Method and device for comprehensively recycling catalyst mother liquor in propylene carbonylation

A carbonylation and catalyst technology, which is applied in the field of comprehensive recycling and utilization of rhodium/triphenylphosphorus waste catalyst mother liquor, and achieves the effects of improving the utilization rate of effective components and solving the loss of butyraldehyde and triphenylphosphine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

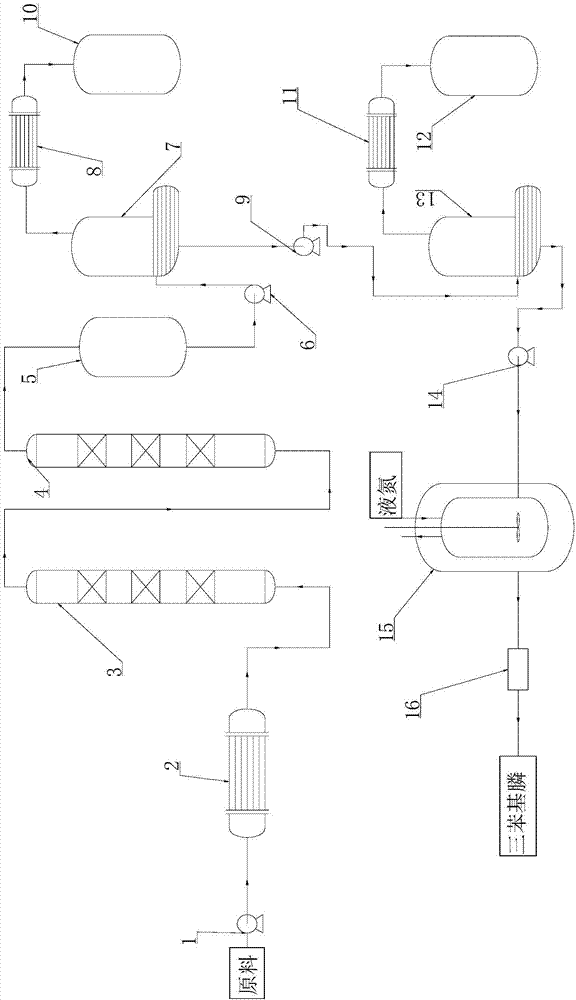

[0065] 1. Butyraldehyde and triphenylphosphine in the spent catalyst mother liquor are recovered, and two adsorption columns are connected in series, which specifically includes the following steps:

[0066] (1) First, pump the deactivated waste catalyst mother liquid into the raw material heat exchanger 2 by the raw material delivery pump 1, and send it into the first adsorption column 3 and the second adsorption column 4 after the raw material heat exchanger 2 is heated to 65°C; One adsorption column 3 and the second adsorption column 4 bed layers are all sulfonated base silica gel resins, (the functional load of grafting on the silica gel resin is 0.8mmol / g, and the average particle diameter of the sulfonated base silica gel resin is 200-500mm) for Adsorb the rhodium in the spent catalyst mother liquor; in order to ensure that the temperature of the catalyst mother liquor is the same or close to the temperature of the adsorption bed, both the first adsorption column 3 and th...

Embodiment 2

[0077] 1. Butyraldehyde and triphenylphosphine in the spent catalyst mother liquor are recovered, and two adsorption columns are connected in series, which specifically includes the following steps:

[0078] (1) First, the spent catalyst mother liquor with reduced activity is pumped into the raw material heat exchanger 2 by the raw material delivery pump 1, and then sent to the first adsorption column 3 and the second adsorption column 4 after being heated to 75° C. through the raw material heat exchanger 2; One adsorption column 3 and the second adsorption column 4 bed layers are all sulfonated base silica gel resins (the functional load of grafting on the silica gel resin is 0.9mmol / g, and the average particle diameter of the sulfonated base silica gel resin is 200-500mm), used for Adsorb the rhodium in the spent catalyst mother liquor; in order to ensure that the temperature of the catalyst mother liquor is the same or close to the temperature of the adsorption bed, both the...

Embodiment 3

[0089] 1. First, the butyraldehyde and triphenylphosphine in the spent catalyst mother liquor are recovered, and two adsorption columns are connected in series, which specifically includes the following steps:

[0090] (1) First, pump the deactivated waste catalyst mother liquor into the raw material heat exchanger 2 by the raw material delivery pump 1, and send it into the first adsorption column 3 and the second adsorption column 4 after the raw material heat exchanger 2 is heated to 85° C.; The first adsorption column 3 and the second adsorption column 4 beds are all sulfonated silica gel resins (the functional loading on the silica gel resin is 1mmol / g, and the average particle diameter of the sulfonated silica gel resin is 200-500mm), which are used for adsorption Rhodium in the spent catalyst mother liquor; in order to ensure that the temperature of the catalyst mother liquor is the same or close to the temperature of the adsorption bed, the first adsorption column 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com