Composite porous carbon material and preparation method and application thereof

A technology of porous carbon and composite carbon, applied in chemical instruments and methods, carbon compounds, multi-walled carbon nanotubes, etc., can solve the problem of not being able to fully reflect the advantages of graphene materials, affect the performance of composite porous carbon materials, and fail to meet practical applications Demand and other issues, to achieve high specific capacitance, reduce film cost, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

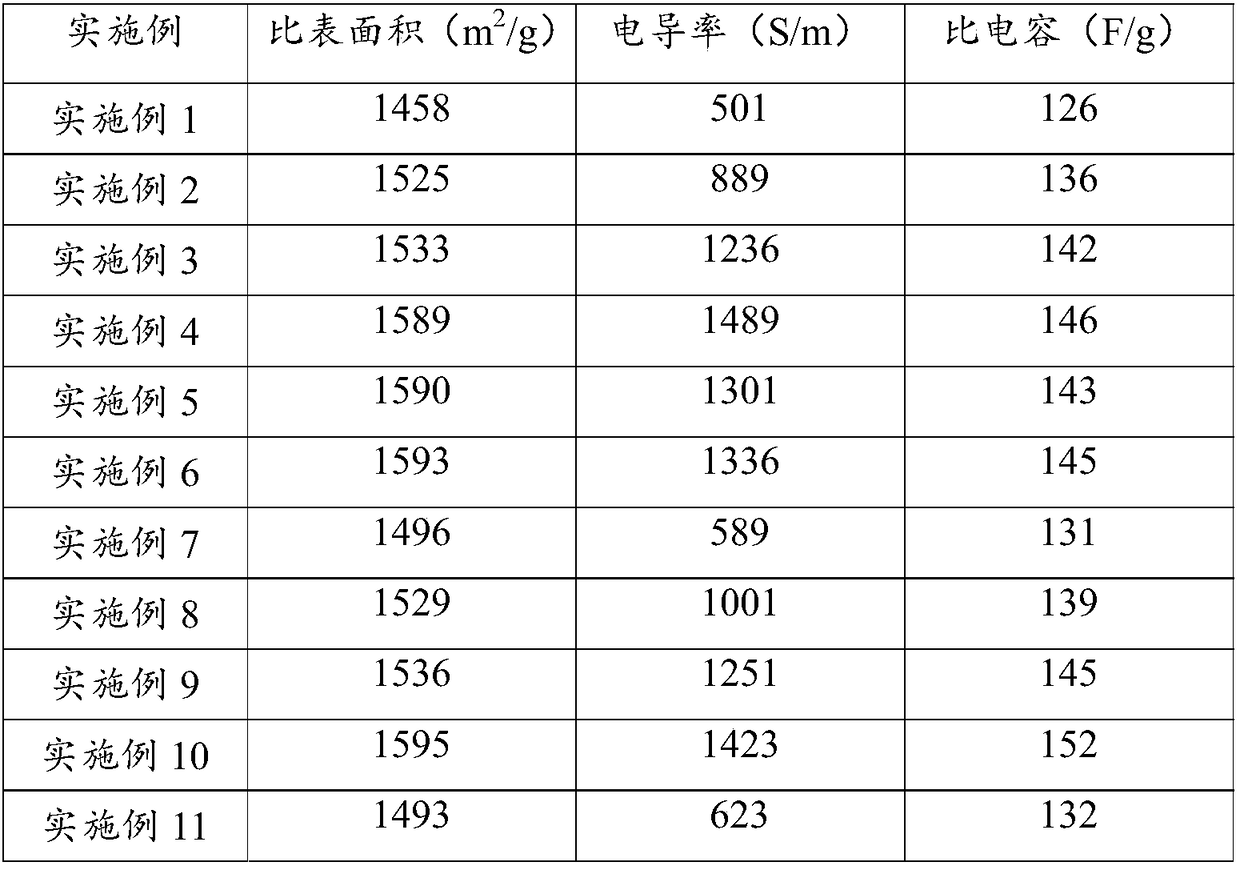

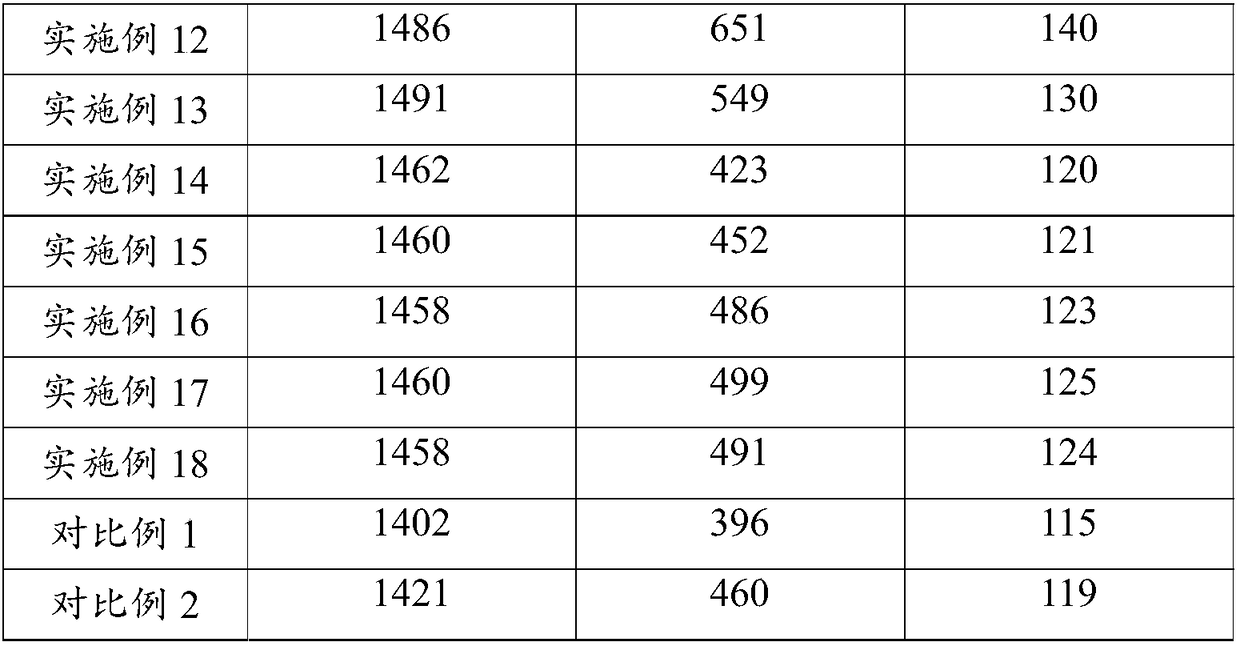

Examples

Embodiment 1

[0068] A method for preparing a composite porous carbon material, comprising:

[0069] 1) Curing and pulverizing the phenolic resin at 150°C for subsequent use;

[0070] 2) Put the pulverized material in a vacuum tube furnace, raise the temperature to 550 °C at a heating rate of 5 °C / min and keep the temperature constant for 2 hours to obtain a carbonized material;

[0071] 3) ultrasonically dispersing graphene oxide in distilled water to obtain a 0.5wt% graphene oxide material solution;

[0072] 4) Weigh 100 parts of the above dried carbonized material, add deionized water according to the ratio of carbonized material to deionized water 1:10 and stir evenly, and then follow the ratio of carbonized material: graphene oxide: hydrazine hydrate 100:0.01:0.01 , adding graphene oxide aqueous solution and hydrazine hydrate, stirring evenly;

