Method for catalytic synthesis of benzyl toluene by activated clay-loaded ferric trichloride (FeCl3) solid acid catalyst

A technology of solid acid catalyst and activated clay, which is applied to carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of high preparation cost, inability to overcome equipment corrosion, complex process, etc., and achieves low preparation cost and catalytic reaction. The effect of high yield and selectivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A, preparation of activated clay supported solid acid catalyst

[0029] Add 270g of water and 30g of concentrated sulfuric acid to a 1000mL four-necked bottle, then add 30g of calcium-based swelling, reflux and stir for 6h, cool down to room temperature for 12h, filter, and dry at 120°C for 8h; solid activated clay is obtained and used as a catalyst carrier for later use;

[0030] B. Activated clay loaded with FeCl 3 Preparation of solid acid catalyst

[0031] FeCl 3 Dissolve in the acetonitrile solution, add the activated clay prepared by step A, the activated clay and FeCl 3 The mass ratio is 12:1, stirred at room temperature for 24 hours, filtered, and then activated at 120°C for 4 hours to obtain FeCl loaded on activated clay 3 solid acid catalyst;

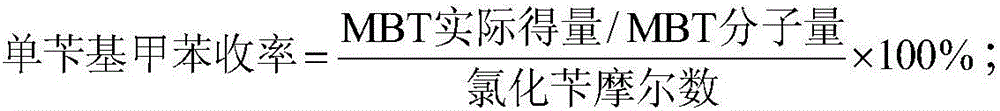

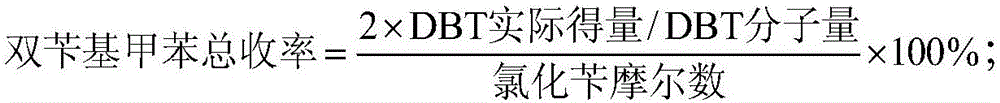

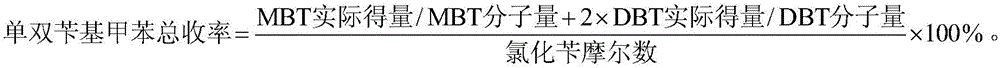

[0032] C. Alkylation synthesis reaction of benzyltoluene

[0033] Activated clay loaded FeCl 3 The solid acid catalyst is added to the alkylation reaction system of benzyl chloride and toluene for catalytic reacti...

Embodiment 1

[0041] A, preparation of activated clay supported solid acid catalyst

[0042] Add 270g of water and 30g of concentrated sulfuric acid to a 1000mL four-neck bottle, then add 30g of calcium-based swelling, reflux and stir for 6 hours, cool down to room temperature for 12 hours, filter, and dry at 120°C for 8 hours to obtain solid activated clay;

[0043] B. Activated clay loaded with FeCl 3 Preparation of solid acid catalyst

[0044] Weigh anhydrous FeCl 3 1.0g, dissolved in 30mL acetonitrile, fully stirred until FeCl 3 Completely dissolve, use 12.0g of activated clay prepared in step A as a catalyst carrier, stir at room temperature for 12h, filter, wash the solid with 10mL of n-hexane x 3 times, and dry at 120°C for 4h to obtain FeCl loaded on activated clay 3 Solid acid catalyst (F / C catalyst);

[0045] C. Alkylation synthesis reaction of benzyltoluene

[0046]Take 4g of F / C catalyst and put it into a 500mL four-neck flask, then add 280g of toluene, raise the temperatu...

Embodiment 2

[0048] A, preparation of activated clay supported solid acid catalyst

[0049] Add 270g of water and 30g of concentrated sulfuric acid to a 1000mL four-necked bottle, then add 30g of calcium-based swelling, reflux and stir for 6 hours, cool down to room temperature for 12 hours, filter, and dry at 120°C for 8 hours to obtain solid activated clay;

[0050] B. Activated clay loaded with FeCl 3 Preparation of solid acid catalyst

[0051] Weigh anhydrous FeCl 3 1.0g, dissolved in 30mL acetonitrile, fully stirred until FeCl 3 Completely dissolve, use 12.0g of activated clay prepared in step A as a catalyst carrier, stir at room temperature for 12h, filter, wash the solid with 10mL of n-hexane x 3 times, and dry at 120°C for 4h to obtain FeCl supported on activated clay 3 Solid acid catalyst (F / C catalyst);

[0052] C. Take 3.2g of F / C catalyst and put it into a 500mL four-necked bottle, then add 240g of toluene, raise the temperature to 105°C, add 80g of benzyl chloride dropwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com