Method for degrading dioxin in fly ash through wet catalytic oxidation

A technology of wet catalytic oxidation and fly ash, which is applied in the direction of protection devices against harmful chemicals, and can solve the problem of low dioxin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0030] The preparation of the cerium copper catalyst supported by embodiment 1 titania

[0031] The titania-supported cerium-copper catalyst was prepared by conventional co-precipitation method. Ce(SO with a mass ratio of 1:0.25:14 4 ) 2 4H 2 O, CuSO 4 ·5H 2 O and Ti(SO 4 ) 2 2H 2 After O was dissolved in a certain amount of ion-exchanged water, ammonia solution was slowly added (at a rate of less than 0.3 mL / min), while vigorously stirring to achieve the effect of co-precipitation until the pH value of the solution reached 9.5. After washing and filtering to remove sulfate ions, the precipitate was first dried in a water bath at 80°C for 4 hours, then dried in a vacuum oven at 50°C for 12 hours, and finally dried at 110°C for 4 hours. The final product obtained is calcined at 500° C. for 5 hours under air condition to obtain the desired catalyst.

Embodiment 2

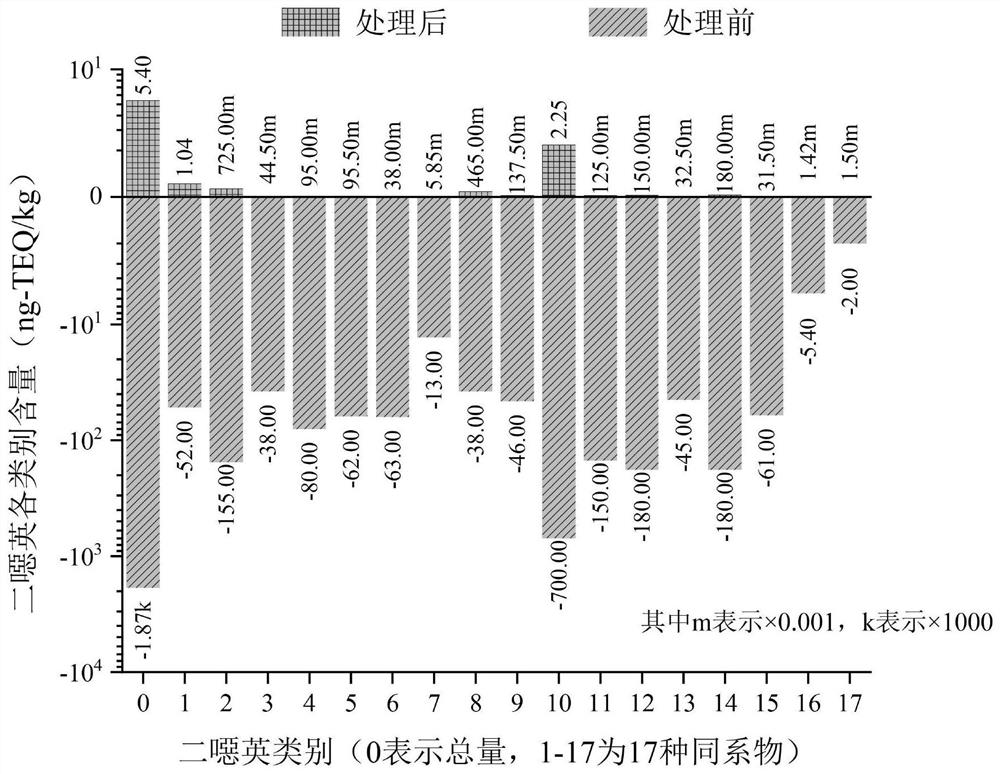

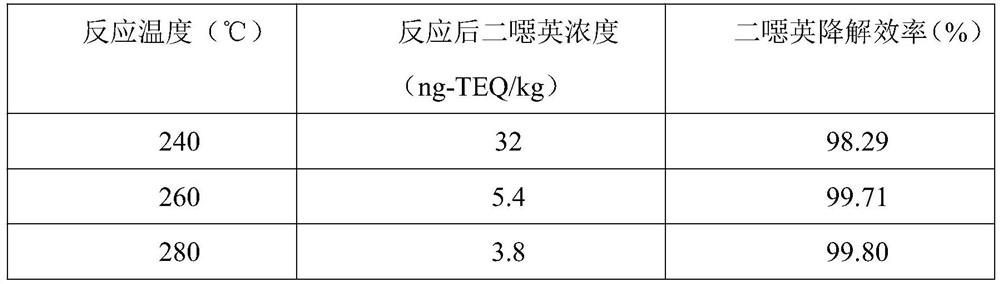

[0033] The fly ash incinerated from grate furnace domestic waste was washed three times with countercurrent water at a liquid-solid ratio of 4:1g / mL, and fully dried. After drying, the mass content of chlorine in the fly ash was about 1.8%, and the content of dioxin It is 1.87μgTEQ / kg. Using an electrically heated high-temperature and high-pressure reactor (CJ type reactor) equipped with mechanical stirring produced by