Patents

Literature

53results about How to "Meet the requirements of green development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite porous carbon material and preparation method and application thereof

InactiveCN108217648AIncrease the amount addedAvoid reunionCell electrodesSingle layer grapheneCvd grapheneCapacitance

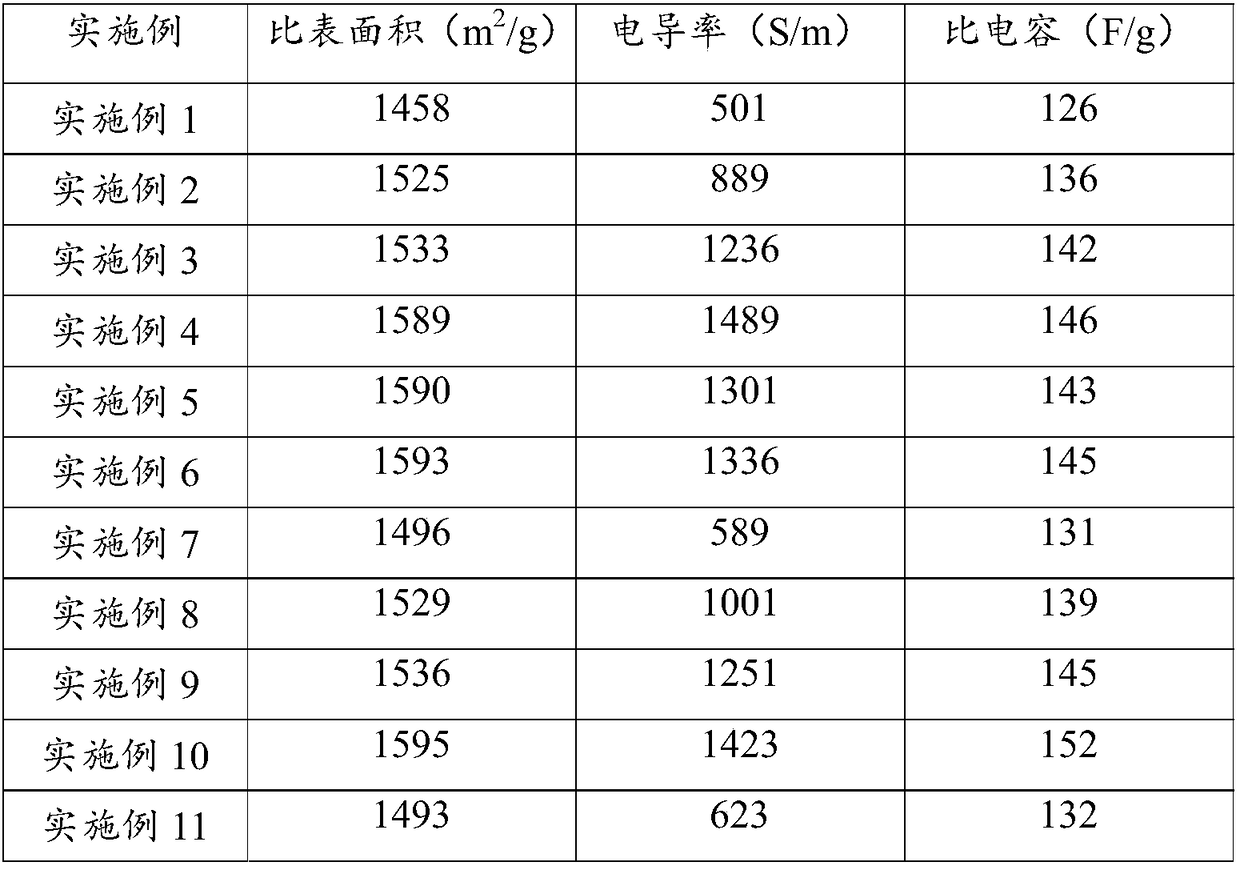

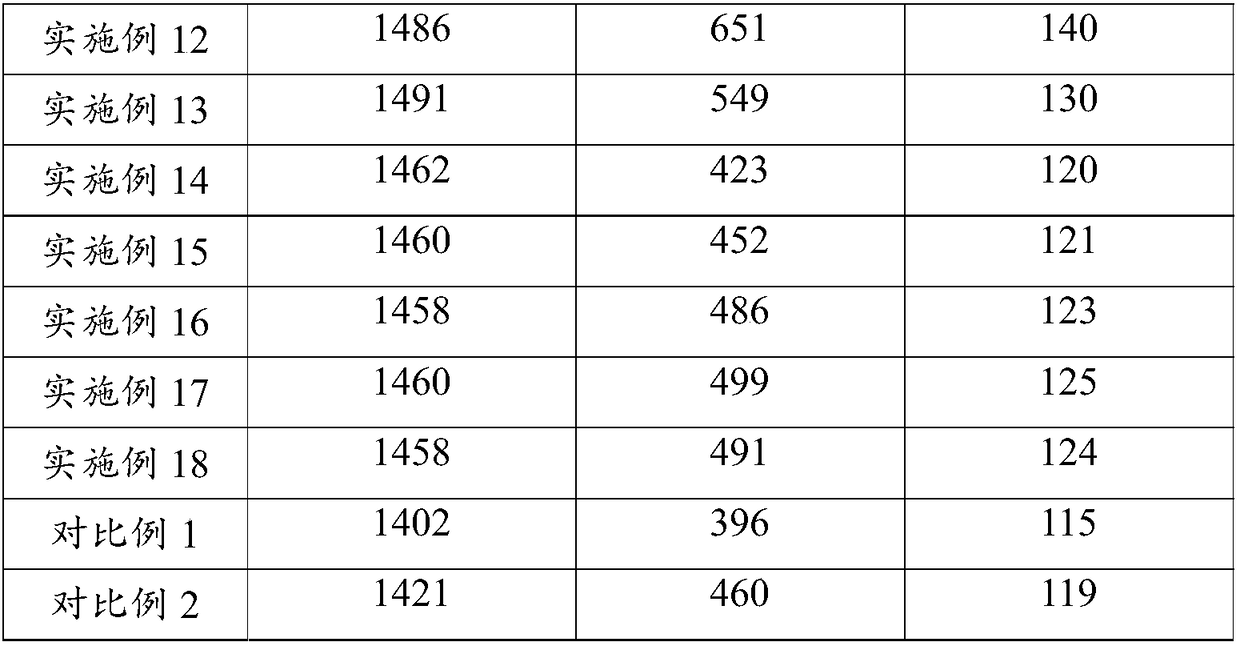

The invention provides a composite porous carbon material and a preparation method and application thereof. The preparation method for the composite porous carbon material is characterized in that carbonized materials and graphene materials are adopted as raw materials, a composite carbon material is prepared through hydrothermal reaction, and the composite porous carbon material is obtained through activation and aftertreatment. By use of the method, the additive amount of the graphene materials can be effectively improved, the agglomeration of the graphene materials is avoided, the advantages of the graphene materials are fully performed, the specific surface area, the specific capacitance and the conduction performance of the composite porous carbon material can be effectively improved,and the overall performance of the composite porous carbon material can be improved. In addition, the preparation method for the composite porous carbon material has the advantages of simple technology and light pollution and conforms to the requirement of green development. The composite porous carbon material has the advantages of high specific surface area, high specific capacitance, good conduction performance and excellent overall performance and can be used for preparing electronic elements.

Owner:山东省圣泉生物质石墨烯研究院

Method for improving fermentation yield of rifamycin SV

ActiveCN102660598ASimple operation processImprove controllabilityMicroorganism based processesFermentationRifamycin BAmycolatopsis mediterranei

The invention discloses a method for improving the fermentation yield of rifamycin SV. In the process of fermentation culture, oxalate with the final concentration of 0.2-0.5g / L and soybean oil with the final concentration of 2-5mL / L are sterilely added into a fermentation tank the fermentation culture cycle of amycolatopsis mediterranei of which is 60-80 hours. The titer of the rifamycin SV is increased by 3.0% on average, the titer is increased by 5.4% on average in case of one billion tanks, carbohydrate supplementation is decreased by 17% and the raw material cost of every tank is saved by***. The supplementary materials in the method are all agricultural and industrial commodities with high affordability. In addition, the operational process is simple and the controllability is strong, thus the method is applicable to large-scale fermentation production, the production increase effect is stable and the method conforms to the green development requirement of energy conservation in fermentation industry by the state.

Owner:河南省南街村(集团)有限公司

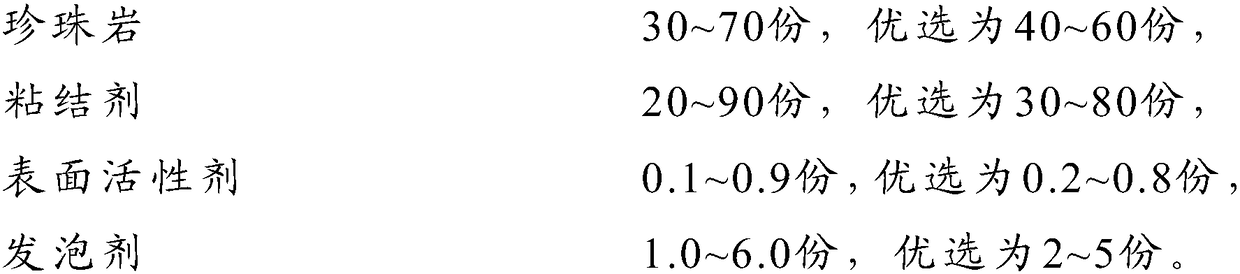

Novel inorganic heat-insulating board prepared through normal-temperature foaming of perlite powder and preparation method thereof

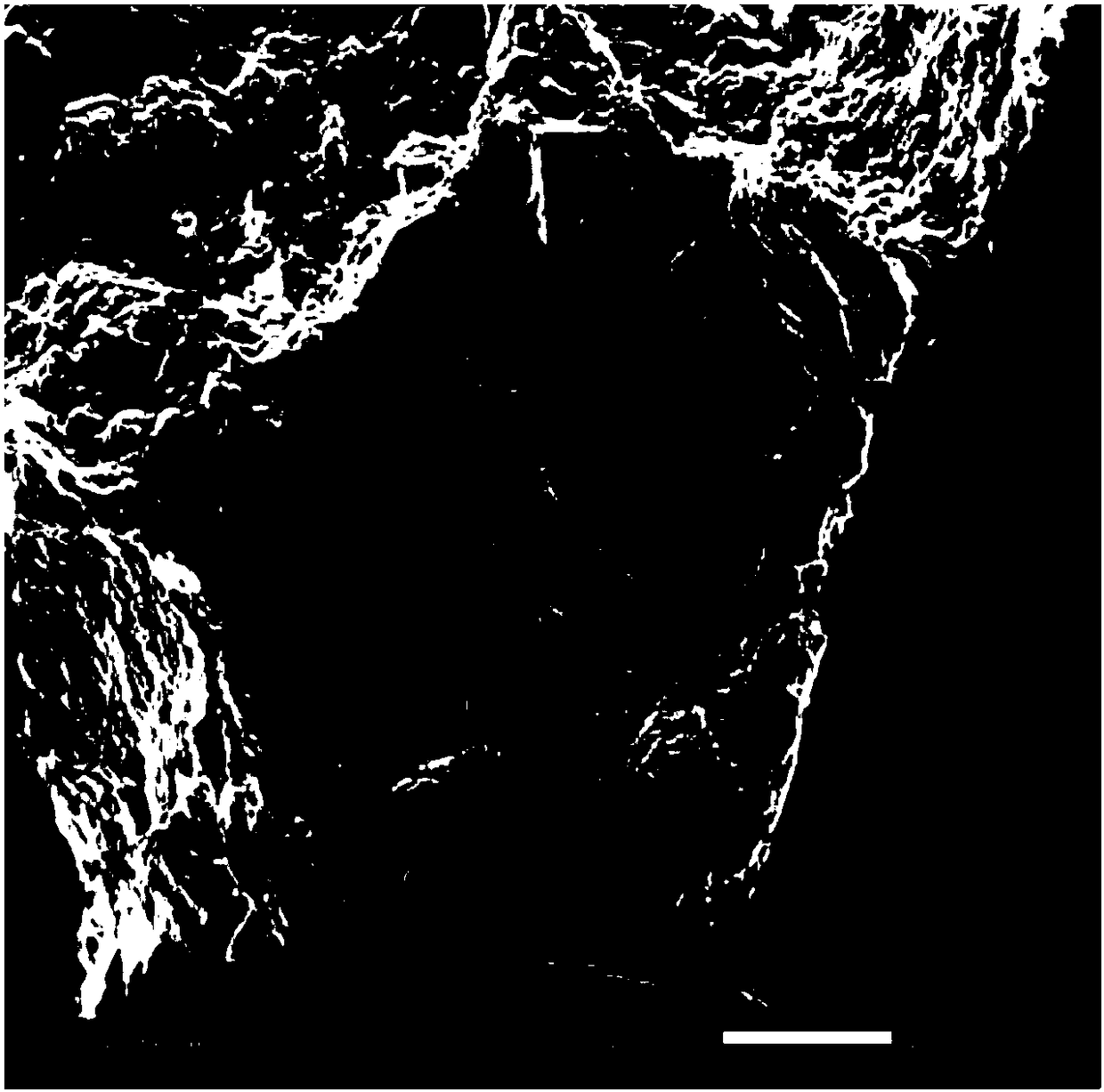

ActiveCN108585924AOvercome the disadvantages of energy consumptionLow costCeramicwareFiberHeat conducting

The invention discloses a novel inorganic heat-insulating board prepared through normal-temperature foaming of perlite powder and a preparation method thereof. The novel inorganic heat-insulating board is prepared by taking perlite powder (containing perlite tailings) as a main raw material, adding a binder, a surfactant, a foamer, hydrophobic powder and inorganic fiber and adopting a normal-temperature foaming method. The heat-insulating board is low in heat conducting coefficient, high in compressive strength, low in water absorption rate, good in fireproof performance and high in durability. The preparation method is simple in process, mild in preparation condition, energy-saving and environment-friendly, waste perlite tailing powder can be utilized, resources are saved, and the novel inorganic heat-insulating board is suitable for large-scale industrial production.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

