Zero-discharge comprehensive utilization system for waste of large-scale pig farm

A technology for farms and wastes, applied in the field of animal breeding, can solve the problems of unstable treatment effect and high operating costs, and achieve the effects of fast chemical reaction rate, enhanced thermal movement, and improved ammonia nitrogen removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

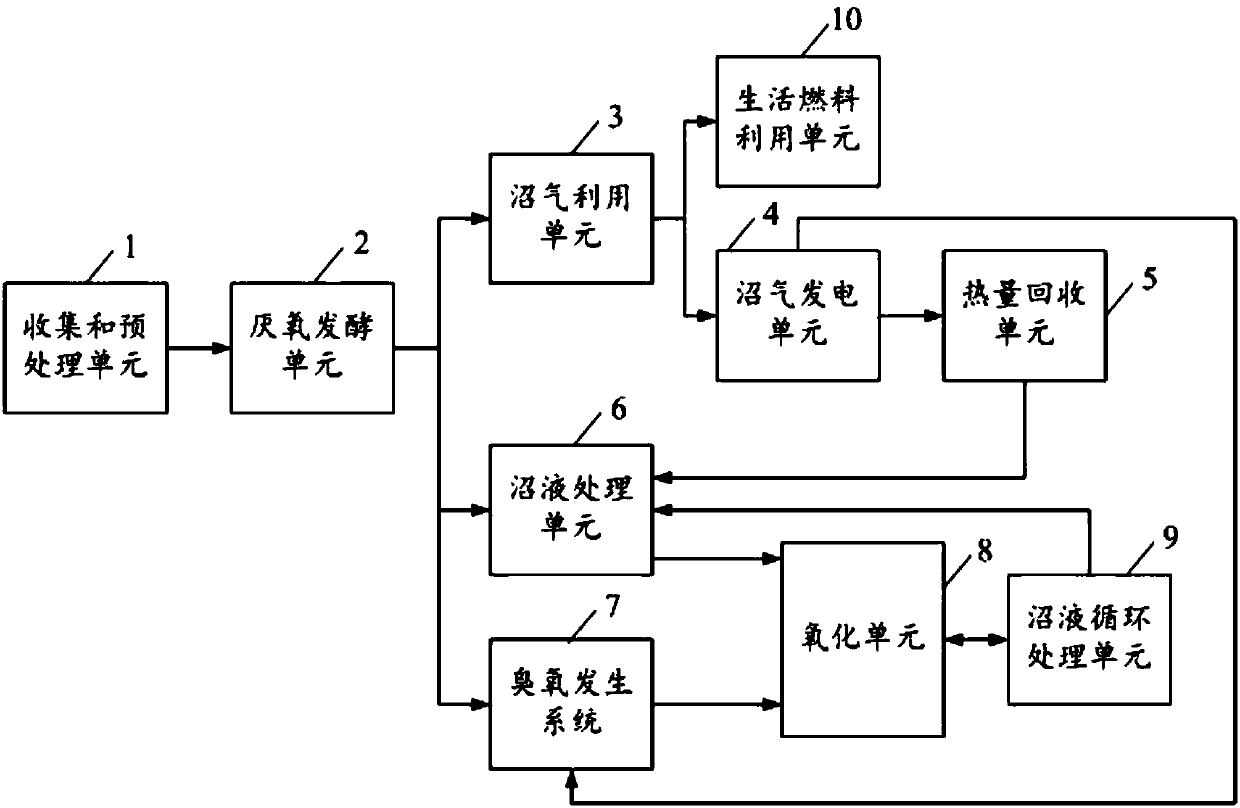

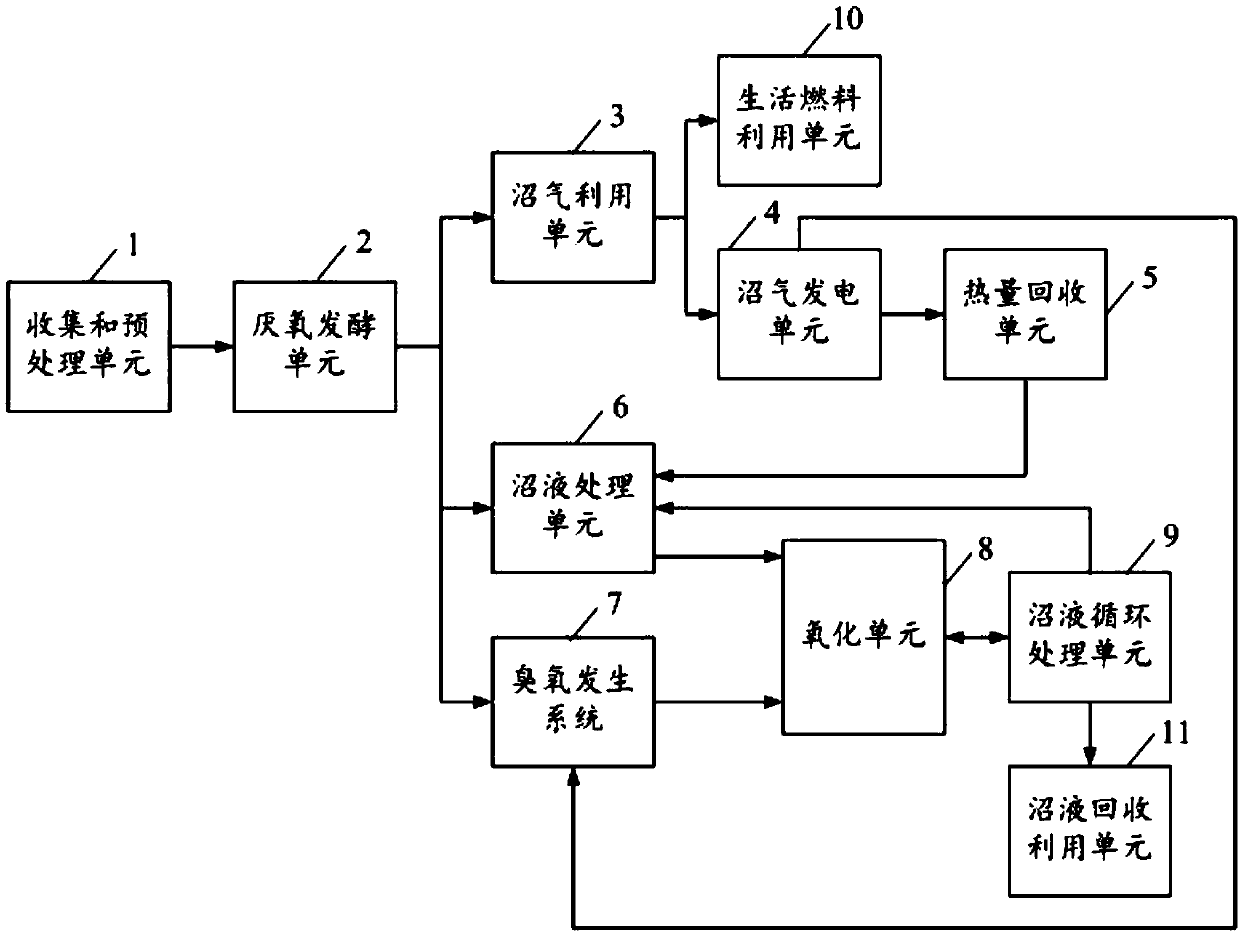

[0045] Such as figure 1 As shown, the present invention provides a comprehensive zero-discharge comprehensive utilization system for large-scale pig farm waste, including:

[0046] Collection and pretreatment unit 1 for collecting and pretreatment of pig manure;

[0047]Connected with the collection and pretreatment unit 1, it is used for anaerobic fermentation of pig manure to obtain anaerobic fermentation unit 2 of biogas, biogas slurry and biogas residue;

[0048] Connected with the anaerobic fermentation unit 2, a biogas utilization unit 3 for dehydrating and purifying the biogas;

[0049] Connected with the biogas utilization unit 3, for using the biogas treated by the biogas utilization unit 3 as a biogas power generation unit 4 for power generation;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com