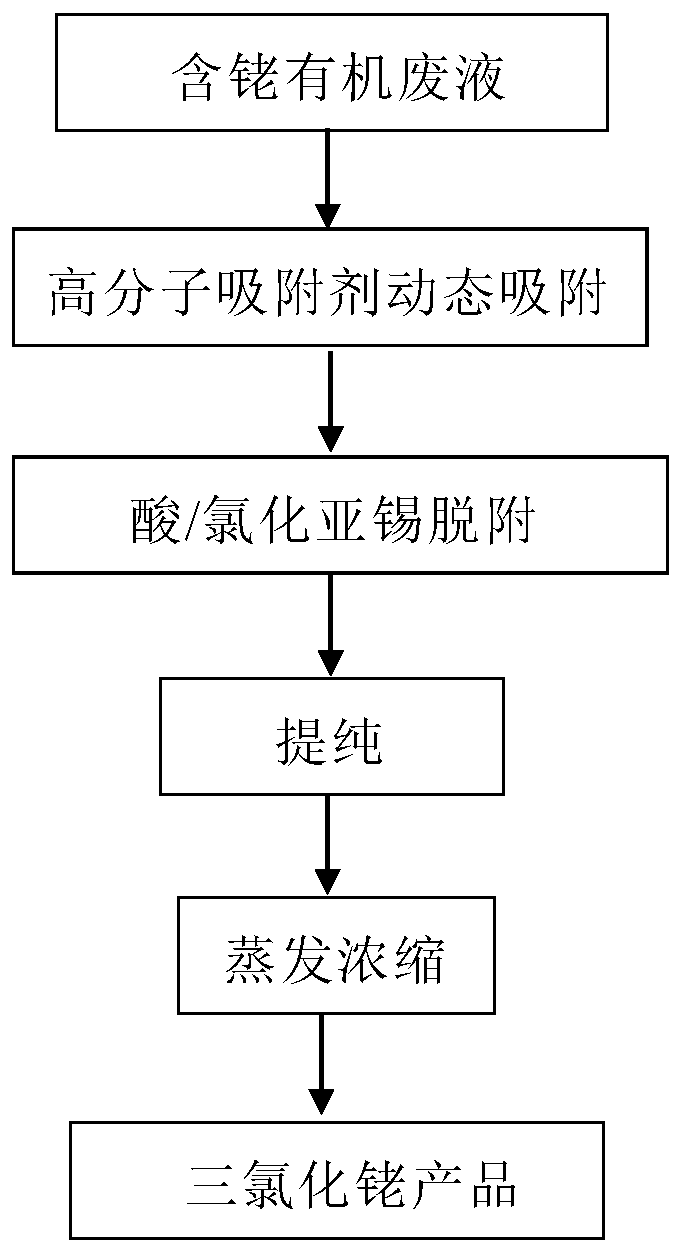

Method for recovering rhodium from rhodium-containing organic wastewater to prepare rhodium chloride

An organic waste liquid, rhodium trichloride technology, applied in chemical instruments and methods, inorganic chemistry, preparation of ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, etc., to achieve large adsorption capacity, easy operation, high adsorption rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