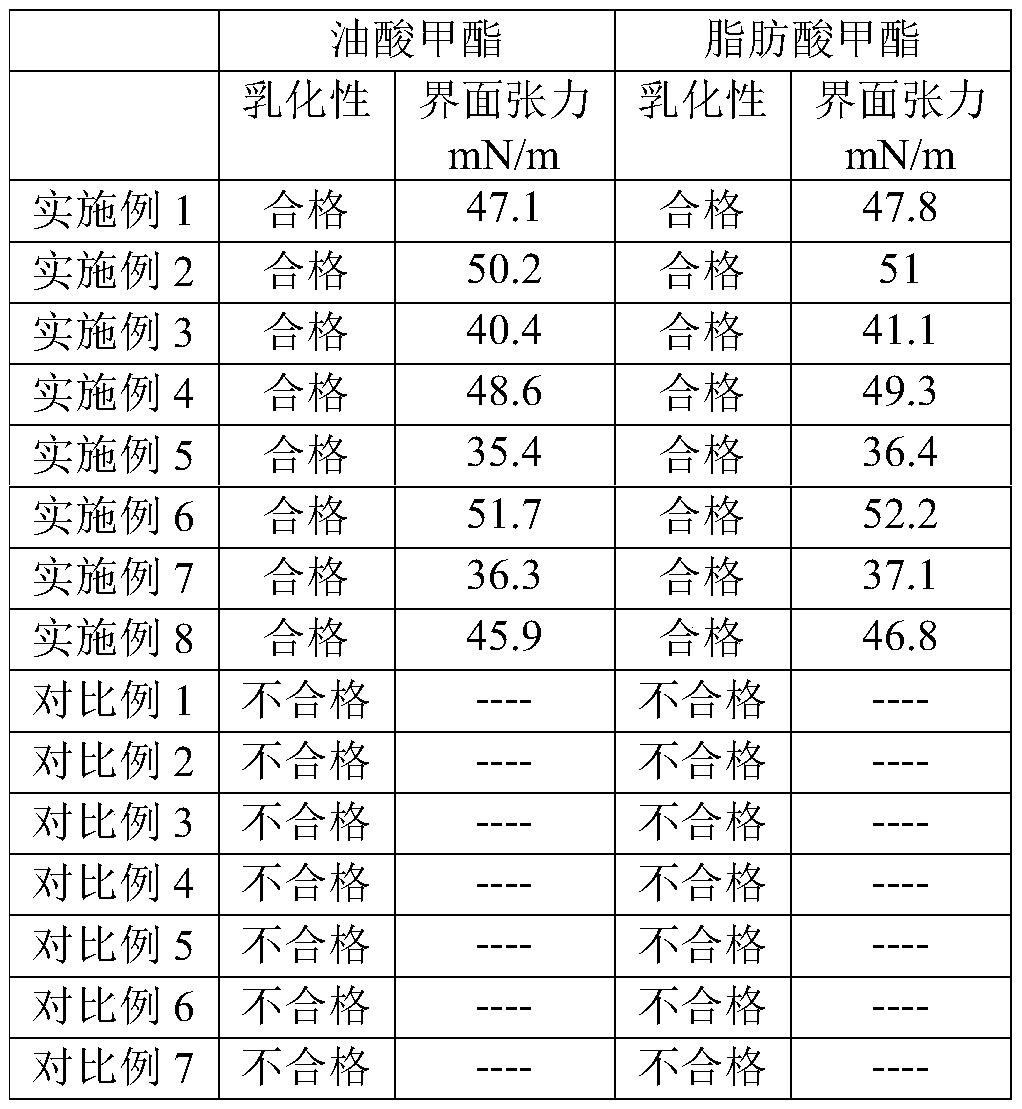

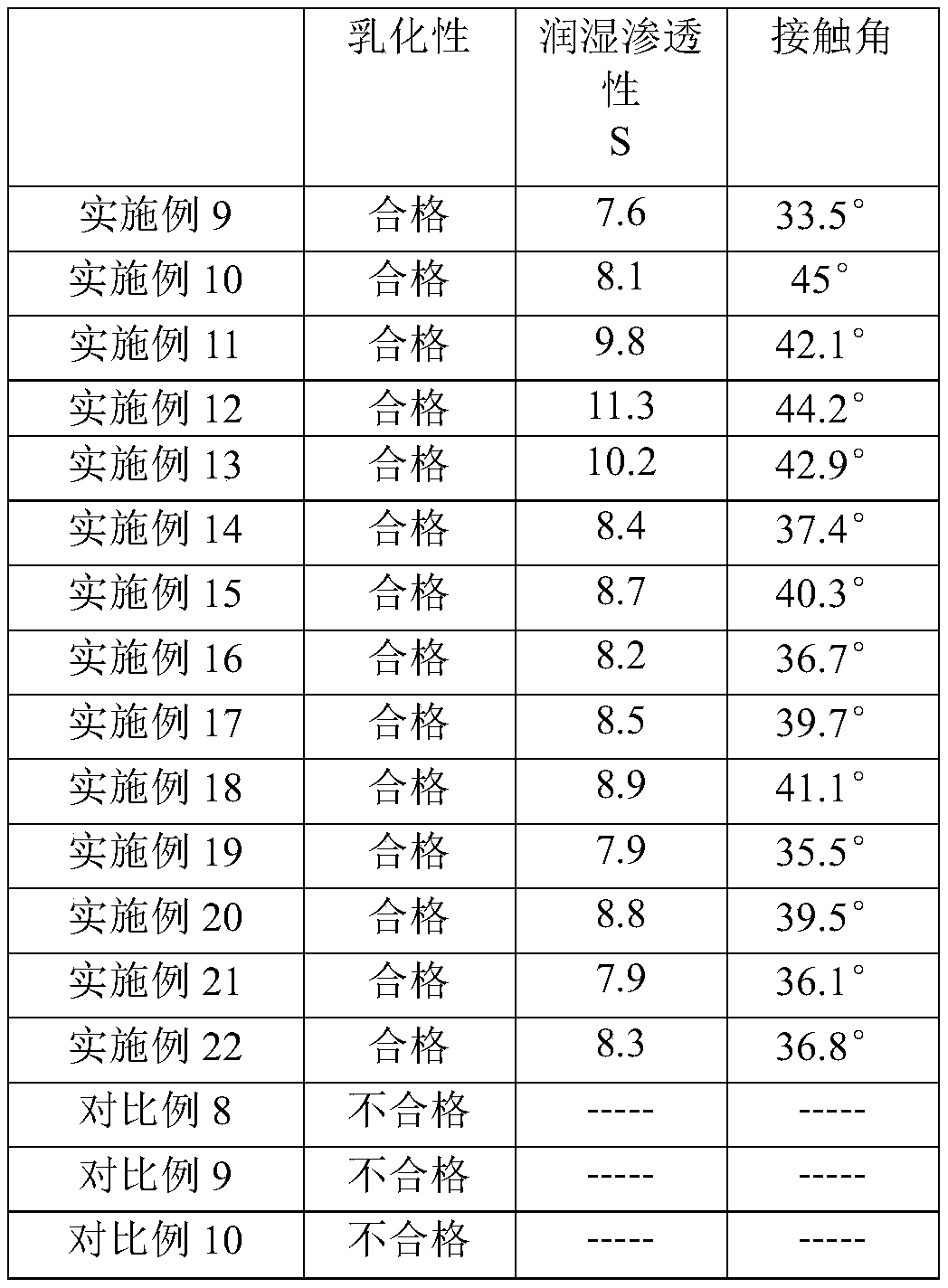

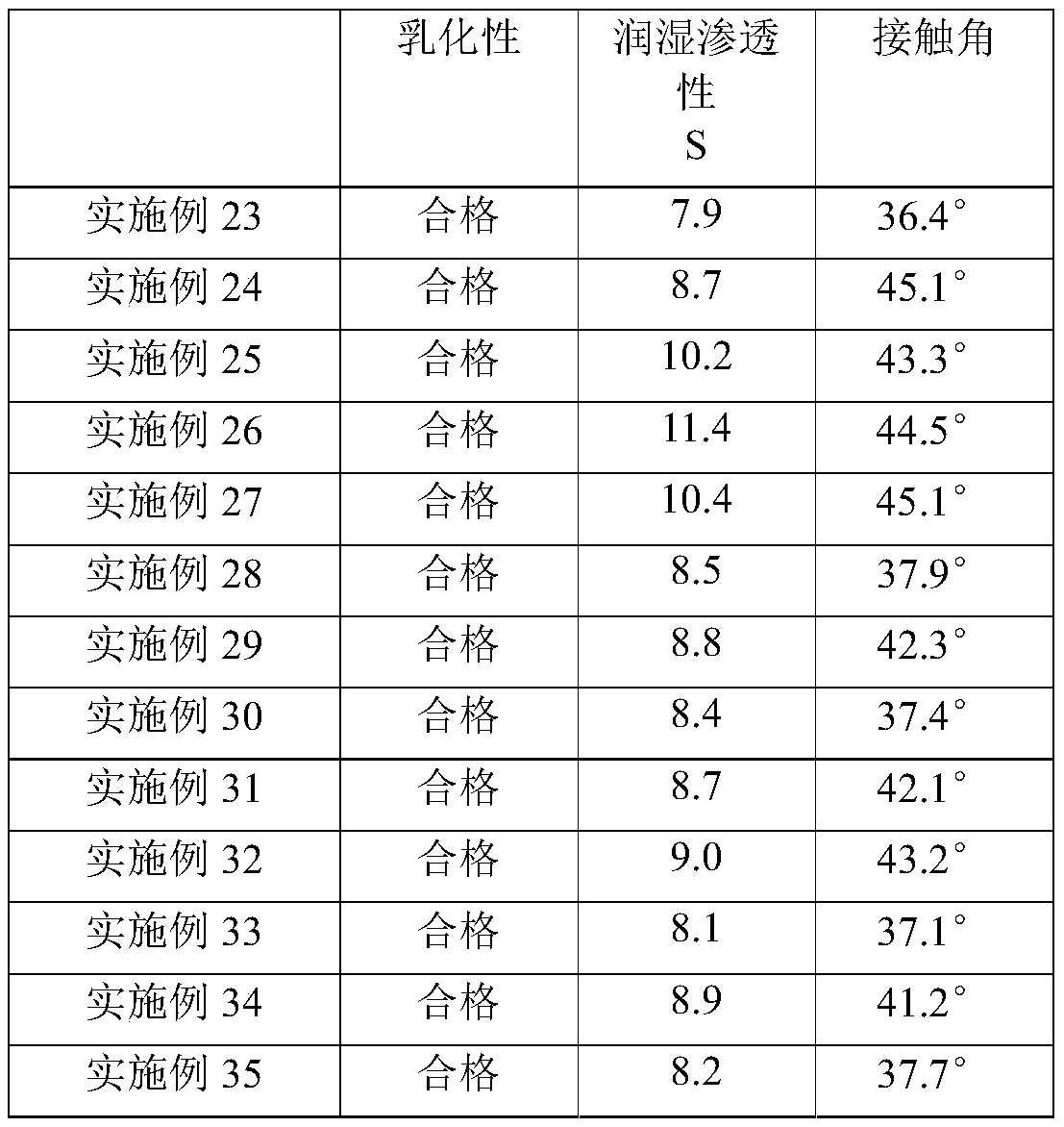

Emulsifier, and application of assistant containing emulsifier in pesticide preparation processing

ActiveCN110663687AImprove permeabilityIncrease viscosityBiocideAnimal repellantsAlkylphenolPolyethylene glycol

The invention provides an emulsifier, and an application of an assistant containing the emulsifier in pesticide preparation processing, and relates to the technical field of pesticides. The emulsifiercomprises a component A and a component B, wherein the component A comprises one or more of alkylphenol polyoxyethylene ether, nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether,castor oil polyoxyethylene ether, span, potassium fatty alcohol ether phosphate, potassium lauryl phosphate, calcium dodecylbenzene sulfonate and Tween; and the component B comprises one or more of maleic rosin octylphenol polyoxyethylene ether diester carboxylate sodium, rosin polyethylene glycol citrate, sodium N-lauroylsarcosinate and sodium diethylhexyl sulfosuccinate. The emulsifier can effectively emulsify biomass solvents, and alleviates the lack of an emulsifier for processing pesticide preparations by using the biomass solvents in the prior art.

Owner:HEBEI TIANFA CHEM TECH CO LTD

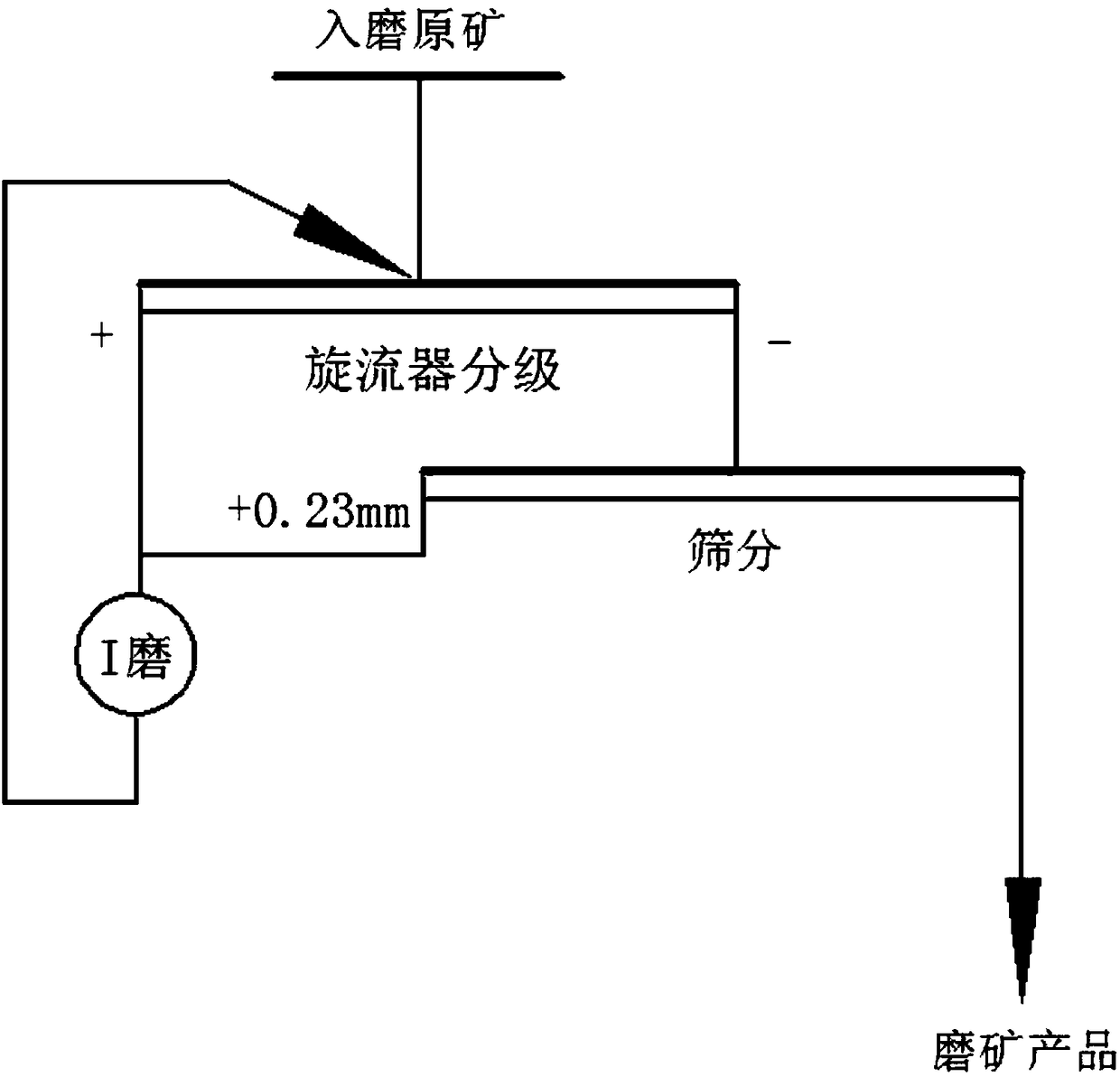

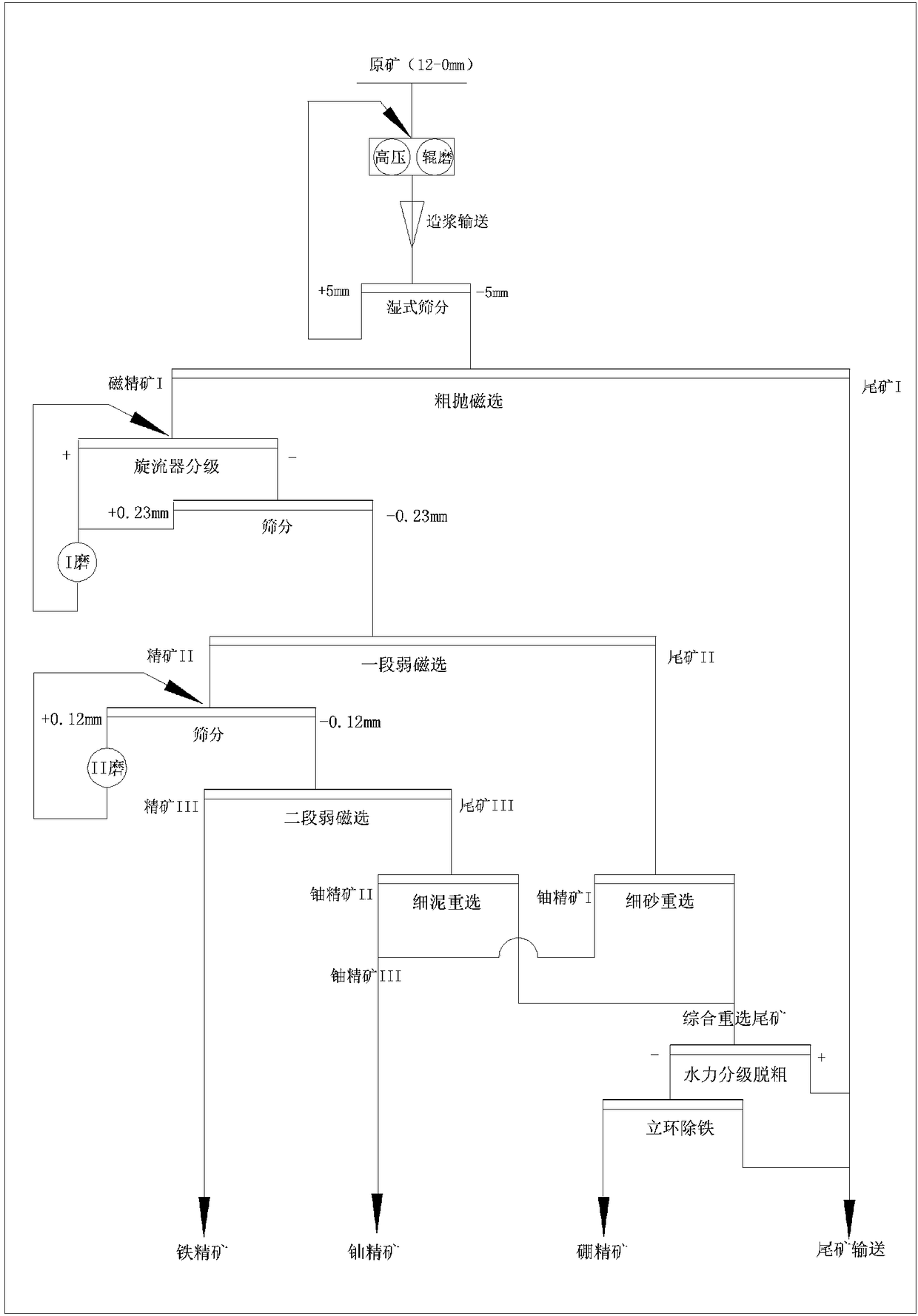

Closed circuit grinding method by adopting unified classification mode

ActiveCN108144742AImprove grindabilityImprove passabilityGrain treatmentsWet separationLower gradeEngineering

The invention relates to the technical field of mineral processing, in particular to a closed circuit grinding method by adopting a unified classification mode. The method comprises the steps that (1)ground pulp is directly fed into a hydrocyclone for classification; (2) hydrocyclone fine-grained overflow pulp in the first step is conveyed into a vibrating sieve, and the sieve mesh size is 0.23mm; (3) pulp according with the grain size requirement and passing the vibrating sieve in the second step is conveyed to the next working procedure, and plus sieve rough grains and hydrocyclone underflow jointly return to a mill for ore grinding; and (4) a product after ore grinding and ground raw ore are jointly fed again into the hydrocyclone for classification, forming a section of closed circuitgrinding of unified classification. The mineral separation processing cost is reduced, and meanwhile the comprehensive utilization level of low-grade uranium-boron-iron associated minerals is improved.

