Preparation method of high-purity rhodium triiodide

A rhodium triiodide and high-purity technology is applied in the field of preparation of high-purity rhodium triiodide, which can solve the problems of low yield and low purity, and achieve the effects of uniform crystal grains, high purity and good industrialization prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

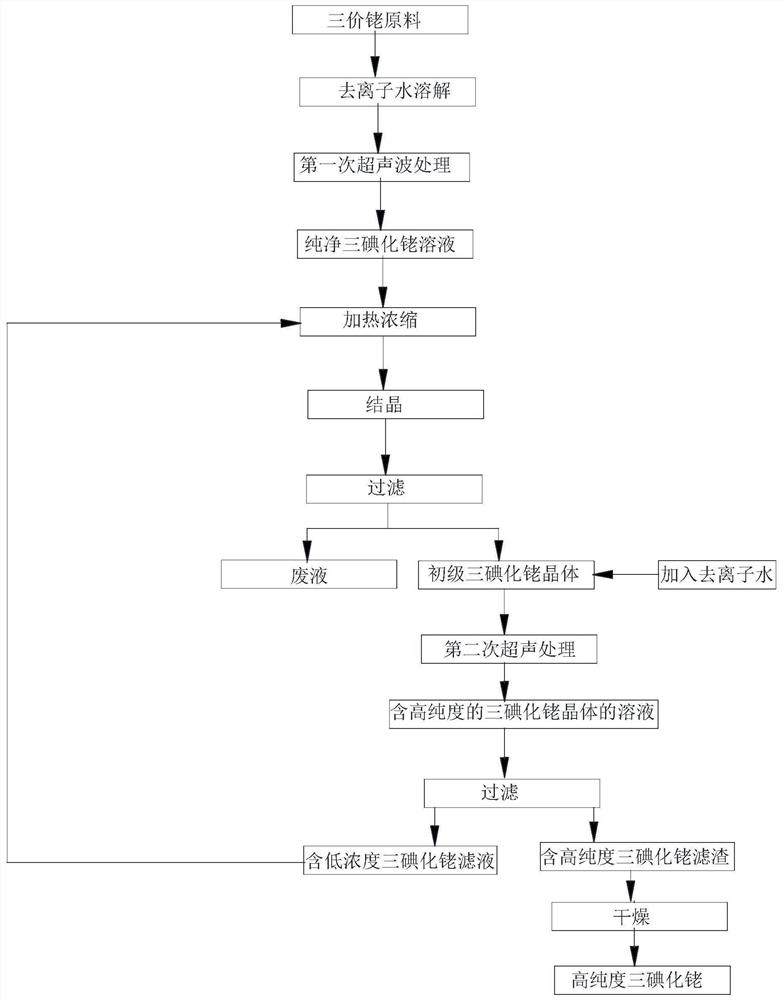

[0024] Such as figure 1 Shown, the preparation method of the high-purity rhodium triiodide provided by the present embodiment comprises the following steps:

[0025] In this embodiment, the trivalent rhodium raw material deionized aqueous solution is dissolved, and the mass concentration of rhodium is controlled to be 15g / L, placed in an ultrasonic field, the addition of hydroiodic acid is 1.05 times of stoichiometric, and the addition rate of hydroiodic acid is 10ml / min , to form a mixed solution, the mixed solution is ultrasonically treated for the first time, and the ultrasonic radiation time is 60min; then an appropriate amount of hydrogen peroxide is added to the mixed solution, wherein the hydrogen peroxide addition is 20% of the mass ratio added by adding hydroiodic acid, and heated to At 65°C, oxidize the residual trace amount of hydriodic acid into volatile elemental iodine. After the iodine volatilizes completely, stop the ultrasonic radiation treatment to obtain a s...

Embodiment 2

[0028] Such as figure 1 Shown, the preparation method of the high-purity rhodium triiodide provided by the present embodiment comprises the following steps:

[0029] In this embodiment, the trivalent rhodium raw material deionized aqueous solution is dissolved, and the mass concentration of rhodium is controlled to be 20g / L, placed in an ultrasonic field, the addition of hydroiodic acid is 1.08 times of stoichiometric, and the addition rate of hydroiodic acid is 15ml / min , to form a mixed solution, the mixed solution is ultrasonically treated for the first time, and the ultrasonic radiation time is 40min; then an appropriate amount of hydrogen peroxide is added to the mixed solution, wherein the hydrogen peroxide addition is 15% of the mass ratio added by adding hydroiodic acid, and heated to At 75°C, oxidize the residual trace amount of hydriodic acid into volatile elemental iodine, stop the ultrasonic radiation treatment after the iodine volatilizes completely, and obtain a ...

Embodiment 3

[0032] Such as figure 1 Shown, the preparation method of the high-purity rhodium triiodide provided by the present embodiment comprises the following steps:

[0033] In this embodiment, the trivalent rhodium raw material deionized aqueous solution is dissolved, and the mass concentration of rhodium is controlled to be 25g / L, placed in an ultrasonic field, the addition of hydroiodic acid is 1.10 times of stoichiometric, and the addition rate of hydroiodic acid is 10ml / min , to form a mixed solution, the mixed solution is ultrasonically treated for the first time, and the ultrasonic radiation time is 60min; then an appropriate amount of hydrogen peroxide is added to the mixed solution, wherein the hydrogen peroxide addition is 25% of the mass ratio added by adding hydroiodic acid, and heated to At 55°C, oxidize the residual trace amount of hydriodic acid into volatile elemental iodine. After the iodine is completely volatilized, stop the ultrasonic radiation treatment to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com