Patents

Literature

58results about "Ruthenium/rhodium/palladium/osmium/iridium/platinum halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

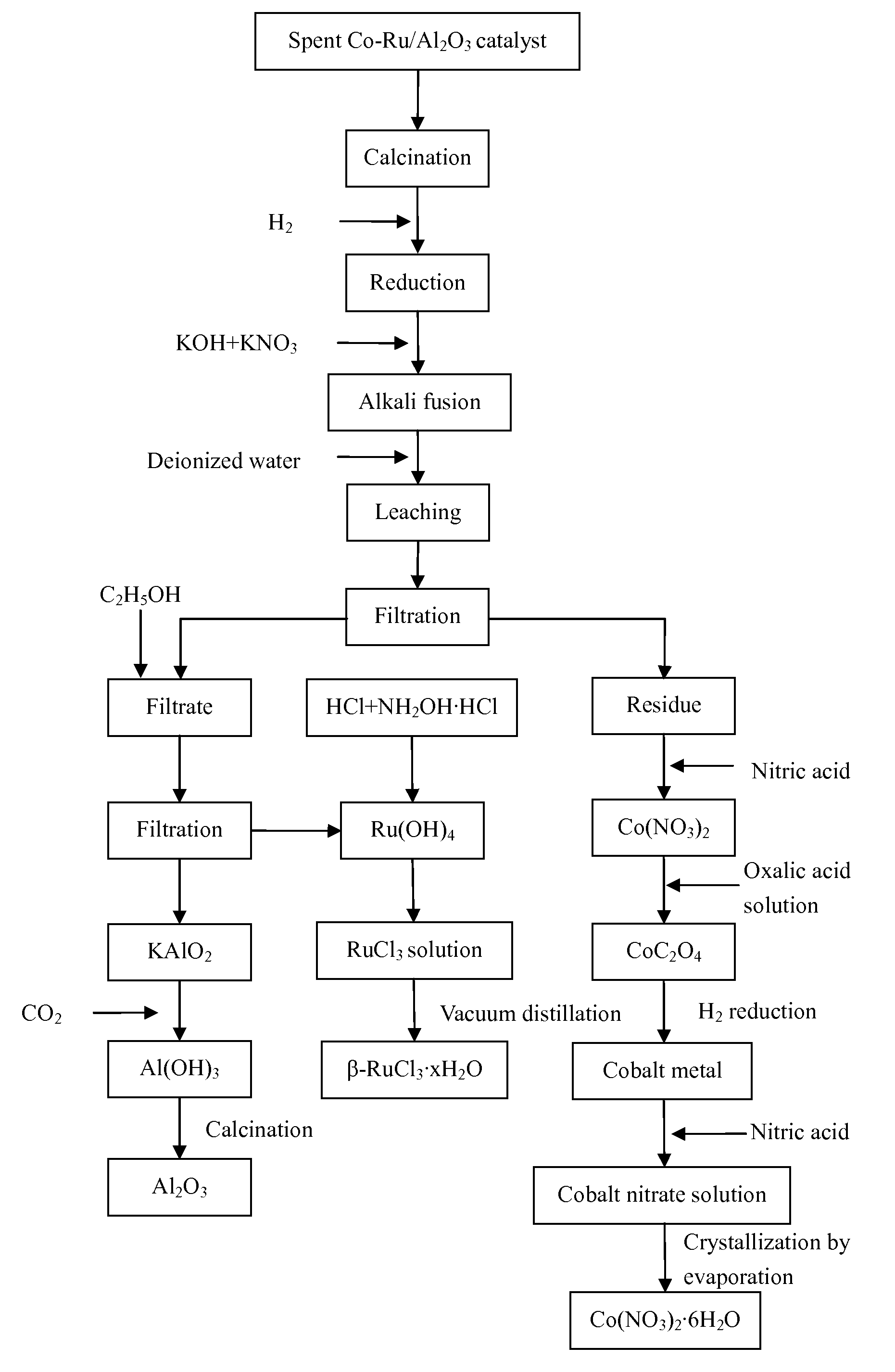

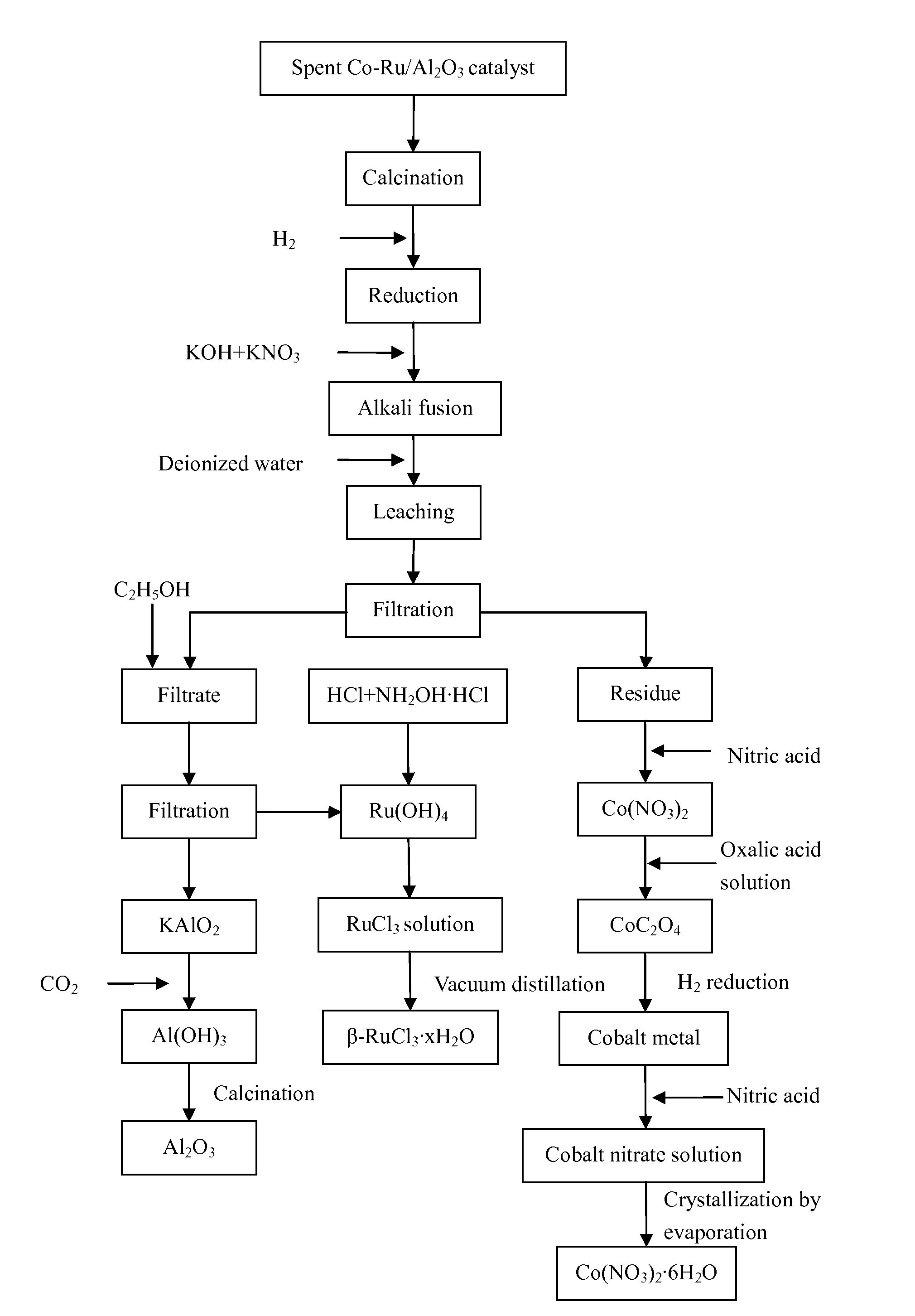

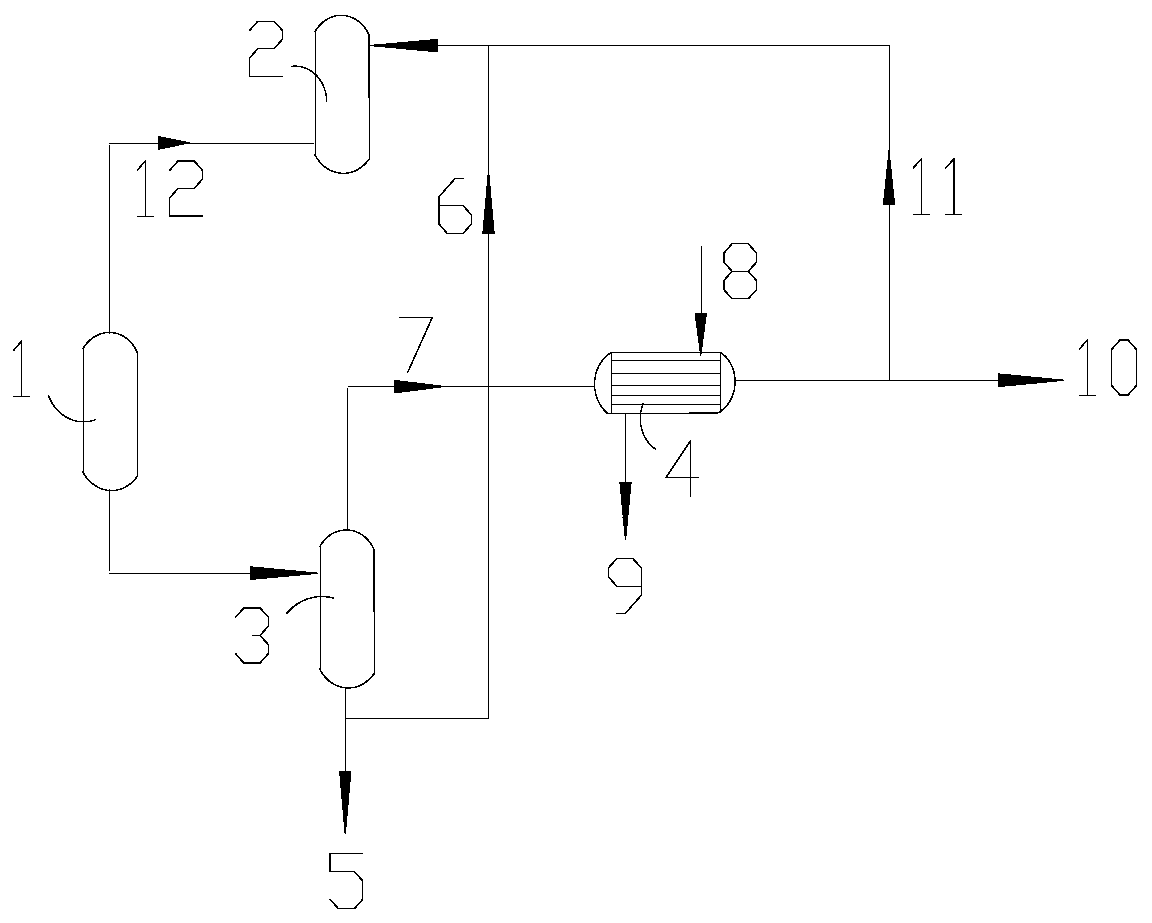

Method for comprehensively recovering metallic cobalt, ruthenium and aluminum from Fischer-Tropsch synthesis dead catalyst Co-Ru/Al2O3

ActiveCN102796873AHigh purityOperational securityProductsAluminium compoundsDistillationAluminium hydroxide