Owner:LIAONING SHOUGANG BORON IRON

Non-chrome composite passivation solution for surface of galvanized steel sheet part of pump

InactiveCN107419253AImprove performanceReduce pollutionMetallic material coating processesMolybdateSheet steel

The invention discloses a non-chrome composite passivation solution for the surface of a galvanized steel sheet part of a pump, and relates to the technical field of metal surface processing. The non-chrome composite passivation solution is composed of molybdate, tungstate, zirconate, tannic acid, phytic acid, potassium permanganate, a passivation assistant and water. According to the finally obtained non-chrome composite passivation solution, the safety is good, pollution is small, the requirements for green development of modern enterprises are met, in addition, the quality of a processed workpiece surface is high, the performance of a passivating film is excellent, the processing and producing efficiency is high, and high market competitiveness is achieved.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

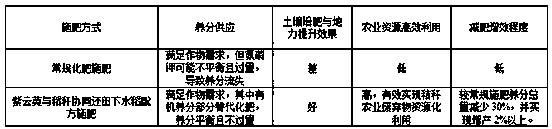

Single cropping rice formula fertilization method under green manure and straw synergic field returning

InactiveCN109566308APromote early growthPromote decompositionFertilising methodsRice cultivationAgricultural scienceDecomposition

The invention provides a single cropping rice formula fertilization method under green manure and straw synergic field returning. The method comprises the following steps that 1, in every September toOctober, milk vetch is sown at the bottom southern rice field rice in an undersow mode, rice mechanical high stubbles are harvested, the stubbles are 30-40 cm high, the other is smashed and returnedto a field, straw is concentrated at the coverage position, the growth seedling stage is stirred up by bamboo poles, and it is ensured that milk vetch seedlings receive sunshine; 2, in the next April,a rotary cultivator is used for performing dry tillage to perform ploughing milk vetch and straw under to great depth to the tillage layer by 15 cm or below; 3, turning, burying and decomposition areperformed till May to June, water feeding and field uniforming are performed, and single cropping rice is planted; 4, at the single cropping rice fertility stage, the total nitrogen phosphorus and potassium nutrient total content is lowered by 30% compared with conventional fertilizer amount, and the content ratio of N to P2O5 to K2O in nitrogen phosphorus and potassium fertilizer is 1:0.3:0.7. Due to milk vetch and straw synergic field returning, the rice nitrogen phosphorus and potassium fertilizer ratio and consumption are controlled, and the purposes that application of the single cropping rice fertilizer nitrogen phosphorus and potassium can be reduced by 30%, and the production can be increased by 2% or above are achieved.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

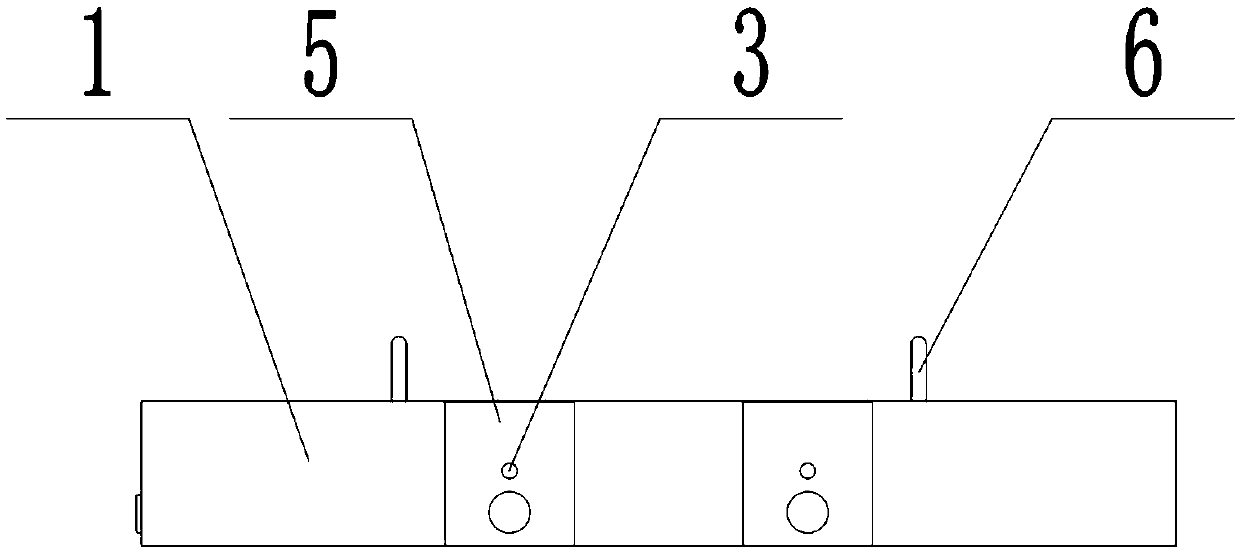

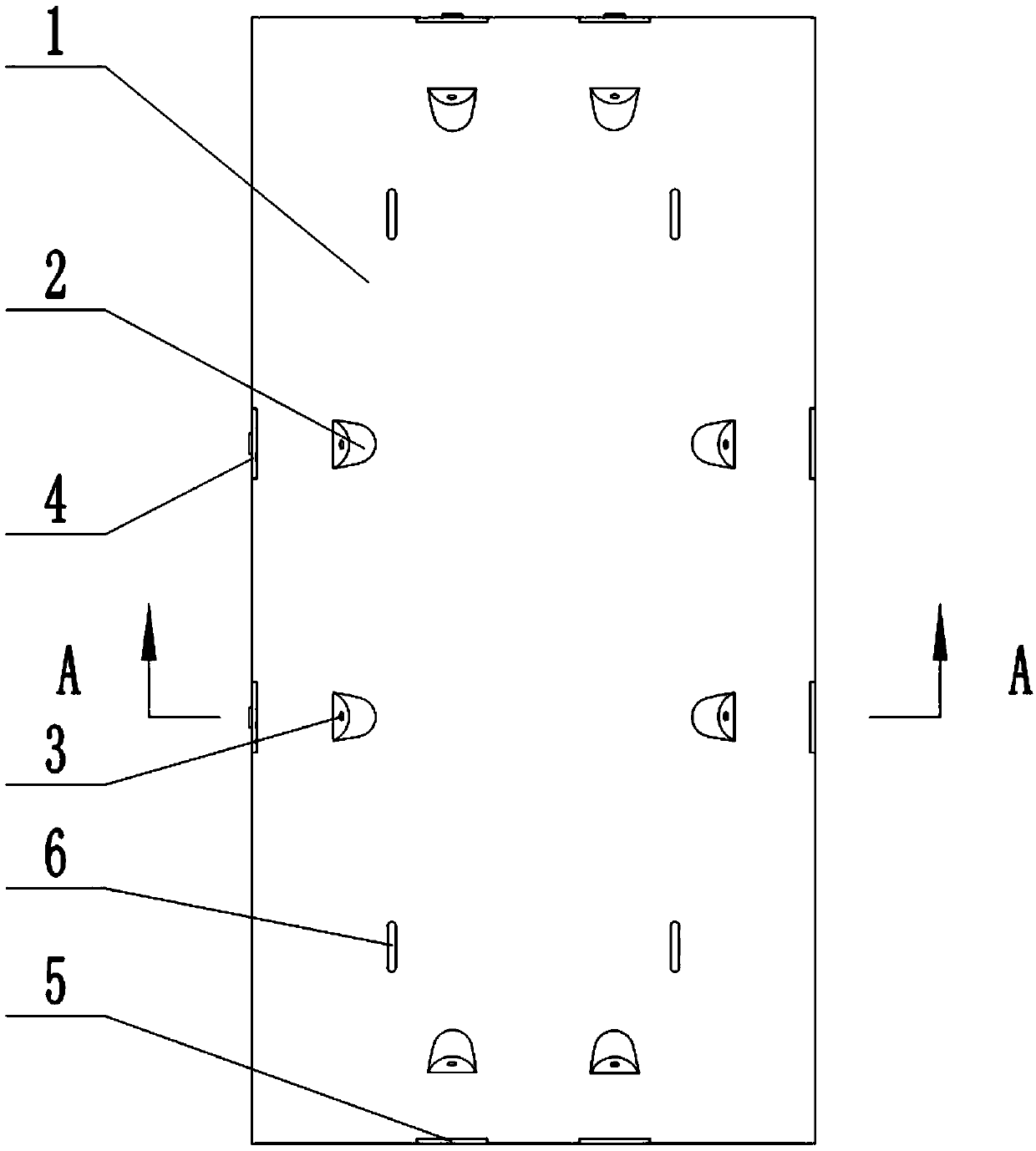

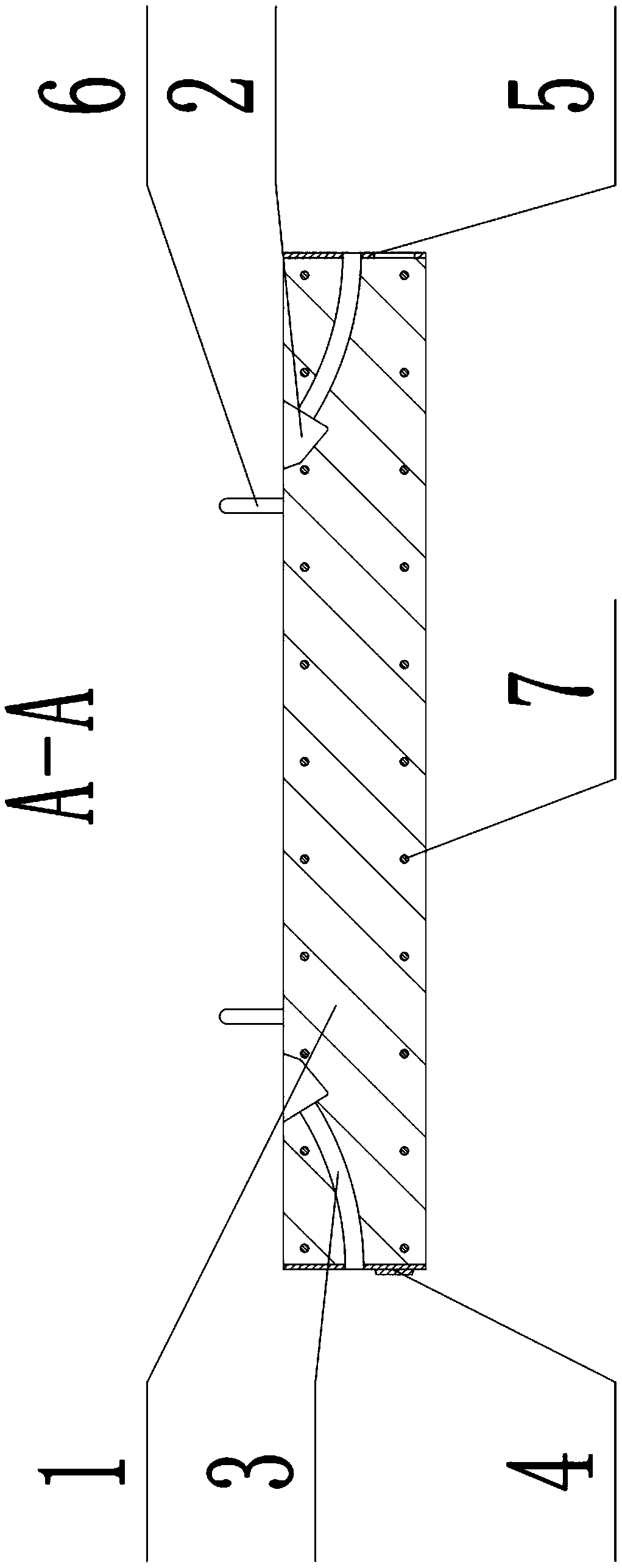

Prefabricated road board connected with bolt with one end bent back as well as production method and connection technologyof prefabricated road board

The invention provides a prefabricated road board connected with a bolt with one end bent back as well as a production method and a connection technology of the prefabricated road board. The prefabricated road board comprises a road board main body, wherein the top of the road board main body is provided with a horseshoe groove, the interior of the road board main body is provided with an arc-shaped hole, and construction specifically comprises the following steps that the construction procedure that reinforcing meshes are tied manually and then the reinforcing meshes are integrally carried into a mold is adopted; template construction is conducted, side forms are assembled and then placed on a special steel platform, and the situation that a demolding agent pollutes prefabricated board reinforcing steel bars in a process of entering a mold needs to be avoided; pre-buried pieces are mounted, the horseshoe groove needs to be pre-buried before pouring of the prefabricated road board, andthe horseshoe groove is fixed to a limiting frame through a bolt; convex and concave steel plates are pre-buried at four sides of a prefabricated form respectively; concrete construction is conducted, manual vibration is conducted, and the concrete is vibrated compactly and uniformly; and concrete curing is conducted, the formed prefabricated road board is placed into a steam curing tank by usingan elevator to be subjected to steam curing. The prefabricated road board has the beneficial effects that firstly, the cost is low; secondly, the safety coefficient is high; thirdly, the constructionefficiency is high; fourthly, the construction quality is guaranteed; and fifthly, the pollution to the environment is less.

Owner:中国雄安集团基础建设有限公司 +4

Method for preparing high-performance compound machine-made charcoal

The invention relates to a method for preparing high-performance compound machine-made charcoal, and belongs to the technical field of resource comprehensive utilization. The method comprises the following steps: respectively grinding a biomass raw material with a moisture content of lower than 5 percent and lignite into particles having granularity of less than 1cm; pyrolyzing the biomass raw material particles to obtain charcoal; uniformly mixing charcoal, lignite, an adhesive, a combustion improver and water to obtain a mixed material, and pressing the mixed material into charcoal rods with center holes; and heating the charcoal rods with center holes to 400-700 DEG C at a heating speed of 30-200 DEG C / min, carbonizing for 1-12 hours, and cooling to obtain the compound machine-made charcoal. The preparation process adopts biomass which is rich in source and low in price, is regenerative and can be easily ground and lignite with low price as carbon sources, has the potentials of low large-scale production price, high yield, high heat value and high porosity, and is well accepted by the market.

