Green synthesis method of palladium chloride

A green synthesis, palladium chloride technology, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, inorganic chemistry, etc., can solve problems such as adverse effects on environmental protection and social stability, and inconsistent development goals , to achieve good promotion and application value, facilitate large-scale production, and save waste heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

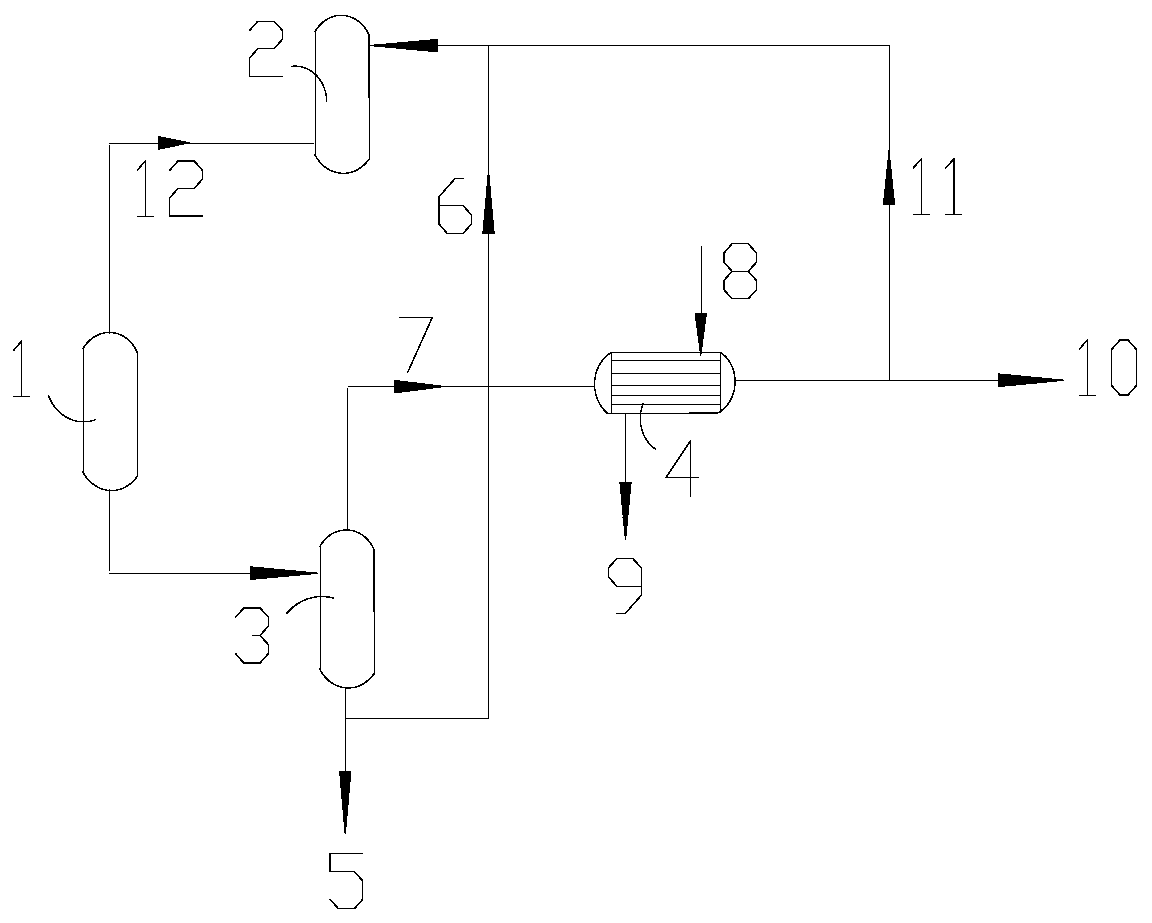

[0028] like figure 1 , a kind of palladium chloride green synthetic method, comprises the steps:

[0029] The production of the crude product in step S1: adding the metal palladium powder in the reactor 1 with the dropping funnel at one time, and adding hydrochloric acid therein, stirring at a certain temperature, while stirring, passing through the dropping funnel to the reactor 1 gradually Add the aqueous solution of the oxidant dropwise, and finish the addition within 20 minutes. After the dropwise addition, continue the insulation reaction for 0.5 hours to obtain the crude product;

[0030] Step S2 tail gas treatment: the HCl gas 12 that may be volatilized during the production process of step S1 is passed into the tail gas absorption tower 2, and the tail gas is absorbed by spraying;

[0031] Step S3 vacuum distillation to remove water: the crude product produced in step S1 is added to the evaporator 3 for vacuum distillation operation, the slight excess of hydrochloric ...

Embodiment 2

[0041] like figure 1 , a kind of palladium chloride green synthetic method, comprises the steps:

[0042] The production of the crude product in step S1: adding the metal palladium powder in the reactor 1 with the dropping funnel at one time, and adding hydrochloric acid therein, stirring at a certain temperature, while stirring, passing through the dropping funnel to the reactor 1 gradually Add the aqueous solution of the oxidizing agent dropwise, and complete the addition within 23 minutes. After the dropwise addition is completed, continue the heat preservation reaction for 0.9 hours to obtain the crude product;

[0043] Step S2 tail gas treatment: the HCl gas 12 that may be volatilized during the production process of step S1 is passed into the tail gas absorption tower 2, and the tail gas is absorbed by spraying;

[0044] Step S3 vacuum distillation to remove water: the crude product produced in step S1 is added to the evaporator 3 for vacuum distillation operation, the ...

Embodiment 3

[0054] like figure 1 , a kind of palladium chloride green synthetic method, comprises the steps:

[0055] The production of the crude product in step S1: adding the metal palladium powder in the reactor 1 with the dropping funnel at one time, and adding hydrochloric acid therein, stirring at a certain temperature, while stirring, passing through the dropping funnel to the reactor 1 gradually Add the aqueous solution of the oxidizing agent dropwise, and complete the addition within 25 minutes. After the dropwise addition, continue the heat preservation reaction for 1.3 hours to obtain the crude product;

[0056] Step S2 tail gas treatment: the HCl gas 12 that may be volatilized during the production process of step S1 is passed into the tail gas absorption tower 2, and the tail gas is absorbed by spraying;

[0057] Step S3 vacuum distillation to remove water: the crude product produced in step S1 is added to the evaporator 3 for vacuum distillation operation, the slight excess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com