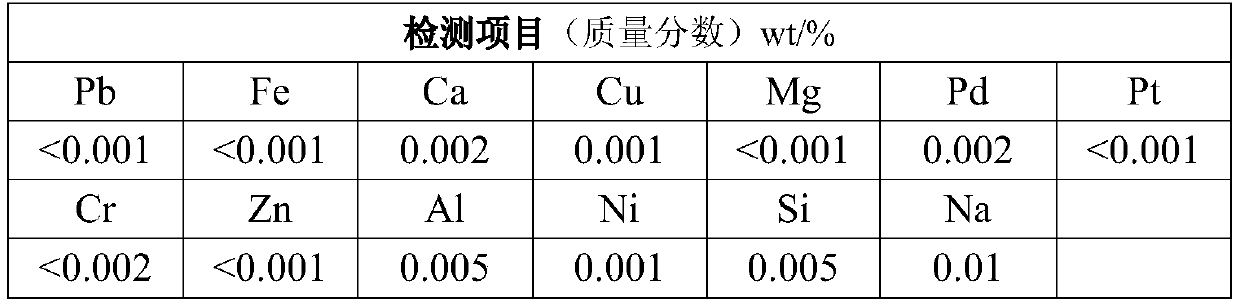

[0034] Step 1. Adsorption: Adsorb the rhodium in the rhodium-containing organic waste liquid produced in the production process of the rhodium homogeneous catalyst onto the polymer adsorbent in the form of dynamic adsorption to obtain the rhodium-containing adsorbent; the specific process is: A polymer adsorbent with imino groups (such as a polymer bonded with dihydrocarbyl sulfide, the polymer is a polymer of N,N-methylenebisacrylamide and vinylimidazole, or Polymer of ethylene glycol dimethacrylate and acrylic acid) 10g filled into In the adsorption column, use a peristaltic pump to pass 1500mL rhodium-containing organic waste liquid through the adsorption column at a speed of 1mL / min, and the rhodium in the rhodium-containing organic waste liquid is adsorbed on the polymer adsorbent in the form of dynamic adsorption to obtain agent; the temperature of the adsorption is 25 ℃, and the mass content of rhodium in the rhodium-containing organic waste liquid is 156ppm; the rhod...

Embodiment 2

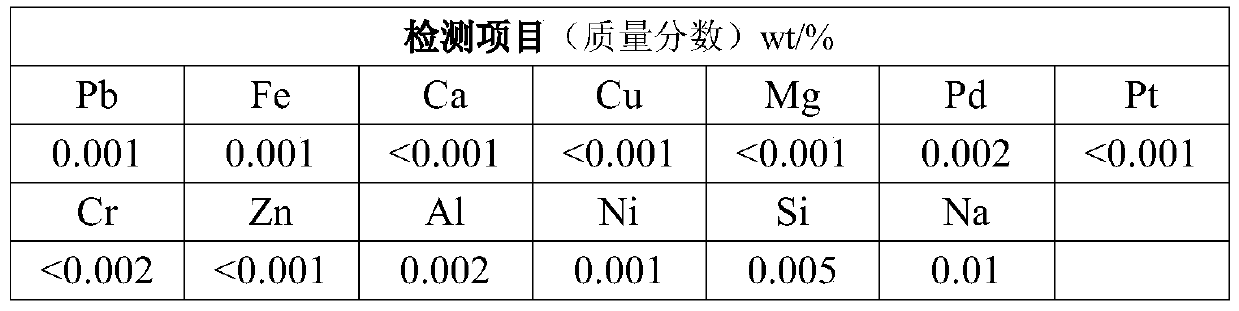

[0042] Step 1. Adsorption: Adsorb the rhodium in the rhodium-containing organic waste liquid produced in the production process of the rhodium homogeneous catalyst onto the polymer adsorbent in the form of dynamic adsorption to obtain the rhodium-containing adsorbent; the specific process is: the rhodium containing sulfoxide Polymer adsorbents with groups and imino groups (such as polymers bonded with dihydrocarbyl sulfoxides, wherein the polymers are polymers of N,N-methylenebisacrylamide and vinylimidazole, or polymer of ethylene glycol dimethacrylate and acrylic acid) 10g filled into In the adsorption column, use a peristaltic pump to pass 30000mL rhodium-containing organic waste liquid through the adsorption column at a speed of 30mL / min, and the rhodium in the rhodium-containing organic waste liquid is adsorbed on the polymer adsorbent in the form of dynamic adsorption to obtain agent; the temperature of the adsorption is 40 ℃, and the mass content of rhodium in the rhod...

Embodiment 3

[0050] Step 1. Adsorption: Adsorb the rhodium in the rhodium-containing organic waste liquid generated during the production process of the rhodium homogeneous catalyst onto the polymer adsorbent in the form of dynamic adsorption to obtain the rhodium-containing adsorbent; the specific process is: containing sulfoxide group and a polymer adsorbent of imino group (such as a polymer bonded with dihydrocarbyl sulfoxide, wherein the polymer is a polymer of N,N-methylenebisacrylamide and vinylimidazole, or Polymer of ethylene glycol dimethacrylate and acrylic acid) 50g filled into In the adsorption column, use a peristaltic pump to pass 5000mL of rhodium-containing organic waste liquid through the adsorption column at a speed of 1mL / min, and the rhodium in the rhodium-containing organic waste liquid is adsorbed on the polymer adsorbent in the form of dynamic adsorption to obtain agent; the temperature of the adsorption is 60 ℃, and the mass content of rhodium in the rhodium-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com