Owner:KUNMING UNIV OF SCI & TECH

Silicone rubber composition and preparation method thereof

The invention discloses a silicone rubber composition and a preparation method thereof. The composition comprises composite insulator silicone rubber powder and room temperature cured silicone rubber,the composite insulator silicone rubber powder is obtained by processing retired composite insulator silicone rubber; preferably, the composite insulator silicone rubber powder is retired composite insulator silicone rubber powder modified by a coupling agent. The composition has good mechanical properties. The invention also provides a preparation method of the silicone rubber composition; the preparation method has the advantages of easily available raw materials, simple process, mild conditions and easy realization, and achieves the cyclic utilization of the retired composite insulator silicone rubber, so the material cost is reduced, the resources are saved, and the environment is protected.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

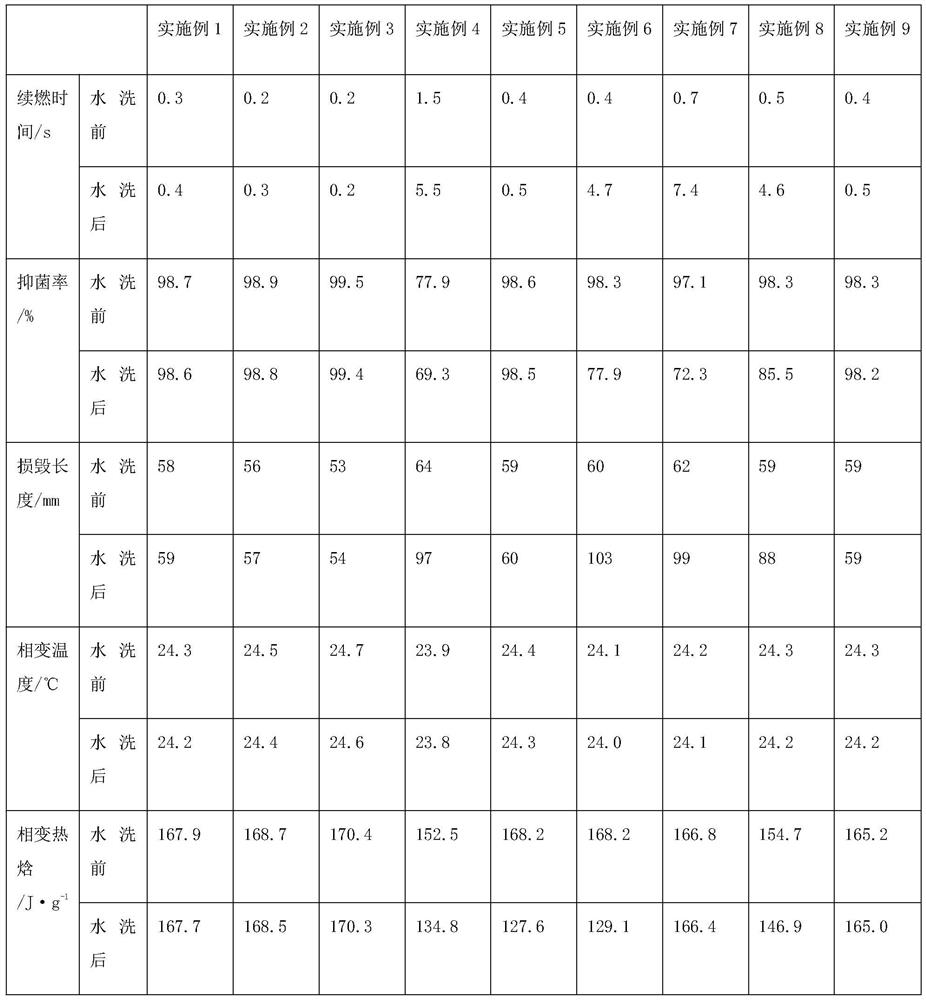

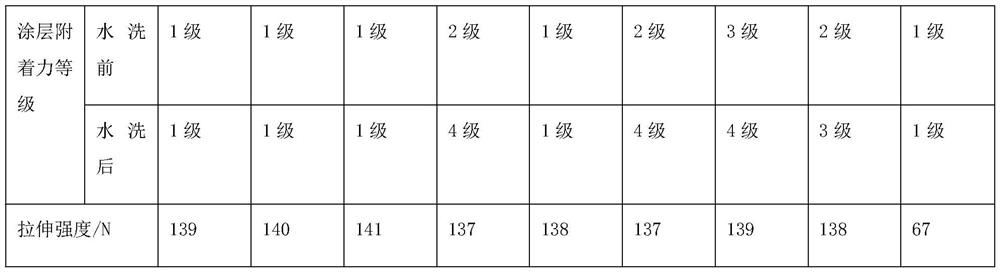

Flame-retardant temperature-regulating environment-friendly non-woven fabric and preparation method thereof

ActiveCN112411198AImprove thermal stabilityImprove compactnessTextiles and paperPolyelectrolytePolymer science

The invention discloses a flame-retardant temperature-regulating environment-friendly non-woven fabric and a preparation method thereof. The preparation method comprises the following steps: graftingamino and nano-silver on the surface of a modified carbon nanotube, introducing the modified carbon nanotube into a non-woven fabric base material, grafting sulfydryl and hydroxyl on a temperature-regulating capsule to modify the modified temperature-regulating capsule, respectively preparing a cationic flame-retardant coating and an anionic flame-retardant coating, sequentially coating thenon-woven fabric base material with a modified temperature-regulating capsule coating, the cationic flame-retardant coating and the anionic flame-retardant coating, and adsorbing polyelectrolyte or nanoparticles with opposite charges between the coatings by utilizing intermolecular force between the coatings and the non-woven fabric base material. Thus, the non-woven fabric with flame-retardant and temperature-regulating functions is constructed within a nanoscale range, a core material in the prepared non-woven fabric temperature-regulating capsule is not prone to leakage, the adhesive force betweenthe coatings is good, the non-woven fabric is more washable, meanwhile, the non-woven fabric has a certain antibacterial function, and market requirements can be met.

Owner:李建勋

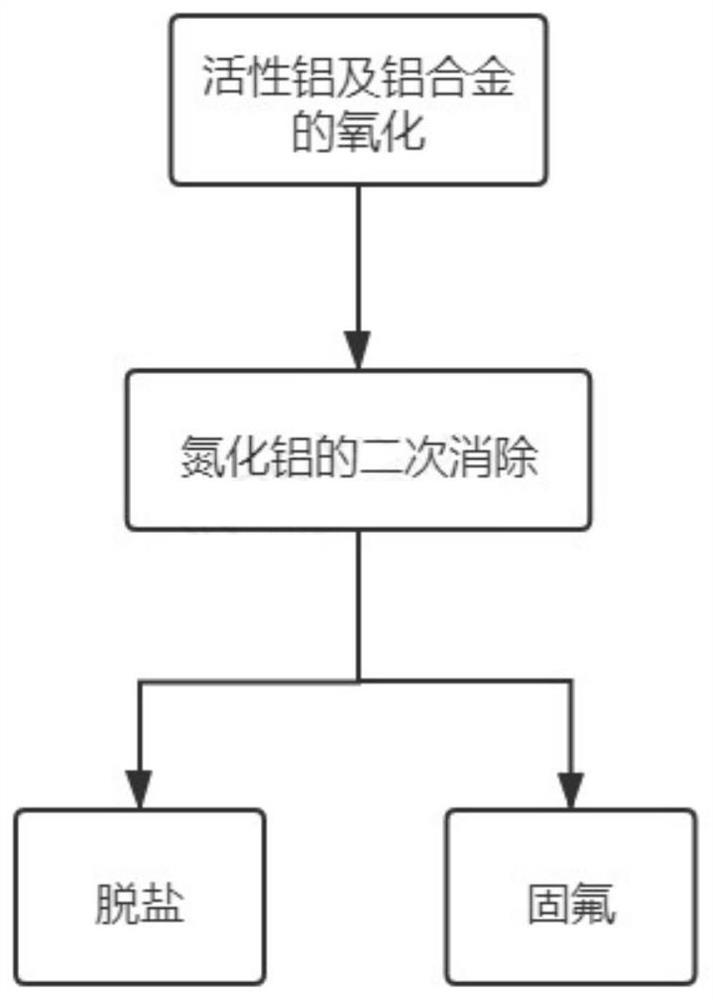

Harmless treatment method of aluminum ash

PendingCN113912097AEasy to handleEfficient recyclingCalcium/strontium/barium fluoridesAluminium chloridesAluminium hydroxideHazardous substance

The invention discloses a harmless treatment method of aluminum ash, which comprises the following treatment steps: oxidation of active aluminum and aluminum alloy: calcining the aluminum ash at 750-1100 DEG C to oxidize the active aluminum and aluminum alloy in the aluminum ash and oxidize part of aluminum nitride in the aluminum ash; and secondary elimination of aluminum nitride: adding water and an oxidizing agent into the calcined aluminum ash, reacting the aluminum nitride in the aluminum ash with the water under the action of the oxidizing agent to generate aluminum hydroxide and nitrogen, and obtaining an aluminum ash suspension after the reaction. The aluminum element in the aluminum ash can be effectively recycled, harmful substances such as ammonia gas are not generated while flammable and explosive phenomena are avoided, the influence on the surrounding environment is effectively reduced, the aluminum ash can be efficiently treated, secondary pollution to the external environment is avoided, the aluminum ash can be effectively recycled and reused, and the requirements of green development are met.

Owner:佛山市吉力达铝材科技有限公司

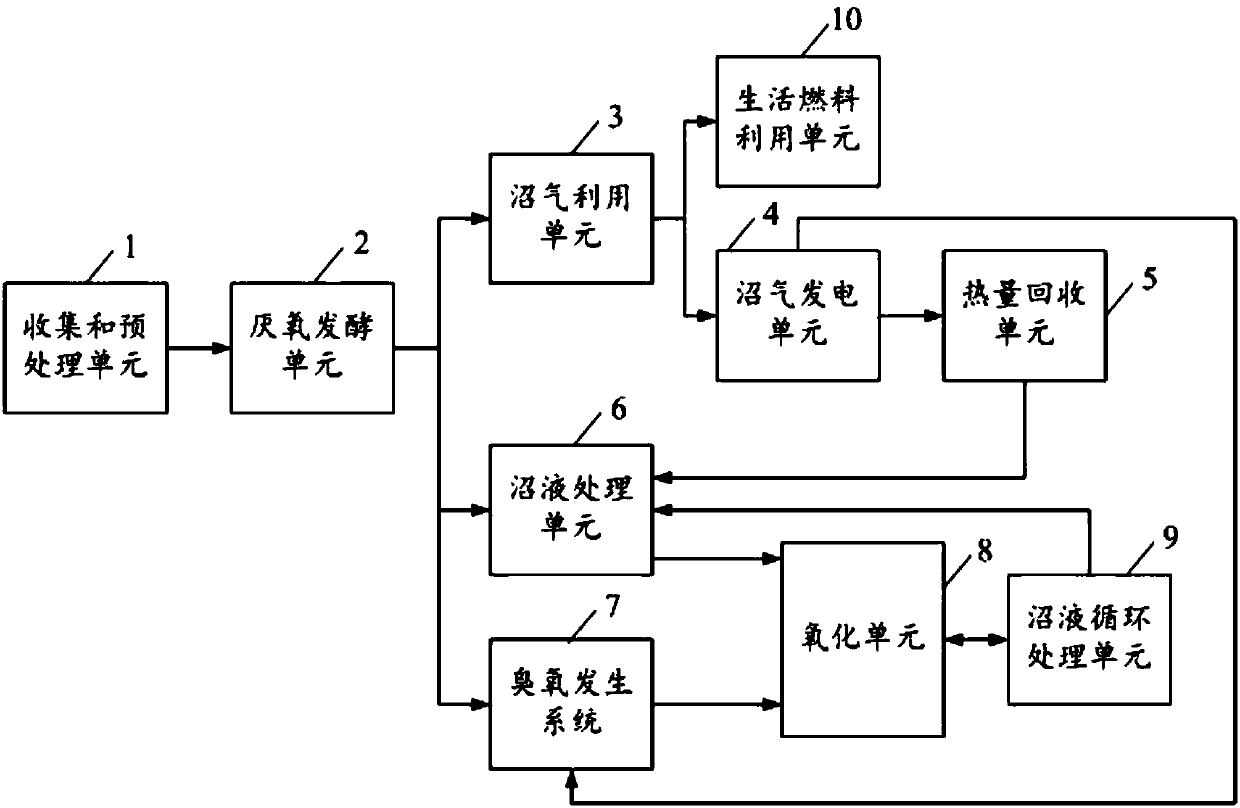

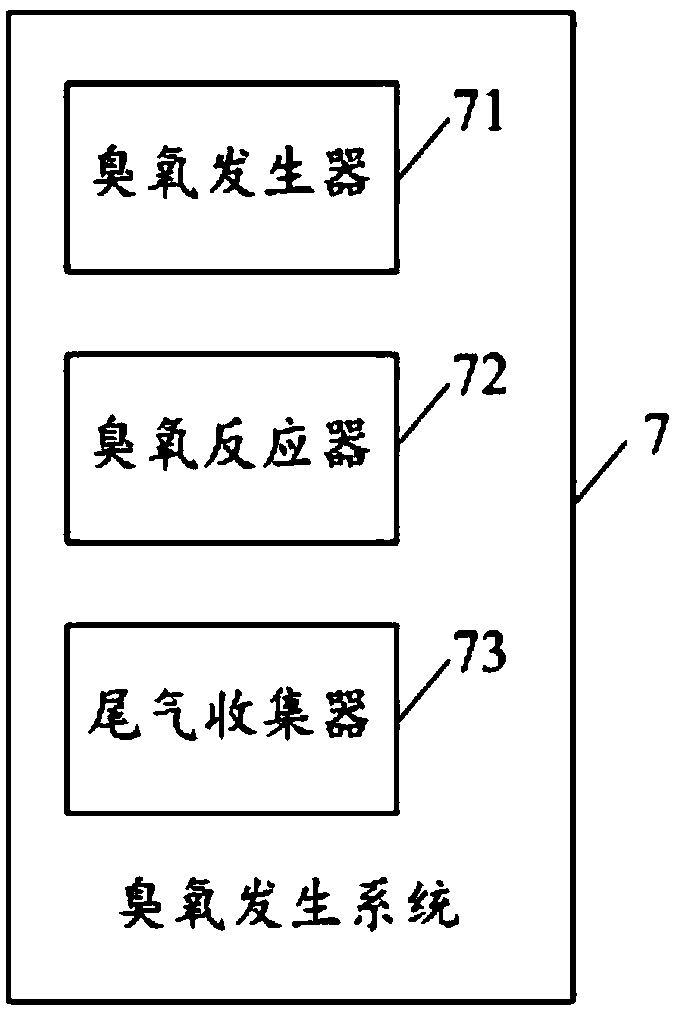

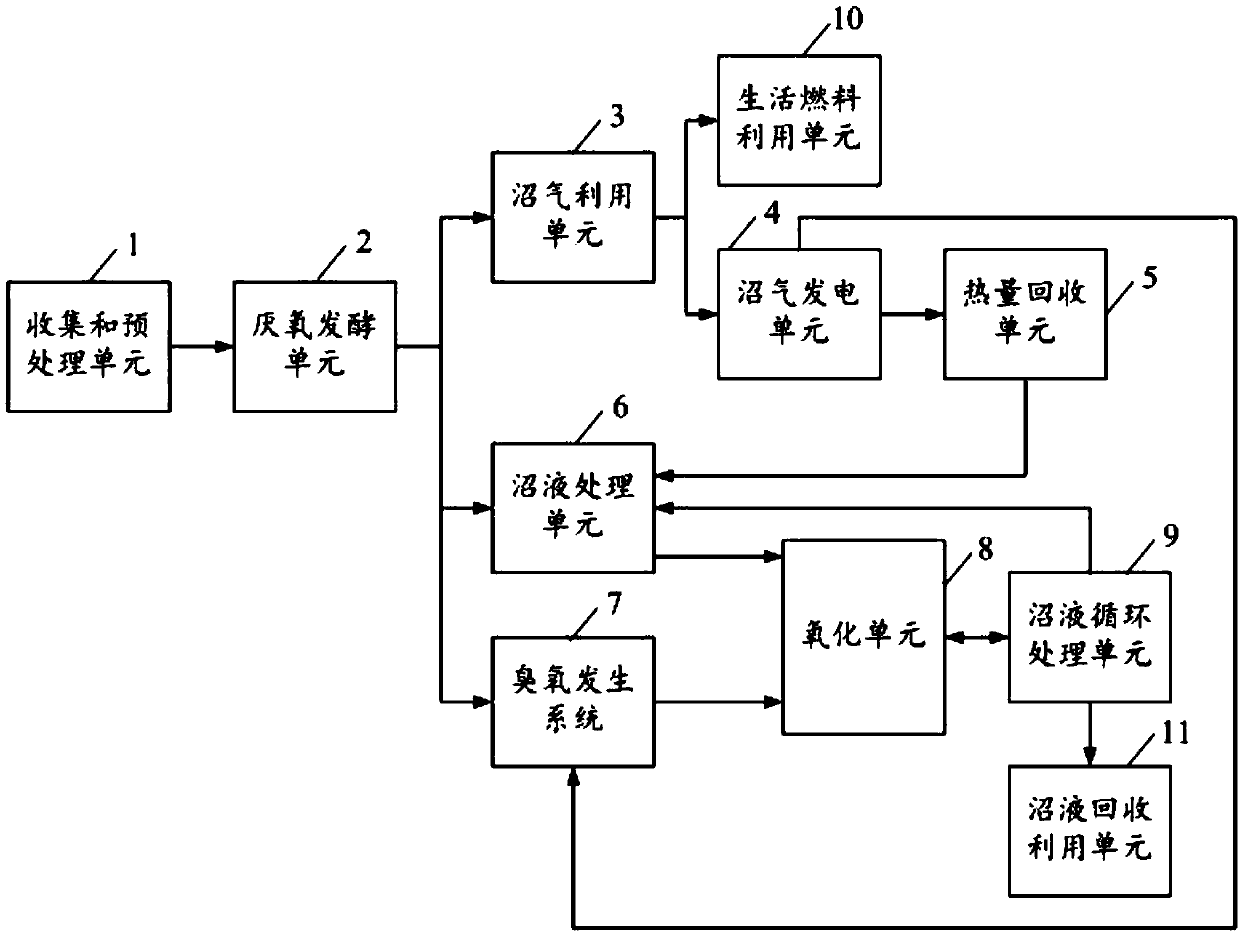

Zero-discharge comprehensive utilization system for waste of large-scale pig farm

PendingCN108046559ASpeed up thermal motionGood for volatilizationWater/sewage treatment by irradiationInternal combustion piston enginesPig farmsSlurry

The invention discloses a zero-discharge comprehensive utilization system for the waste of a large-scale pig farm. The zero-discharge comprehensive utilization system comprises a collecting and preprocessing unit, an anaerobic fermentation unit, a biogas utilization unit, a biogas power generation unit, a heat recycling unit, a biogas slurry processing unit, an ozone generating system, an oxidizing unit and a biogas slurry circulating processing unit. The zero-discharge comprehensive utilization system has the advantages that the system is efficient, thorough, free of secondary pollution, capable of lowering pig cultivation environment protection cost, capable of creating high economic benefits, capable of saving water and capable of protecting ambient environments; pig manure is used forperforming anaerobic fermentation, generated biogas is used for generating power to reduce the production and living power consumption cost of the pig farm, the high power consumption cost problem ofa O3 / UV advanced oxidation treatment process can be solved, and grid-connected power generation can be achieved to earn electricity fee income; processed biogas slurry tail water can be used for washing pig houses, water can be saved, pig epidemic diseases and pig house mosquitoes and flies can be reduced, and production efficiency is increased.

