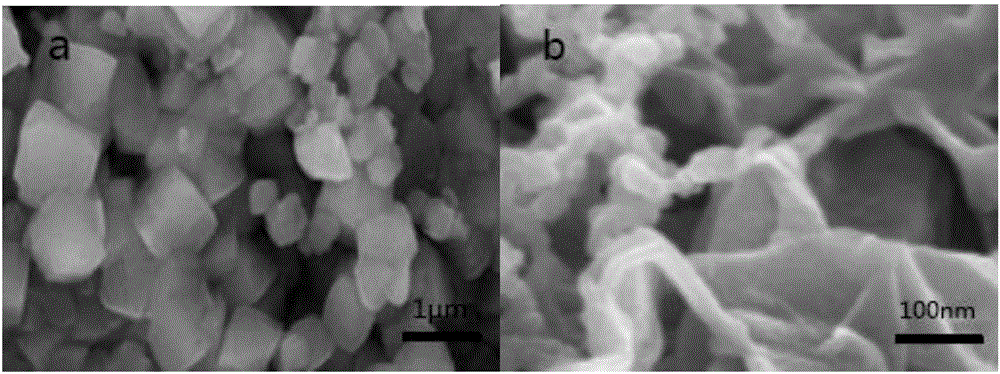

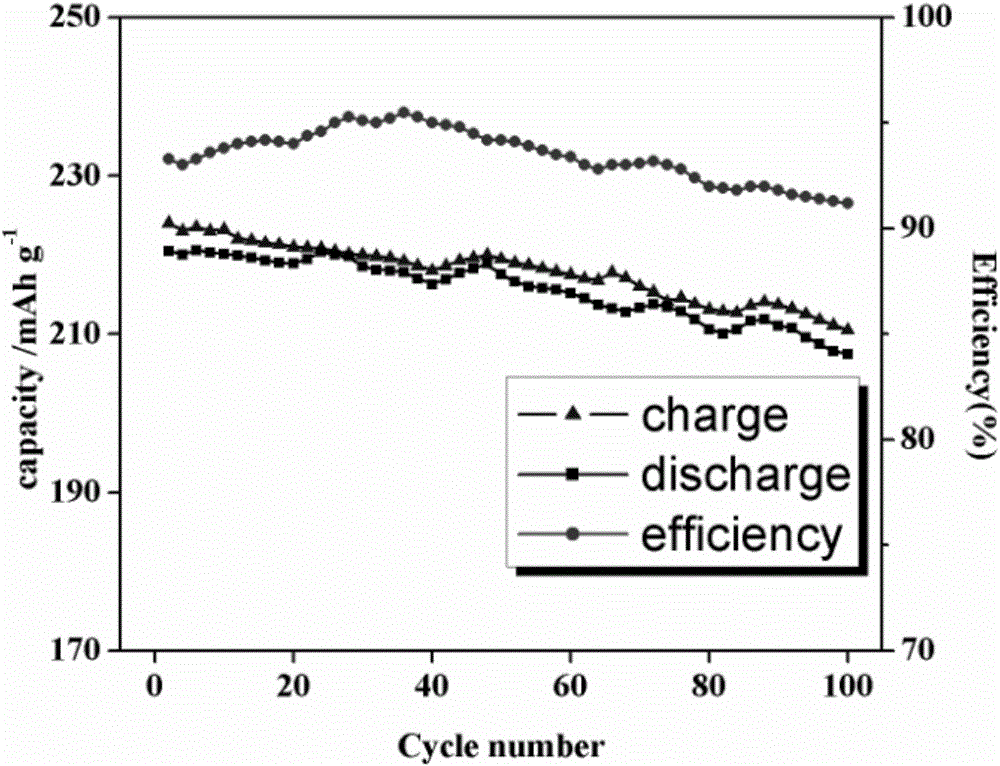

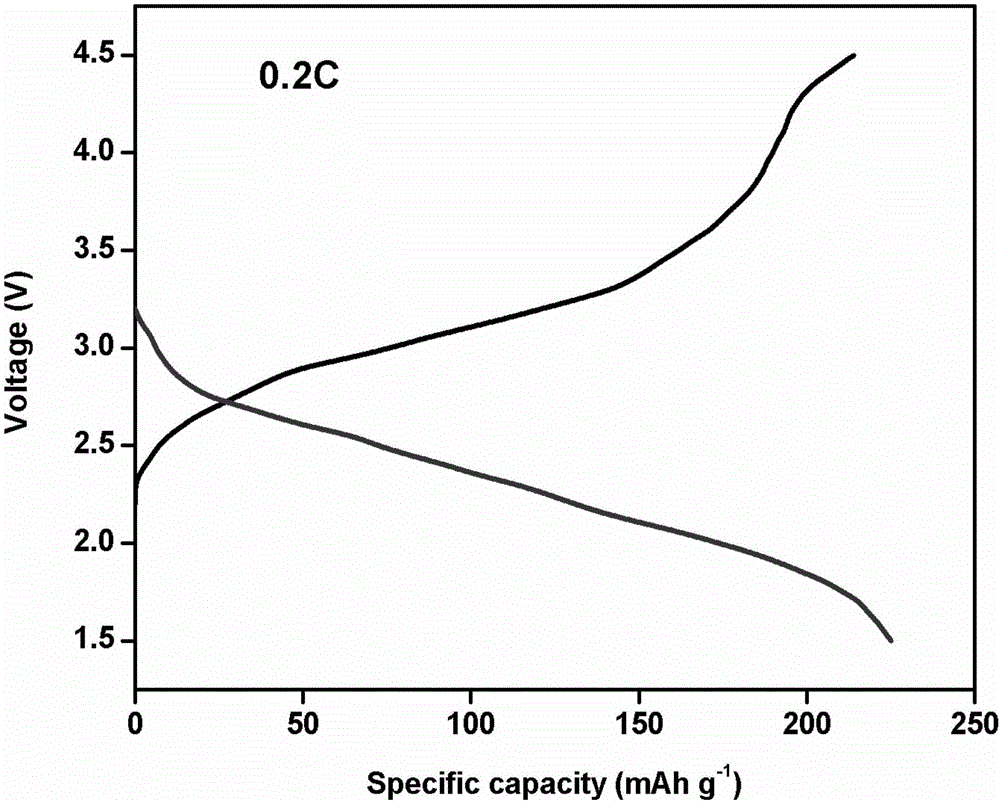

Ferric fluoride/conducting polymer composite material, preparation method thereof and lithium secondary battery

InactiveCN105977448AImprove stabilityIncrease capacityCell electrodesSecondary cellsPolymer scienceIn situ polymerization

The invention provides a ferric fluoride / conducting polymer composite material. The ferric fluoride / conducting polymer composite material comprises ferric fluoride and a conducting polymer compounded to the surface of ferric fluoride. The invention further provides a preparation method of the ferric fluoride / conducting polymer composite material. The preparation method comprises the step of mixing ferric fluoride powder, a ferric trichloride solution, conducting polymer monomers, an anionic surfactant and an organic solvent to react, so as to obtain the ferric fluoride / conducting polymer composite material. Aiming at the problems that ferric trichloride has over-low electronic conductivity and expands along the polarization in charging and discharging processes, ferric trifluoride nanoparticles are coated with the conducting polymer by virtue of in situ polymerization and compounding, so that the polarization phenomenon of a ferric trifluoride material in the charging and discharging processes can be effectively overcome, the stability and capacity of the cathode material can be enhanced, meanwhile, the problem that the conductivity of a ferric trifluoride cathode material is too low can be well solved, and therefore, the electrochemical performance of the ferric trifluoride cathode material is improved.

