Comprehensive utilization method for arsenic and acid wastewater

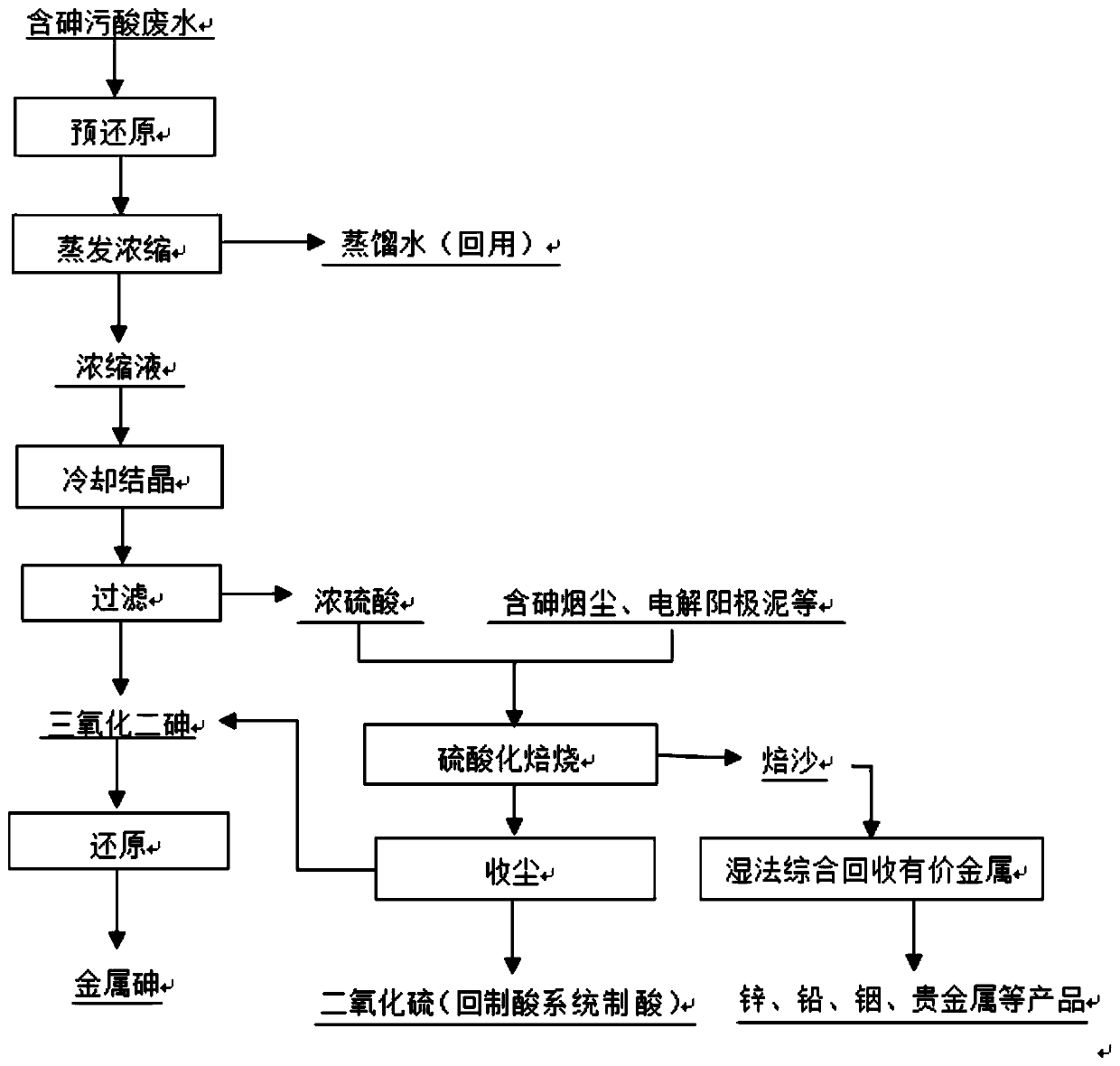

The technology of polluted acid wastewater and arsenic polluted acid is applied in the directions of arsenic compounds, chemical instruments and methods, and the improvement of process efficiency, which can solve the problems of secondary pollution, the generation of arsenic-containing waste residues, and the high treatment cost, so as to save the treatment cost, The effect of improving the recovery rate and lowering the treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The arsenic-containing polluted acid wastewater produced by copper smelting in an Isa furnace has a sulfuric acid concentration of 149.47g / L, of which the arsenic content is 23.9g / L. It is evaporated by two-stage heating, and the sulfuric acid content after mixing the two-stage concentrate is 1736.37g / L , the arsenic content of the distilled water evaporated in the second stage is 94mg / L, the concentrated solution is cooled and crystallized, and the purity is obtained through filtration and separation to obtain arsenic trioxide with a purity of 98.76%. , containing 7.6% zinc) according to the ratio of 1L / kg and stirred evenly, after mixing evenly, place it in a tube furnace for roasting for 60min at a roasting temperature of 300°C, use a bag dust collector to collect the smoke generated by roasting, and use sodium hydroxide to absorb the tail gas After roasting, the calcine contains 0.8% arsenic, and the dust contains 96.3% arsenic. The calcine is leached by sulfuric aci...

Embodiment 2

[0042] The arsenic-containing waste acid wastewater produced by an Osmelt furnace copper smelting enterprise has a sulfuric acid content of 126.3g / L, of which the arsenic content is 13.9g / L. The polluted acid is evaporated by primary heating, the concentrated sulfuric acid content is 1675.2g / L, the concentrated acid is cooled and crystallized, solid-liquid separation and drying to obtain arsenic trioxide with a purity of 99%, and the filtered concentrated sulfuric acid and arsenic-containing smoke ( Arsenic 5.7%, zinc 11.2%) were mixed evenly at a ratio of 0.5L / kg, and the mixed material was added to a tube furnace for roasting for 90 minutes at a roasting temperature of 350 degrees Celsius, and dust was collected from the roasting flue gas with a cloth bag to obtain arsenic containing 98.4 % of arsenic trioxide, the baked sand is ground and soaked in water, and the leaching rate of zinc reaches 81%. Mix the arsenic trioxide obtained in Examples and Examples with charcoal, put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com