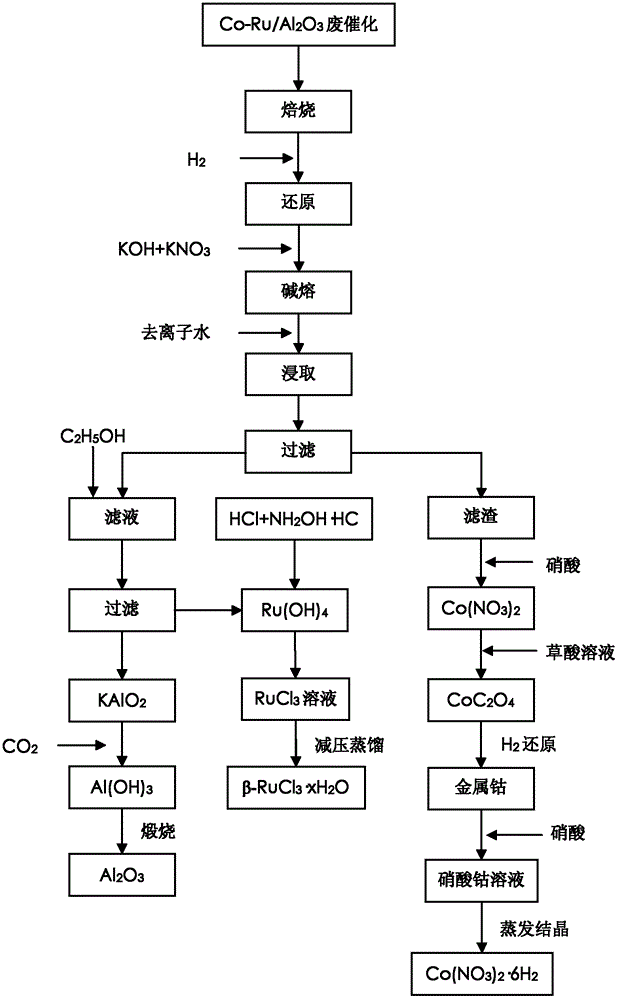

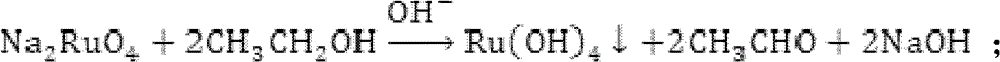

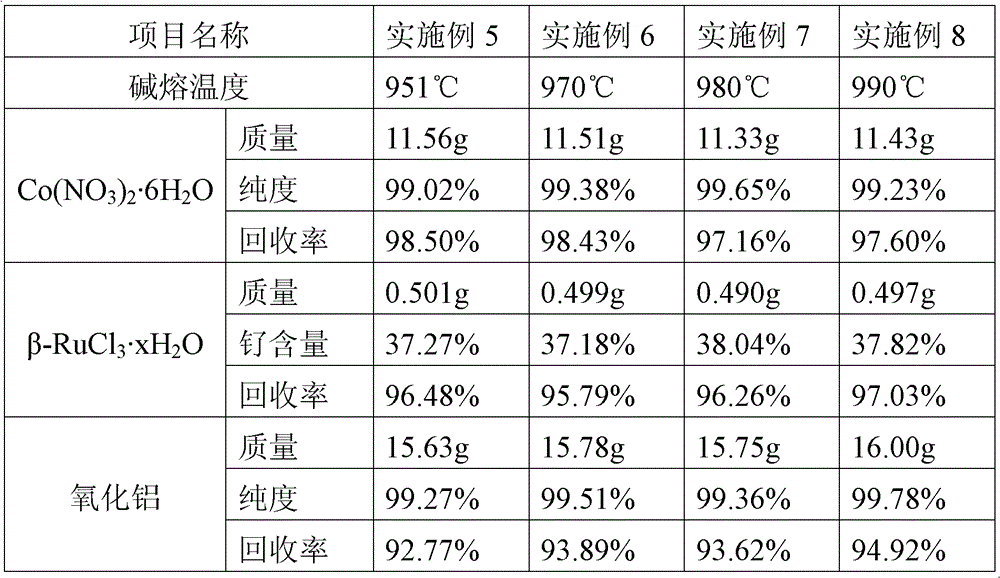

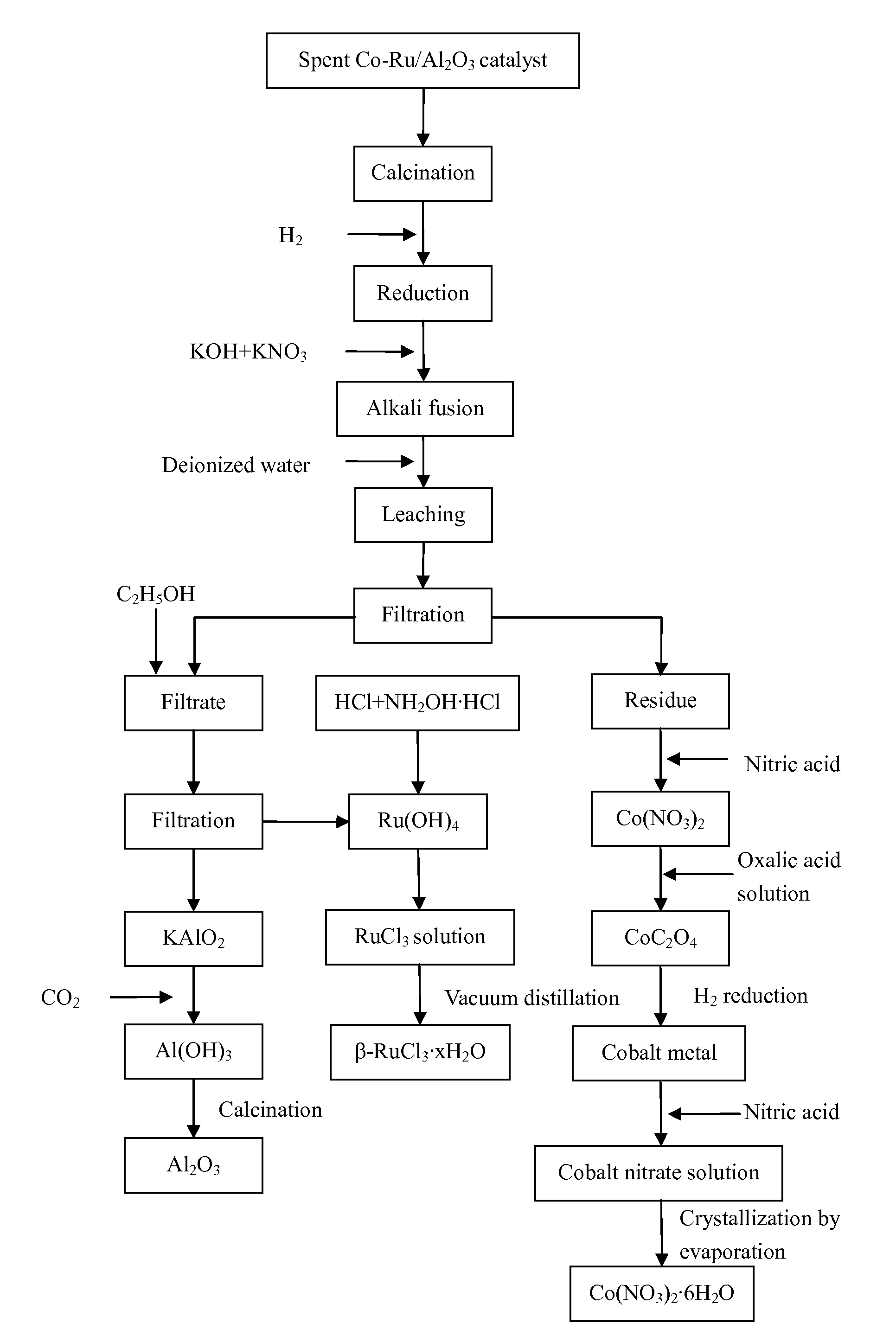

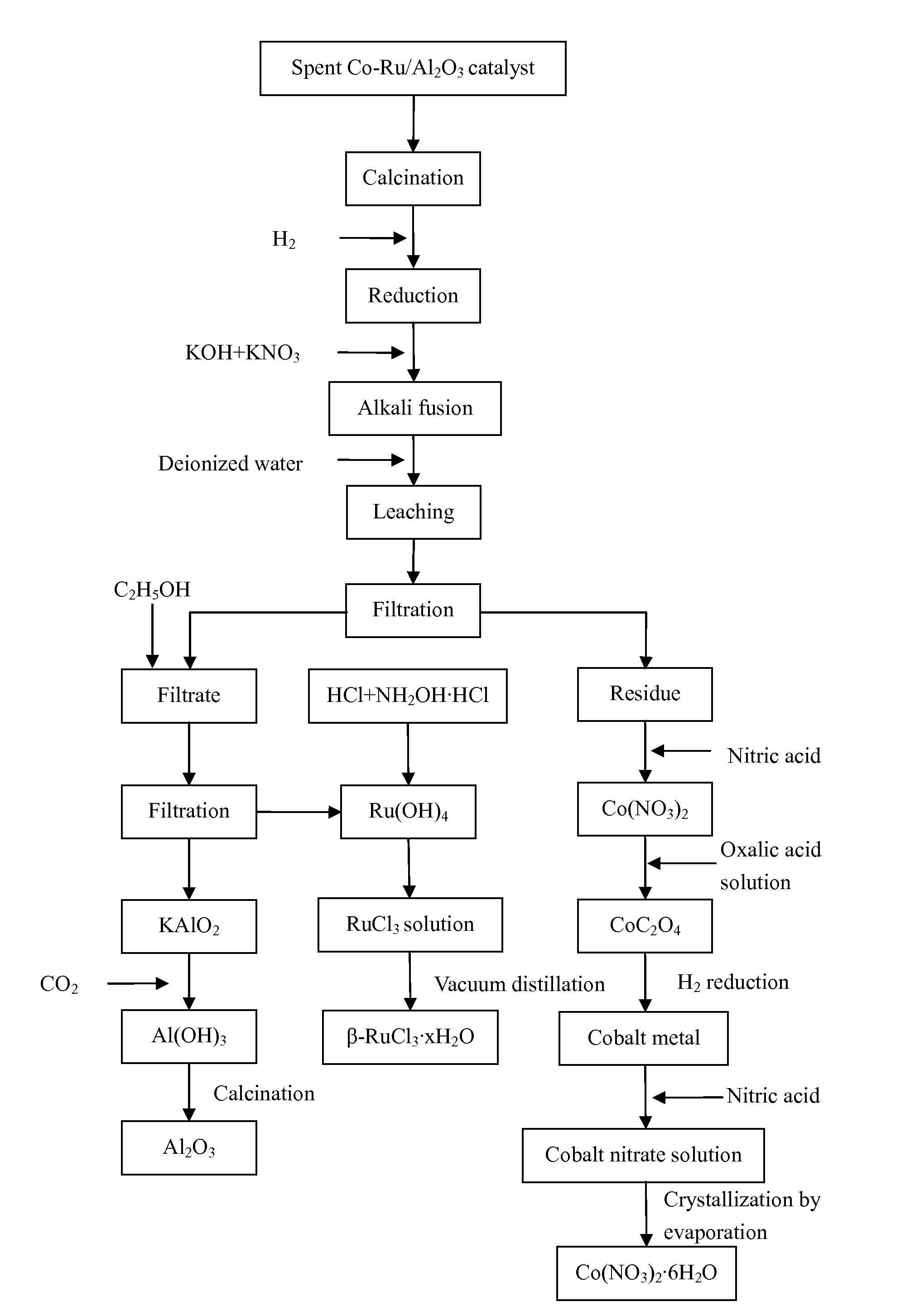

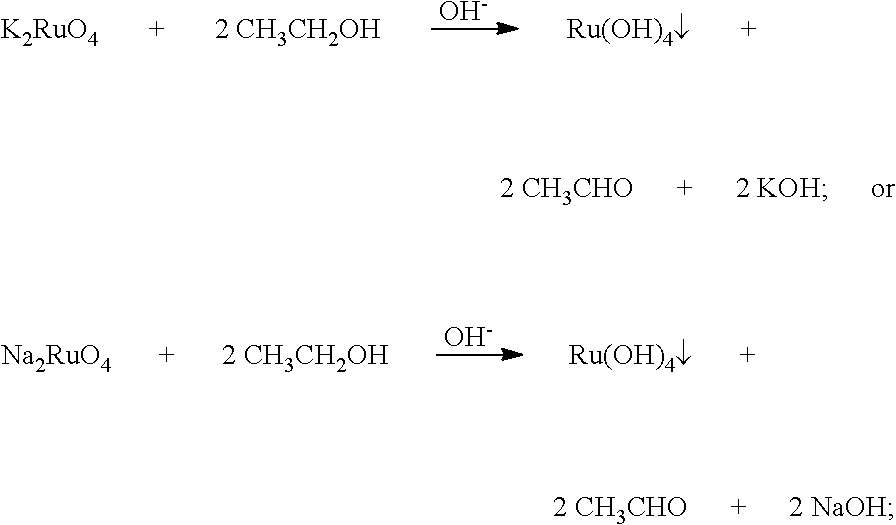

The invention discloses a method for comprehensively recovering metallic cobalt, ruthenium and aluminum from a Fischer-Tropsch synthesis dead catalyst Co-Ru / Al2O3, and the method can be used for effectively separating and comprehensively recovering valuable metallic cobalt, ruthenium and aluminum from the Fischer-Tropsch synthesis dead catalyst Co-Ru / Al2O3. The method comprises the steps of: firstly carrying out hydrocarbon removal and reductive treatment on the dead catalyst; effectively separating cobalt slag in an alkali fusion step; and carrying out acid leaching on the cobalt slag, oxalate or oxalate deposited cobalt, reducing cobalt oxalate, dissolving the metallic cobalt via nitric acid and the like to obtain Co(NO3)2.6H2O. Ruthenate is obtained by the steps of alkali fusion and deionized water leaching; and steps of ethanol reduction, concentrated hydrochloric acid dissolution, reduced pressure distillation and the like are carried out on the ruthenate to obtain a beta-RuCl1.xH2O product which is high in purity. By using a CO2 carbon dioxide decomposition method, the parameters such as reaction temperature, CO2 flow velocity, pH value of reaction destination and the like are controlled and aluminum hydroxide is prepared from meta-aluminate solution; high-temperature calcination is carried out to obtain aluminum oxide; and the product quality meets the quality requirement of first-level aluminum oxide of national standard and the process is economic and environment-friendly. According to the invention, the metallic recovery rate is high, wherein the recovery rate of cobalt is greater than or equal to 97%, the recovery rate of ruthenium is greater than or equal to 95% and the recovery rate of aluminum is greater than or equal to 92%.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

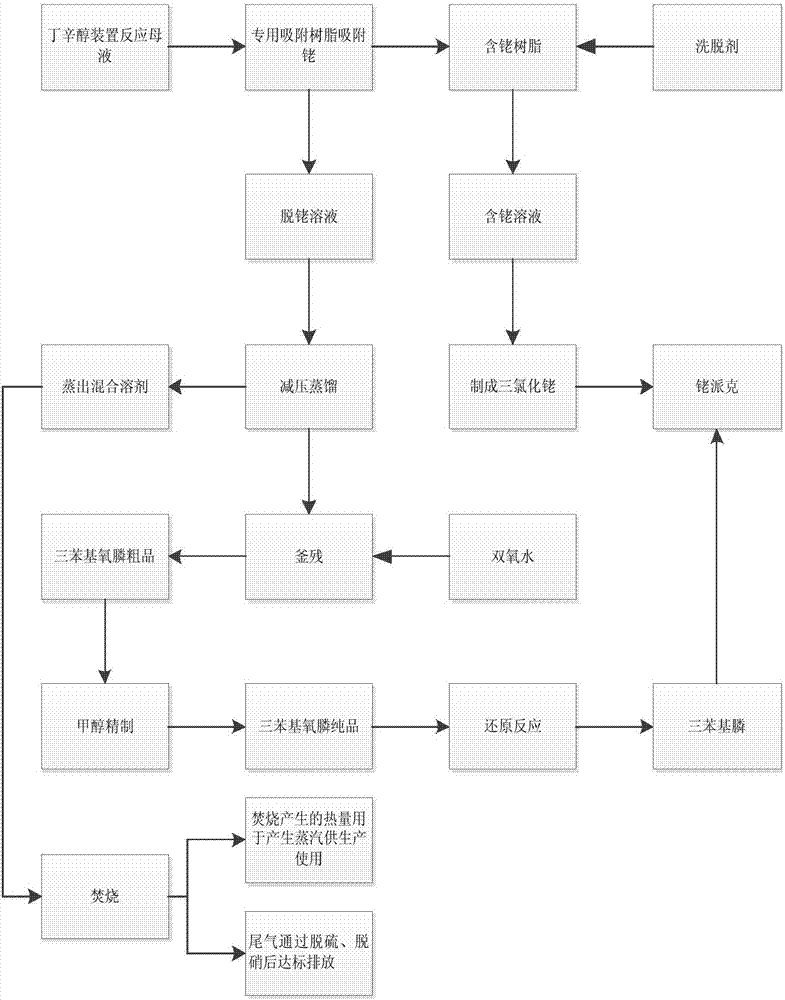

Resource cyclic utilization method of rhodium-containing waste liquid of butanol-octanol device

ActiveCN107021983AAchieve recyclingReduce pollutionRhodium organic compoundsGroup 5/15 element organic compoundsCombustionEconomic benefits

The invention relates to a resource cyclic utilization method of rhodium-containing waste liquid of a butanol-octanol device. The cyclic utilization of effective sources, namely rhodium and triphenylphosphine is ensured and a useless resource, namely a waste solvent, is combusted and converted into energy for production, so that materials are put into the best use; tail gas generated by combustion is subjected to desulfurization treatment and denitration treatment and is discharged after reaching standards, so that the discharged gas is pollution-free and environment-friendly resource cyclic utilization is realized. In an important link of recycling of the rhodium, an absorption method is adopted and a loading type rhodium ligand and a waste rhodium catalyst are mixed and alternately used for absorbing; then the rhodium is displaced from a triphenylphosphine ligand. The method is little in investment, environmentally friendly and high in rhodium recycling rate; the triphenylphosphine is sufficiently recycled and economic benefits and market competitiveness are greatly improved.

Owner:山东博苑医药化学股份有限公司

Process for recovery of ruthenium from a ruthenium-containing supported catalyst material

InactiveUS20080287282A1High purityHigh purity gradeCell electrodesFinal product manufactureHydrogen halideRuthenium Compounds

Process to recover ruthenium in the form of ruthenium halide, particularly ruthenium chloride, from a ruthenium-containing supported catalyst material comprising:a) chemically decomposing the ruthenium-containing supported catalyst material;b) producing a raw ruthenium salt solution;c) purifying the raw ruthenium salt solution and optionally stripping gaseous ruthenium tetroxide from the raw ruthenium salt solution; andd) treating the purified ruthenium compound obtained in c), particularly the ruthenium tetroxide, with hydrogen halide or hydrohalic acid to obtain ruthenium halide, particularly with hydrogen chloride or hydrochloric acid to obtain ruthenium chloride.

Owner:BAYER MATERIALSCIENCE AG

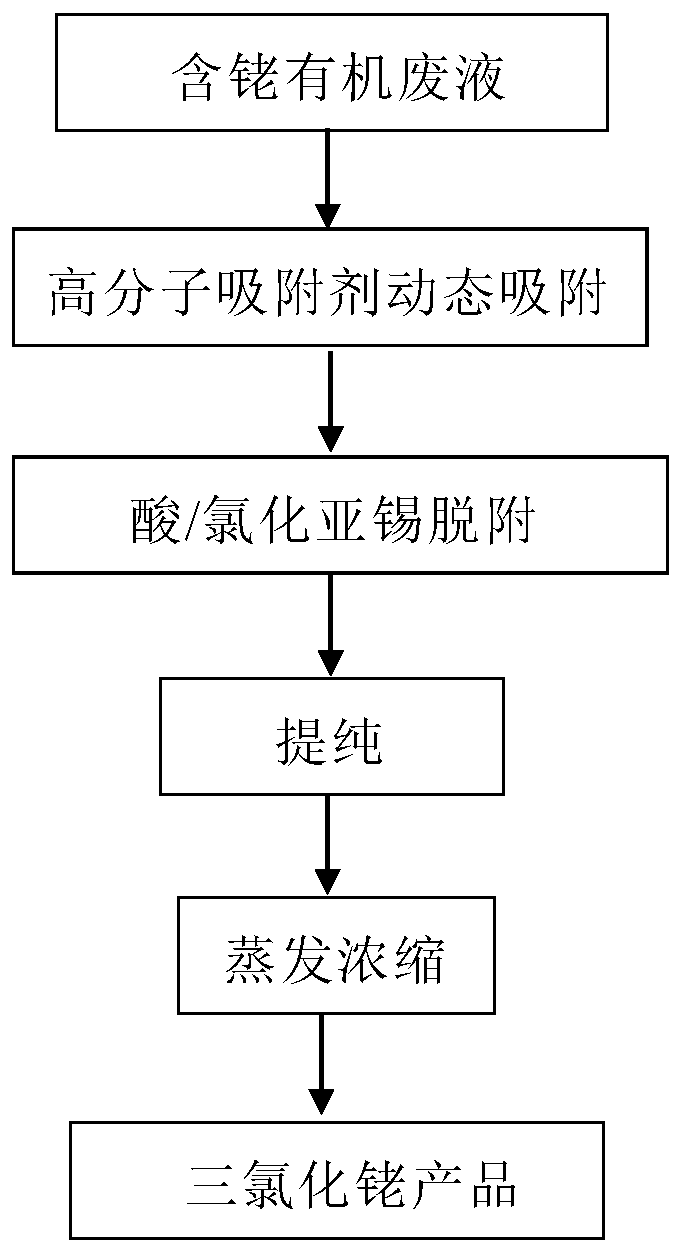

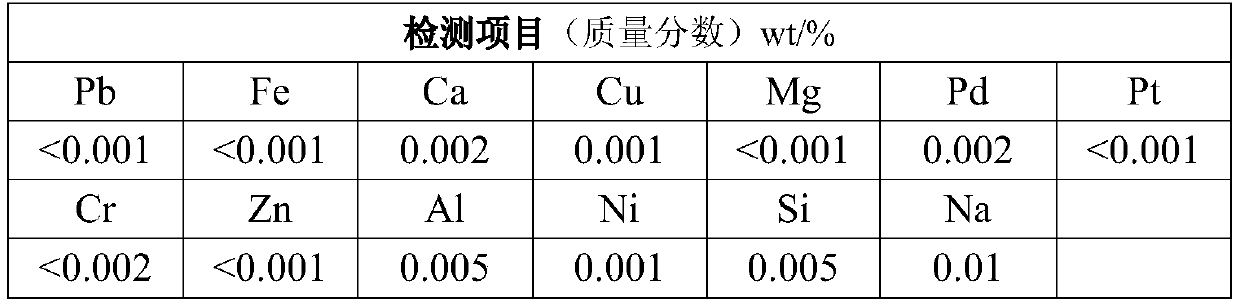

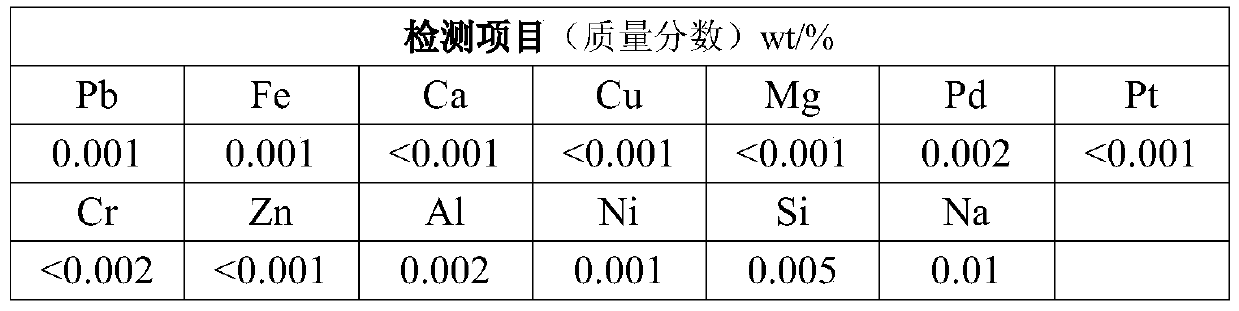

Method for recovering rhodium from rhodium-containing organic wastewater to prepare rhodium chloride

ActiveCN110607448ASimple and fast operationAccelerate the speed of entering the acidic solutionRuthenium/rhodium/palladium/osmium/iridium/platinum halidesRuthenium/rhodium/palladium/osmium/iridium/platinum compounds preparationFiltrationSorbent

The invention discloses a method for recovering rhodium from rhodium-containing organic wastewater to prepare rhodium chloride. The method includes the steps that first, a macromolecule adsorbent is adopted for adsorbing the rhodium in the rhodium-containing organic wastewater produced in the production process of a rhodium homogeneous catalyst onto an adsorbent in a dynamic adsorption mode; second, the rhodium-containing adsorbent is put into acid solvent, a certain amount of stannous chloride is added, backflow stirring is conducted, the rhodium is transferred into the solvent from the solidadsorbent, and a rhodium-containing aqueous phase solution is obtained by means of filtration; third, purification is performed; and fourth, the rhodium chloride is obtained through evaporation and concentration. The method is suitable for the rhodium-containing organic wastewater produced in the production process of the homogeneous catalyst, and the problem of recovering the rhodium from an organic phase is solved. The method is easy and simple to handle, no secondary exhaust gas and wastewater can be produced, going green and environmental protection are realized, and the recovery rate ofthe rhodium can reach 95% or above.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