Owner:广东广垦畜牧工程研究院有限公司 +1

Method for improving boron concentrate grade by adopting high-gradient vertical ring magnetic separator through deironing

ActiveCN108144741AImprove grindabilityImprove passabilityHigh gradient magnetic separationHigh gradient magnetic separatorsPower flowLower grade

The invention relates to the technical field of mineral processing, in particular to a method for improving the boron concentrate grade by adopting a high-gradient vertical ring magnetic separator through deironing. The method is characterized by comprising the following steps that firstly, rough boron concentrates in a pulp form are conveyed to the high-gradient vertical ring magnetic separator;secondly, the current of the high-gradient vertical ring magnetic separator in the first step is adjusted to make the background field intensity be 0.6T; and thirdly, weakly magnetic mineral verticalring concentrates adsorbed out by vertical ring media in the second step are collected as boron tailings, and vertical ring tailing pulp which is not adsorbed by the media is final boron concentrate pulp. The mineral separation processing cost is reduced, and meanwhile the comprehensive utilization level of low-grade uranium-boron-iron associated minerals is improved.

Owner:LIAONING SHOUGANG BORON IRON

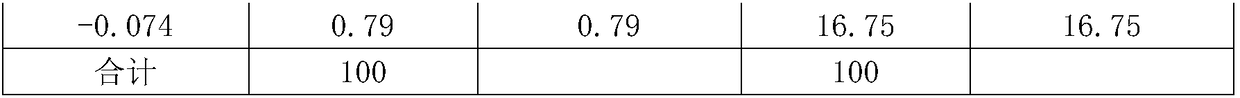

Electrolytic copper foil surface treatment technology

The invention discloses an electrolytic copper foil surface treatment technology. The technology comprises the follow steps of carrying out pretreatment; carrying out roughening, wherein roughening treatment is carried out on original foil subjected to pretreatment in a solution containing copper sulfate, sulphuric acid, sodium silicate and stannous sulfate; carrying out curing, wherein one layerof dense metallic copper is deposited in a gap between every two adjacent nodular particles of the copper foil subjected to roughening; carrying out electroplating of dissimilar metal, wherein in an inert gas atmosphere, the copper foil is heated to form a brass layer and then is subjected to antioxidant treatment, and antioxidant liquid is prepared by dissolving chromium trioxide and a glucose solution into water; soaking the obtained copper foil into the antioxidant liquid for one second to four seconds; carrying out coating, wherein a silane coupling agent is sprayed to the surface of the copper foil after the copper foil is subjected to antioxidant treatment, and then the copper foil is dried in an air-blowing manner; and carrying out oven drying. According to the electrolytic copper foil surface treatment technology, because the tin sulfate is added in an electroplating dissimilar metal technology to serve as an additive instead of arsenic in a traditional technology, the electrolytic copper foil surface treatment technology is friendly to the environment, and accords with the concept of green development.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

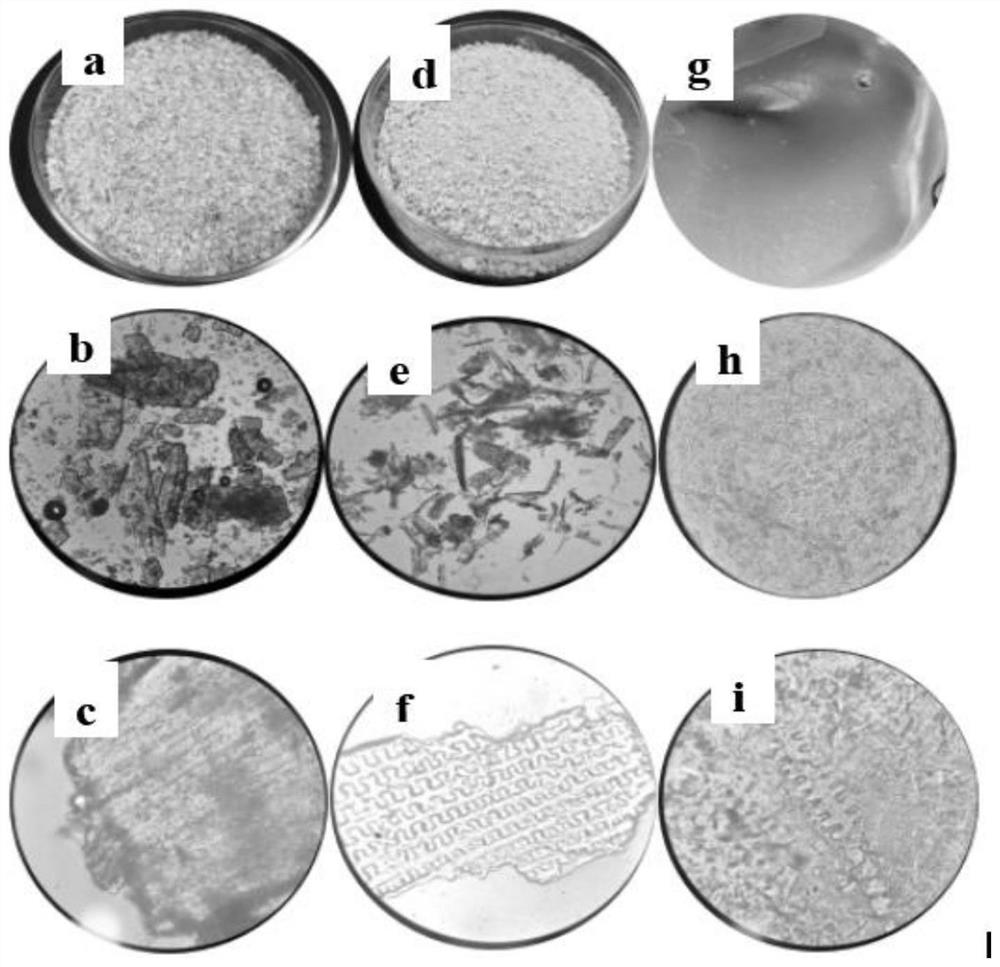

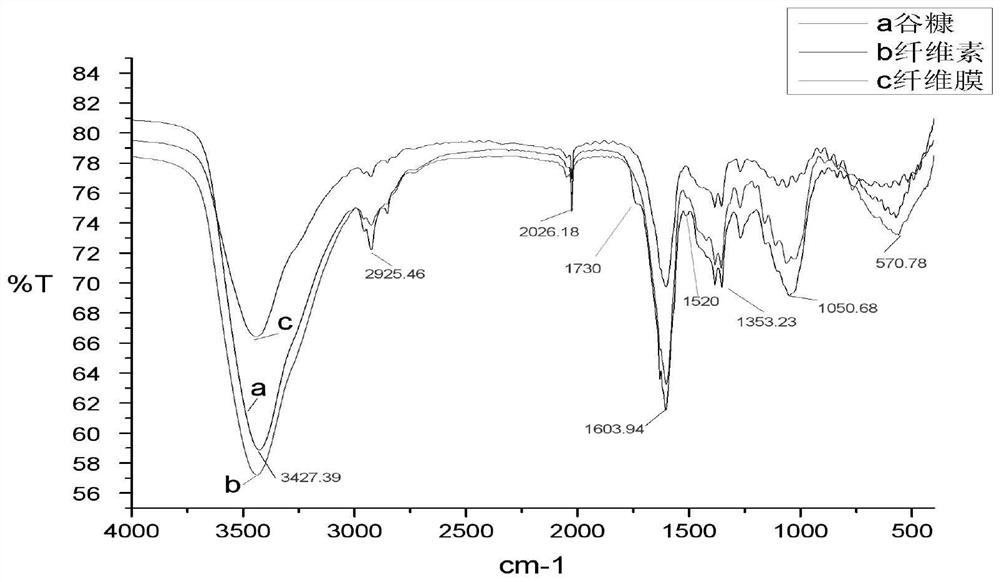

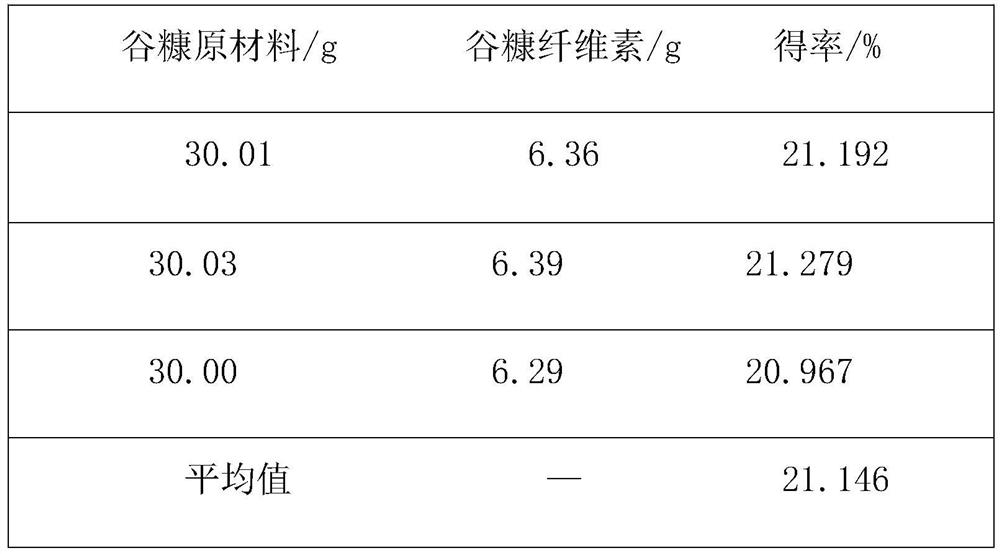

Extraction method of bran coat cellulose and preparation method of bran coat fiber membrane

The invention provides an extraction method of bran coat cellulose and a preparation method of a bran coat fiber membrane. According to the extraction method, impurity components in bran coat crude fibers can be fully removed, the relatively pure bran coat cellulose is finally obtained, and the groove structure on the surface of the bran coat cellulose enables the cellulose to have better reactionactivity, so that the reaction capacity with subsequent reagents is improved. The bran coat cellulose subjected to decolorization treatment is used for preparing the bran coat fiber membrane which has better light transmission. The preparation process of the bran coat cellulose film is simple and pollution-free, the green development requirement is met, the prepared bran coat cellulose film material belongs to a renewable biomass material, and has good antibacterial and fresh-keeping properties, so that the material is expected to be applied to the fields of food packaging and fresh keeping.

Owner:ZHONGBEI UNIV

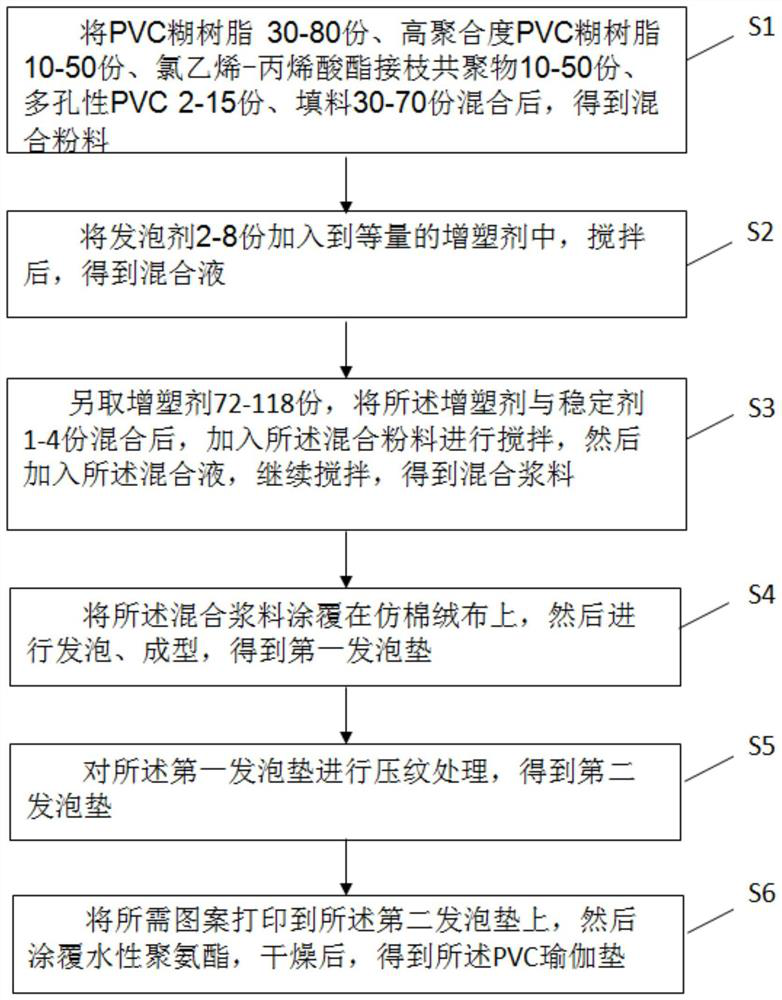

PVC yoga mat and preparation method thereof

ActiveCN114196136AGood flexibilityIncrease elasticityShock absorber matsPolymer scienceFoaming agent

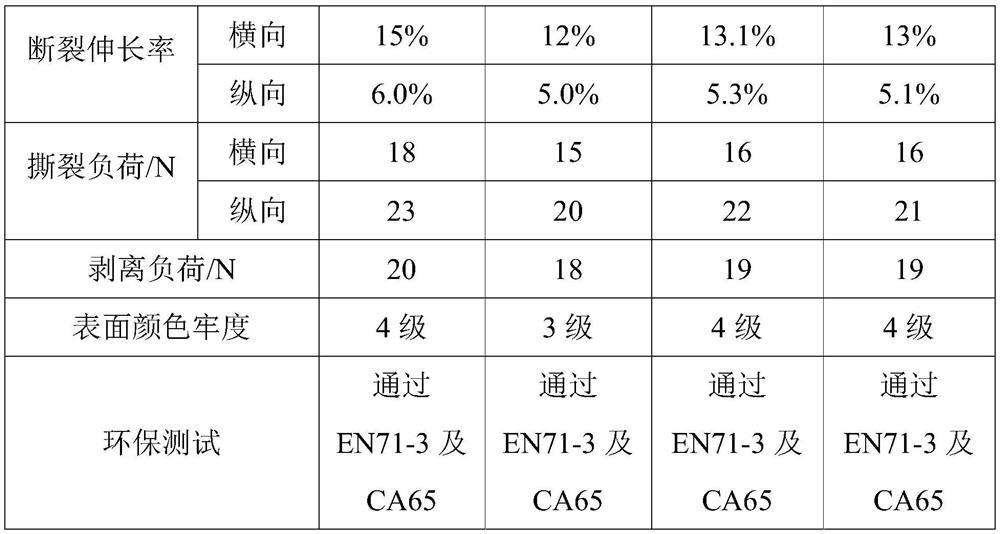

The invention discloses a PVC (polyvinyl chloride) yoga mat and a preparation method thereof, and the PVC yoga mat is prepared from the following raw materials in parts by weight: 30 to 80 parts of PVC paste resin, 10 to 50 parts of high polymerization degree PVC paste resin, 30 to 70 parts of filler, 10 to 50 parts of vinyl chloride-acrylate grafted copolymer, 2 to 15 parts of porous PVC, 80 to 120 parts of plasticizer, 2 to 8 parts of foaming agent and 1 to 4 parts of stabilizer. According to the PVC yoga mat, the adopted PVC paste resin material can be recycled and is good in environmental protection property, the rebound resilience can be improved by adding the high-polymerization-degree paste resin and the vinyl chloride-acrylate grafted copolymer, meanwhile, the precipitation of a plasticizer can be reduced by adopting the porous PVC, and the flexibility and rebound resilience of the PVC yoga mat are further enhanced. The PVC yoga mat provided by the invention has the advantages of high rebound resilience, high wear resistance, high flexibility and lasting rebound resilience and flexibility, accords with EN71-3 and CA65 environmental protection standards, and accords with national green development requirements.