Owner:GUANGDONG UNIV OF TECH

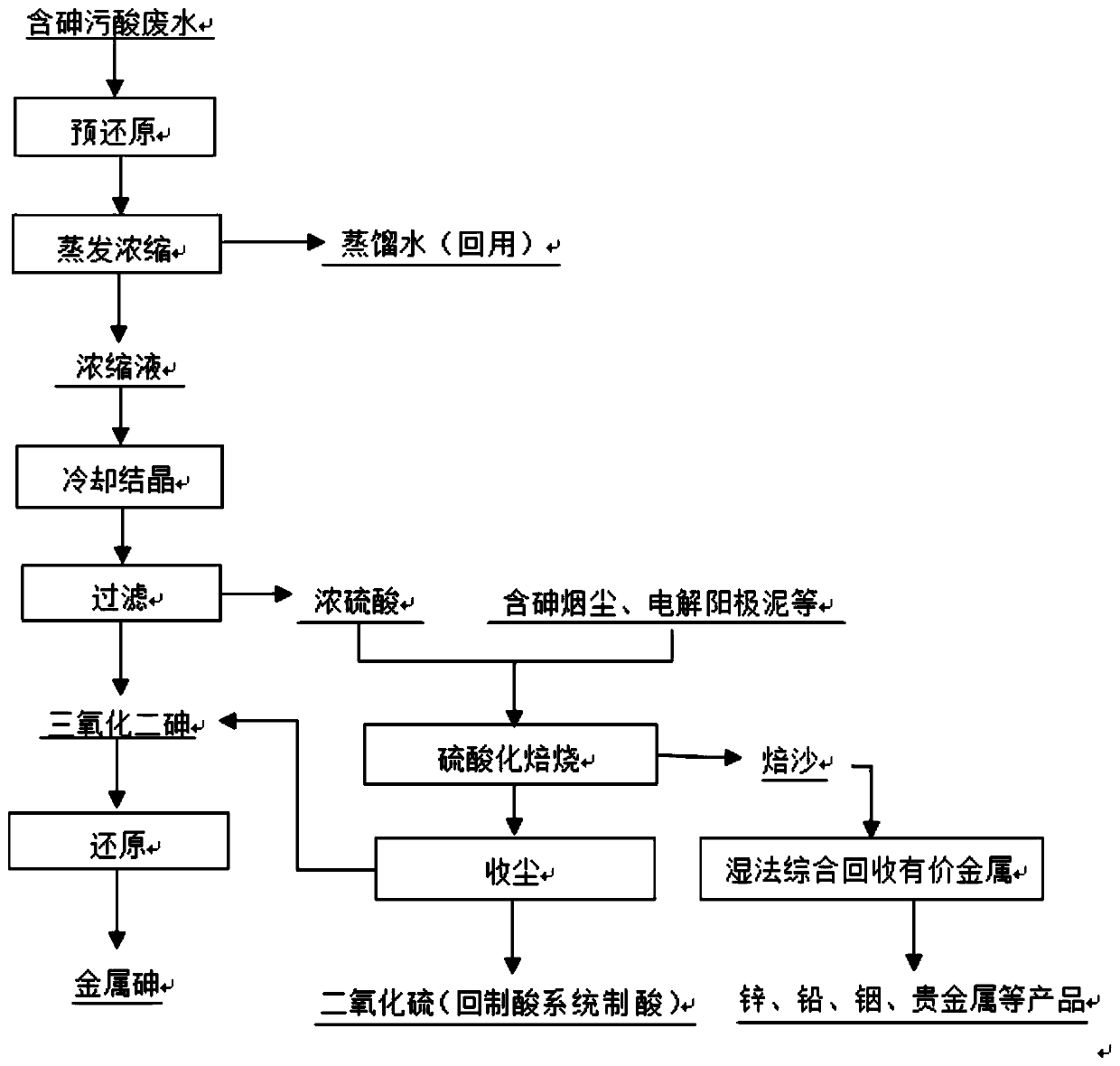

Comprehensive utilization method for arsenic and acid wastewater

InactiveCN109881007AReduce processing costsSolve environmental problemsProcess efficiency improvementArsenic compoundsSlagFiltration

The invention discloses a comprehensive utilization method for arsenic and acid wastewater, Arsenic and acid wastewater generated by nonferrous metallurgy and sulfuric acid industries is used as a process object, prereduction, evaporation and concentration are conducted, after concentrated liquid is cooled, trivalent arsenic is crystallized in the form of arsenic trioxide, through filtration separation and drying, arsenic trioxide is obtained, the evaporating liquid is condensed and reused, filtered concentrated acid and arsenic-containing soot are mixed for briquetting, sulfatizing roasting is conducted, arsenic trioxide in soot is recovered and used as a crude white product or further reduced for preparing metal arsenic with the crystallized arsenic trioxide, generated roasting sand is subjected to wet leaching, and valuable metal is extracted. Waste acid does not need to be neutralized, arsenic-containing waste slag is not generated, waste is controlled through waste, comprehensiverecycling of all elements of valuable components is achieved, meanwhile, the process is short, operation is simple, the treatment cost is low, the economic benefits are considerable, and the problem of acid wastewater treatment in the industry can be solved.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