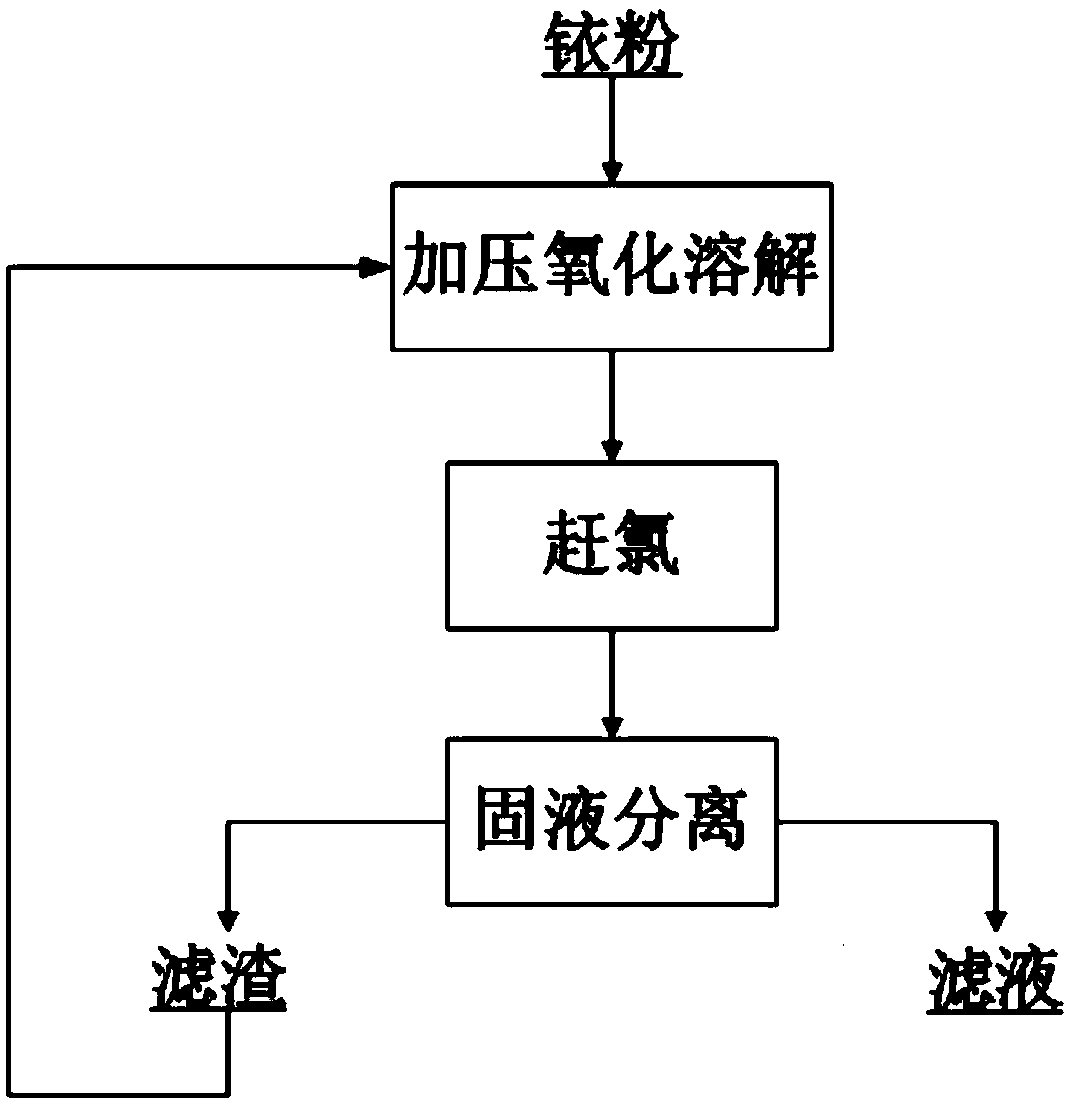

Rapid dissolution method for indissolvable metal iridium

ActiveCN108658133ADissolve fastSimple processRuthenium/rhodium/palladium/osmium/iridium/platinum halidesIridiumRoom temperature

The invention discloses a rapid dissolution method for indissolvable metal iridium. The method comprises the following steps: 1, adding iridium powder and hydrochloric acid into a reaction kettle, introducing a chlorine gas into the reaction kettle, and performing a reaction under certain reaction conditions; 2, after the reaction of the iridium powder, the hydrochloric acid and the chlorine gas is completed, reducing pressure of the reaction kettle to normal pressure, adding concentrated hydrochloric acid in batches, continuing a stirring reaction under the temperature condition of 70-90 DEGC for 1-5 h, removing a free chlorine gas in the reaction liquid, and performing cooling to room temperature; and 3, after the reaction system is cooled to the room temperature, performing solid-liquid separation, wherein the obtained filtrate is a chloroiridic acid solution. According to the method disclosed by the invention, a one-time dissolution leaching rate of the indissolvable metal iridiumpowder achieves 70% or more, and the dissolution method disclosed by the invention has the advantages of a simple process, a short process, a large processing amount and no introduction of impurity ions, and is a high-efficiency low-cost and environmentally-friendly method.

Owner:XIAN RAREALLOYS

Production process of ruthenium trichloride

ActiveCN106335932ANo pollutionShorten the production cycleRuthenium/rhodium/palladium/osmium/iridium/platinum halidesAlcoholSolvent

The invention relates to a production process of ruthenium trichloride. According to the process, RuO4 gas is produced according to a traditional method; diluted hydrochloric acid is adopted for absorbing the RuO4 gas till the concentration of Ru in the solution ranges from 59 g / L to 61 g / L, meanwhile, the pH value is adjusted to range from 1.9 to 2.1, and a ruthenium-containing solution is obtained; a dispersing solvent is added into the ruthenium-containing solution, the adding volume of the dispersing solution is 9.8-10.2% of the volume of the ruthenium-containing solution, and the dispersed ruthenium-containing solution is obtained; the dispersing solvent is a mixture of hydrogen peroxide, ethyl alcohol and acetone according to the volume ratio of 1:(7.9-8.1):(0.95-1.05), the obtained dispersed ruthenium-containing solution is spray-dried through a spray dryer, and ruthenium trichloride powder is obtained. A traditional production process of ruthenium trichloride is improved, continuous, large-scale and equipment production is achieved, and the purposes of being short in production period, low in cost and free of polluting the environment are achieved.

Owner:昆明铂磊科技有限公司

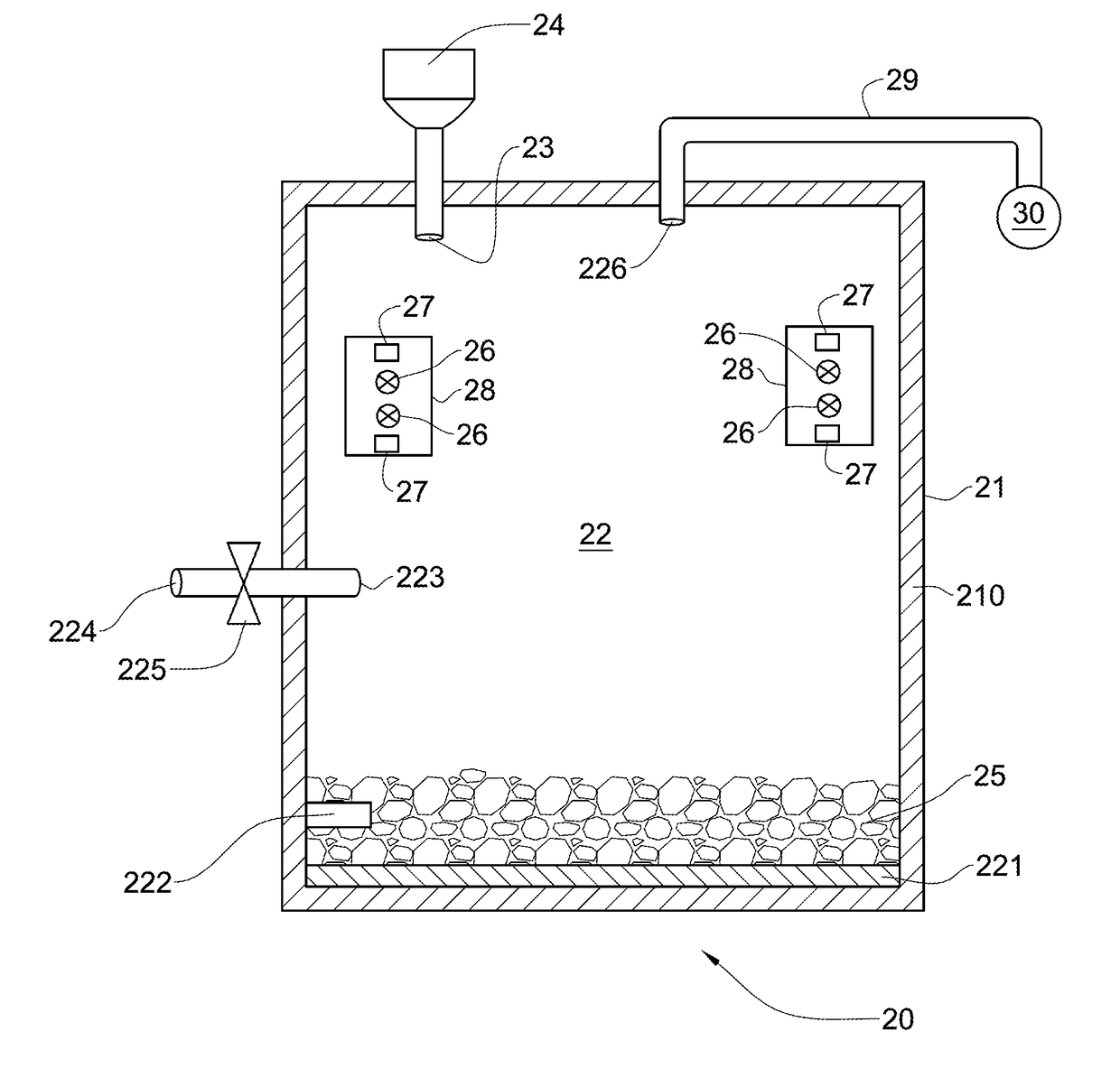

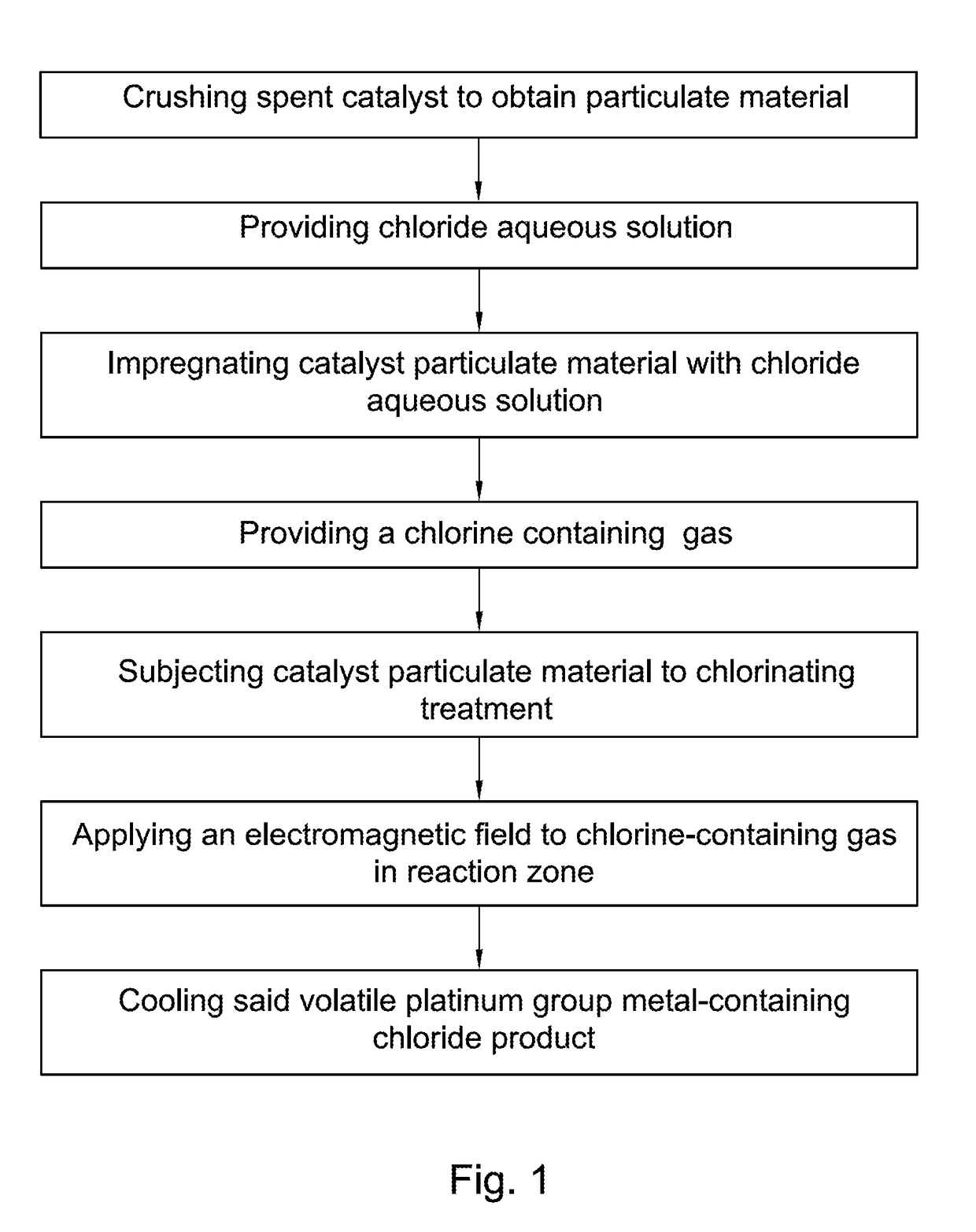

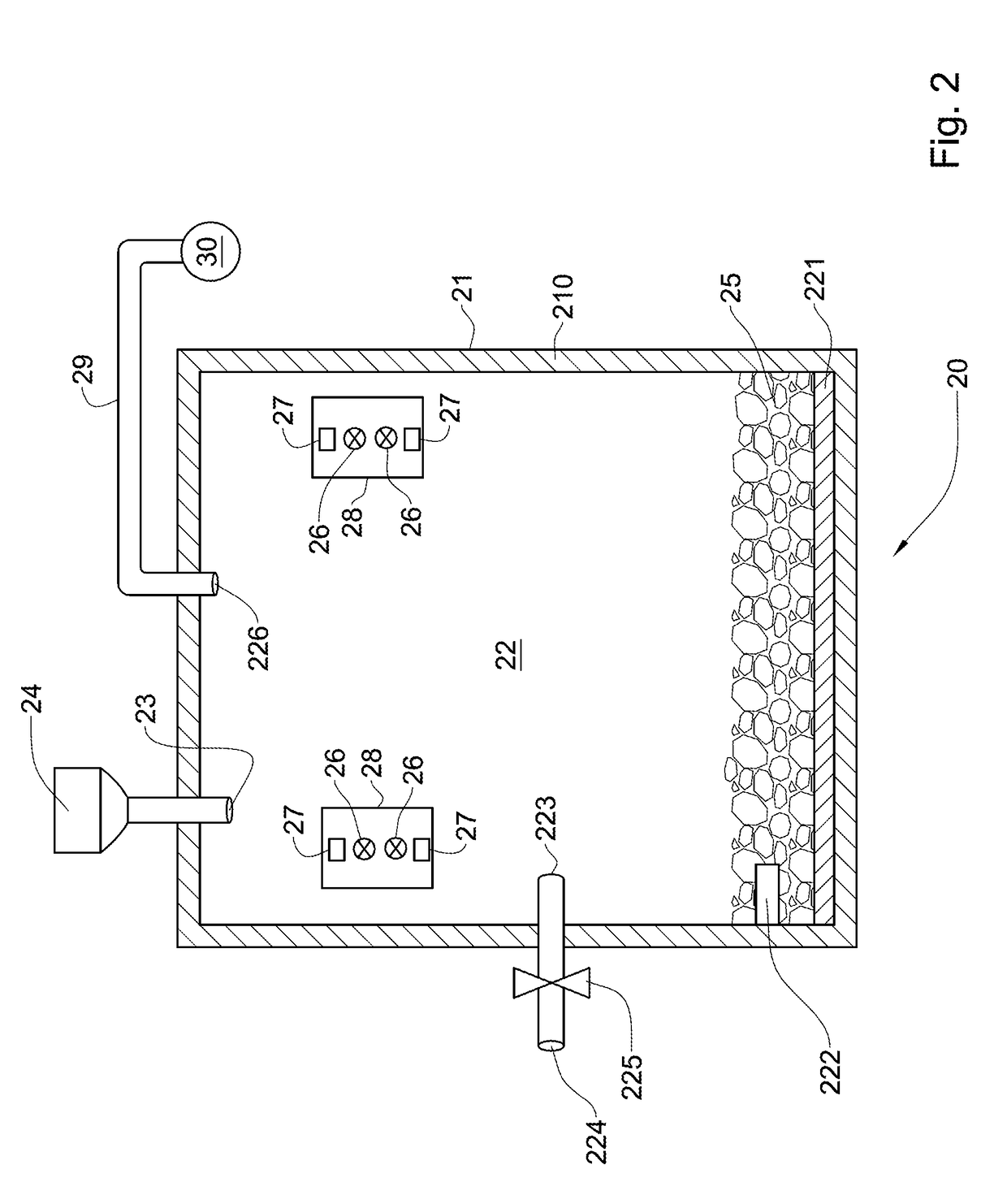

Method for platinum group metals recovery from spent catalysts

ActiveUS20170145542A1Great contributionRuthenium/rhodium/palladium/osmium/iridium/platinum halidesEnergy based chemical/physical/physico-chemical processesChemical reactionChloride

A method for recovery of platinum group metals from a spent catalyst is described. The method includes crushing the spent catalyst to obtain a catalyst particulate material including particles having a predetermined grain size. The method includes subjecting the catalyst particulate material to a chlorinating treatment in the reaction zone at a predetermined temperature for a predetermined time period by putting the catalyst particulate material in contact with the chlorine containing gas. The method also includes applying an electromagnetic field to the chlorine-containing gas in the reaction zone to provide ionization of chlorine; thereby to cause a chemical reaction between platinum group metals and chlorine ions and provide a volatile platinum group metal-containing chloride product in the reaction zone. Following this, the volatile platinum group metal-containing chloride product is cooled to convert the product into solid phase platinum group metal-containing materials.

Owner:YEDA RES & DEV CO LTD

Method of recycling ruthenium trichloride from waste carbon ruthenium-supporting catalyst

InactiveCN106186090ASolve the problem of insolubility in strong acidsEfficient separationRuthenium/rhodium/palladium/osmium/iridium/platinum halidesChemical recyclingStrong acidsIncineration

The invention discloses a method of recycling ruthenium trichloride from waste carbon ruthenium-supporting catalyst. The recycled carbon ruthenium-supporting catalyst or other noble metal catalysts are subjected sequentially to incineration, alkali solution, leaching, oxidative absorption and smelt-drying to finally extract ruthenium trichloride; by combining the alkali solution method, the oxidative absorption method and the traditional recycling process for the noble metal, ruthenium, it is possible to solve the problem that the metal ruthenium is insoluble in a strong acid; the oxidative absorption method may effectively separate ruthenium from other metals; the ruthenium trichloride recycled by using method has little impurity and good quality and may serve as a raw material for direct use in the preparation of catalysts, and no secondary pollution is caused to the environment during recycling.

