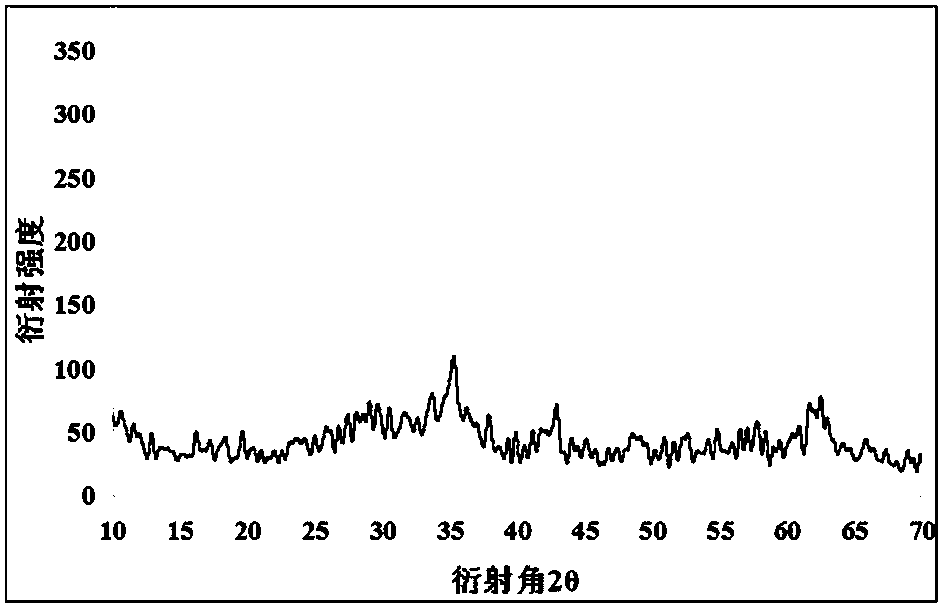

Porous magnetic iron oxide red with abundant lattice defects and preparation method thereof

A technology of magnetic iron oxide red and lattice defects, applied in iron oxide, chemical instruments and methods, iron oxide/iron hydroxide, etc., can solve the problem of difficult control of iron oxide particle size, crystal plane orientation and growth rate, and unfavorable sewage treatment Practical application and other issues, to achieve the effect of low cost, low temperature, and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing porous lattice-defect-rich magnetic iron oxide, comprising the following steps:

[0036] 1) Preparation of ferric hydroxide: Mix anhydrous sodium hydroxide and anhydrous potassium hydroxide, and melt at 166 ℃ ± 1 ℃, 0.1 MPa for 60 min ± 2 min to prepare mixed alkali clarification liquid; Add ferric chloride powder into the mixed alkali clarified liquid, stir for 5-6min to obtain sodium hydroxide+potassium hydroxide+ferric chloride molten liquid; put sodium hydroxide+potassium hydroxide+ferric chloride molten liquid at 166 Under the conditions of ℃±1 ℃ and 0.1 MPa, keep warm for 2160 min±10 min to obtain a molten solution containing ferric hydroxide;

[0037] 2) Add hydrochloric acid solution with pH=1 to the molten solution containing ferric hydroxide while it is hot, stir for 10 min, then cool to room temperature naturally, centrifuge, and take the reddish-brown product in the lower layer;

[0038] 3) After washing the reddish-brown product with...

Embodiment 1

[0046]A method for preparing porous lattice-defect-rich magnetic iron oxide, comprising the following steps:

[0047] 1) Preparation of ferric hydroxide: Mix anhydrous sodium hydroxide and anhydrous potassium hydroxide, melt at 166 °C and 0.1 MPa for 60 min to obtain a mixed alkali clarification liquid; add ferric chloride powder to mix In the clarified alkali solution, stir for 5 minutes to obtain a molten solution of sodium hydroxide + potassium hydroxide + ferric chloride; keep the molten solution of sodium hydroxide + potassium hydroxide + ferric chloride at 166 ° C and 0.1 MPa for 2160 min, to obtain a melt containing ferric hydroxide;

[0048] 2) Add hydrochloric acid solution with pH=1 to the molten solution containing ferric hydroxide while it is hot, stir for 10 min, then cool to room temperature naturally, centrifuge, and take the reddish-brown product in the lower layer;

[0049] 3) The red-brown product was washed with deionized water and absolute ethanol respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com