Owner:广东远华新材料股份有限公司

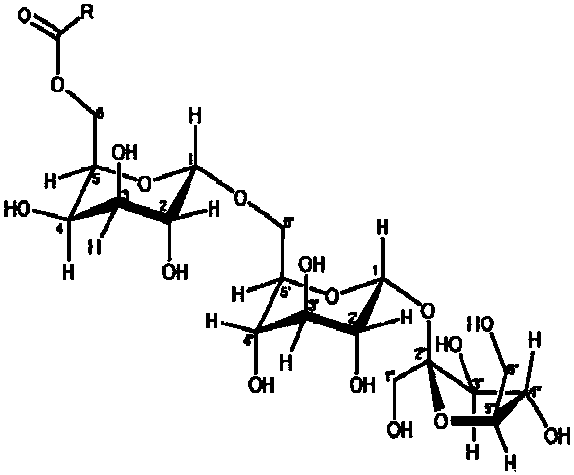

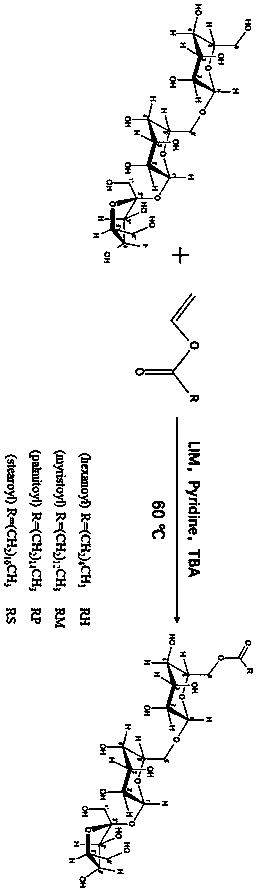

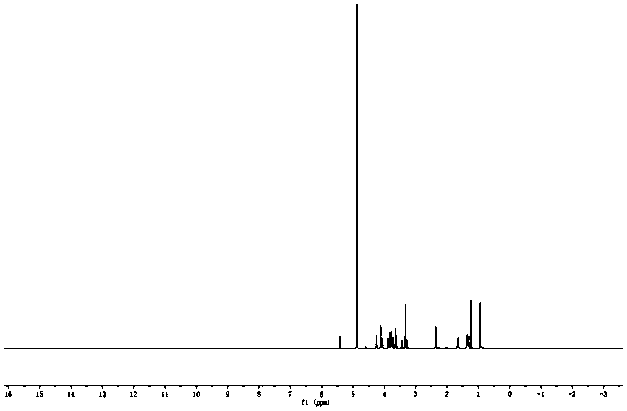

6-O-acyl raffinose monoester and synthesis method thereof

InactiveCN110272926ACan't ignore the health effectPrecise constructionEsterified saccharide compoundsSugar derivativesFoaming agentSynthesis methods

The invention provides a 6-O-acyl raffinose monoester and a synthesis method thereof. On the basis of designing a novel structural model of a raffinose monoester, four kinds of 6-O-acyl raffinose monoesters with different carbon chain lengths are successfully synthesized for the first time. In the synthesis method, reactants with fatty chains of different lengths are selected, through enzymatic reaction, the structure of a glycosyl ester can be accurately formed a reaction site can be controlled, and the molecular weight and structure of the glycosyl ester are changed by continuously forming new fatty chains; and then, the 6-O-acyl raffinose monoester with the required molecular weight and structure is obtained by rapid chromatography elution separation. According to the 6-O-acyl raffinose monoester and the synthesis method thereof, products of different properties are obtained to meet different product requirements, and the synthesis method has simple steps, convenient to operate, significantly shortened in time consumption and environment-friendly; the produced raffinose glycosyl ester has good performance and can be used as an excellent foaming agent and emulsifier; and the monoester output is high and the cost is low, and the 6-O-acyl raffinose monoester is suitable for large-scale industrial production.

Owner:JINAN UNIVERSITY

Anti-UV cloth fiber and manufacture method thereof

InactiveCN106906536AImproved UV protectionImprove toughnessConjugated cellulose/protein artificial filamentsArtifical filament manufactureFiberTemperature resistance

The invention provides an anti-ultraviolet fabric fiber and a manufacturing method thereof. The composition includes waste wood products, bamboo, bagasse, cotton wool, talcum powder, zinc oxide, pottery clay, calcium carbonate and water. The waste wood products, bamboo, bagasse and cotton linters are crushed and mixed, the zinc oxide and calcium carbonate are crushed, the pottery clay is dried and crushed, the zinc oxide, calcium carbonate, pottery clay powder and water are mixed, stirred evenly, and finally the waste Wood products, bamboo, bagasse and cotton wool powder are added, then stirred evenly, dehydrated and dried, sliced, spun, wound and stretched to form fabric fibers. The cloth fiber made by the invention has excellent anti-ultraviolet function, is non-toxic and harmless to the human body, has good fiber toughness, high strength, wear resistance and high temperature resistance, and does not produce heavy feeling. The invention has low cost, simple manufacturing method, and The materials used are mainly environmentally friendly materials, which have certain environmental protection significance and meet the requirements of society's green development.

Owner:合肥云都棉花有限公司

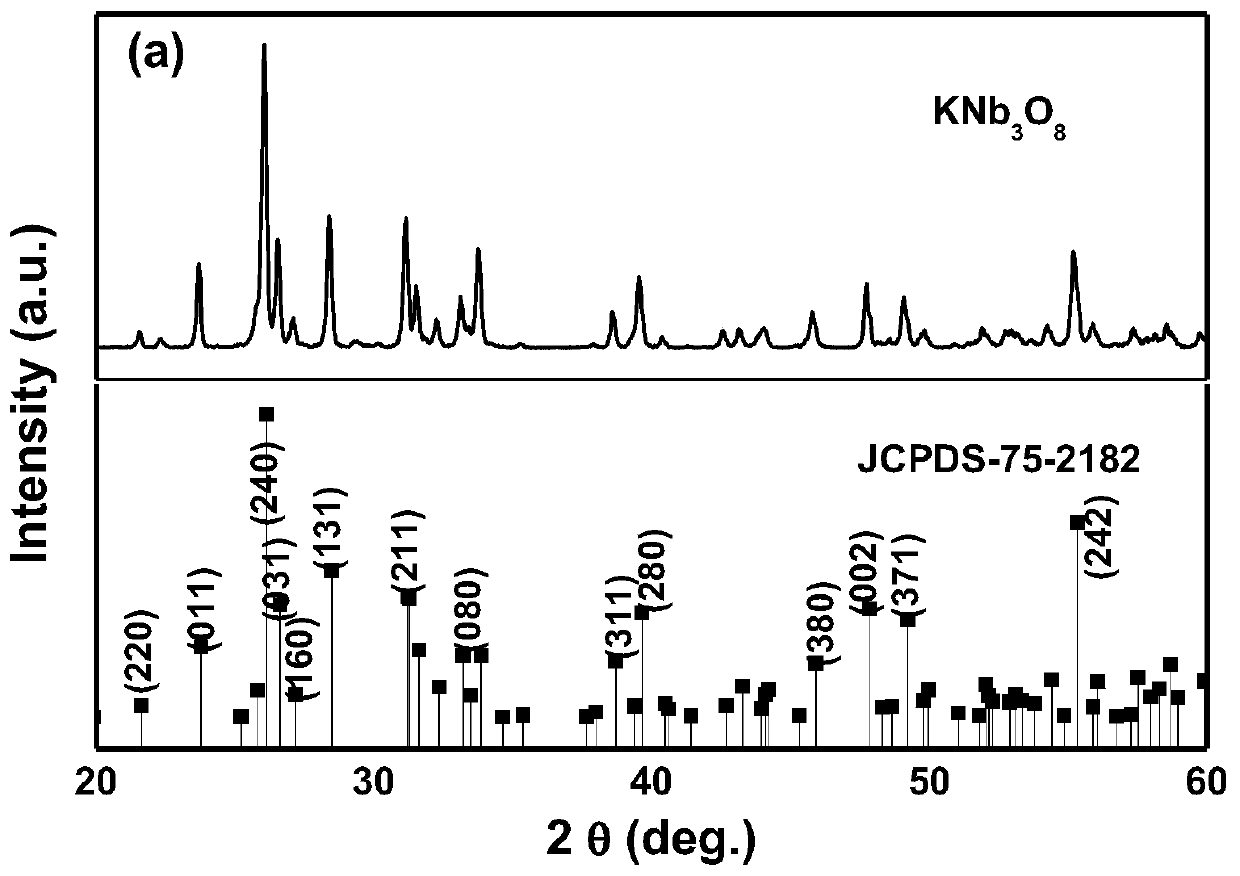

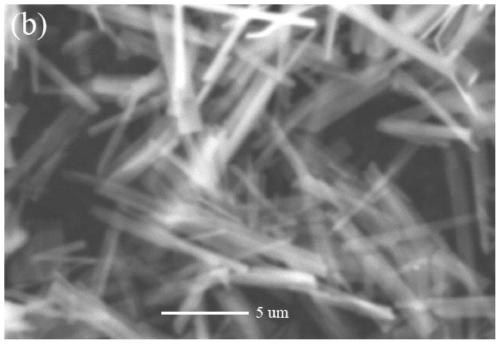

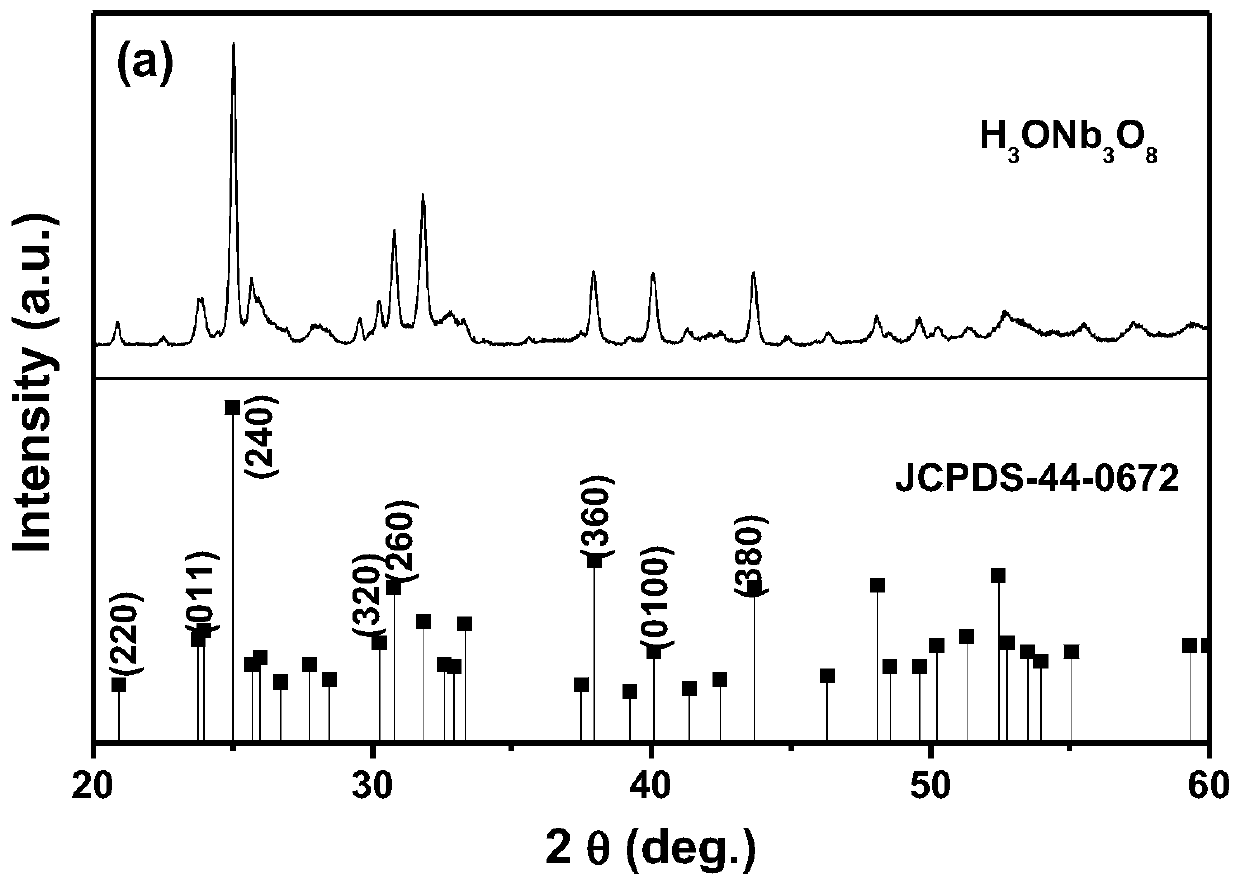

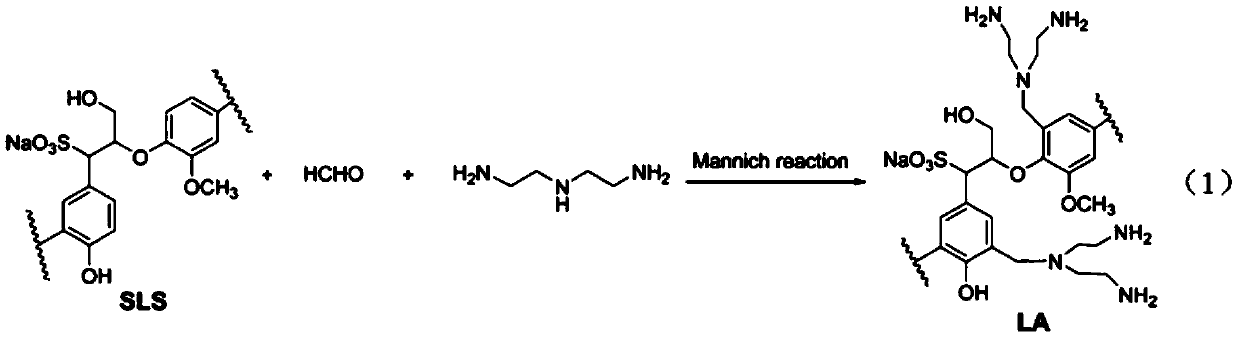

One-dimensional rod-like M-Nb2O5 and preparation method thereof

The invention discloses a one-dimensional rod-like M-Nb2O5 and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing one-dimensional KNb3O8 by a moltensalt method, then carrying out ion exchange on the KNb3O8 and HNO3 to prepare one-dimensional rod-like H3ONb3O8, and finally, carrying out heating decomposition on the H3ONb3O8 to obtain one-dimensional rod-like M-Nb2O5 microcrystalline powder. The production method disclosed by the invention is simple in process. The one-dimensional rod-like M-Nb2O5 microcrystalline powder is relatively uniformin size and morphology. The invention provides a new way for preparing a large amount of one-dimensional rod-like M-Nb2O5 microcrystalline powder, wherein no toxic organic metal compound is used in the preparation process, so that no toxic additional product is generated, and the requirement for green development is met.

Owner:WUHU INST OF TECH

Soilless culture substrate and preparation method thereof

ActiveCN110235747AIncrease profitUtilization rate, and has good mechanical strengthGrowth substratesCulture mediaEnvironmental resistancePapermaking

The invention discloses a soilless culture substrate and a preparation method thereof. The substrate is a porous swelling material into which commercial fertilizer is embedded, and the porous swelling material is lignin hydrogel which is synthesized in situ among porous structures of wood chip particles and has a water absorption swelling property. A large amount of fertilizer is loaded into a network structure formed by wood chips and the hydrogel. Through the adsorption performance of the wood chips, not only is the capability of the single hydrogel to load the fertilizer improved, but also leaching of the fertilizer and hydrogel which are adsorbed in hole cell cavities of the wood chips during a reaction is avoided. The substrate has not only the dual functions of water retention and slow fertilizer release but also high mechanical strength, the fertilizer utilization rate is increased, and the plant growth can be effectively promoted. The soilless culture substrate adopts waste generated by wood processing and the papermaking by-product lignosulfonate as non-toxic raw materials and has the advantages of being degradable, safe, environmentally friendly, low in cost, simple in operation, convenient to use and the like, and large-scale application and popularization are easy.

Owner:YANGTZE NORMAL UNIVERSITY

Paper sheet containing bentonite and preparation method thereof

InactiveCN106958166AIncrease surface areaRich in channelsWaste product additionCorrosion-inhibiting/anti-oxidant agent additionPulp and paper industryPaper sheet

The invention provides a paper sheet containing bentonite and a preparation method thereof. The paper sheet contains the following components: bentonite, talcum powder, needle wood pulp, waste paper, retention agent, pulp dispersing agent, antioxidant and water. The preparation method comprises the following steps: 1) drying bentonite and then grinding into powder; 2) mixing the bentonite powder, talcum powder, needle wood pulp, waste paper and water, stirring and pulping, thereby acquiring the pulp in concentration of 5-8%; 3) adding retention agent, pulp dispersing agent and antioxidant, uniformly stirring, pouring the pulp into a mold, pressing and forming; 4) drying the pressed and formed pulp, cutting and forming, thereby acquiring the end product. The paper sheet provided by the invention is degradable, low in cost, excellent in paper sheet property and high in quality; the added bentonite can effectively improve the smoothness, whiteness and writing property of the paper sheet and can promote the quality of the paper products; the technological process is simple; the manufacturing process is free from pollutant discharge and meets the requirement for green development in the modern society.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

Method for extracting protein from cottonseed meal

The invention provides a method for extracting protein from cottonseed meal. The method comprises the following steps: a, adding water and mixing after smashing the cottonseed meal, and carrying out centrifugal separation; b, filtering a solution, removing residues, then carrying out alkali dissolution, adding protease, heating, and keeping the temperature be 40 to 50 DEG C, the pH (Potential of Hydrogen) value of the solution be 7.5 to 8.0 and the heating time be 3 to 5 hours; c, quickly rising the temperature to 80 to 90 DEG C, and stopping heating after carrying out sterilization and enzyme deactivation treatment; d, then adding sodium chloride in the solution, and concentrating and drying the solution after uniformly stirring, thus obtaining the protein in the cottonseed meal. According to the method provided by the invention, the resource is fully utilized, the protein which is high in nutritive value in the cottonseed meal is extracted, the extracted protein is high in purity and few in impurities and has no residue of an industrial extraction additive, a preparation technology is simple, the cost is low, but the value is high, and the method is suitable for industrial large-scale production.