Owner:陕西瑞科新材料股份有限公司

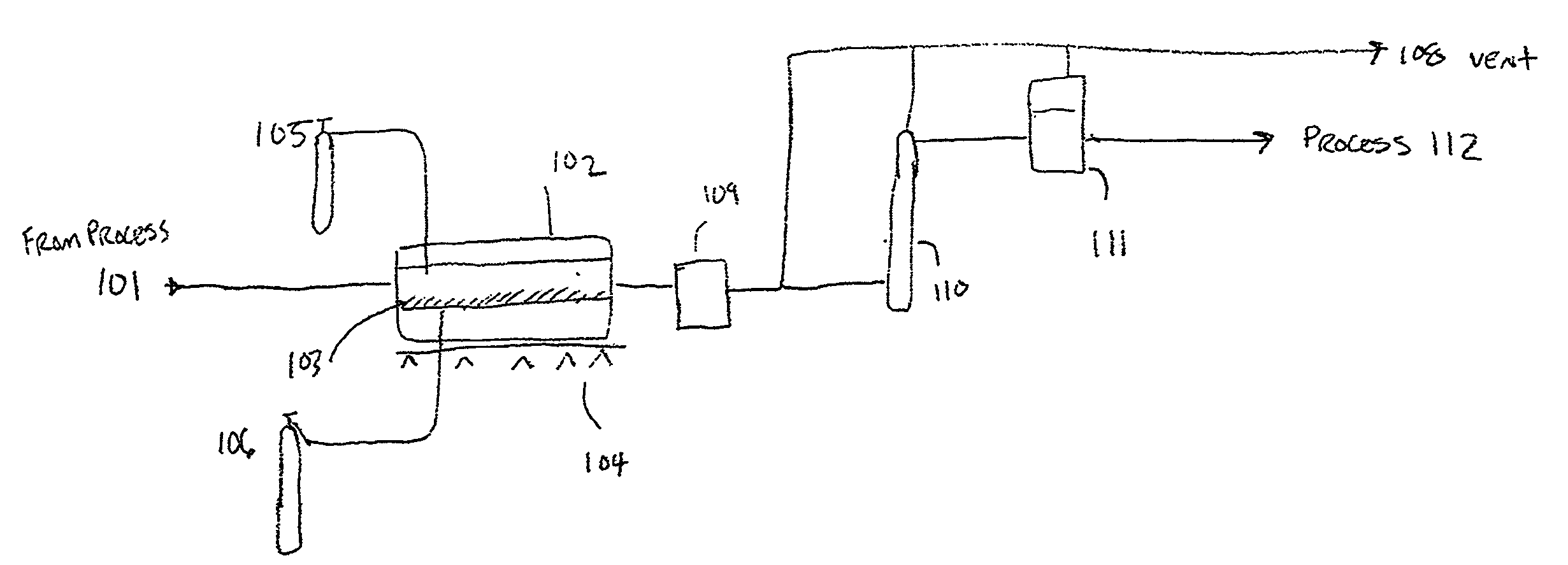

Method for the recycling and purification of an inorganic metallic precursor

InactiveUS20080253948A1High purityRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesRuthenium/rhodium/palladium/osmium/iridium/platinum halidesHydrogenDistillation

Methods and apparatus for the recycling and purification of an inorganic metallic precursor. A first gaseous stream containing ruthenium tetroxide is provided, and transformed into a solid phase lower ruthenium oxide. This lower phase ruthenium oxide is reduced with hydrogen to form ruthenium metal. The ruthenium metal is contacted with an oxidizing mixture to produce a stream containing ruthenium tetroxide, and any remaining oxidizing compounds are removed from this stream through a distillation.

Owner:GATINEAU JULIEN +1

Method for recovering rhodium chloride from rhodium slag

ActiveCN111410242AHigh purityHigh yieldRuthenium/rhodium/palladium/osmium/iridium/platinum halidesProcess efficiency improvementFormateChloride

The invention relates to a method for recovering rhodium chloride from rhodium slag. The method comprises the steps of: performing rhodium ash pretreatment, rhodium ash acid pickling, acid salt melting of alkali metal, cationic resin adsorption, evaporative crystallization and formic acid reduction; pretreating rhodium ash by formate; performing re-pickling, washing away most base metals, after drying, uniformly mixing with acid salt of alkali metal and an auxiliary agent to form powder, and carrying out melting reaction in a muffle furnace; adding deionized water to leach a melt, enabling thetreated leach liquor to pass through cationic resin, thoroughly removing base metals, performing concentrating and drying to obtain high-purity rhodium trichloride, eluting the resin by using hydrochloric acid after the resin adsorbs iron to be saturated, and adding formic acid into the eluent to reduce rhodium, thereby realizing separation of rhodium and iron in the resin eluent. The invention aims to provide a method for recovering rhodium chloride from rhodium slag, which has the advantages of simple recovery technique, no environmental pollution and high rhodium chloride purity for rhodium chloride recovery.