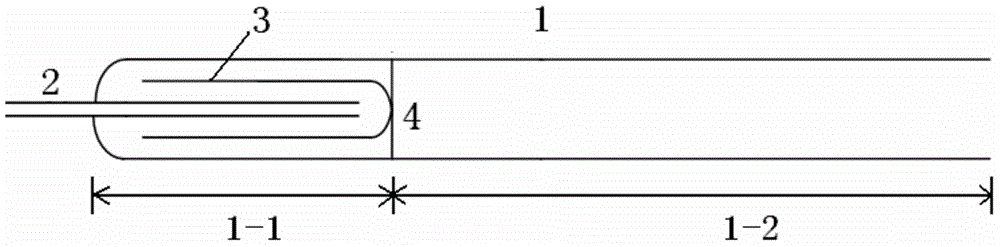

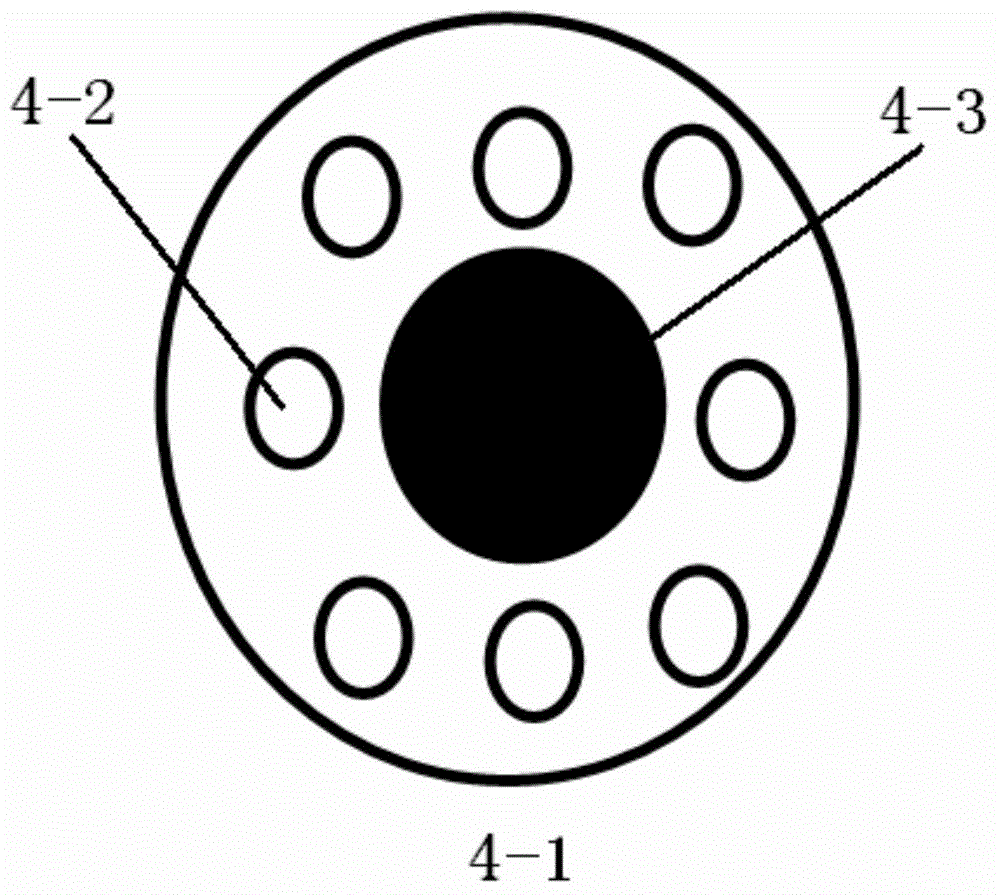

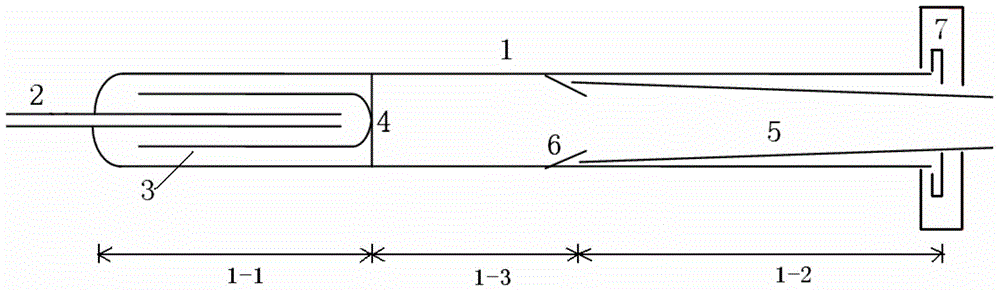

Hydrogenation reduction device for high-purity arsenic production and high-purity arsenic preparing method

The invention belongs to the field of high-purity arsenic and particularly relates to a hydrogenation reduction device for high-purity arsenic production and a high-purity arsenic preparing method. The hydrogenation reduction device for high-purity arsenic production comprises a hydrogenation reduction pipe. A feed pipe is arranged at the feed end of the hydrogenation reduction pipe. A reaction section and a deposition section are arranged inside the hydrogenation reduction pipe in sequence in the airflow advancing direction. A partition board with a hole is arranged at the air outlet end of the reaction section. A return pipe with an opening facing the feed end of the hydrogenation reduction pipe is arranged on the reaction section. The return pipe is fixed to the partition board. The discharge end of the feed pipe stretches into the return pipe. The air outlet end of the deposition section is located at the air outlet end of the hydrogenation reduction pipe. According to the hydrogenation reduction device for high-purity arsenic production, the return pipe is arranged on the reaction section of the hydrogenation reduction pipe, in this way, the contact duration of arsenic trichloride and hydrogen is prolonged, the purity of products is improved, and the yield of the products is increased.

Owner:威科赛乐微电子股份有限公司

Synthesis method of arsenic trichloride

The invention provides a synthesis method of arsenic trichloride. The synthesis method of arsenic trichloride comprises the following steps: S1, adding arsenic trioxide into concentrated hydrochloricacid, starting to stir and enabling the arsenic trioxide and the concentrated hydrochloric acid to react, after reaction is finished, continuing stirring and adding the concentrated hydrochloric aciduntil completely dehydrated, placing reaction liquor in a liquor separating device and standing for layering, and then collecting liquid on the lower layer to obtain coarse arsenic trichloride; and S2, placing the coarse arsenic trichloride in a distilling device, heating for distilling and purifying, and collecting fractions at the temperature of 130-135 DEG C to obtain transparent and clear arsenic trichloride liquid. The synthesis method has the advantages of high purity of products, high synthesis yield, low cost, easiness in control of a process, stable process and low requirement for equipment, and thus, the synthesis method is suitable for large-scale industrial production.