Owner:合肥云都棉花有限公司

Liquid barium-zinc composite heat stabilizer for high-transparency PVC product

InactiveCN113354870ASolve the precipitation problemEnsure transparencyComposite materialOrganic acid

The invention discloses a liquid barium-zinc composite heat stabilizer for a high-transparency PVC product, which relates to the technical field of plastic additives. The invention relates to a liquid barium-zinc composite heat stabilizer for a high-transparency PVC product. The liquid barium-zinc composite heat stabilizer consists of the following components in percentage by weight: 18-23 parts of mixed organic acid, 22-27 parts of barium hydroxide monohydrate, 10-13 parts of zinc oxide, 5-10 parts of composite phosphite ester, 8-10 parts of an additive, 8-10 parts of a chelating agent, 1-2 parts of an antioxidant, 1-2 parts of an anti-precipitation agent and 20-25 parts of a solvent. The total amount of the components is 100 parts. According to the liquid barium-zinc composite heat stabilizer for the high-transparency PVC product, the composite phosphite ester, the additive, the chelating agent and the anti-precipitation agent are added and matched together, so that the stability of the barium-zinc composite heat stabilizer is greatly improved, precipitation or precipitation of barium and zinc is avoided, the transparency of the PVC product is ensured, and a synthetic material is simple in component and wide in source, large-scale production is facilitated, and the formula is high in flexibility, non-toxic and harmless, and meets the national green development requirements.

Owner:黄山佳宝新材料科技有限公司

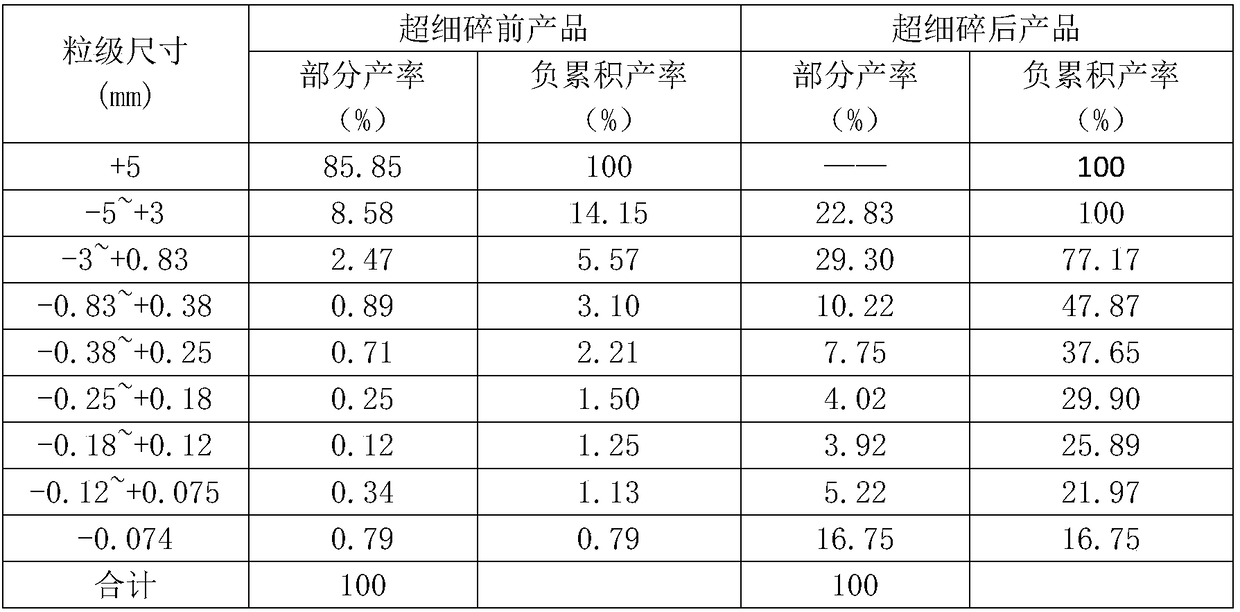

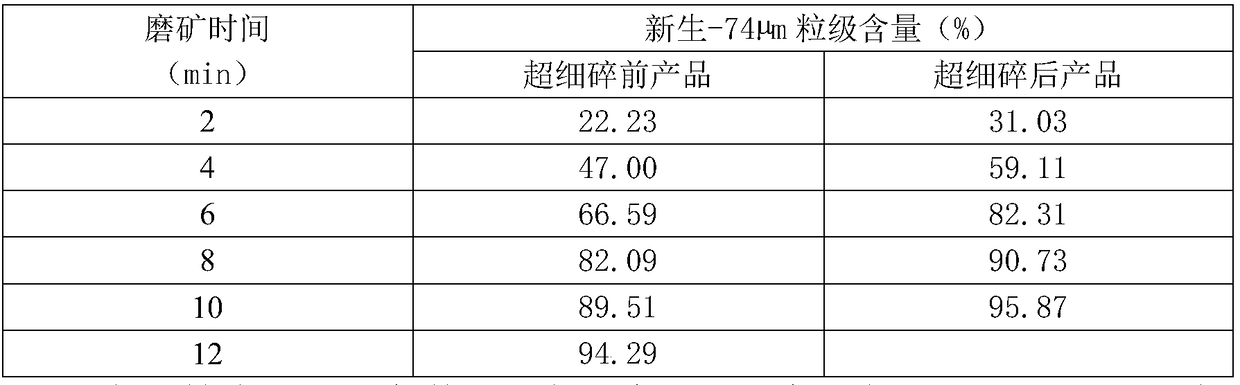

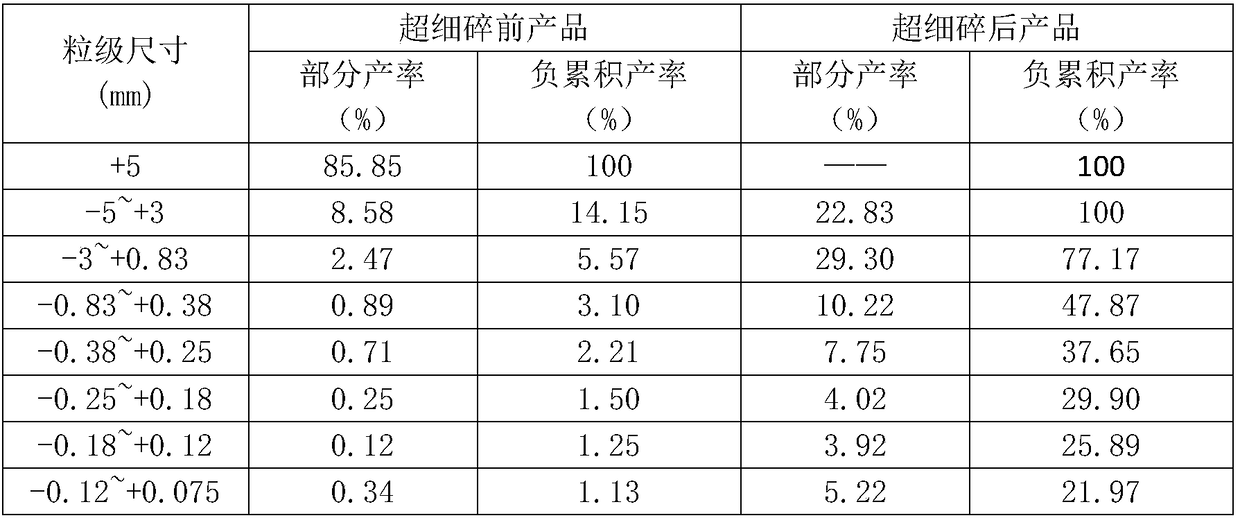

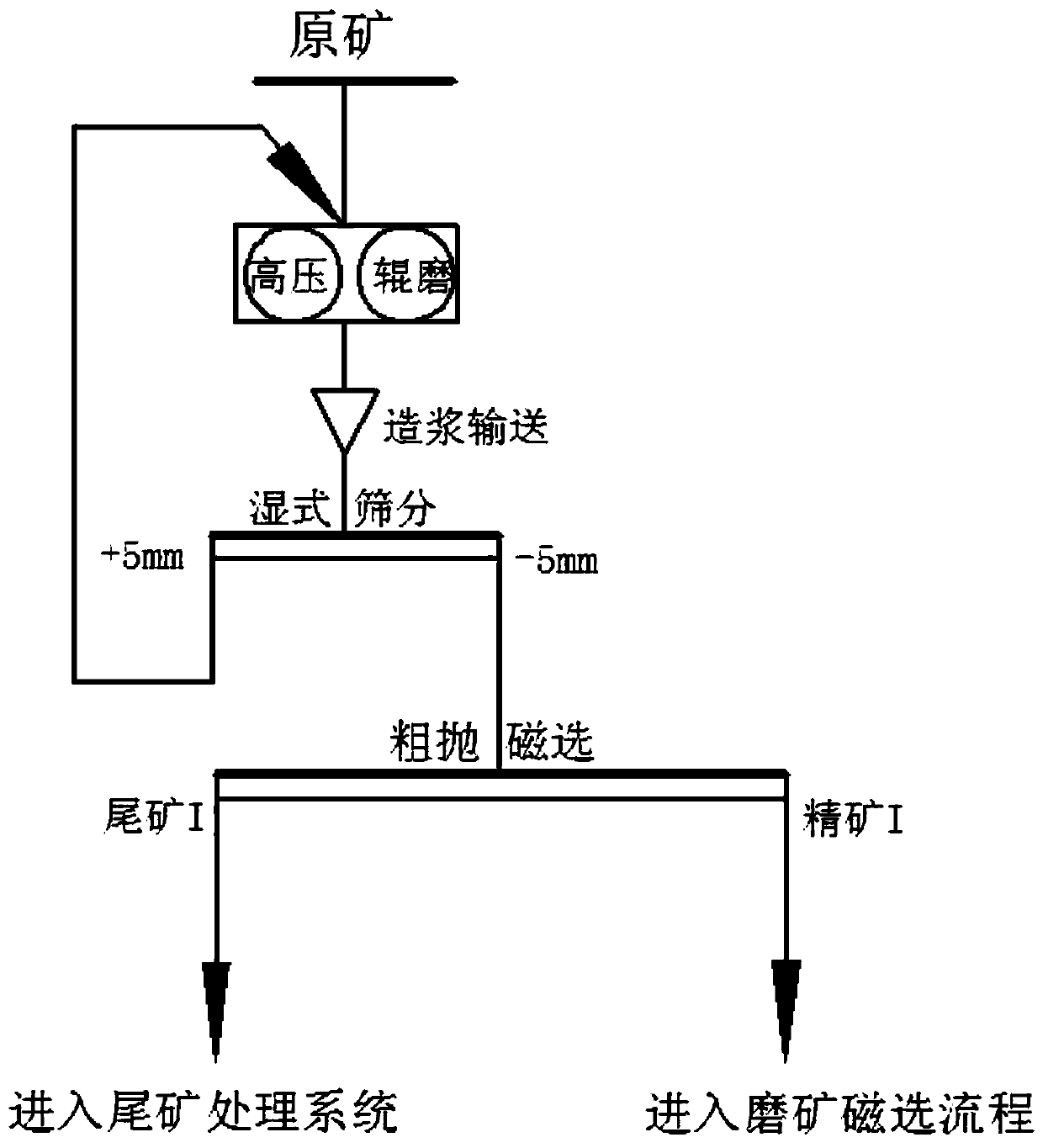

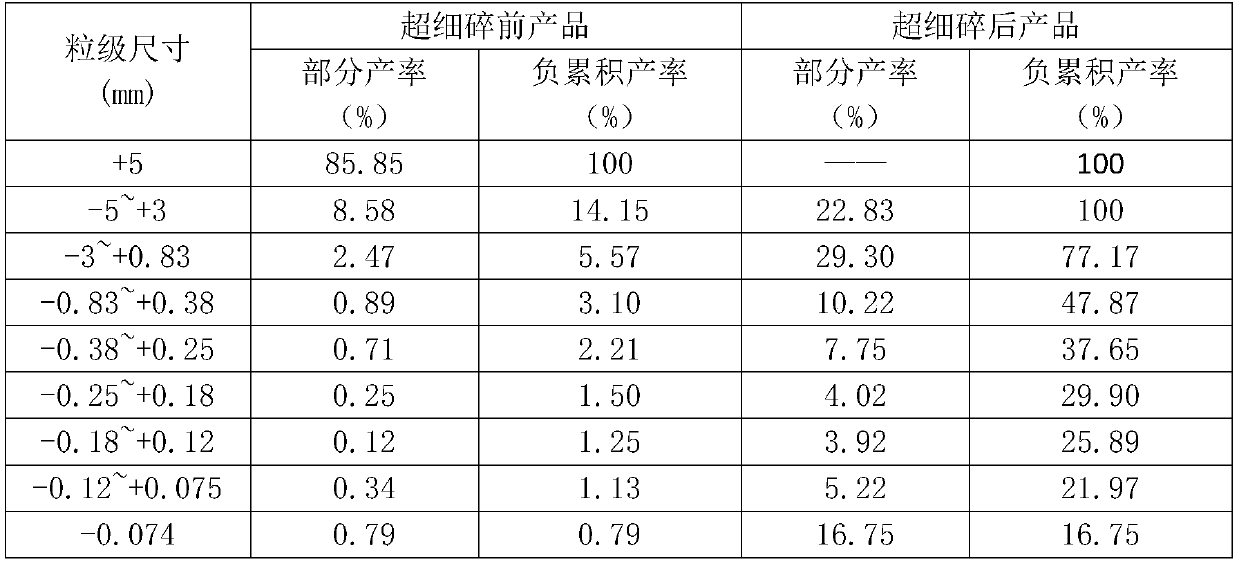

High-pressure roller mill ultra-fine crushing and coarse-grain tailing method applied to mafic ore

ActiveCN108144740BImprove grindabilityImprove passabilityGrain treatmentsWet separationLudwigiteMaterials science