Owner:LUXI CATALYST

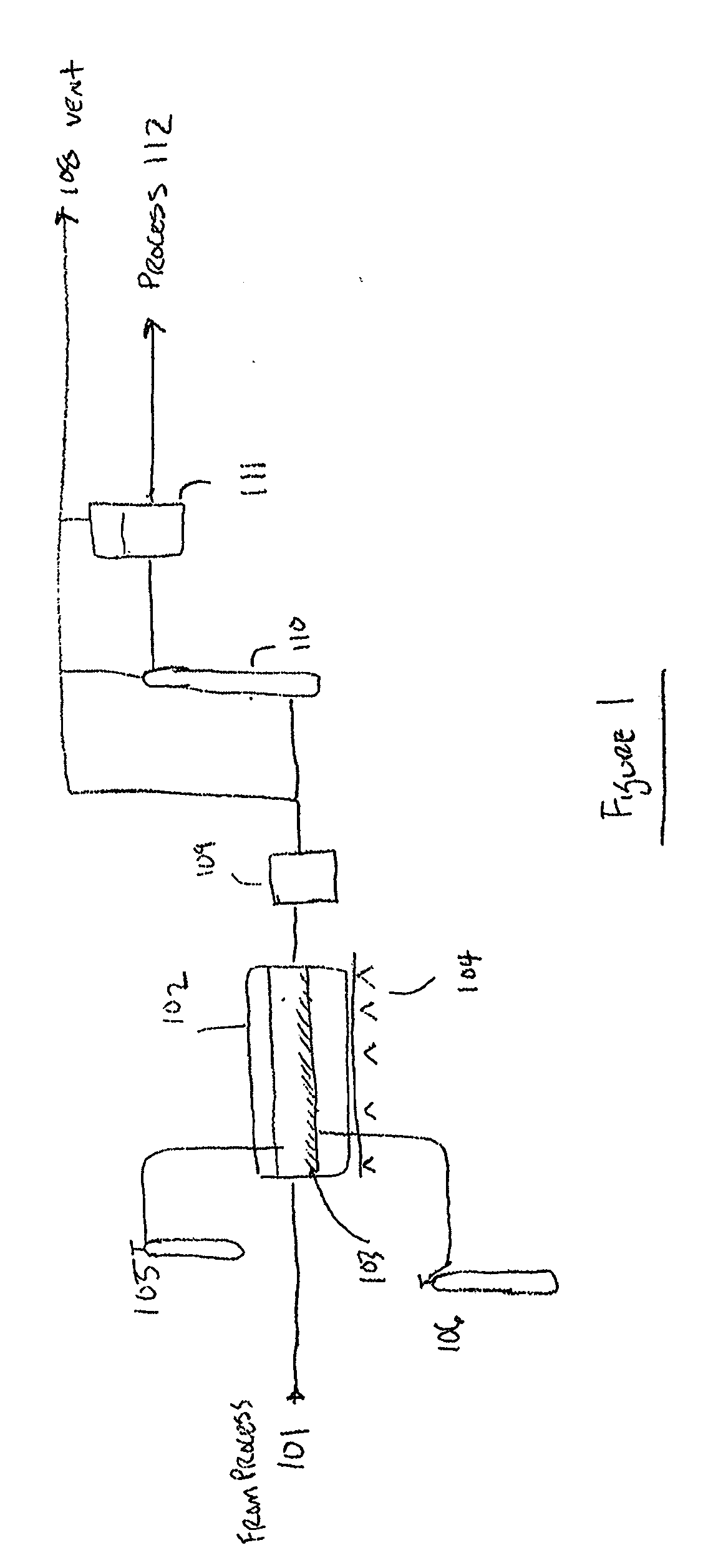

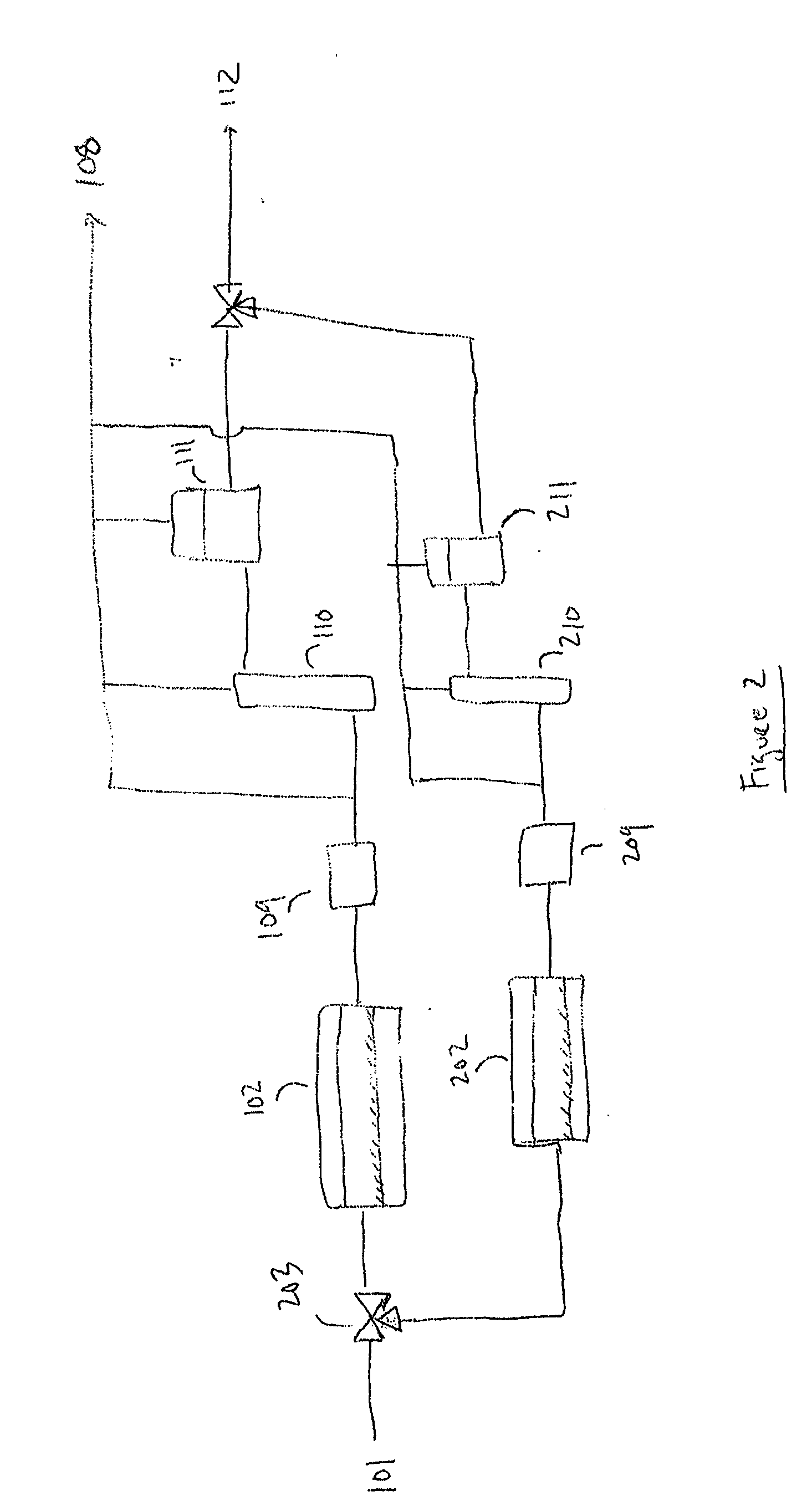

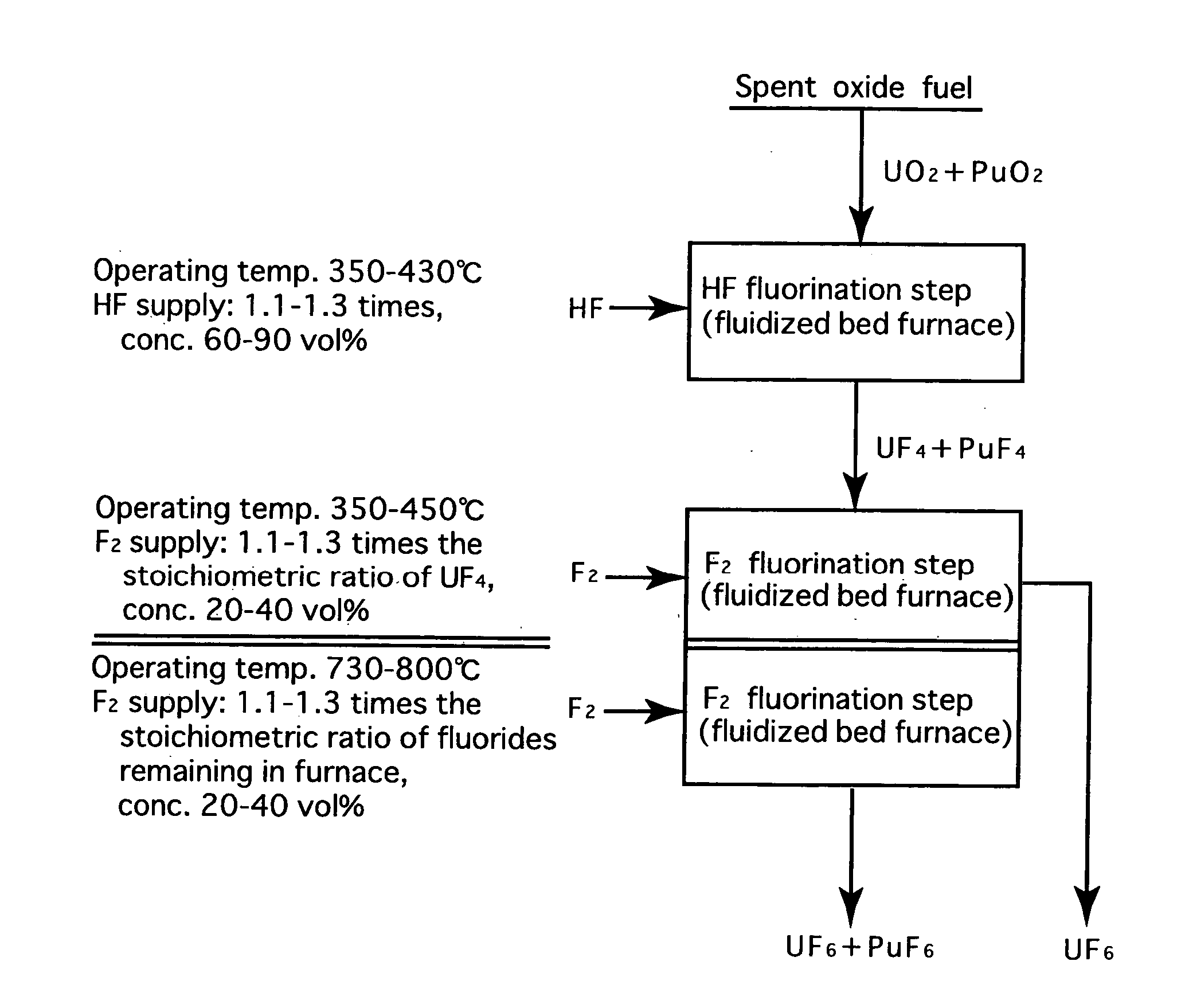

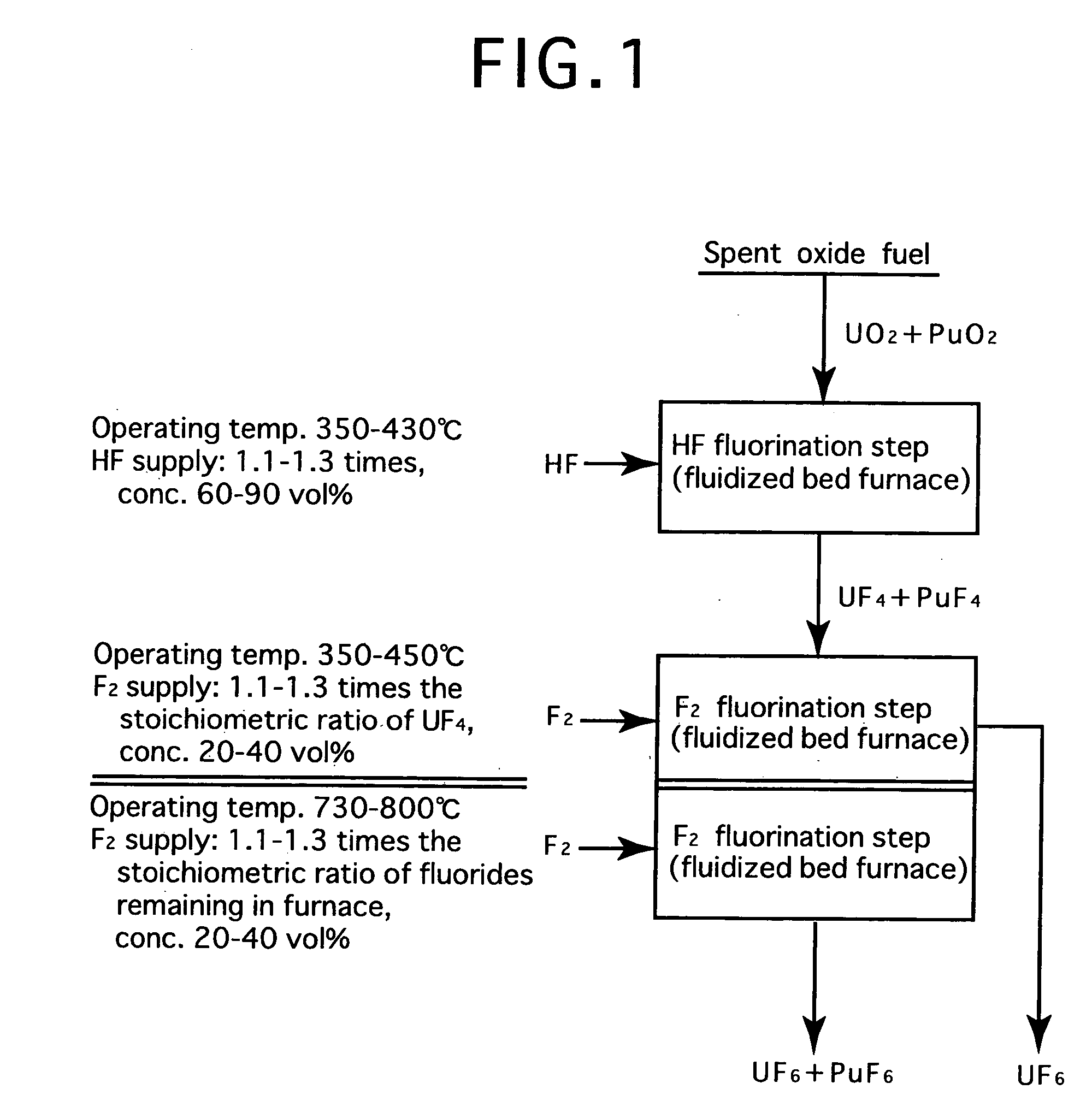

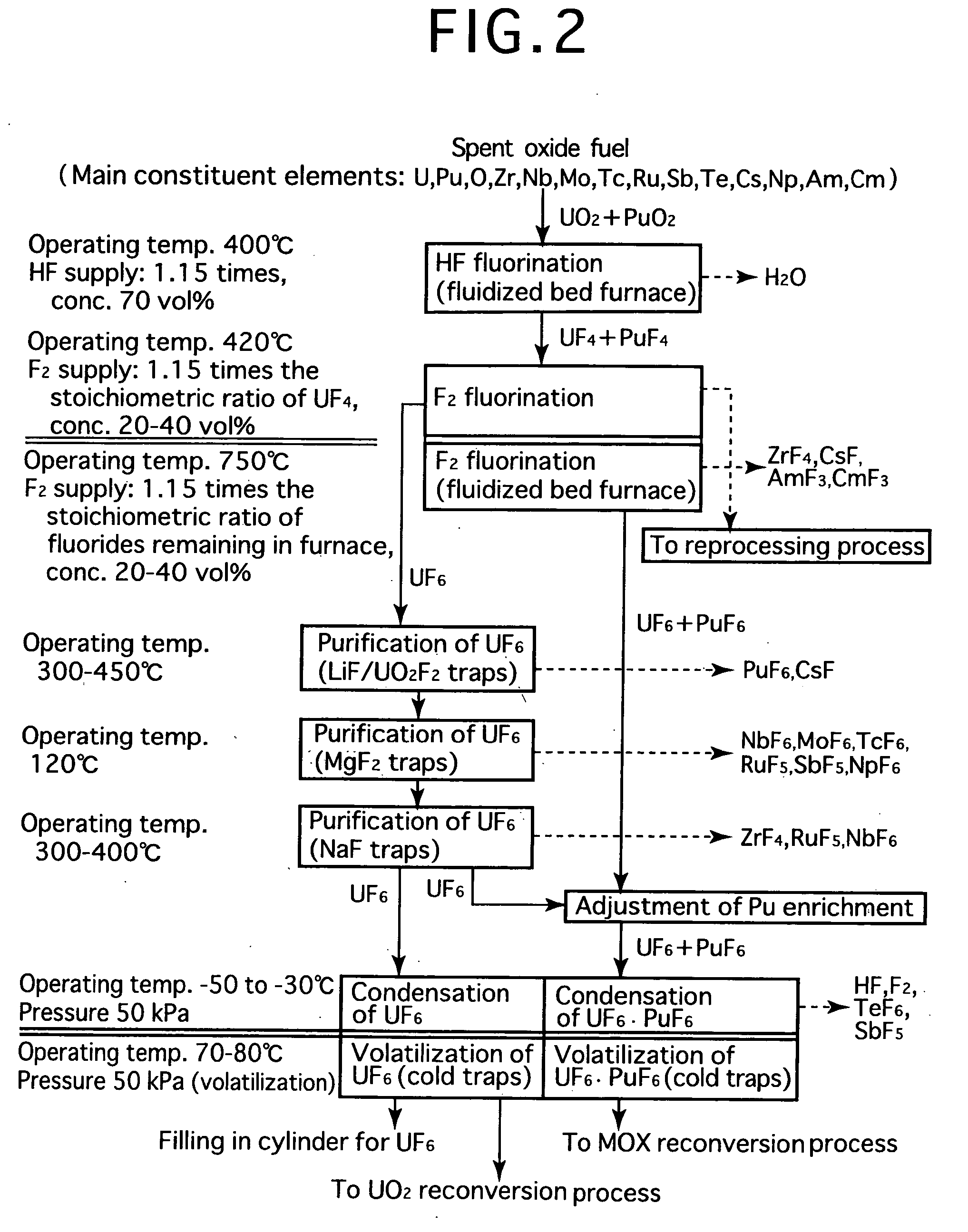

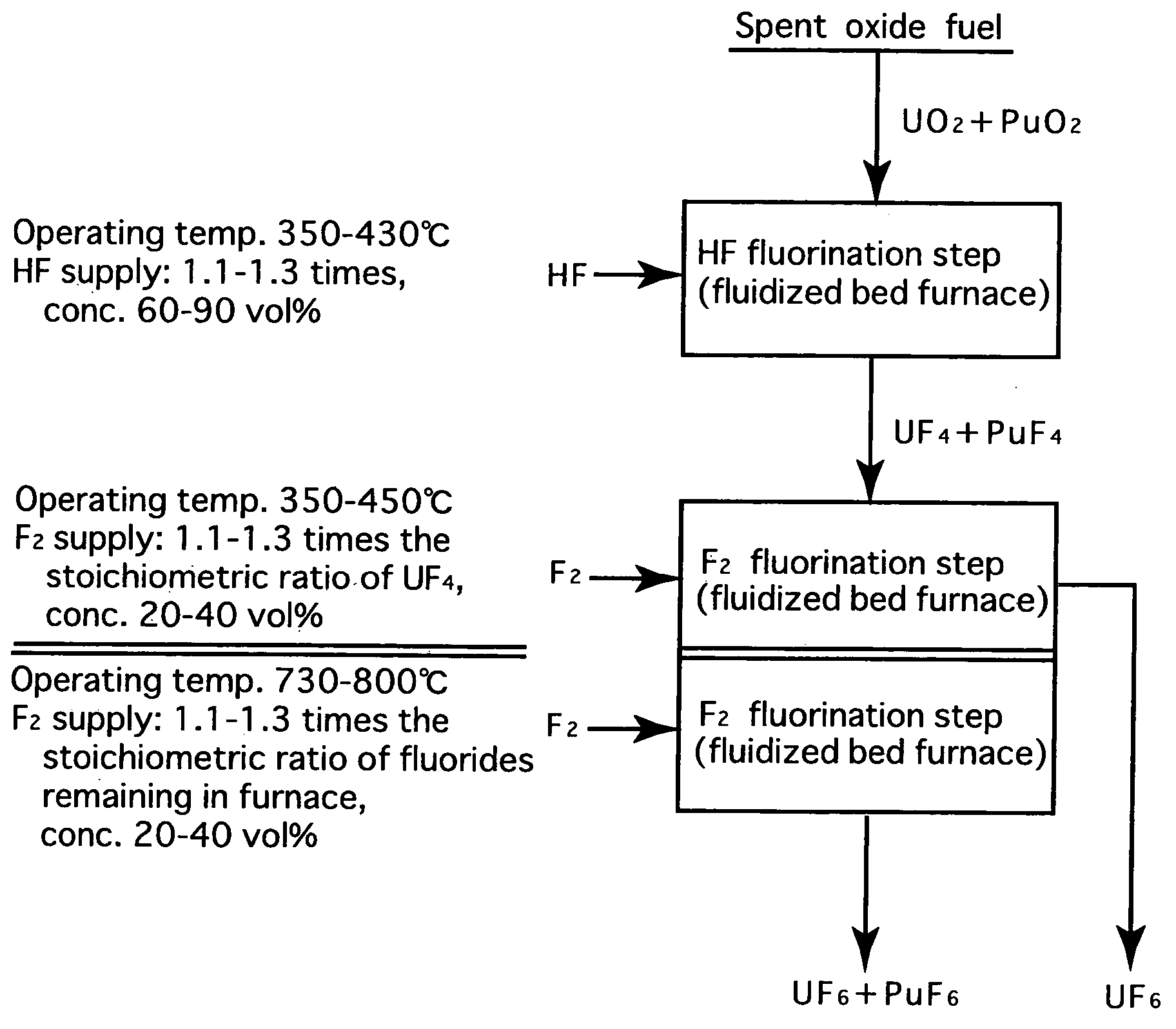

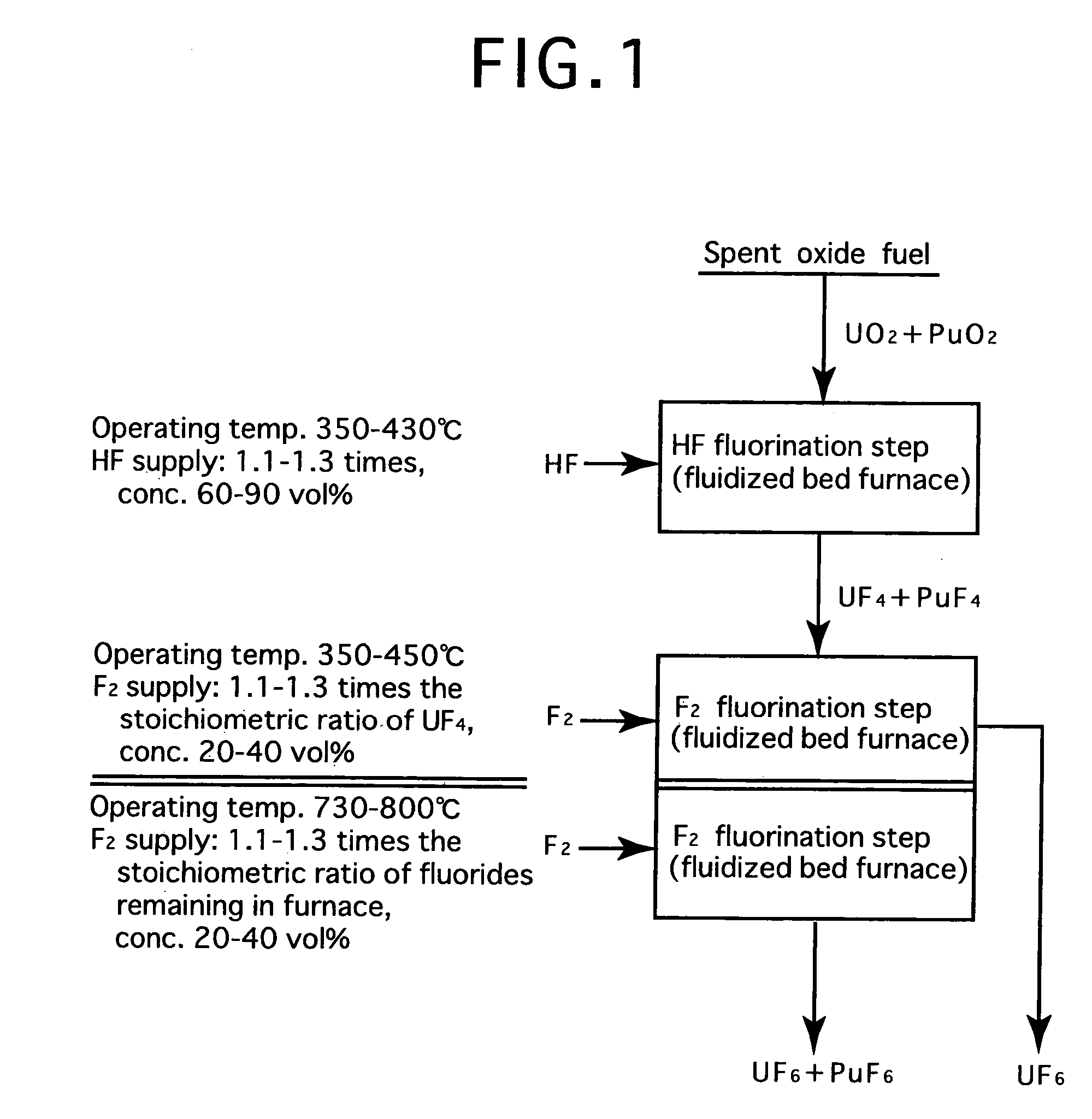

Reprocessing method by fluoride volatility process using solid-gas separation

InactiveUS20060057043A1Simple stepsEasy to separatePlutonium compoundsFluoride preparationFluoride volatilityHexafluoride

Fluorine or a fluorine compound is subjected to a reaction with a spent oxide fuel to produce fluorides of uranium and plutonium, and the fluorides are recovered using a difference in volatility behavior. The spent oxide fuel is subjected to a reaction with an HF gas, whereby uranium, plutonium and most impurities are converted into solid fluorides having low valences or remained as oxides to inhibit volatilization thereof, and then in an F2 fluorination step, the HF fluorination product is subjected to a reaction with a fluorine gas in two stages: one at a low temperature and the other at a high temperature, whereby a certain amount of gaseous uranium and volatile impurities are separated with plutonium kept in a solid form in the first stage, and mixed fluorides of remaining uranium and plutonium are fluorinated into hexafluorides at the same time in the second stage. By such a reprocessing method, plutonium enrichment can be adjusted, uranium and plutonium can be purified, and steps are simplified as well. In addition, reactors are hard to be corroded or deteriorated.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

Method for preparing rhodium chloride through recovering rhodium from incinerated waste rhodium residues

ActiveCN107879382AImprove roasting conditionsSimplify follow-upRuthenium/rhodium/palladium/osmium/iridium/platinum halidesIon exchangeHydrogen peroxide

The invention provides a method for preparing rhodium chloride through recovering rhodium from incinerated waste rhodium residues. The method comprises the steps of firstly carrying out aerobic high-temperature roasting on waste catalyst roasting rhodium residues with incompletely removed organic matters, thus thoroughly removing the organic matters, and obtaining rhodium ash; then adding hydrofluoric acid and perchloric acid into the rhodium ash for pretreating, adding hydrochloric acid and hydrogen peroxide for directly dissolving the rhodium residues, and filtering to obtain a coarse rhodium acid solution; finally adopting an ion exchange method for the coarse chlororhodic acid solution to remove ion impurities such as Fe, Ni and Ca, and then concentrating and drying to obtain rhodium chloride hydrate. According to the method provided by the invention, a roasted rhodium residue post-treatment process is simplified, the efficiency is high, the rhodium loss is less, and the rhodium yield is larger than 99 percent.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

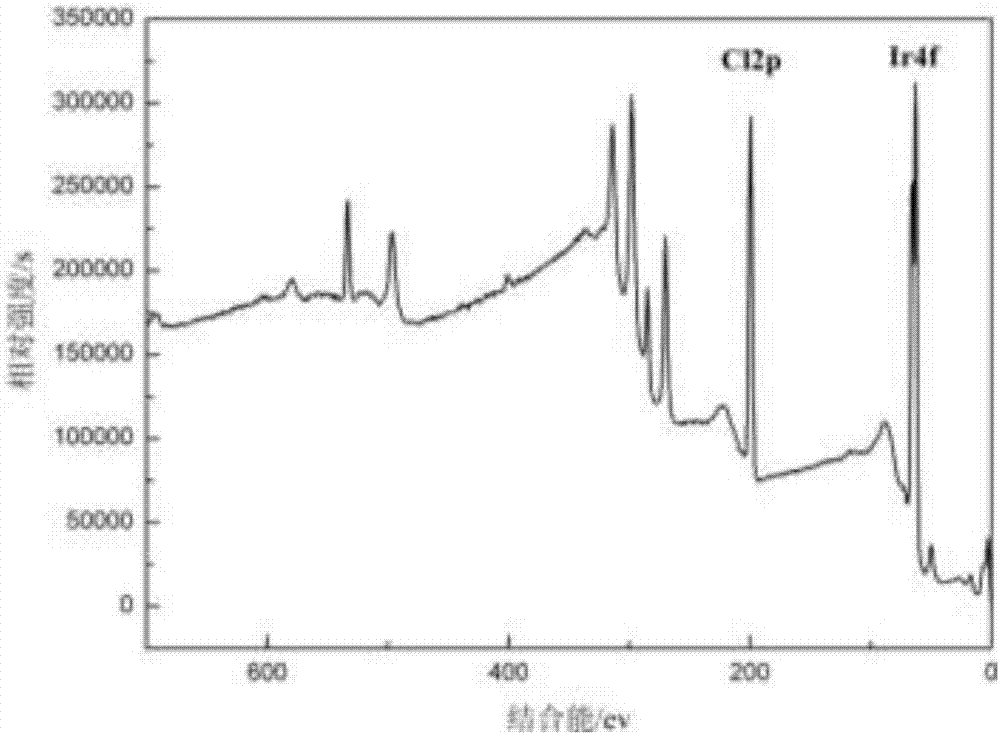

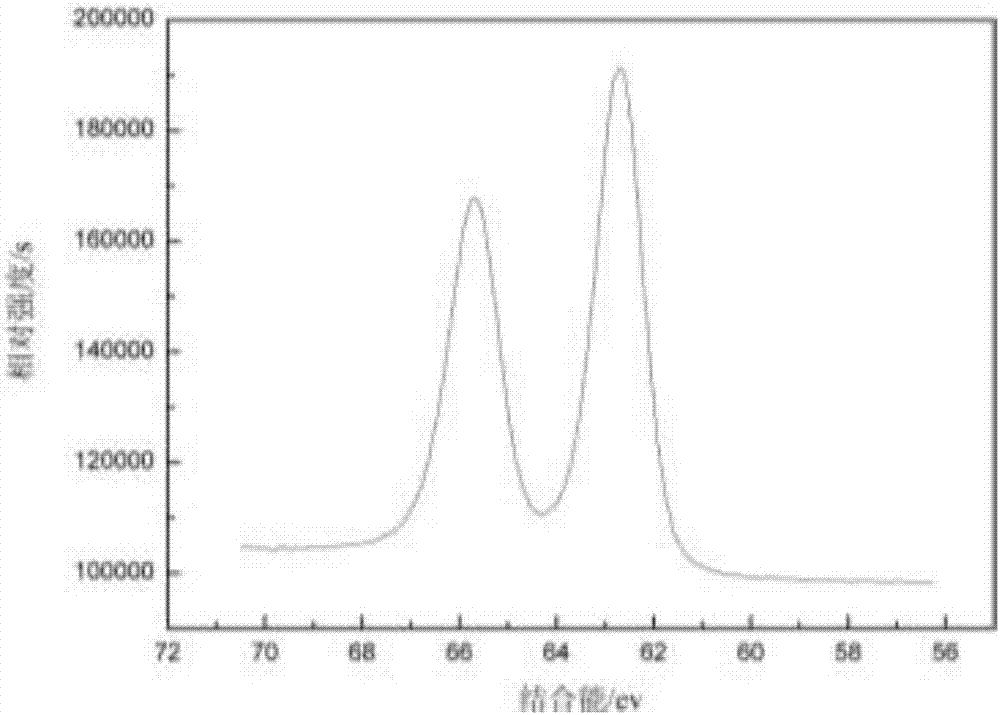

Preparation method of high-purity iridium trichloride

PendingCN114105229AIncrease productivityHigh yieldRuthenium/rhodium/palladium/osmium/iridium/platinum halidesProcess efficiency improvementNitrosoWater chlorination

The invention discloses a method for preparing high-purity iridium trichloride. Iridium powder is used as a raw material to be subjected to alkali fusion under the mixing action of sodium peroxide, sodium hydroxide and sodium carbonate; dissolving the alkali fusion solid with aqua regia, adding ammonium chloride into the filtered solution to form precipitated ammonium chloroiridate, reacting the ammonium chloroiridate with hydrazine hydrochloride to form ammonium chloroiridate, further removing impurities by sodium sulfide and ammonium sulfide, filtering, oxidizing the filtrate by hydrochloric acid / hydrogen peroxide, and precipitating by an ammonium chloride solution to obtain ammonium chloroiridate with higher purity; the preparation method comprises the following steps: removing nitrate from ammonium chloroiridate by using an aqua regia solution, adding sodium nitrite / potassium chloride into the obtained chloroiridate solution, boiling to obtain a potassium hexanitroso iridate solid, filtering, adding hydrochloric acid into the solid, boiling, dissolving, removing nitrate, adding a proper amount of hydrazine hydrochloride, and carrying out rotary evaporation and vacuum calcination on the solution to obtain an iridium trichloride solid with the purity of more than 99.995%.