Owner:清远先导材料有限公司

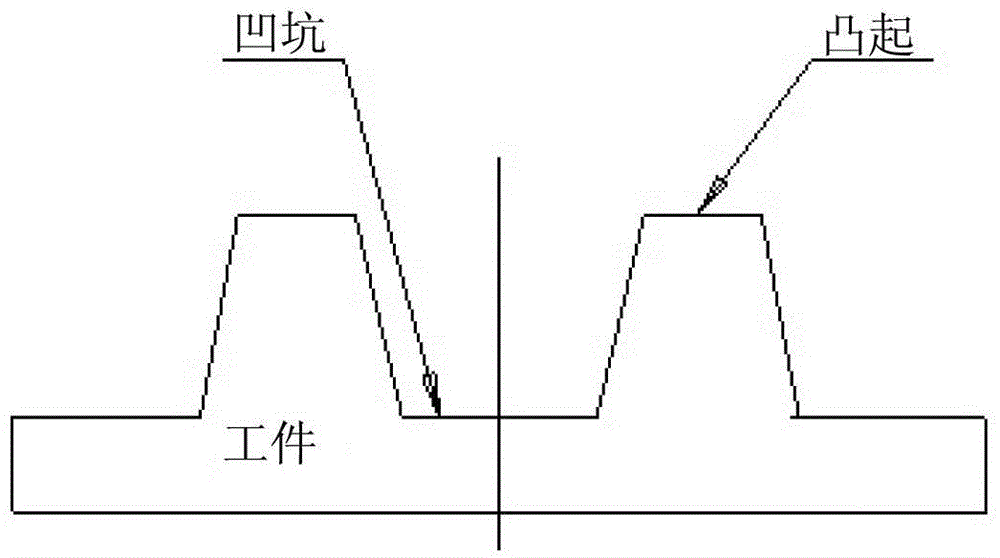

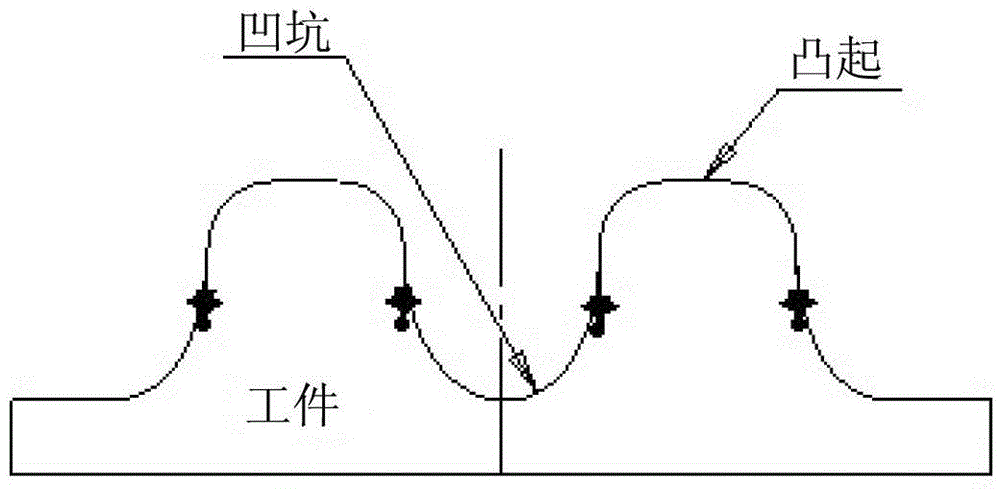

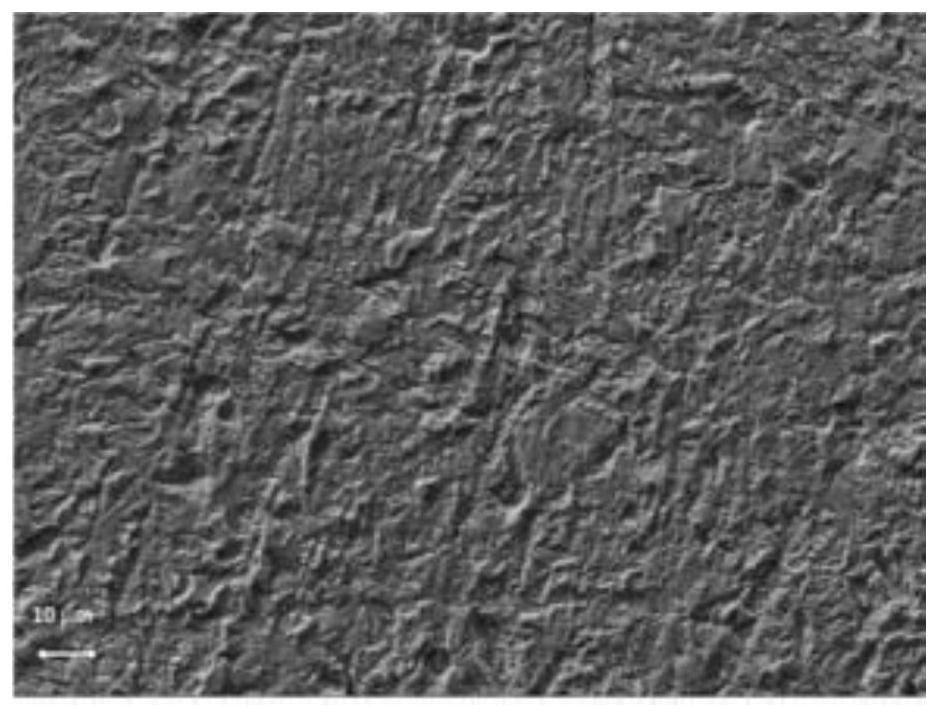

Etching solution

The invention provides an etching solution which is prepared from the following components by weight: 15%-25% of ferric trichloride, 30%-50% of hydrofluoric acid, 2%-5% of phosphoric acid, and the balance being water. Preferably, in the etching solution, on a weight basis, the content of ferric trichloride is 20%-25%, the content of hydrofluoric acid is 35%-50%, the content of phosphoric acid is 2%-3%, and the balance is water. The etching solution of the present invention can realize high etching efficiency and excellent processing effect, and can also form convex-concave fluctuating and smooth transitional surface microstructures.

Owner:SAMSUNG GUANGZHOU MOBILE R&D CENT +1

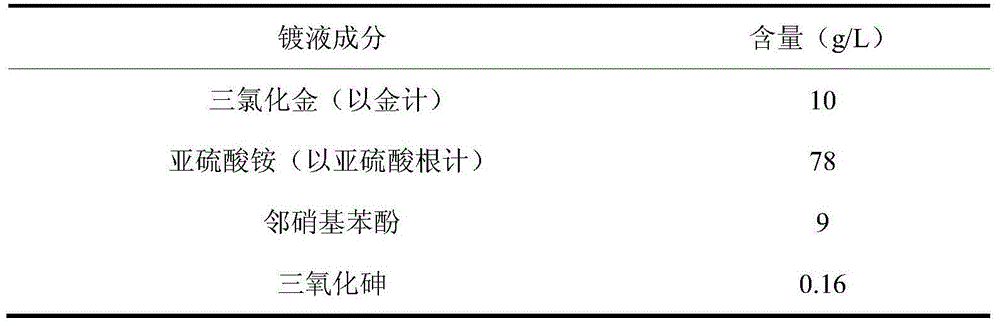

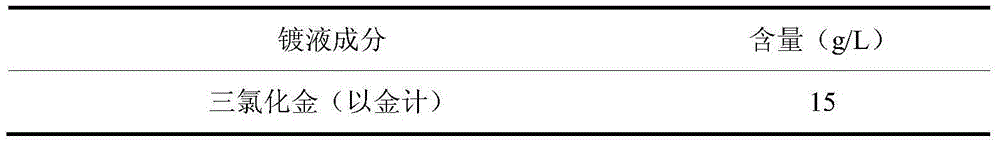

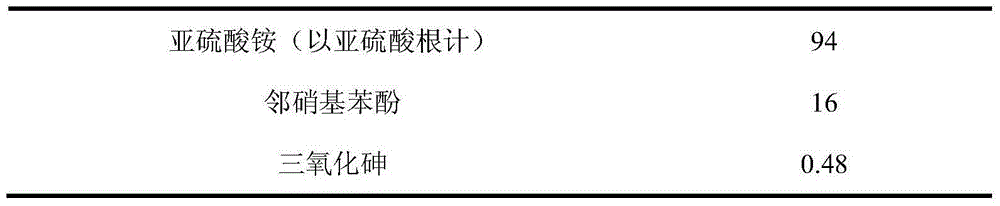

Arsenic-contained sulfite cyanide-free plated gold electroplating liquid and electroplating method

The invention discloses arsenic-contained sulfite cyanide-free plated gold electroplating liquid and an electroplating method. The electroplating liquid comprises 10-15 g / L of gold trichloride calculated by gold, 78-94 g / L of sulfite calculated by sulfurous acid radical, 9-16 g / L of nitrophenol and 0.16-0.48 g / L of arsenic trichloride. The electroplating liquid uses the sulfite as a main coordination agent, the nitrophenol as a stable positioning agent, the arsenic trichloride as a brightening agent and the gold trichloride as gold main salt, so that the electroplating liquid is better in dispersibility and deep plating capacity, high in cathode current efficiency and excellent in plating liquid performance. A plating layer electroplated by the plating liquid under the alkaline condition is low in porosity, high in brightness and excellent in plating layer quality.