Owner:LIAONING SHOUGANG BORON IRON

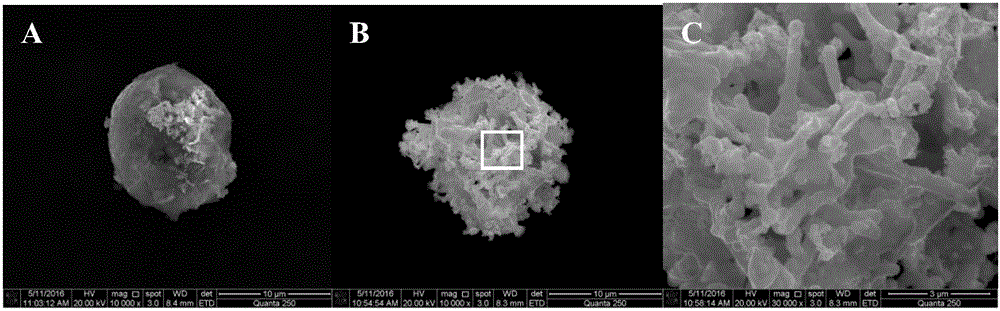

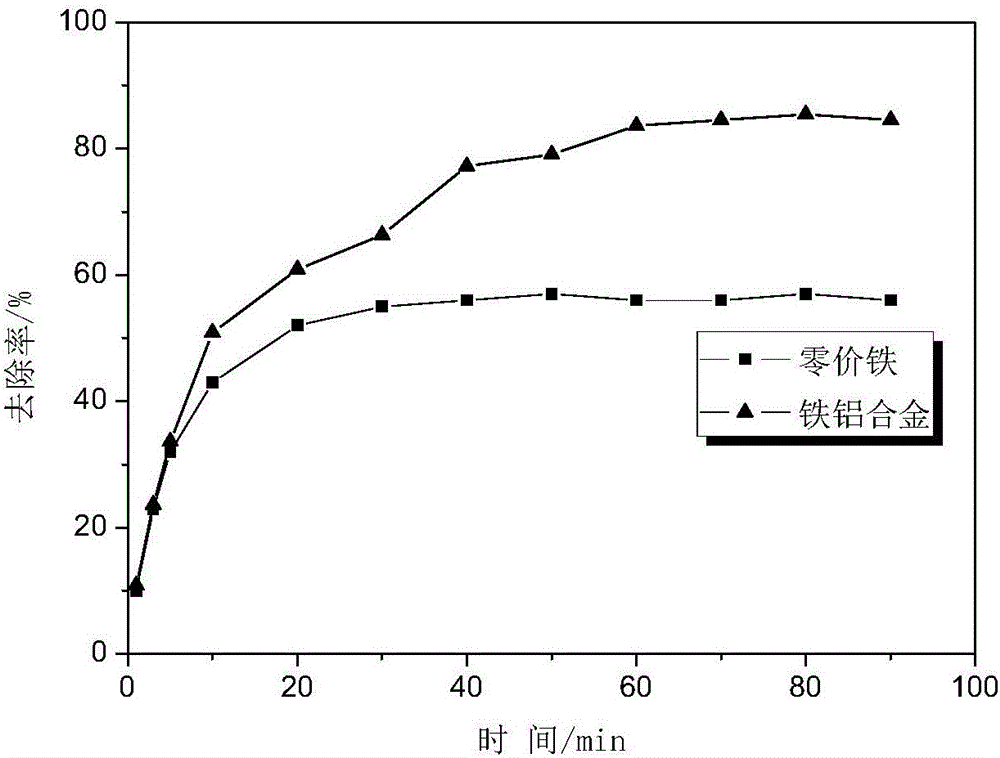

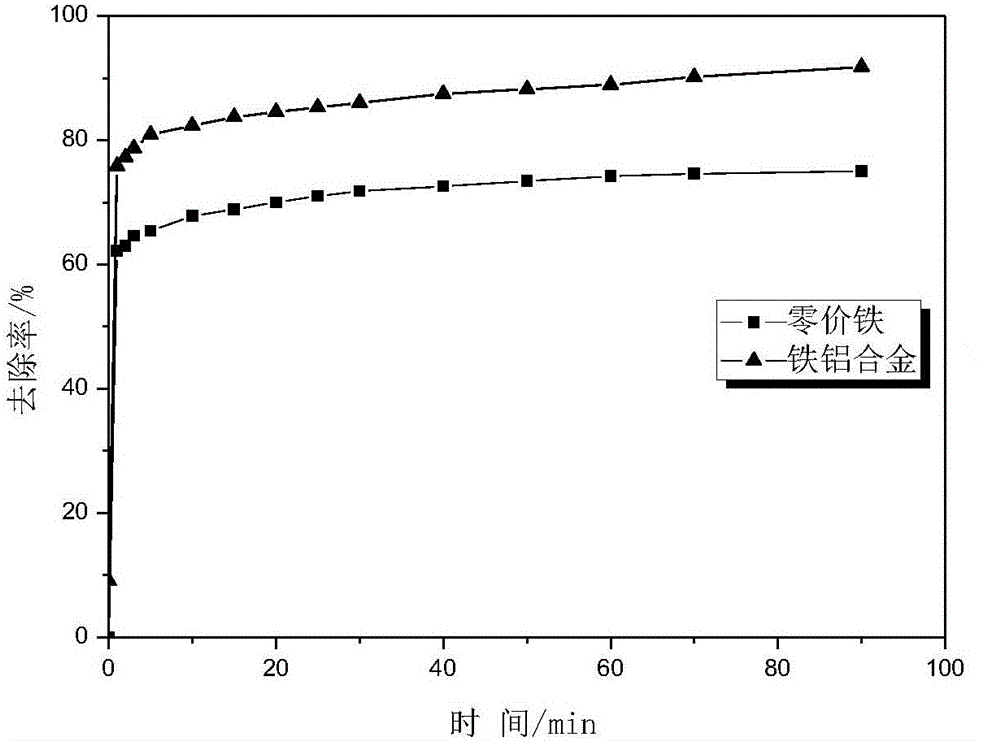

Preparing method and application of load type environment-friendly iron-aluminum alloy

InactiveCN106112010AReduce generationMeet the requirements of green developmentWater contaminantsWater/sewage treatment by electrochemical methodsAcetic acidHydrogen

The invention relates to the preparation and application field of a loaded environment-friendly iron-aluminum alloy, in particular to a preparation method of a loaded iron-aluminum alloy used for removing pollutants in water bodies. It is characterized in that the load-type environment-friendly iron-aluminum alloy of the present invention uses elemental aluminum as a carrier, carries out the loading of zero-valent iron through the hydrogen reduction atmosphere formed by elemental aluminum and acetic acid and its own replacement, and utilizes polyaspartic acid in the iron-aluminum alloy A protective layer is formed on the surface to prevent oxidation. This protective layer has high environmental compatibility, and its decomposition in the environment will not cause secondary pollution. It can minimize the generation of polluting waste in the process of preparation and application, and avoid the phenomenon of pollution without treatment. Through the galvanic effect of iron and aluminum, the prepared iron-aluminum alloy not only improves its remediation efficiency for pollutants, but also avoids various problems in the remediation of pollutants by zero-valent iron alone, and actively responds to China's green development The requirements are conducive to the further promotion of the application of iron and aluminum alloys.

Owner:BEIJING UNIV OF CHEM TECH

An electric furnace smelting stainless steel method for controlling chromium pollution in steel slag

ActiveCN112342338BImprove solubilityEmission reductionProcess efficiency improvementElectric furnaceChromium contaminationSlag

Owner:WISDRI ENG & RES INC LTD

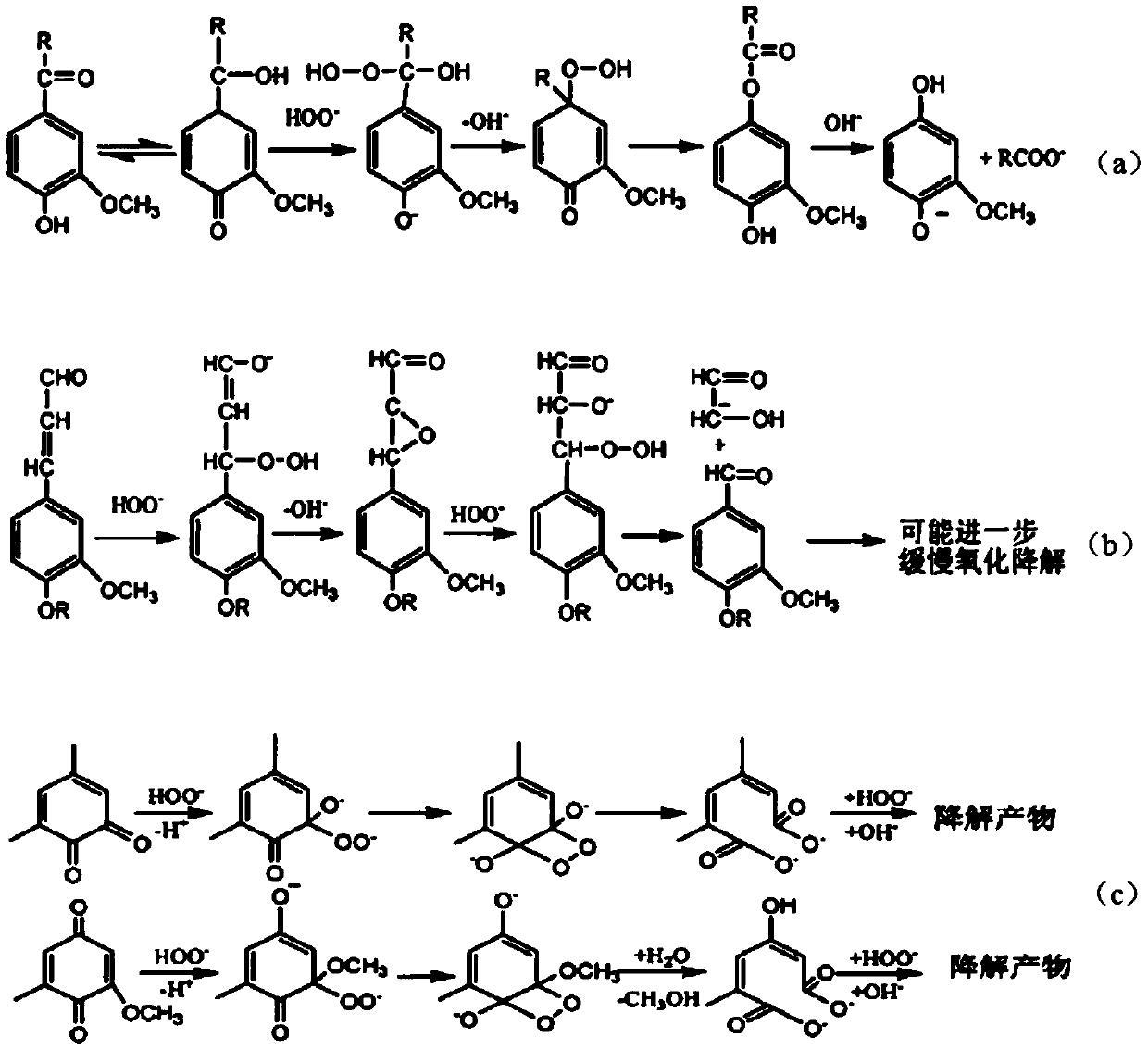

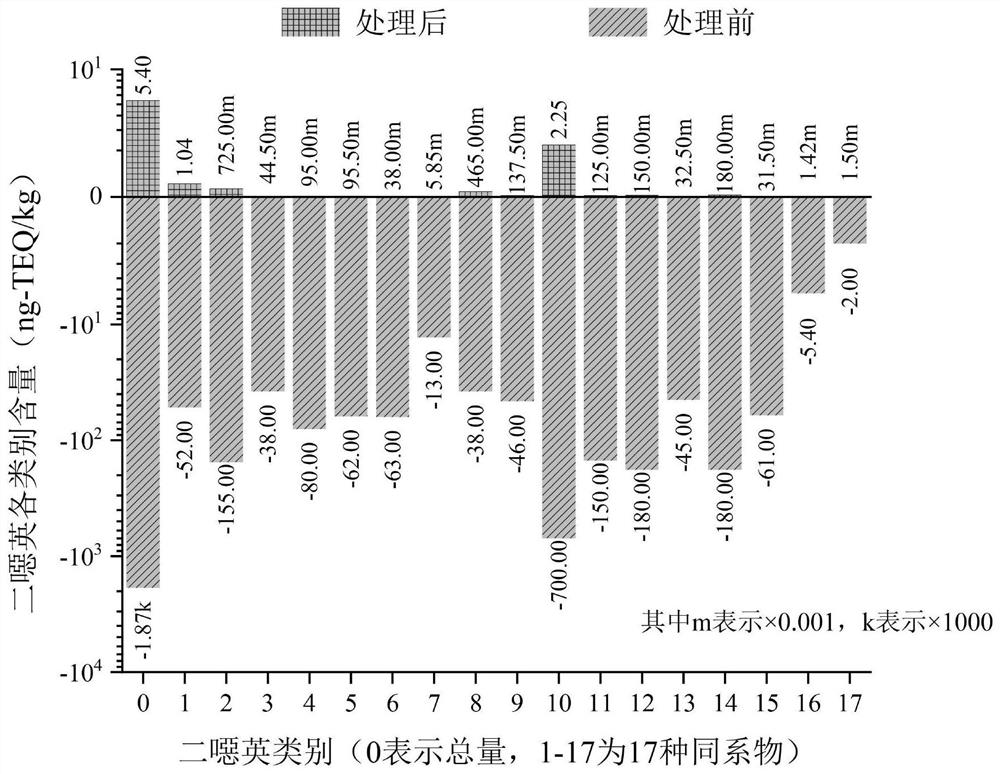

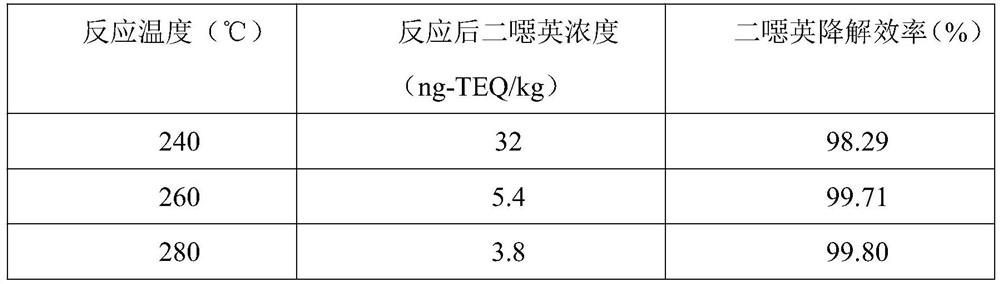

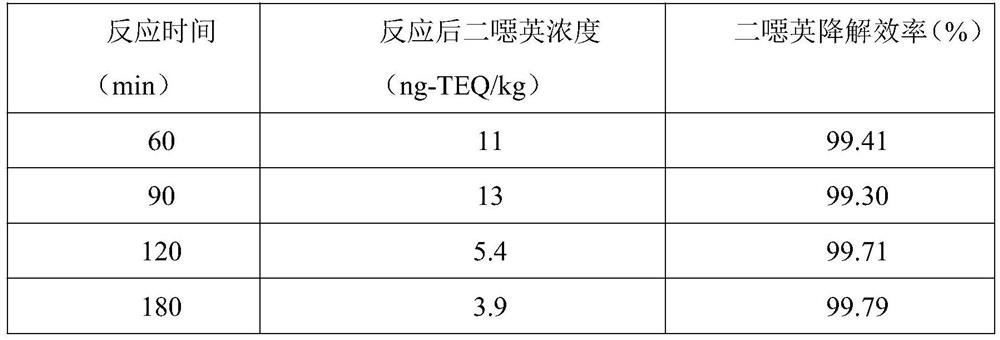

Method for degrading dioxin in fly ash through wet catalytic oxidation

InactiveCN113181590AImprove reaction efficiencyLow reaction temperatureChemical protectionPtru catalystCatalytic oxidation

The invention discloses a method for degrading dioxin in fly ash by wet catalytic oxidation, which comprises the step of performing catalytic reaction on a mixture of fly ash and water under an alkaline condition through a titanium dioxide loaded cerium-copper catalyst to degrade the dioxin. The method provided by the invention not only can degrade the fly ash containing dioxin with the toxic equivalent of 0.5-3 [mu] gTEQ / kg to 50 ng-TEQ / kg or below to meet the requirements of household garbage incineration fly ash pollution control technical specifications, but also can reduce the reaction temperature, shorten the reaction time and further reduce the energy consumption while improving the reaction efficiency.

Owner:NANJING NORMAL UNIVERSITY +1

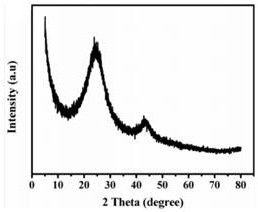

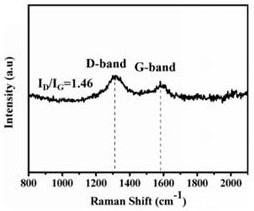

Preparation method of waste tire thermal cracking carbon black electrode material for supercapacitor

InactiveCN113372737APromote resource utilizationLow costPigmenting treatmentHybrid capacitor electrodesCapacitanceSupercapacitor

The invention discloses a preparation method of a waste tire thermal cracking carbon black electrode material for a supercapacitor, waste tire thermal cracking carbon black is used as a raw material, and the electrode material obtained by composite activation not only retains the original graphitization degree of the material, but also increases part of defects. The electrode material has a certain pore structure, and the interface area between the electrode material and an electrolyte is increased, so that higher specific capacitance is obtained, and the standard of the electrode material for the supercapacitor is achieved. According to the invention, the preparation of the electrode material for the waste tire thermal cracking carbon black based super capacitor is successfully realized, the resource utilization of the waste tire is improved, the cost of the electrode material for the super capacitor is reduced, the national green development requirement is met, and the application prospect is good.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Method for preparing ruthenium trichloride from ruthenium-containing waste

ActiveCN110255632AMeet the requirements of green developmentReactor smallRuthenium/rhodium/palladium/osmium/iridium/platinum halidesSodium chlorateReaction rate

The invention relates to a method for preparing ruthenium trichloride from ruthenium-containing waste. The method is characterized by comprising the following steps: (1) roasting: enabling the ruthenium-containing waste to be roasted, wherein roasting temperature is 200-800 DEG C, and roasting time is 4-8h; (2) preparation of RuO4: enabling the roasted ruthenium-containing waste to be added into a reaction kettle, then adding sodium chlorate, liquid bromine and water, stirring to react in a condition of 60-100 DEG C, and reacting for 1.5-5h, wherein the proportion of the ruthenium-containing quantity of the ruthenium-containing waste to the sodium chlorate to the liquid bromine to the water is 100 to (150-550) to (2-6) to (300-800) in parts by ewight; (3) preparation of an H2RuCl5 ;absorbing RuO4 generated via reaction in the step (2) by adopting hydrochloric acid at normal temperature to obtain the H2RuCl5 solution; and (4): drying: enabling the generated H2RuCl5 solution to be heated and concentrated to crystallize, and then carrying out infrared drying to obtain a hydrated ruthenium trichloride crystal. The method has the characteristics of fast reaction rate, high conversion rate, good safety, low energy consumption and the like.

Owner:JIANGXI HANS PRECIOUS METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com