Owner:英特派铂业股份有限公司

Controlled reduction preparation method of iridium trichloride

ActiveCN106854001AAvoid introducingHigh purityRuthenium/rhodium/palladium/osmium/iridium/platinum halidesRefluxIridium chloride

Belonging to the technical field of reduction, the invention discloses a controlled reduction preparation method of iridium trichloride. The method includes: adding a quadrivalent iridium chloride and a reducing agent in a three-mouth flask according to certain proportion, under a magnetic stirring condition, and conducting constant temperature reduction until quadrivalent iridium in the solution is completely converted to trivalence. A condensation reflux device is used in the reaction process to reduce the volatilization of the reducing agent and control the reaction system stable. The method has the advantages of simple operation, short process, fully controllable reduction process and stable content, can guarantee that quadrivalent iridium can be completely reduced to trivalence, and the prepared iridium trichloride product has high purity.

Owner:GRIKIN ADVANCED MATERIALS

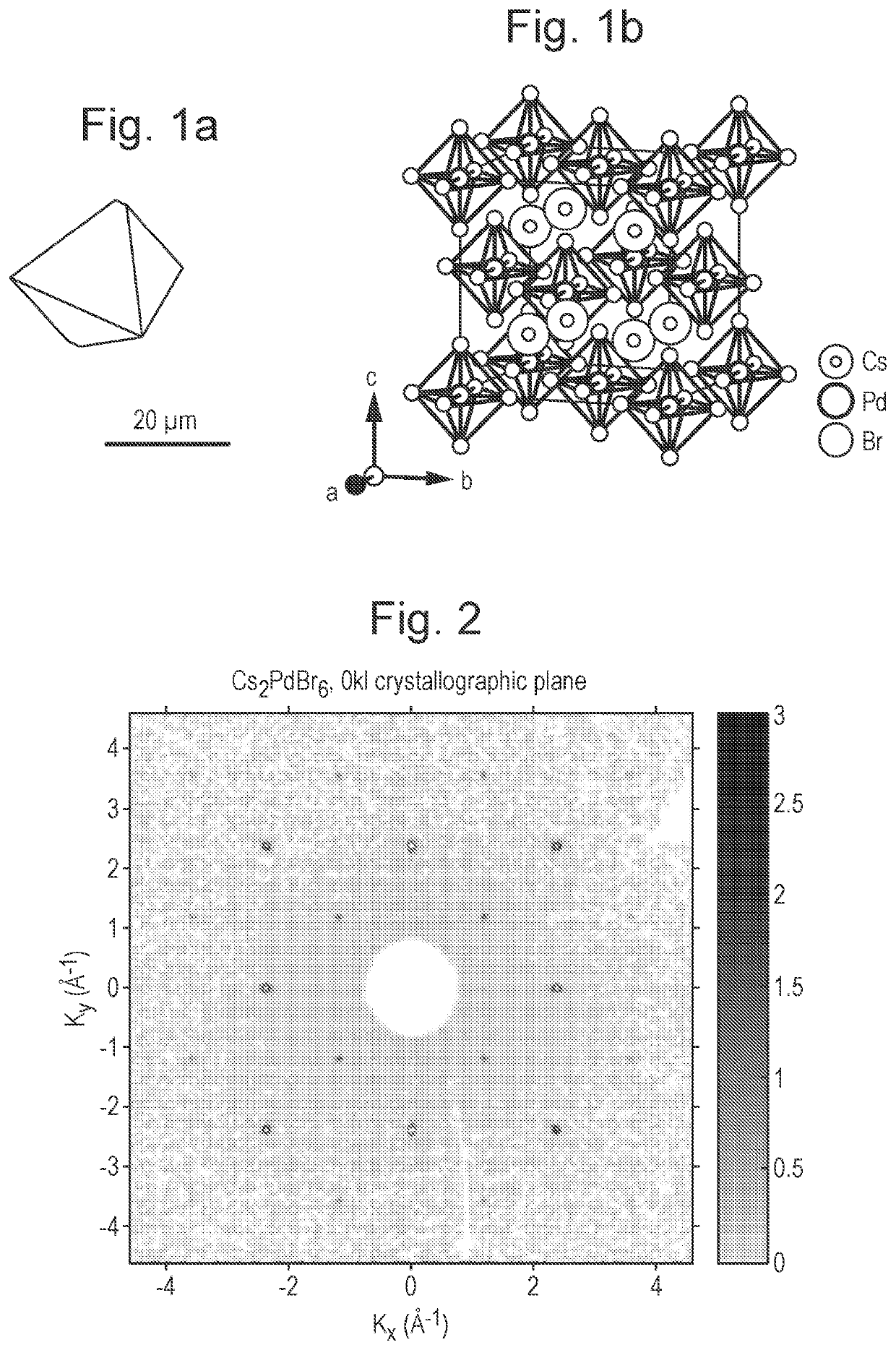

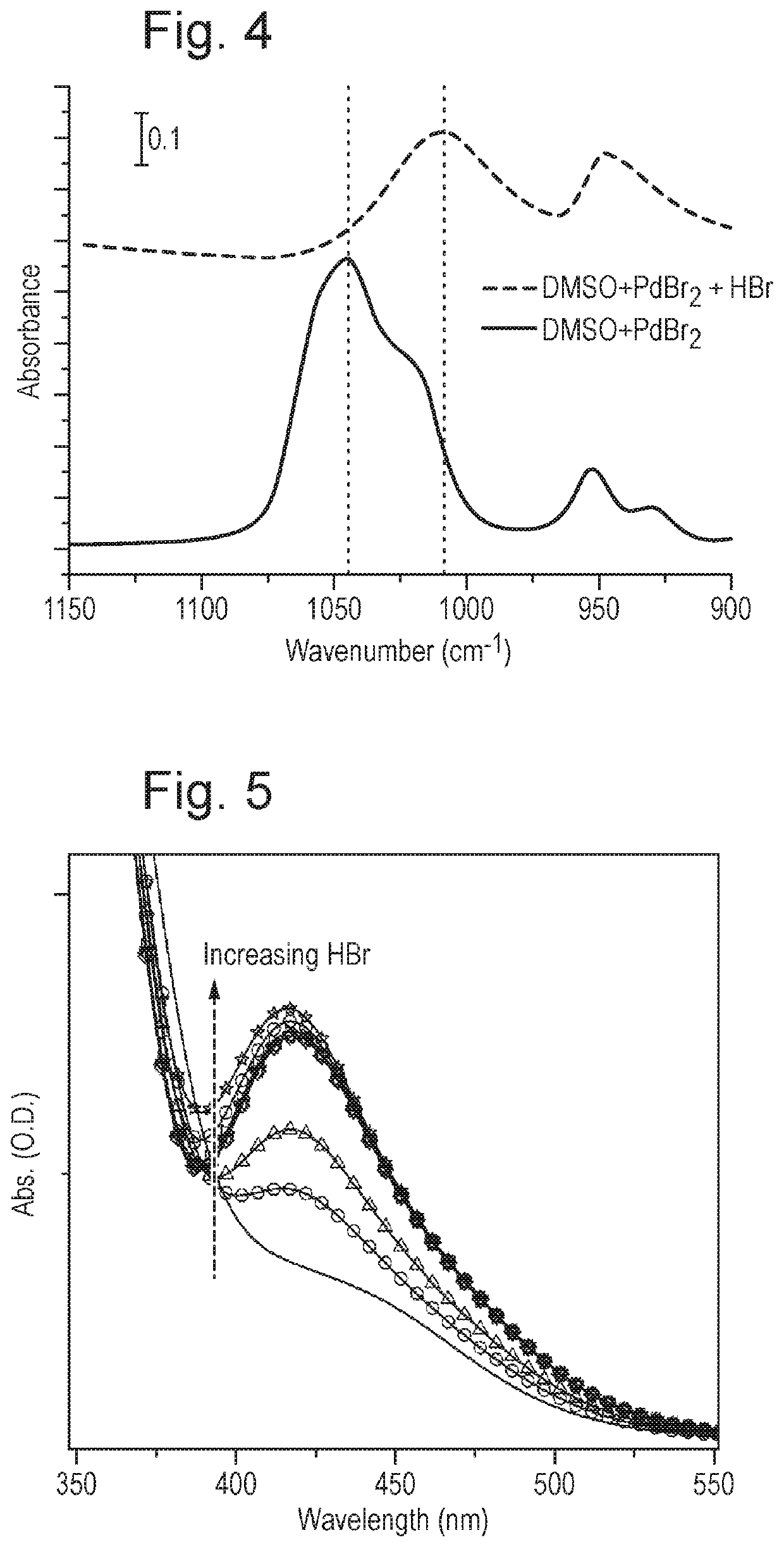

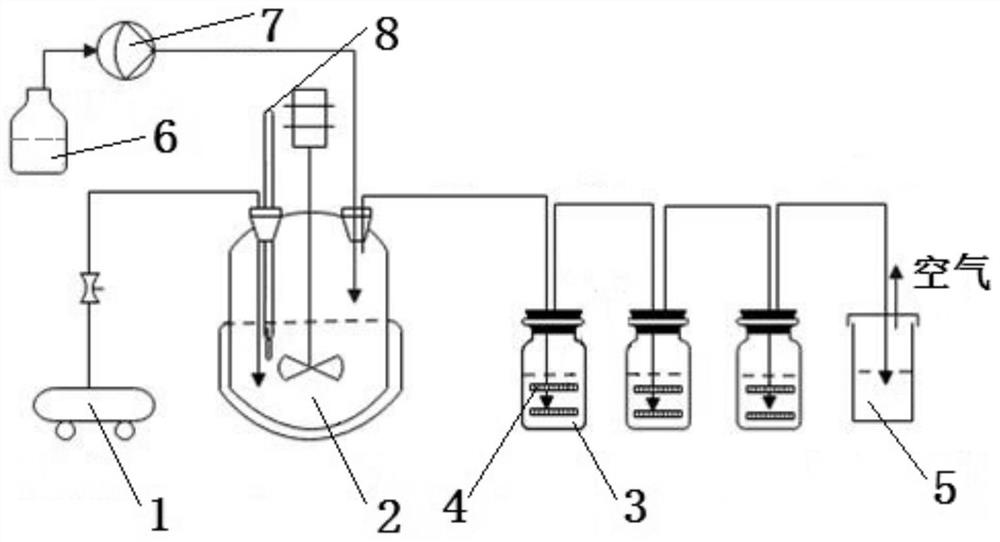

Semiconductor device comprising halopalladate

ActiveUS20200044102A1Easy to produceRuthenium/rhodium/palladium/osmium/iridium/platinum halidesSolid-state devicesSemiconductor materialsDevice material

The present invention relates to a semiconductor device comprising a semiconducting material, wherein the semiconducting material comprises a halometallate compound comprising: (a) cesium; (b) palladium; and (c) one or more halide anions [X]. The invention also relates to a layer comprising the semiconducting material. The invention further relates to a process for producing a halometallate compound of formula (IV): [A]2[MIV][X]6, which process uses a H[X] and a compound comprising a sulfoxide group.

Owner:OXFORD UNIV INNOVATION LTD

Method for preparing ruthenium trichloride hydrate by adopting ruthenium-containing wastewater

PendingCN113860612AExtended pathIncrease contact areaRuthenium/rhodium/palladium/osmium/iridium/platinum halidesWater contaminantsSpeciality chemicalsWater chlorination

The invention provides a method for preparing ruthenium trichloride hydrate by adopting ruthenium-containing wastewater, and belongs to the technical field of special chemicals. The method comprises the following steps: mixing ruthenium-containing wastewater and an oxidizing agent, reacting at 25-50 DEG C to obtain ruthenium tetroxide gas, introducing compressed gas into the ruthenium-containing wastewater to transfer the ruthenium tetroxide gas into an absorption device containing an absorption liquid, and reacting ruthenium tetroxide with the absorption liquid to obtain the absorption liquid containing ruthenium trichloride or H2RuCl5; and carrying out reduced pressure evaporation on the absorption liquid containing ruthenium trichloride or H2RuCl5 to obtain the ruthenium trichloride hydrate. The method provided by the invention is low in energy consumption and mild in reaction, and can realize recovery of trace (ppm level) Ru in the aqueous solution.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

A kind of production technology of ruthenium trichloride

ActiveCN106335932BNo pollutionShorten the production cycleRuthenium/rhodium/palladium/osmium/iridium/platinum halidesAlcoholSolvent

The invention relates to a production process of ruthenium trichloride. According to the process, RuO4 gas is produced according to a traditional method; diluted hydrochloric acid is adopted for absorbing the RuO4 gas till the concentration of Ru in the solution ranges from 59 g / L to 61 g / L, meanwhile, the pH value is adjusted to range from 1.9 to 2.1, and a ruthenium-containing solution is obtained; a dispersing solvent is added into the ruthenium-containing solution, the adding volume of the dispersing solution is 9.8-10.2% of the volume of the ruthenium-containing solution, and the dispersed ruthenium-containing solution is obtained; the dispersing solvent is a mixture of hydrogen peroxide, ethyl alcohol and acetone according to the volume ratio of 1:(7.9-8.1):(0.95-1.05), the obtained dispersed ruthenium-containing solution is spray-dried through a spray dryer, and ruthenium trichloride powder is obtained. A traditional production process of ruthenium trichloride is improved, continuous, large-scale and equipment production is achieved, and the purposes of being short in production period, low in cost and free of polluting the environment are achieved.