Owner:无锡永发电镀有限公司

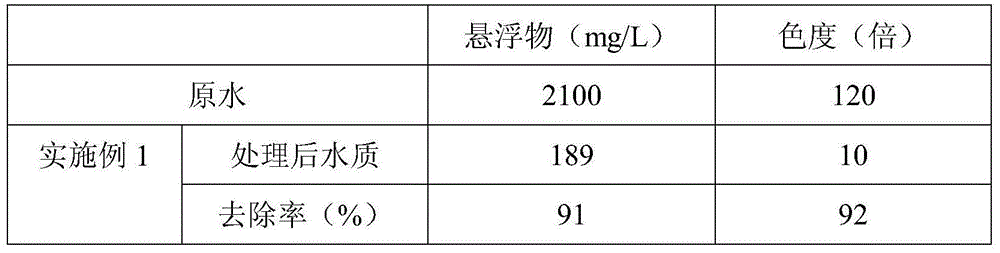

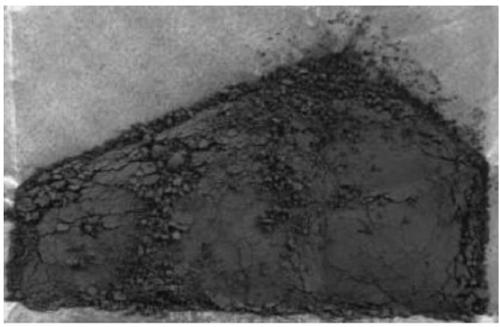

Flocculant and preparation method thereof

ActiveCN104085968APromote flocculationImprove precipitation effectWater/sewage treatment by flocculation/precipitationWastewaterArsenic trichloride

The invention provides a water treatment flocculant and a preparation method thereof, which belongs to the technical field of environment friendliness. The water treatment flocculant comprises raw materials, namely, attapulgite, ferric trichloride and titanium trichloride. The novel attapulgite-ferric trichloride hybridized flocculant is prepared by hybridizing an inorganic flocculant ferric trichloride and attapulgite in the presence of a catalyst titanium trichloride, and the flocculant is applied to treatment on coal separation wastewater, is simple in synthesis process and low in price.

Owner:ZHENGZHOU UNIV +1

Arsenic removal method of arsenic-containing waste residues

InactiveCN106676257AEfficient removalSave resourcesProcess efficiency improvementTime rangeReaction temperature

The invention discloses a method for removing arsenic in arsenic-containing waste residues through a chloridizing volatilization method. The arsenic-containing waste residues and ferric chloride are mixed, the mass ratio of the arsenic-containing waste residues to the added ferric chloride is 100:(0.1-100):1, and chloridizing volatilization arsenic removal is carried out under the conditions that the reaction temperature ranges from 280 DEG C to 300 DEG C and the reaction time ranges from 40 min to 60 min. According to the method, the arsenic can be removed in the mode of arsenic trichloride relatively smaller in toxicity in a gas volatilization manner, the arsenic removal rate can reach about 90%, the recycling efficiency of other valuable metal elements in the arsenic-containing waste residues is improved, and the removal process is simple. The method can be widely applied to arsenic removal treatment of copper soot and various metallurgy arsenic-containing waste residues, provides a new thought for arsenic removal basic study and is a quite economical and effective arsenic removal method.

Owner:JIANGXI UNIV OF SCI & TECH

Method of producing high-purity arsenical trichloride

The invention relates to a preparation method for high purity arsenic trichloride, relating to an improvement of one-step reaction synthetic method for metallic arsenic and chlorine. The reaction is carried under negative pressure, with vacuum degree of 0.085 to 0.096MPa, primary reaction temperature of 80 DEGC to 85DEG C and chlorine feeding speed of 2.0 to 5.2mol / min. with the improved technology, the yield of arsenic trichloride is increased to 94 to 95 percent (counting with As), and the purity is reached to 99.5 to 99.8 percent, the environmental pollution and the unsafe problem caused by the gasification escape of chlorine and arsenic trichloride is avoid, therefore, the invention has the advantages of easy operation, easy control, environmental pollution improvement and safe production. The invention relates to a preparation method for high purity arsenic trichloride being suitable to the industrial production.

Owner:SHANGHAI NO 4 REAGENT & H V CHEM

Impurity removal method for arsenic trichloride high-boiling residues

The invention provides an impurity removal method of an arsenic trichloride high-boiling residue, the impurities of the arsenic trichloride high-boiling residue comprise Se, Sb, Fe and Bi, and the method comprises the following steps: step 1, mixing the arsenic trichloride high-boiling residue with a sulfuric acid solution according to a certain proportion, stirring, and separating to obtain a crude arsenic trichloride solution and a sulfuric acid solution containing impurities; and 2, distilling the crude arsenic trichloride solution obtained in the step 1 at 130-140 DEG C to further remove impurities so as to obtain a fine arsenic trichloride liquid. According to the method, the arsenic trichloride high-boiling residues are washed to remove impurities by adopting the sulfuric acid solution, the purity of the obtained arsenic trichloride is high after sulfur removal in a distillation mode, the refined arsenic trichloride enters a high-purity arsenic production system to be recycled, generation of arsenic-containing wastewater and waste residues is reduced, and the method is easy to operate, small in reagent dosage and environmentally friendly.

Owner:FIRST RARE MATERIALS CO LTD

Ruthenium acetate and preparation method thereof

PendingCN109096094AHigh yieldHigh purityRuthenium organic compoundsOrganic compound preparationRefluxHalogen

The invention discloses a preparation method of ruthenium acetate. Ruthenium trichloride is taken as an initial material, ruthenium hydroxide is obtained after alkali is added and dissolved by nitricacid, ruthenium hydroxide is precipitated after alkali is added, an acetic acid solution is added after filtration and washing, heating reflux is performed for 1-4 h, and concentration is performed after cooling to obtain a liquid or solid ruthenium acetate product. By means of the method, the high-yield and high-purity ruthenium acetate product is obtained under the condition that no additive isadded, the synthesis time is short, and for solid ruthenium acetate, the halogen impurity content is lower than 500 ppm.

Owner:CHENZHOU GAOXIN PLATINUM +1

A kind of production technology of ruthenium trichloride

ActiveCN106335932BNo pollutionShorten the production cycleRuthenium/rhodium/palladium/osmium/iridium/platinum halidesAlcoholSolvent

The invention relates to a production process of ruthenium trichloride. According to the process, RuO4 gas is produced according to a traditional method; diluted hydrochloric acid is adopted for absorbing the RuO4 gas till the concentration of Ru in the solution ranges from 59 g / L to 61 g / L, meanwhile, the pH value is adjusted to range from 1.9 to 2.1, and a ruthenium-containing solution is obtained; a dispersing solvent is added into the ruthenium-containing solution, the adding volume of the dispersing solution is 9.8-10.2% of the volume of the ruthenium-containing solution, and the dispersed ruthenium-containing solution is obtained; the dispersing solvent is a mixture of hydrogen peroxide, ethyl alcohol and acetone according to the volume ratio of 1:(7.9-8.1):(0.95-1.05), the obtained dispersed ruthenium-containing solution is spray-dried through a spray dryer, and ruthenium trichloride powder is obtained. A traditional production process of ruthenium trichloride is improved, continuous, large-scale and equipment production is achieved, and the purposes of being short in production period, low in cost and free of polluting the environment are achieved.

Owner:昆明铂磊科技有限公司

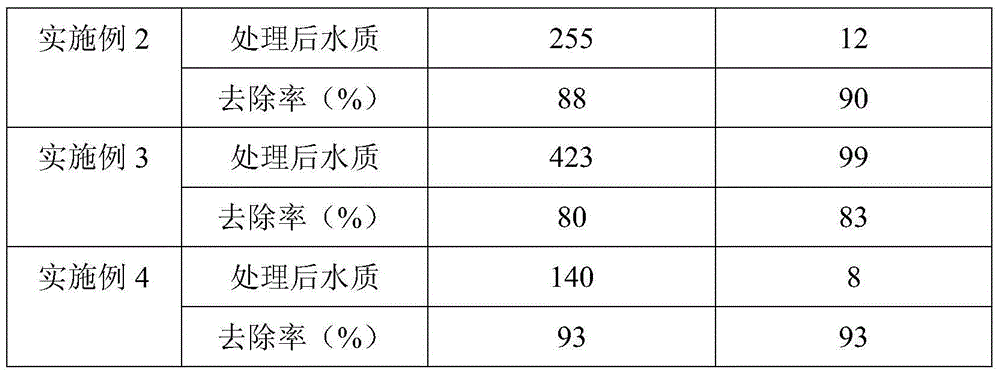

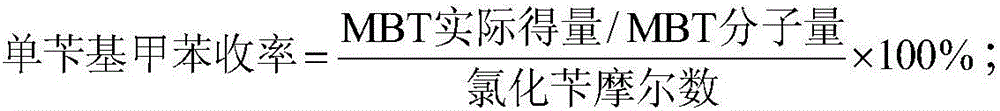

Method for catalytic synthesis of benzyl toluene by activated clay-loaded ferric trichloride (FeCl3) solid acid catalyst