[0073] 5) Pour the above suspension into a stainless steel reaction kettle lined with polytetrafluoroethylene, the filling degree of the rea...

Embodiment 2-6

[0076] Compared with Example 1, Examples 2-6 only changed the ratios of carbonized material, graphene oxide and hydrazine hydrate, respectively 100:0.1:0.1, 100:1:1, 100:5:5, 100:10 : 10 and 100: 20: 20, and the rest of the conditions are exactly the same.

Embodiment 7

[0078] A method for preparing a composite porous carbon material, comprising:

[0079] 1) The phenolic resin is cured at 150°C and pulverized for later use.

[0080] 2) Put the pulverized material in a vacuum tube furnace, raise the temperature to 550 °C at a heating rate of 5 °C / min and keep the temperature constant for 2 hours to obtain a carbonized material;

[0081] 3) ultrasonically dispersing graphene oxide and carbon nanotubes in distilled water to obtain a mixed solution of 0.5wt% graphene oxide and carbon nanotubes, the mass ratio of graphene oxide and carbon nanotubes being 1:0.1;

[0082] 4) Weigh 100 parts of the above-mentioned dried carbonized material, add deionized water according to the ratio of carbonized material to deionized water 1:10 and stir evenly, and then follow the carbonized material: graphene oxide / carbon nanotube mixed solution: hydrazine hydrate 100 : 0.01:0.01 ratio, add graphene oxide and carbon nanotube aqueous solution and hydrazine hydrate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com