Owner:昆明铂磊科技有限公司

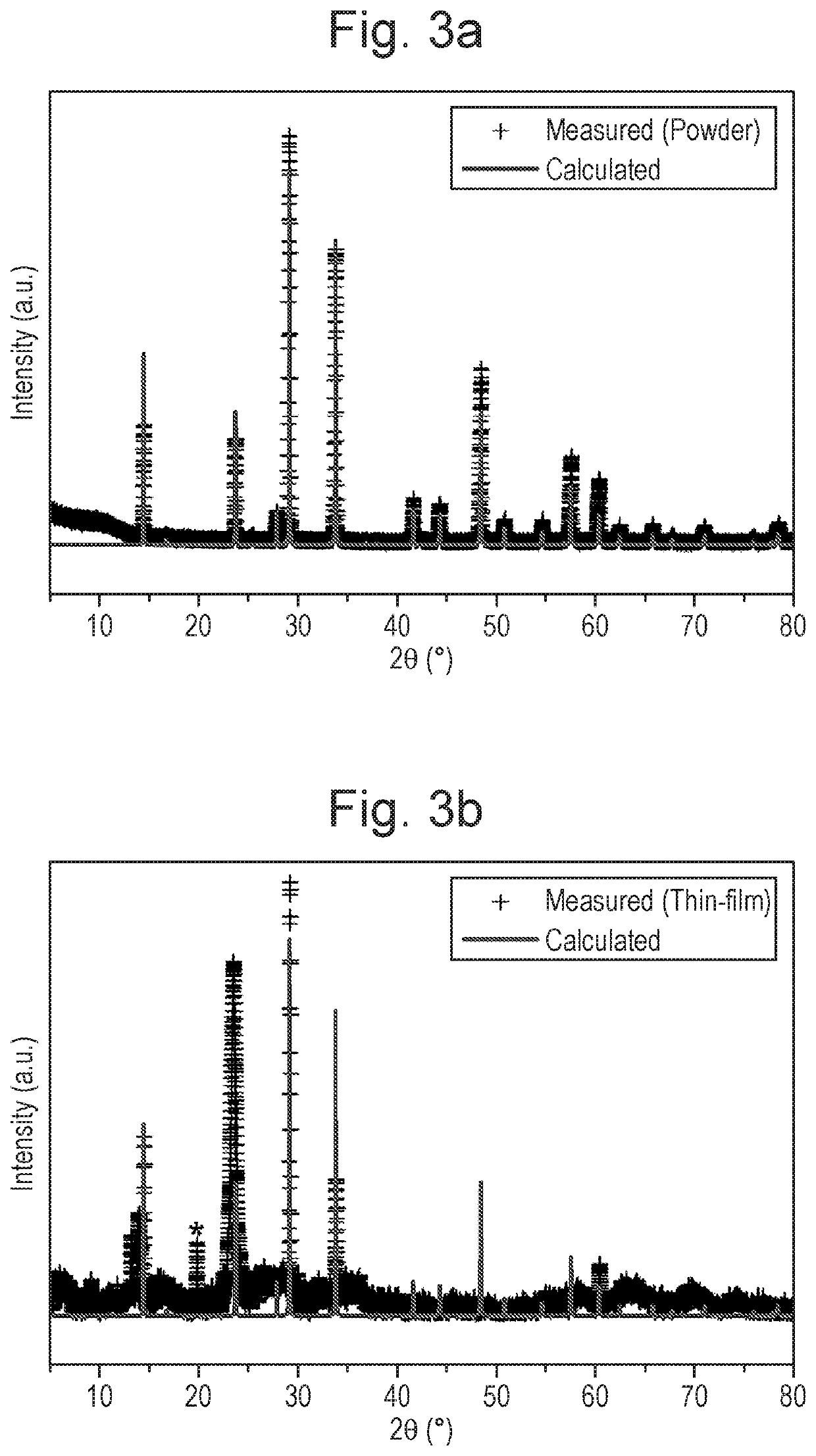

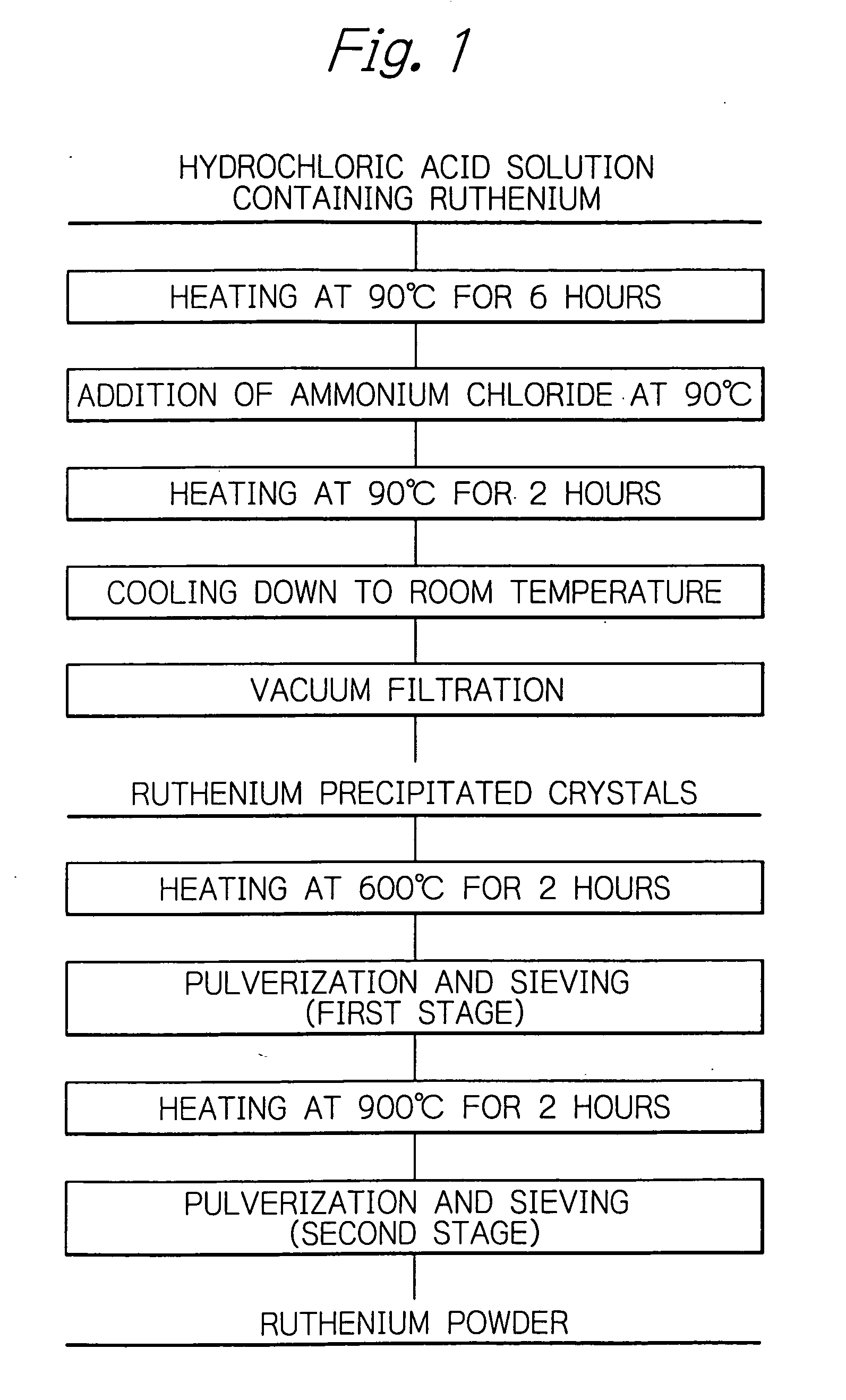

Method for producing ammonium hexachlororuthenate and ruthenium powder, as well as ammonium hexachlororuthenate

InactiveUS20080199386A1Easy to getImprove propertiesRuthenium/rhodium/palladium/osmium/iridium/platinum halidesHalide preparation methodsRutheniumMoisture

Ammonium hexachlororuthenate is produced by adding ammonium chloride to a hydrochloric acid solution containing ruthenium. The ammonium hexachlororuthenate is baked to obtain the ruthenium powder. When the moisture content of the ammonium hexachlororuthenate is high, the baked product is so hard sintered product that its pulverization is not easy. In accordance with the present invention, the following steps are carried out. Hydrochloric acid solution containing ruthenium is held at a temperature of 80 to 95° C. for three hours or longer. The ammonium chloride is then added to the hydrochloric acid solution which is stirred by a stirring mill at the rotation of 200 revolutions per minute or more. The hydrochloric acid solution is held at a temperature of from 85 to 95° C. for 1 hour while being stirred at 200 rpm. The resultant precipitate of ammonium hexachlororuthenate is filtered. The inventive crystals of precipitated ammonium hexachlororuthenate has 10 mass % or less of moisture content.

Owner:JX NIPPON MINING& METALS CORP

Method of quickly separating and extracting ruthenium from low content ruthenium-containing wastes

PendingCN109136533ASimple processReduce energy consumptionRuthenium/rhodium/palladium/osmium/iridium/platinum halidesProcess efficiency improvementDistillationEnergy consumption

The invention discloses a method of quickly separating and extracting ruthenium from low content ruthenium-containing wastes. The method comprises the following steps: adding water into a low contentruthenium-containing resource as a raw material to be soaked, adding a dispersant to be uniformly stirred and filtering and washing the mixture; inputting dispersed residues in a reaction kettle, adding hydrochloric acid, raising the temperature to stir, introducing chlorine gas to react for a period of time after reaching the temperature, and stopping the reaction after the reaction; and filtering the solution, adding alkali into the solution to precipitate, and carrying out oxidative distillation to obtain a product ruthenium trichloride. The method disclosed by the invention has the characteristics of being simple in process flow, low in energy consumption, high in efficiency, high in ruthenium yield and clean and environmentally friendly.

Owner:CHENZHOU GAOXIN PLATINUM +1

Process for recovery of cobalt, ruthenium, and aluminum from spent catalyst

InactiveUS20140377151A1Safe and efficientReduce lossesProductsAluminium compoundsSlagAluminium hydroxide

A method for recovering cobalt, ruthenium, and aluminum from spent Co—Ru / Al2O3 catalyst. First, Co—Ru / Al2O3 spent catalyst is subjected to hydrocarbon removal, reaction with hydrogen, and alkali fusion to obtain a slag. The slag is subjected to acid leaching, precipitation of cobalt with oxalic acid or ammonium oxalate, reduction of cobalt oxalate, and dissolution of cobalt metal with nitric acid to obtain Co(NO3)2.6H2O. The effluent of acid leaching is subjected to reaction with ethanol, filtration to obtain a filtrate and residue, dissolution of the residue with concentrated hydrochloric acid, and vacuum distillation to obtain β-RuCl3.xH2O. Aluminum hydroxide is prepared from the filtrate through carbonation and calcination. The cobalt yield is ≧97%; the ruthenium yield is ≧95%, and the aluminum yield is ≧92%.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

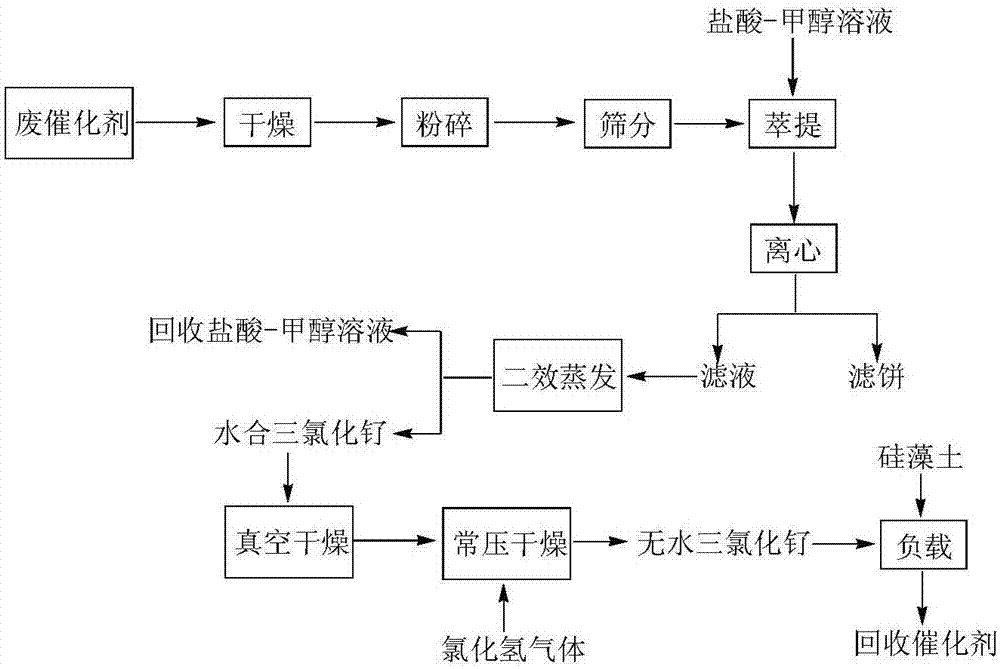

Recovery process of ruthenium trichloride catalyst in trimethylpyruvic acid synthesis work procedure

ActiveCN107162069AReusableNo emissionsRuthenium/rhodium/palladium/osmium/iridium/platinum halidesEnergy inputChemical industryWastewater

The invention relates to the technical field of three-waste treatment in chemical industry, in particular to a recovery process of a ruthenium trichloride catalyst in a trimethylpyruvic acid synthesis work procedure. The waste ruthenium trichloride catalyst is added into a solution and is heated and stirred; then, solid-liquid separation is performed; filter liquid is evaporated to obtain ruodium chloride hydrate; the ruodium chloride hydrate is subjected to heat insulation treatment in hydrogen chloride gas; great energy consumption and great waste water generating quantity of an alkali fusion method can be avoided. The recovered anhydrous ruodium chloride can be directly used in the trimethylpyruvic acid preparation work procedure after being compounded with kieselguhr.

Owner:CHANGZHOU UNIV

Method for recovering rhodium from production waste liquid of rhodium octanoate dimer

InactiveCN110106357AReduce bumpsReduce or avoid splashingRuthenium/rhodium/palladium/osmium/iridium/platinum halidesProcess efficiency improvementOil phaseRaw material

The invention discloses a method for recovering rhodium from production waste liquid of rhodium octanoate dimer. The method comprises the following steps of (1) heating the waste liquid to certain temperature, then, adding hydrochloric acid, cooling to certain temperature after a reaction is made for a period of time, adding an extracting agent, stirring, standing and conducting oil and water separation; (2) adding an anti-boiling agent into an oil phase obtained after separation, performing ashing treatment on the organic phase by employing a temperature programming method after uniform stirring, and absorbing tail gas with a diluted ethanol water solution; (3) washing a product obtained after ashing with water, filtering, drying residues, performing heating, performing drying and absorbing tail gas with water; and (4) performing washing, and taking a solution for concentrating and drying to obtain water-soluble rhodium chloride, wherein the water-soluble rhodium chloride can be reused as a raw material of producing the rhodium octanoate dimer; and the rhodium recovery rate is greater than 96 %, and the rhodium purity is higher than 99 %. The method provided by the invention has asimple process, and is capable of effectively removing a lot of salts, so that roasting efficiency is increased, energy consumption and rhodium losses are effectively reduced, and the recovered rhodium chloride is high in purity, and can be used as the raw material for continued use.

Owner:SINO PLATINUM METALS CO LTD

A kind of method that reclaims rhodium and prepares rhodium chloride from burning waste rhodium slag

ActiveCN107879382BImprove roasting conditionsSimplify follow-upRuthenium/rhodium/palladium/osmium/iridium/platinum halidesSlagCerium

The invention provides a method for preparing rhodium chloride through recovering rhodium from incinerated waste rhodium residues. The method comprises the steps of firstly carrying out aerobic high-temperature roasting on waste catalyst roasting rhodium residues with incompletely removed organic matters, thus thoroughly removing the organic matters, and obtaining rhodium ash; then adding hydrofluoric acid and perchloric acid into the rhodium ash for pretreating, adding hydrochloric acid and hydrogen peroxide for directly dissolving the rhodium residues, and filtering to obtain a coarse rhodium acid solution; finally adopting an ion exchange method for the coarse chlororhodic acid solution to remove ion impurities such as Fe, Ni and Ca, and then concentrating and drying to obtain rhodium chloride hydrate. According to the method provided by the invention, a roasted rhodium residue post-treatment process is simplified, the efficiency is high, the rhodium loss is less, and the rhodium yield is larger than 99 percent.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Process for recovery of cobalt, ruthenium, and aluminum from spent catalyst

A method for recovering cobalt, ruthenium, and aluminum from spent Co—Ru / Al2O3 catalyst. First, Co—Ru / Al2O3 spent catalyst is subjected to hydrocarbon removal, reaction with hydrogen, and alkali fusion to obtain a slag. The slag is subjected to acid leaching, precipitation of cobalt with oxalic acid or ammonium oxalate, reduction of cobalt oxalate, and dissolution of cobalt metal with nitric acid to obtain Co(NO3)2.6 H2O. The effluent of acid leaching is subjected to reaction with ethanol, filtration to obtain a filtrate and residue, dissolution of the residue with concentrated hydrochloric acid, and vacuum distillation to obtain β-RuCl3.x H2O. Aluminum hydroxide is prepared from the filtrate through carbonation and calcination. The cobalt yield is ≧97%; the ruthenium yield is ≧95%, and the aluminum yield is ≧92%.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

Continuous crystallization method of rhodium trichloride

ActiveCN106315697AMeet special needsNo pollutionRuthenium/rhodium/palladium/osmium/iridium/platinum halidesHigh concentrationSolubility

The invention discloses a continuous crystallization method of rhodium trichloride. The continuous crystallization method comprises steps as follows: a blending agent is added to an acid-soluble rhodium chloride solution for adjusting concentration and acidity, and a rhodium chloride solution with high concentration is obtained; the rhodium chloride solution with the high concentration is subjected to spray drying, and rhodium trichloride is obtained. Rhodium trichloride is good in acid solubility and water solubility, stable in product performance and good in consistency, has stable rhodium content, realizes uniform product particles and meets use requirements of catalyst precursors. With the adoption of the continuous crystallization method of rhodium trichloride, continuous production can be realized, the process is simple, the production cycle is short, environmental pollution is avoided, a productive-processing technique realizing reduction of metal loss is adopted, the production loss caused by the long production process is reduced, a precursor material which is more reliable and more convenient to use is provided for the rhodium catalyst industry, an industrial chain of the rare and precious metal industry is extended, market vacancy is filled up, and industrial development is promoted.

Owner:昆明铂磊科技有限公司

Green synthesis method of palladium chloride

InactiveCN110194493AEasy to operateReduce dependenceRuthenium/rhodium/palladium/osmium/iridium/platinum halidesChemical industryGreen consumptionSynthesis methods

The invention provides a green synthesis method of palladium chloride. The method includes: using metal palladium and hydrochloric acid as the reaction raw materials, adopting hydrogen peroxide as theoxidizing agent, controlling the process parameters: feed ratio, feeding rate, reaction time, oxidizing agent concentration, reaction temperature, etc., carrying out reaction, then removing water byreduced pressure distillation, and recycling water and hydrochloric acid water resources. The green synthesis method of palladium chloride disclosed by the invention has a green and environment-friendly technological process, and high technical content, effectively realizes energy saving, emission reduction, and green consumption reduction, and the product has high added value, belongs to one of the necessities of China's high-tech market, and has strong market and technological prospects.

Owner:太仓南净源科技有限公司

Reprocessing method by fluoride volatility process using solid-gas separation

InactiveUS7208129B2Easy to separateReduce consumptionFluoride preparationPlutonium compoundsFluoride volatilityHexafluoride

Fluorine or a fluorine compound is subjected to a reaction with a spent oxide fuel to produce fluorides of uranium and plutonium, and the fluorides are recovered using a difference in volatility behavior. The spent oxide fuel is subjected to a reaction with an HF gas, whereby uranium, plutonium and most impurities are converted into solid fluorides having low valences or remained as oxides to inhibit volatilization thereof, and then in an F2 fluorination step, the HF fluorination product is subjected to a reaction with a fluorine gas in two stages: one at a low temperature and the other at a high temperature, whereby a certain amount of gaseous uranium and volatile impurities are separated with plutonium kept in a solid form in the first stage, and mixed fluorides of remaining uranium and plutonium are fluorinated into hexafluorides at the same time in the second stage. By such a reprocessing method, plutonium enrichment can be adjusted, uranium and plutonium can be purified, and steps are simplified as well. In addition, reactors are hard to be corroded or deteriorated.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

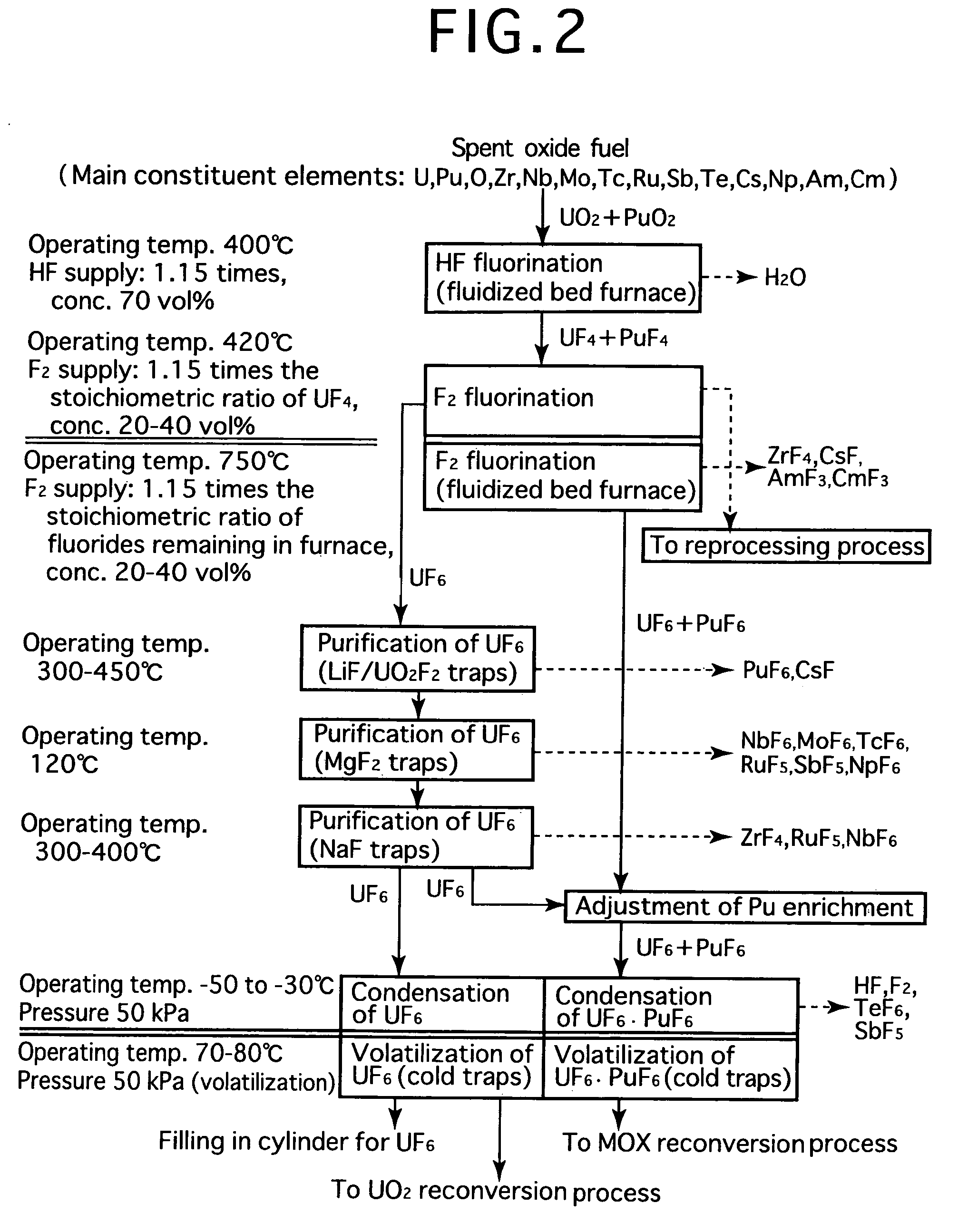

Method of making an inorganic platinum compound

ActiveUS20200180976A1Improved safe and environment-friendlyHigh potential for commercial implementationRuthenium/rhodium/palladium/osmium/iridium/platinum halidesHalogenAqueous solution

Provided is a method of making an inorganic platinum compound. The method includes the steps of: Step (A): providing a platinum material and a halogen-containing oxidizing agent; and Step (B): treating the platinum material with the halogen-containing oxidizing agent in a hydrochloric acid aqueous solution to obtain the inorganic platinum compound, including chloroplatinic acid or chloroplatinate salt; wherein the halogen-containing oxidizing agent excludes chlorine gas. The method of making an inorganic platinum compound is simple, safe, time-effective, cost-effective, and environment-friendly, and has the advantage of high yield.