InactiveCN106673952AHigh reaction conversion rateHigh selectivityPhysical/chemical process catalystsCatalystsDistillationSolid acid

The invention relates to a method for catalytic synthesis of benzyl toluene by an activated clay-loaded ferric trichloride (FeCl3) solid acid catalyst. The method comprises the following steps: adding calcium-based bentonite with concentrated sulfuric acid, performing backflow stirring and drying to obtain solid activated clay; dissolving the FeCl3 in an acetonitrile solution, adding the prepared activated clay, stirring for 24 hours at a room temperature, filtering and activating at a temperature of 120 DEG C to obtain the activated clay-loaded FeCl3 solid acid catalyst; adding the activated clay-loaded FeCl3 solid acid catalyst in an alkylation reaction system of benzyl chloride and toluene for catalytic reaction, filtering and recovering the catalyst; performing reduced-pressure distillation and refinement on a benzyl toluene crude product to obtain benzyl toluene. The method provided by the invention has the advantages that the catalyst is rich in raw material source, low in cost, simple in preparation process, low in energy consumption due to no need of high temperature activation and easy for separation from the product; when the catalyst is used for the synthetic reaction of the benzyl toluene, the reaction conversion rate is high, the selectivity is strong, conditions are mild, the equipment corrosion is low, the catalyst is easy to recover and can be reused, and the environment pollution is less, so that the application prospect is wide.

Owner:郑文亚

Preparation method of modified polymerized ferric sulfate

InactiveCN103172152AExcellent effect of removing turbidityFloc settling speed is fastIron sulfatesWater/sewage treatment by flocculation/precipitationSodium metasilicateIndustrial waste water

The invention provides a preparation method of a modified polymerized ferric sulfate. The preparation method comprises the steps of: step 1) preparation of active silicic acid: mixing sodium metasilicate silicate, ferric trichloride and hydroquinone according to a weight ratio of 85:2.5:1; and step 2) preparation of modified polymerized ferric sulfate: mixing active silicic acid with the polymerized ferric sulfate solution according to a weight ratio of 1:(45-55), and then preparing the modified polymerized ferric sulfate after a filtration step in step 3). In treatment of industrial waste water, by adding the modified polymerized ferric sulfate prepared by the method, the turbidity removal effect is obviously better than that of polymer ferric sulfate and the sedimentation speed of flocculating constituent is faster; the decoloring effect of the waste coking water generated after biological treatment is obviously better than that of the polymer ferric sulfate under the same condition; and the dosage is reduced by 20%-35% than that of the polymer ferric sulfate under the effect.

Owner:庞红信 +2

Preparation method of compound ferrous chloride flocculating agent

InactiveCN109368753AGood flocculation effectTake advantage ofIron halidesWater/sewage treatment by flocculation/precipitationIron(II) chlorideArsenic trichloride

The invention discloses a preparation method of a compound ferrous chloride flocculating agent. The preparation method includes: subjecting waste acid liquid generated after hydrochloric acid is adopted to pickle carbon steel to precipitating, filtering, heating and negative pressure vacuumizing and concentrating, adding an oxidant, and stirring or pump circulating to enable part of divalent ironions in the waste acid liquid after being filtered to be converted into trivalent iron ions to obtain the compound ferrous chloride flocculating agent taking ferrous chloride as a main component and ferric trichloride as an auxiliary component. The waste acid liquid generated after adopting the hydrochloric acid to pickle the carbon steel is taken as a raw material, so that cost is saved, the waste acid liquid is utilized sufficiently, waste resources are reutilized, and environment pollution caused by emission is reduced; the compound ferrous chloride flocculating agent taking ferrous chloride as the main component and ferric trichloride as the auxiliary component has better flocculating effect than unitary ferrous chloride or ferric trichloride flocculating agents.

Owner:嘉兴市环科环保新材料科技有限公司

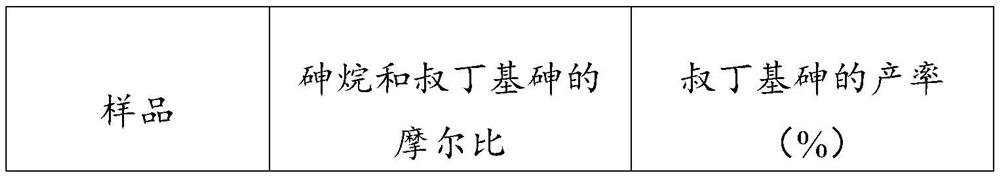

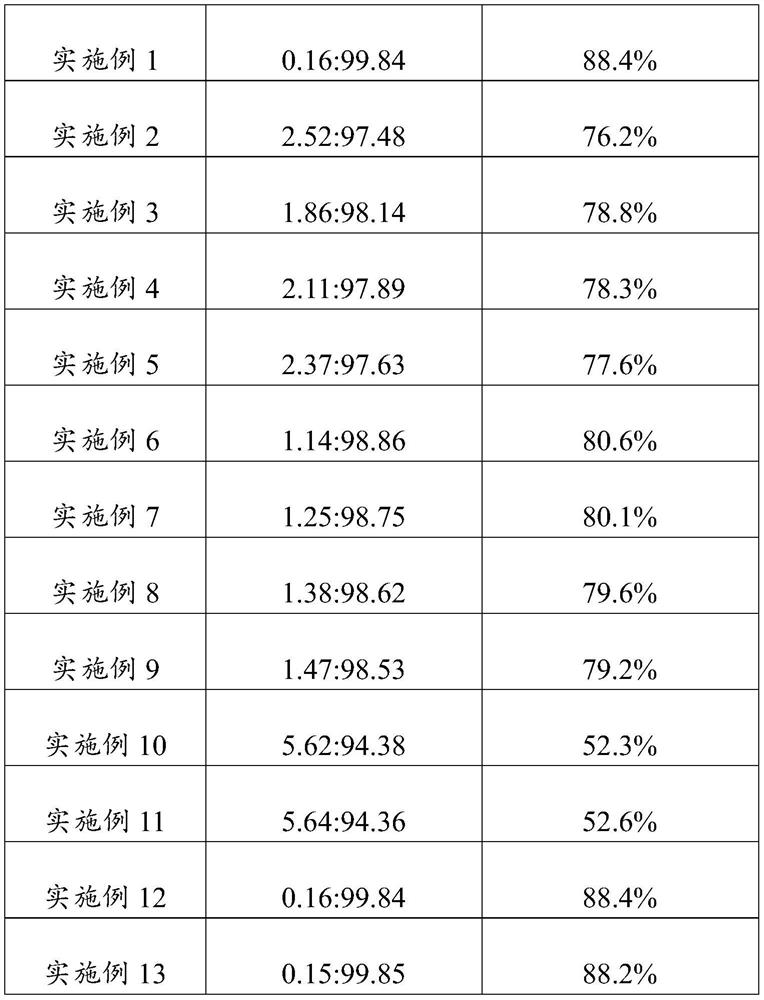

Preparation method of tert-butyl arsenic

PendingCN112159431AHigh purityImprove conversion rateGroup 5/15 element organic compoundsMagnesium organic compoundsArsineTert-Butyl chloride