Weihai Xinyuan Chemical Machinery Co., Ltd., accurately weigh 80g of fly ash and add 320mL of pure water, then add 30% mass fraction of hydroxide The sodium solution adjusted the pH to 10, and then added 0.5 g of titania-supported cerium-copper catalyst ((Ce+Cu) / TiO 2 , Ce: Cu: Ti molar ratio is 1:0.4:20). After adding materials, tighten the screws and valves of the reactor and feed 1MPa pure oxygen. Set the reaction temperature to 260, 280, and 300°C respectively, the reaction time to 120min, and the stirring rate to 120r / min. Cooling water is fed to the mixer...

Embodiment 3

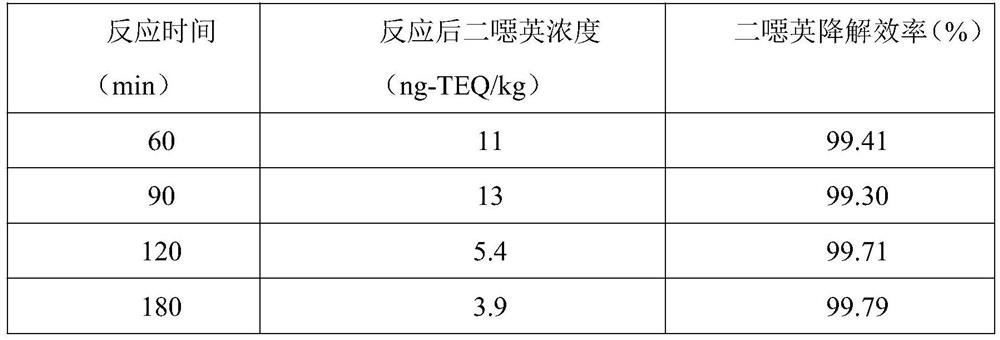

[0038]The fly ash incinerated from grate furnace domestic waste was washed three times with countercurrent water at a liquid-solid ratio of 4:1g / mL, and fully dried. After drying, the mass content of chlorine in the fly ash was about 1.8%, and the content of dioxin It is 1.87μgTEQ / kg. Using an electrically heated high-temperature and high-pressure reactor (CJ type reactor) equipped with mechanical stirring produced by Weihai Xinyuan Chemical Machinery Co., Ltd., accurately weigh 80g of fly ash and add 320mL of pure water, then add 30% mass fraction of hydroxide The sodium solution adjusted the pH to 10, and then added 0.5 g of titania-supported cerium-copper catalyst ((Ce+Cu) / TiO 2 , Ce: Cu: Ti molar ratio is 1:0.4:20). After adding materials, tighten the screws and valves of the reactor and feed 1MPa pure oxygen. Set the reaction temperature to 260°C, the reaction time to 60, 90, 120, and 180 minutes respectively, and the stirring rate to 120r / min. water. The degradation e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com