Owner:TRIPOD NANO TECH CORP

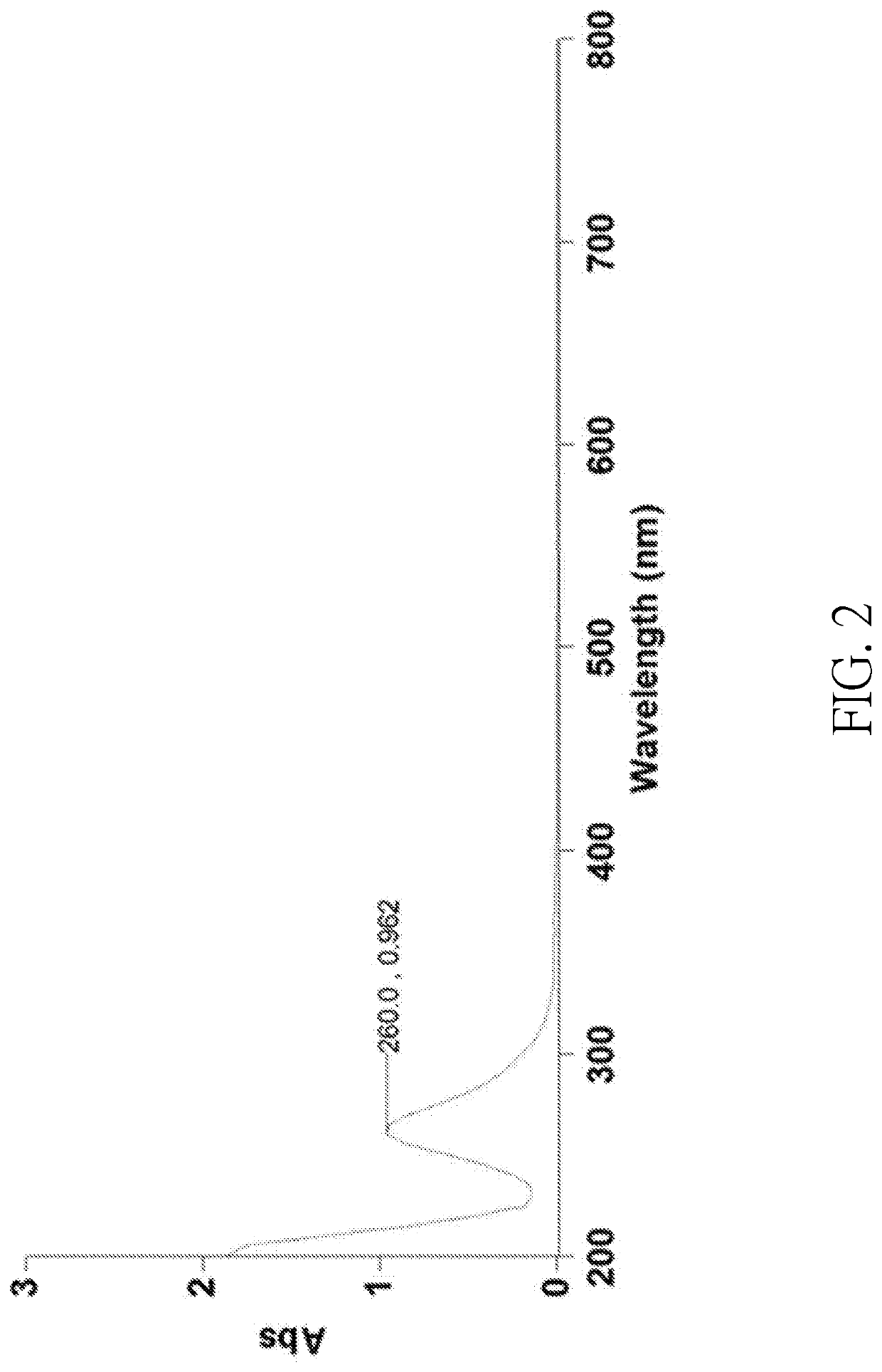

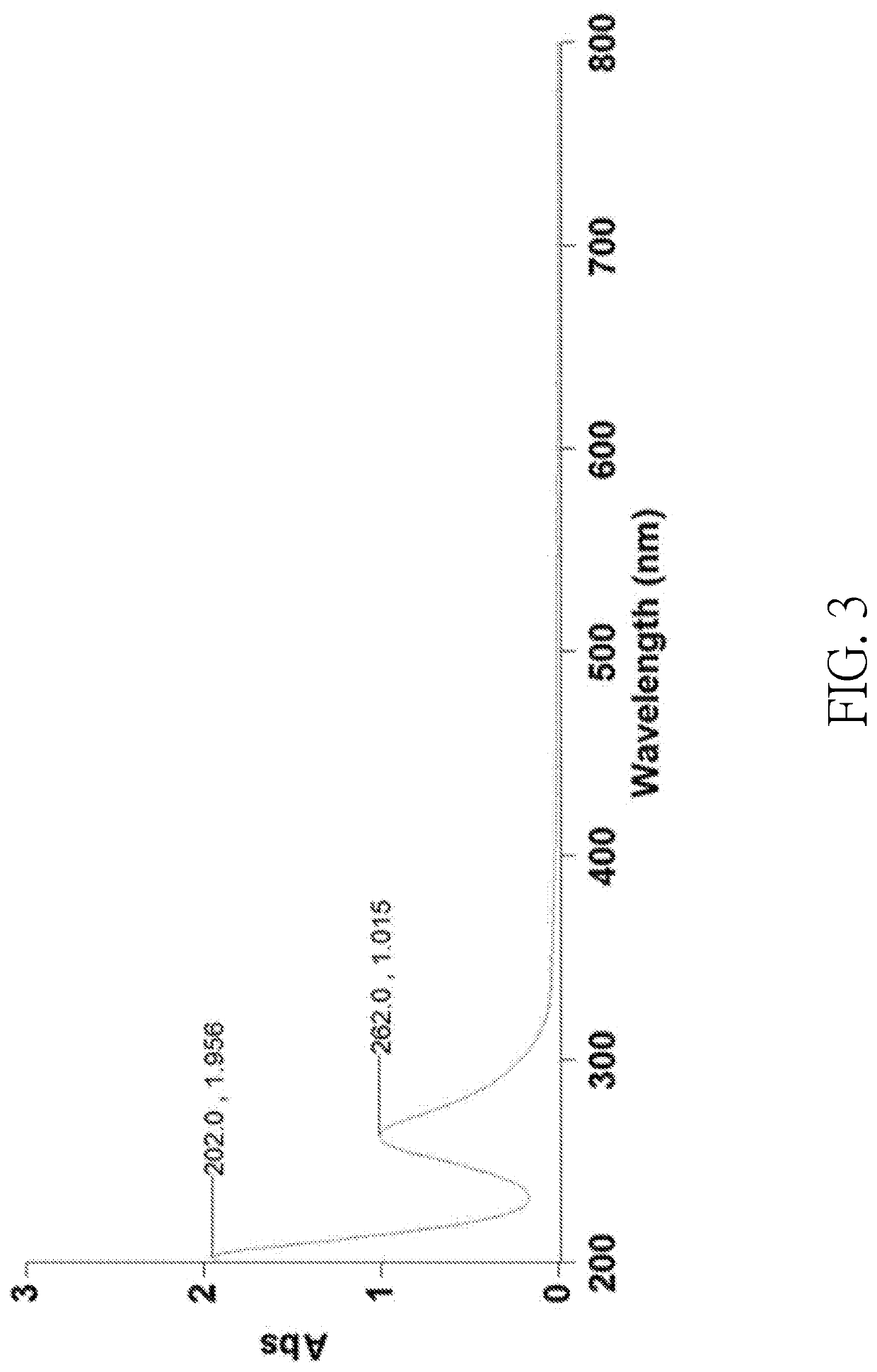

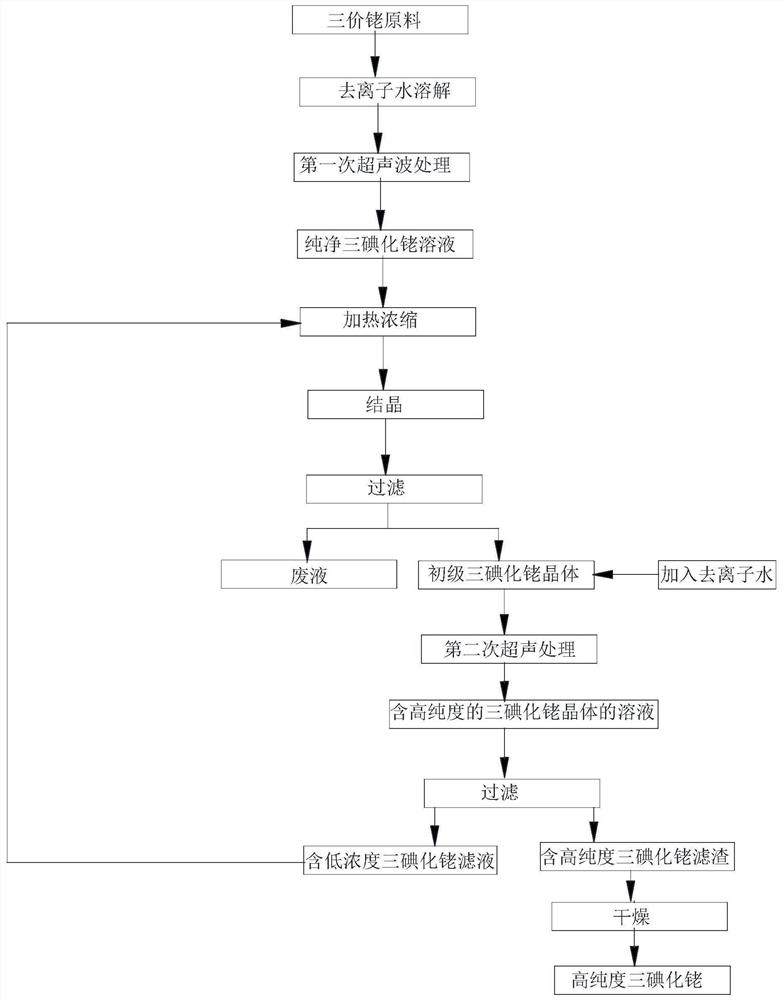

Preparation method of high-purity rhodium triiodide

PendingCN112194204AThorough responseFully elutedRuthenium/rhodium/palladium/osmium/iridium/platinum halidesUltrasonic radiationTriiodide

The invention discloses a preparation method of high-purity rhodium triiodide, which comprises the steps of putting a deionized water solution dissolved with a trivalent rhodium-containing raw material into an ultrasonic field, adding a hydroiodic acid solution into the solution to form a mixed solution, and carrying out primary ultrasonic treatment on the mixed solution; and adding hydrogen peroxide into the mixed solution, heating to completely volatilize elemental iodine generated in the reaction, stopping ultrasonic treatment to obtain a rhodium triiodide-containing solution, heating and concentrating the rhodium triiodide-containing solution, and crystallizing to obtain primary rhodium triiodide crystals. According to the preparation method, under ultrasonic radiation, complete reaction of trivalent rhodium and added hydroiodic acid is promoted, and crystal grains are uniform; ultrasonic radiation washing is carried out, impurities in rhodium triiodide crystals can be fully elutedby utilizing the cavitation effect of ultrasonic waves, and the product purity is effectively improved.

Owner:KUNMING BOREN PRECIOUS METALS +1

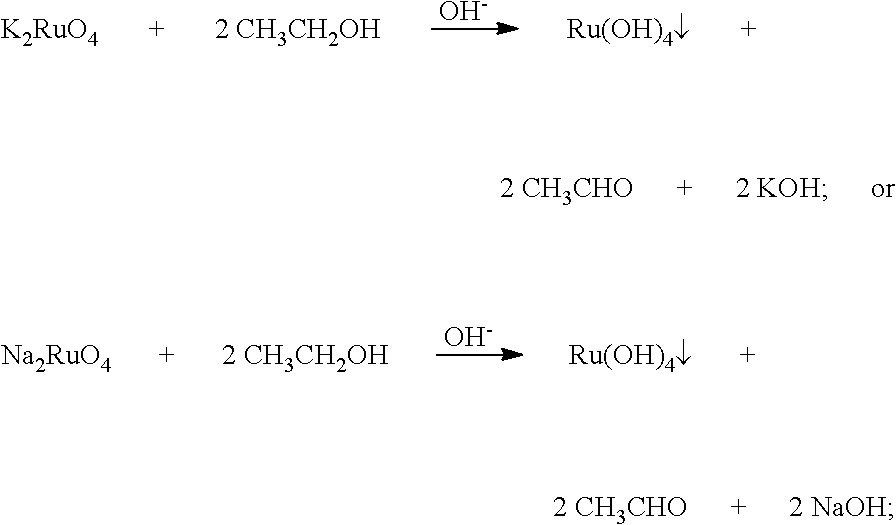

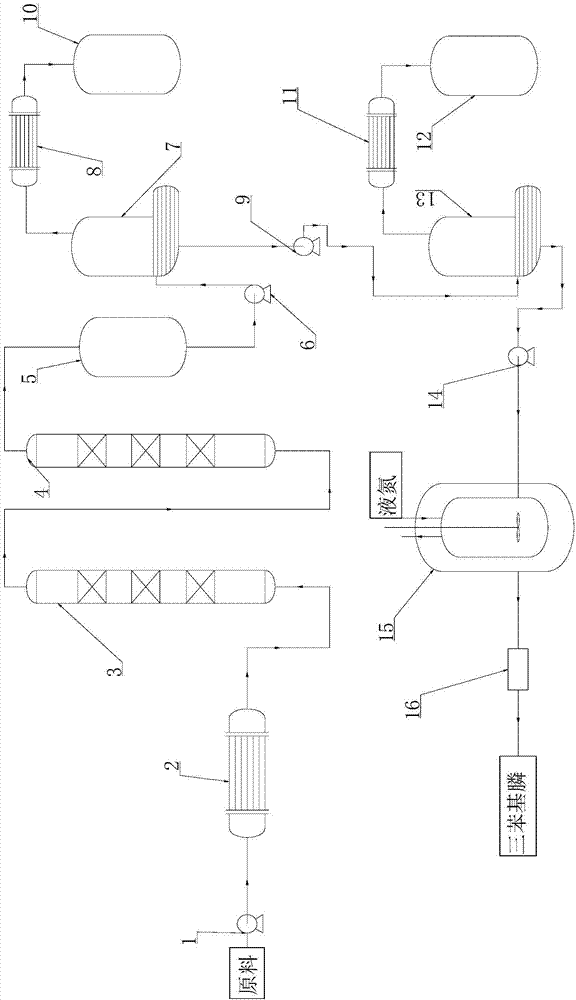

Method and device for comprehensively recycling catalyst mother liquor in propylene carbonylation

PendingCN107955038AThe generation of solutionAvoid lostGroup 5/15 element organic compoundsRuthenium/rhodium/palladium/osmium/iridium/platinum halidesEvaporationProtein carbonyl

The invention relates to a method for comprehensively recycling catalyst mother liquor in propylene carbonylation. The method comprises the following steps: feeding devitalized catalyst mother liquoror catalyst mother liquor with reduced activity into a first adsorption column and a second adsorption column, then feeding into a buffer tank, and feeding into a butyraldehyde removing tower via thebuffer tank; pumping a base solution of the butyraldehyde removing tower into a high polymer removing tower; pumping concentrated triphenylphosphine mother liquor on the bottom of the high polymer removing tower into a reactor and carrying out low-temperature separation by crystallization on triphenylphosphine to obtain crude triphenylphosphine; washing triphenylphosphine solid with water at first, then dissolving the triphenylphosphine solid with ethanol, and carrying out evaporative crystallization to recycle triphenylphosphine; and carrying out evaporation concentration and crystallizationon a purified rhodium trichloride solution under the condition of vacuum to obtain reddish brown rhodium trichloride crystals. Pollution to the environment due to combustion in recycling of precious metal from the catalyst mother liquor and loss of butyraldehyde and triphenylphosphine in an incineration process or a nitrifying process of the catalyst mother liquor by a large amount of waste liquidgenerated by an extraction method are solved, and effective component utilization rate of the catalyst mother liquor is increased.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com