Soilless culture substrate and preparation method thereof

A soilless culture substrate and substrate technology, applied in planting substrates, botanical equipment and methods, culture medium, etc., can solve the problems of inability to meet the nutritional needs of different crops, poor water retention, complicated operations, etc., and achieve the goal of promoting healthy plant growth , Good mechanical strength, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A novel lignin hydrogel-loaded sawdust soilless cultivation substrate is prepared by the following method:

[0030] 1) The waste generated from wood processing is crushed and ground to obtain wood chips with a particle size of 2-3mm.

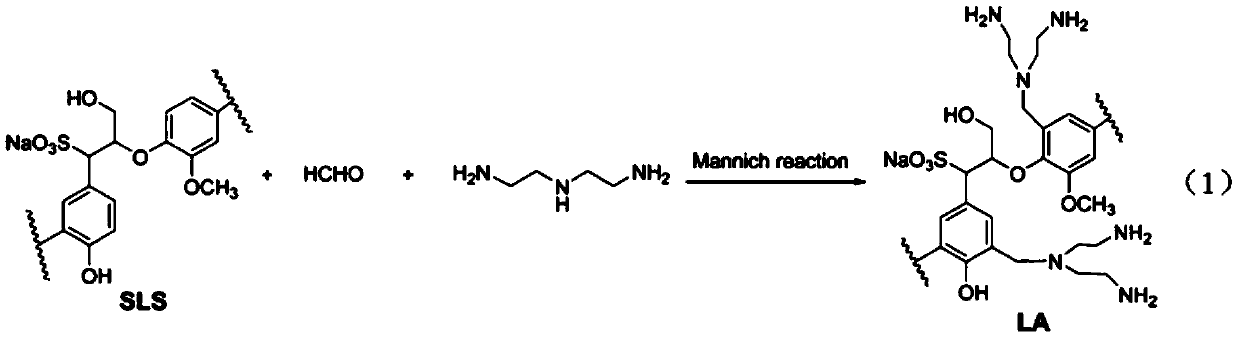

[0031] 2) Through amination modification treatment, introduce a primary amine highly reactive group into sodium lignosulfonate (SLS) to obtain lignin amine (LA), and improve its reactivity. The specific reaction is shown in formula (1);

[0032]

[0033] The specific steps are: take 10g of sodium lignosulfonate and dissolve it in 100mL of deionized water, add 15g of diethylenetriamine solution with a concentration of 98.5%, and adjust the pH of the above solution with 0.1mol / L hydrochloric acid or sodium hydroxide solution. 10-11, then add 10g of formaldehyde solution with a concentration of 37% dropwise. After the dropwise addition, raise the temperature to 50°C and stir for 4 hours. After the reaction, lower the temperature of the re...

Embodiment 2

[0040] A novel lignin hydrogel-loaded sawdust soilless culture substrate is prepared by the following method:

[0041] 1) The waste generated from wood processing is crushed and ground to obtain wood chips with a particle size of 2-3mm.

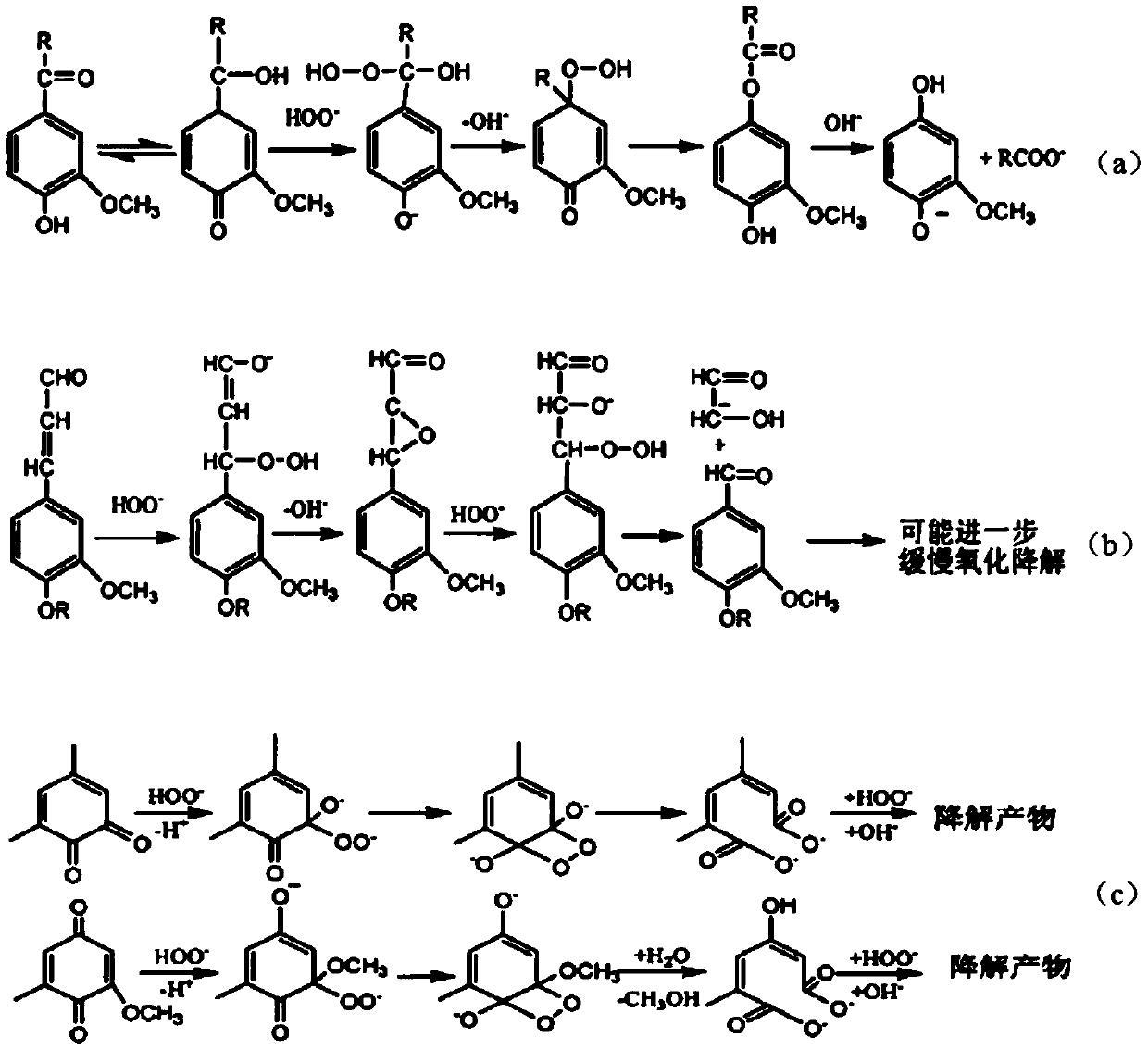

[0042] 2) Through oxidative modification treatment, the content of hydrophilic high-active groups such as hydroxyl and carboxyl groups is introduced into sodium lignosulfonate, and the specific reaction is as shown in formula (a): the reaction of hydrogen peroxide and lignin side chain carbonyl; ( b): the reaction of hydrogen peroxide with the double bond of the side chain of lignin and (c): the reaction of hydrogen peroxide with the benzene ring of the structural unit of lignin.

[0043]

[0044] The specific steps are: weigh 8g of sodium lignosulfonate and dissolve it in 200mL of sodium hydroxide solution with a concentration of 0.25mol / L, add 6mL of hydrogen peroxide with a concentration of 30%, and stir and react at a temperature of 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com