The invention provides a preparation method of tert-butyl arsenic, which comprises the following steps that (1) under the protection of inert gas, magnesium and chlorotert-butane react at 60-80 DEG Cto generate tert-butyl magnesium chloride, carrying out the reaction of magnesium and chlorotert-butane under the condition of an initiator, wherein the initiator is organic aluminum or inorganic aluminum, and the weight ratio of the initiator to magnesium is (3-7): 100; (2) stirring and reacting arsenic trichloride and tert-butyl magnesium chloride at the temperature of 10 DEG C or below to obtain tert-butyl arsenic dichloride; (3) stirring tert-butyl arsenic dichloride and a reducing agent to react at the temperature of 10 DEG C or below to obtain a tert-butyl arsenic crude product; (4) purifying the tert-butyl arsenic crude product obtained in the step (3). According to the method, the reaction efficiency of magnesium and chlorotert-butane is improved, the purity of the intermediate product tert-butyl magnesium chloride is improved, the conversion rate of arsenic trichloride is increased, and arsenic trichloride is prevented from generating side reaction to generate arsine in subsequent reaction, and therefore the purity of the crude tert-butyl arsenic product is improved.

Owner:广东先导微电子科技有限公司

Simple preparation method of ruthenium polypyridine complex

The invention discloses a simple preparation method of an electrochemiluminescent reagent ruthenium polypyridine complex. The preparation method comprises the following steps: dissolving a ruthenium chloride hydrate and 2, 2'-dipyridyl in a mixed solvent of ethanol and ethylene glycol, wherein the ratio of ruthenium trichloride in the ruthenium chloride hydrate to 2, 2'-dipyridylis 1:4-1:5, and the concentration of ruthenium trichloride in the mixed solvent is 0.02-0.025mol / L; heating to react, wherein the reaction temperature is 70-100 DEG C and the reaction time is 6-10 hours; cooling to room temperature and carrying out rotary evaporation to remove ethanol; adding a saturated sodium chloride solution to separate out solids, filtering, adding water to recrystallize and drying to obtain tri(2, 2'-dipyridyl) ruthenium chloride (II) hexahydrate. The synthetic method is simple and convenient, short in reaction step, easy to operate, less in consumption of organic solvents, simple in post-treatment and high in product purity. The conversation ratio of noble metal ruthenium reaches up to 95%, so that the preparation method is less in environmental protection pressure and convenient for industrialized production.

Owner:WUHAN UNIV OF TECH

Method for analyzing copper in copper-containing ferric trichloride with low electronic grade

InactiveCN102735637AAccurate measurementEliminate distractionsPreparing sample for investigationColor/spectral properties measurementsHigh concentrationCyclohexanone

The invention discloses a method for analyzing copper in copper-containing ferric trichloride with low electronic grade, comprising the following specific steps: (1) pre-treating a sample: adding hydrochloric acid and hydrogen peroxide in a copper-containing ferric trichloride sample, boiling for a certain time, adding saturated sodium fluoride solution, and filtering into a volumetric flask by metering volume; and (2) measuring the content of copper by using the modified bis-(cyclohexanone)oxalyl dihydrazone spectrophotometry. According to the method, the content of copper in the copper-containing ferric trichloride with low electronic grade is measured by adopting the bis-(cyclohexanone)oxalyl dihydrazone spectrophotometry, because the concentration of ferrum in the sample is high, the final color comparison is affected. According to the invention, the sodium fluoride is added into the to-be-measured solution for removing ferrum, so that the interference of the high-concentration ferrum can be eliminated, and the trace of the copper in the copper-containing ferric trichloride can be measured accurately.

Owner:昆山市千灯三废净化有限公司

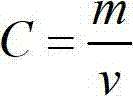

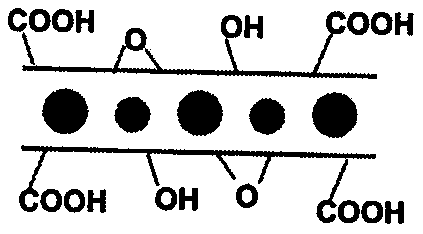

Preparation method of ferric oxide/folded graphene film material

InactiveCN110474048AExtensiveWith uniformityNegative electrodesSecondary cellsFerric hydroxideFiltration

The invention provides a preparation method of a ferric oxide / folded graphene film material. The method comprises the following steps of: preparing a graphene material by alternately intercalating anoxygen-containing group layer and ferric trichloride, stripping off the oxygen-containing group layer, performing suction filtration to form a film, sequentially immersing the film into a hydrogen peroxide solution and an alkaline solution for reaction to obtain a ferric hydroxide / folded graphene oxide film, and performing high-temperature treatment to obtain the ferric oxide / folded graphene film.According to the method, hydrogen peroxide is decomposed to generate a large number of wrinkles in the film, the wrinkles have universality and uniformity, damage to a graphene lamellar structure iseffectively reduced, ferric oxide is uniformly distributed between graphene lamellas, graphene lamellar accumulation and ferric oxide particle aggregation are reduced, the preparation process is simple, the requirement for equipment is low, and the preparation method is suitable for industrial or laboratory operation and has huge application prospects.

Owner:YANCHENG TEACHERS UNIV

Preparation method of high-purity arsenic trichloride

The invention provides a preparation method of high-purity arsenic trichloride. The preparation method comprises the following steps: (1) mixing and stirring arsenic powder and sulfuric acid in a reactor; (2) introducing chlorine into the reactor, reacting until no solid exists, stopping introducing chlorine, and continuously stirring for 2-3 hours to obtain a crude arsenic trichloride solution and an arsenic-containing sulfuric acid solution; and (3) distilling the crude arsenic trichloride liquid, and collecting fractions at 130-140 DEG C to obtain high-purity arsenic trichloride. According to the preparation method, the sulfuric acid solution and the arsenic raw material are mixed in advance in the reactor, chlorine is introduced into the reactor to react with arsenic, the sulfuric acid solution covers the surface of arsenic, the reaction rate can be well controlled, and sulfuric acid can absorb generated impurities of arsenic trichloride, so that the impurity removal effect is achieved. Moreover, the method does not need to sublimate the arsenic powder and then react with chlorine, so that the energy consumption can be reduced, and the obtained arsenic trichloride is good in purity and high in yield.

Owner:FIRST RARE MATERIALS CO LTD

Electroplating solution for enhancing electrical conductivity of electronic copper foil, preparation method and electroplating process

The invention discloses an electroplating solution for enhancing the electrical conductivity of electronic copper foil, a preparation method and an electroplating process. The electroplating solution comprises the following components: a mixed solution of 100-150 parts of 1-ethyl-3-methylimidazolium chloride (EMIMCl) and 63-95 parts of absolute ethyl alcohol (AE) serves as a solvent, and 1-6 parts of anhydrous arsenic trichloride (AsCl3), 2-9 parts of anhydrous niobium pentachloride (NbCl5), 10.3-20.8 parts of a cosolvent and 0.1-0.5 part of an additive serve as solutes. According to the electroplating solution, the preparation method and the electroplating process, a NbAs alloy film layer is electrically deposited on the electronic copper foil, the electrical conductivity of the electronic copper foil is enhanced, the bonding capacity of the prepared NbAs alloy film layer and the electronic copper foil is high, the electrical conductivity and heat conductivity are high, the chemical stability is good, in addition, the process is simple, environmental pollution is avoided, the energy consumption is small, and the repeatability is high.

