Rapid dissolution method for indissolvable metal iridium

A metal iridium, insoluble technology, applied in chemical instruments and methods, ruthenium/rhodium/palladium/osmium/iridium/platinum halides, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, etc., can solve the operating environment Harsh, long process, high energy consumption and other problems, to achieve the effect of simple process, friendly environment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

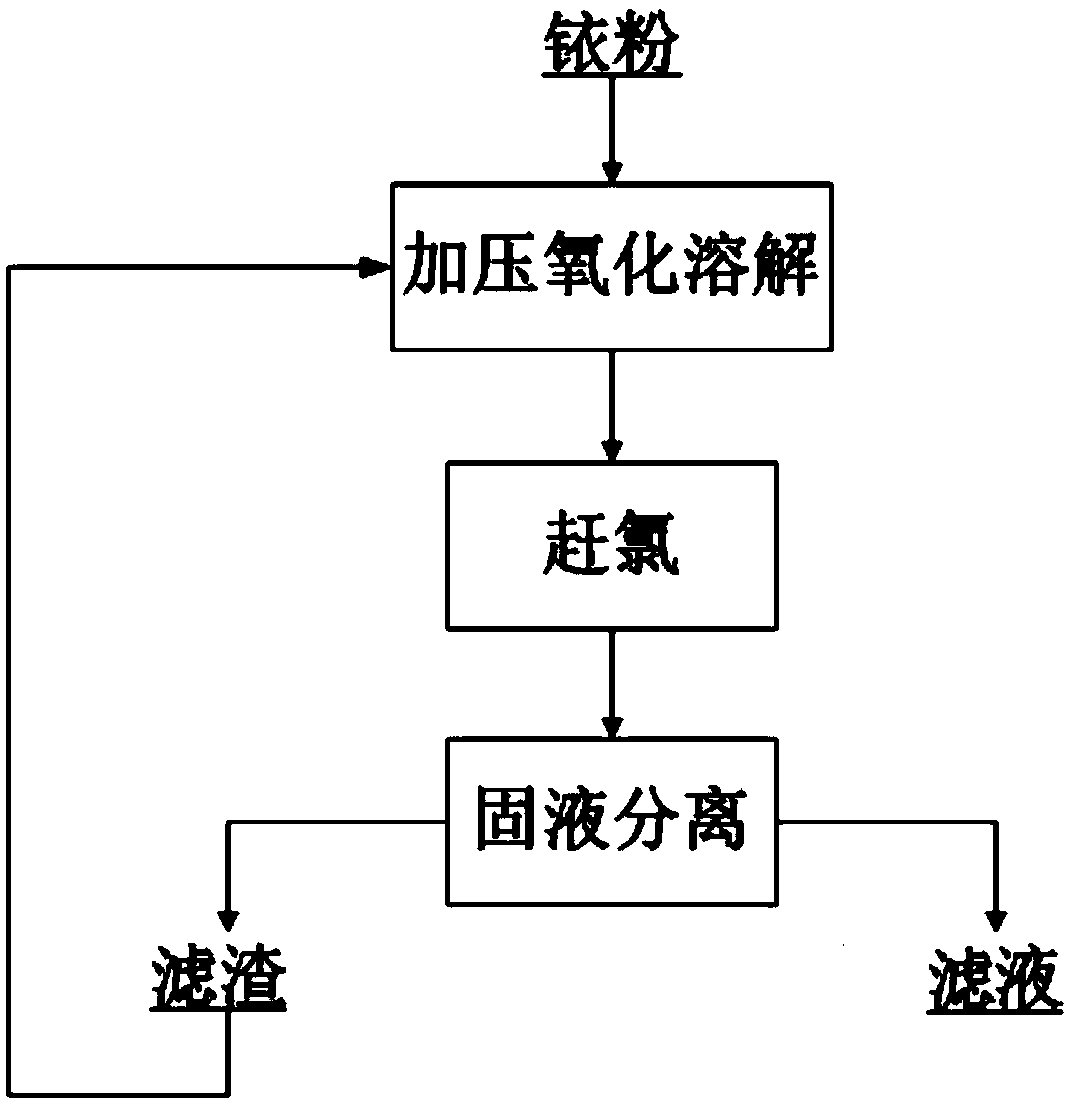

[0027] Such as figure 1 Shown, the method for rapidly dissolving insoluble metal iridium powder of the present embodiment comprises the following steps:

[0028] Step 1, pressurized oxidation and dissolution: add 2kg iridium powder and hydrochloric acid with a mass concentration of 36% into the reactor while stirring and feed chlorine gas. The temperature in the reactor is 200°C, the pressure is 2MPa, and the rotating speed is 200r / Stirring reaction 3h under the condition of min, stop feeding chlorine after reaction finishes, the flow of described chlorine is 800mL / min; The mass content of iridium in the described iridium powder is greater than 99.95%, the volume of described hydrochloric acid and the quality of iridium powder The ratio is 8:1, the volume unit of the hydrochloric acid is mL, and the mass unit of the iridium powder is g;

[0029] Step 2, chlorine removal: after the reaction in step 1, open the pressure relief valve of the reactor, reduce the pressure of the r...

Embodiment 2

[0032] Such as figure 1 Shown, the method for rapidly dissolving insoluble metal iridium powder of the present embodiment comprises the following steps:

[0033] Step 1, pressurized oxidation and dissolution: add 2kg of iridium powder and hydrochloric acid with a mass concentration of 25% into the reactor and feed chlorine gas while stirring. The temperature in the reactor is 150°C, the pressure is 0.6MPa, and the rotation speed is 160r Stirring reaction 5h under the condition of / min, stop feeding chlorine gas after the end of reaction, the flow of described chlorine gas is 500mL / min; The mass content of iridium in the described iridium powder is greater than 99.95%, the volume of described hydrochloric acid and the quality of iridium powder The ratio of the hydrochloric acid is 4:1, the volume unit of the hydrochloric acid is mL, and the mass unit of the iridium powder is g;

[0034] Step 2, chlorine removal: after the reaction in step 1, open the pressure relief valve of t...

Embodiment 3

[0037] Such as figure 1 Shown, the method for rapidly dissolving insoluble metal iridium powder of the present embodiment comprises the following steps:

[0038] Step 1, pressurized oxidation and dissolution: add 2kg of iridium powder and hydrochloric acid with a mass concentration of 15% into the reactor and feed chlorine gas while stirring. The temperature in the reactor is 100°C, the pressure is 0.1MPa, and the rotation speed is 120r Under the condition of stirring reaction 8h under the condition of / min, stop feeding chlorine gas after the end of reaction, the flow rate of described chlorine gas is 200mL / min; The ratio of the hydrochloric acid is 2:1, the volume unit of the hydrochloric acid is mL, and the mass unit of the iridium powder is g;

[0039] Step 2, chlorine removal: after the reaction in step 1, open the pressure relief valve of the reactor, reduce the pressure of the reactor to normal pressure, and use the negative pressure system of the reactor to reduce the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com