Owner:ANHUI TONGGUAN COPPER FOIL +2

Preparation technology and equipment for sulfur-free arsenious oxide

The invention relates to a preparation technology and equipment for sulfur-free arsenious oxide. A special horizontal ceramic tubular reformer is adopted, and the technology is characterized in that the simple substance arsenic is oxidized at high temperature in an oxygen enrichment condition so as to remove sulfur to obtain the sulfur-free arsenious oxide. The equipment comprises a tubular structure A, a tubular structure B and a tubular structure C, wherein the tubular structure A is taken as a material section, the tubular structure B is taken as a reaction section, the tubular structure C is taken as a transition section, the diameters of the tubular structure A, the tubular structure B and tubular structure C are identical, and the preparation technology comprises two forms of interrupted feeding or uninterrupted feeding. The equipment has a simple structure, is convenient to use and easy to operate, has short processes, can be used for rapidly and effectively preparing plenty of arsenious oxide products with sulfur content less than 50PPb, and provides raw materials with low sulfur content for preparation of high purity arsenic by adopting arsenic trichloride through rectification or arsenic trioxide through distillation.

Owner:JIANGXI HAICHEN OPTOELECTRONICS

A method for deep dearsenization of arsenic-containing material by roasting

ActiveCN106222398BHigh removal rateSimple processRotary drum furnacesCrucible furnacesNonferrous metalReducing atmosphere

The invention discloses a method for deep roasting arsenic removal of an arsenic-containing material, and belongs to the technical field of non-ferrous metallurgy. The fine grinded arsenic-containing material is evenly mixed with a proper quantity of chlorinating agents and water, pelletizing is carried out to obtain pellets, then the pellets are fed into a roasting furnace after being dried, roasting is carried out by controlling the atmosphere in the furnace, and roasted ore with the arsenic content being lower than or equal to 0.1% is obtained. According to the method, chloride such as calcium chloride, sodium chloride and magnesium chloride serves as roasting arsenic removal flux, roasting is carried out in a weak oxidation atmosphere or a weak reduction atmosphere, arsenic is converted into the form of arsenic chloride easy to volatilize so as to be removed from the arsenic -containing material, the process is simple, the arsenic removal rate is high, and the quality of the roasted ore is good.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Porous magnetic iron oxide red with abundant lattice defects and preparation method thereof

ActiveCN109896548AHigh purityHigh porosityMaterial nanotechnologyWater/sewage treatment by irradiationLattice defectsPotassium hydroxide

The invention relates to a porous magnetic iron oxide red with abundant lattice defects and a preparation method thereof. Mixed sodium hydroxide and potassium hydroxide are taken as the molten solvent; iron trichloride is taken as the raw material; a hydrochloric acid solution with a pH value of 1 and deionized water are taken as a washing agent, a detergent and an extracting agent; anhydrous ethanol is taken as the detergent and a drying carrier; reactions are carried out in a liquid alkali environment at a temperature of 166 to 180 DEG C under a normal pressure; due to low surface energy, oriented connection easily happens on a crystal plane to generate lattice defects; after deionized water extraction, iron hydroxide is formed, then iron hydroxide is burned at a temperature of 300 to 500 DEG C to obtain the iron oxide red with a porous structure, the purity is high, and the iron oxide red is stable, nontoxic, and magnetic. During the synthesis process, no dispersant is used, the rawmaterials are few, the technical process is short, the operation is simple, and the cost is low. The method is a very ideal method for preparing the porous magnetic iron oxide red with abundant lattice defects.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Preparation method of loose type polyaluminum ferric chloride flocculants

ActiveCN102765796BGood flocculation effectImprove adsorption capacityAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateChloride

A preparation method of loose type polyaluminum ferric chloride flocculants includes the steps: mixing univalent soluble salt solution serving as loosening agents with polyaluminum chloride solution and ferric trichloride solution, and stirring for continuous reaction for 4h at a rotation speed of 150r / min at the temperature of 40-100 DEG C, so that the loose type polyaluminum ferric chloride flocculants can be obtained. The preparation method has the advantages that the flocculants not only have the excellent flocculation performance and a powerful charge neutralization function of polyaluminum chloride, but also have the advantages of ferric chloride, including high adsorbability, high sedimentation speed, large formed floccules and the like, are better than the ferric chloride in effluent color contamination and have the advantages of good coagulation effects, rapid action, less consumption, wide application range and the like. The base materials of polyaluminum chloride and ferric trichloride used in the method are sufficient in source, so that powerful support is provided for large-scale industrialization. The polyaluminum ferric chloride flocculants are ideal environment-friendly water-treatment flocculants as discharge of waste residues and wastes is basically avoided during production, and environmental pollution is reduced.

Owner:TIANJIN PIPELINE ENG GROUP

Method for preparing ruthenium trichloride from ruthenium-containing waste

ActiveCN110255632AMeet the requirements of green developmentReactor smallRuthenium/rhodium/palladium/osmium/iridium/platinum halidesSodium chlorateReaction rate

The invention relates to a method for preparing ruthenium trichloride from ruthenium-containing waste. The method is characterized by comprising the following steps: (1) roasting: enabling the ruthenium-containing waste to be roasted, wherein roasting temperature is 200-800 DEG C, and roasting time is 4-8h; (2) preparation of RuO4: enabling the roasted ruthenium-containing waste to be added into a reaction kettle, then adding sodium chlorate, liquid bromine and water, stirring to react in a condition of 60-100 DEG C, and reacting for 1.5-5h, wherein the proportion of the ruthenium-containing quantity of the ruthenium-containing waste to the sodium chlorate to the liquid bromine to the water is 100 to (150-550) to (2-6) to (300-800) in parts by ewight; (3) preparation of an H2RuCl5 ;absorbing RuO4 generated via reaction in the step (2) by adopting hydrochloric acid at normal temperature to obtain the H2RuCl5 solution; and (4): drying: enabling the generated H2RuCl5 solution to be heated and concentrated to crystallize, and then carrying out infrared drying to obtain a hydrated ruthenium trichloride crystal. The method has the characteristics of fast reaction rate, high conversion rate, good safety, low energy consumption and the like.

Owner:JIANGXI HANS PRECIOUS METALS CO LTD

Preparation method of modified polymerized ferric sulfate

InactiveCN103172152BExcellent effect of removing turbidityFloc settling speed is fastIron sulfatesWater/sewage treatment by flocculation/precipitationSodium metasilicateIndustrial waste water

The invention provides a preparation method of a modified polymerized ferric sulfate. The preparation method comprises the steps of: step 1) preparation of active silicic acid: mixing sodium metasilicate silicate, ferric trichloride and hydroquinone according to a weight ratio of 85:2.5:1; and step 2) preparation of modified polymerized ferric sulfate: mixing active silicic acid with the polymerized ferric sulfate solution according to a weight ratio of 1:(45-55), and then preparing the modified polymerized ferric sulfate after a filtration step in step 3). In treatment of industrial waste water, by adding the modified polymerized ferric sulfate prepared by the method, the turbidity removal effect is obviously better than that of polymer ferric sulfate and the sedimentation speed of flocculating constituent is faster; the decoloring effect of the waste coking water generated after biological treatment is obviously better than that of the polymer ferric sulfate under the same condition; and the dosage is reduced by 20%-35% than that of the polymer ferric sulfate under the effect.

Owner:庞红信 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com