Resource cyclic utilization method of rhodium-containing waste liquid of butanol-octanol device

A recycling and waste liquid technology, applied in chemical instruments and methods, rhodium organic compounds, compounds containing elements of Group 8/9/10/18 of the periodic table, etc., can solve triphenylphosphine damage, waste of resources, etc. problems, to achieve the effect of high recovery rate, less three wastes and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

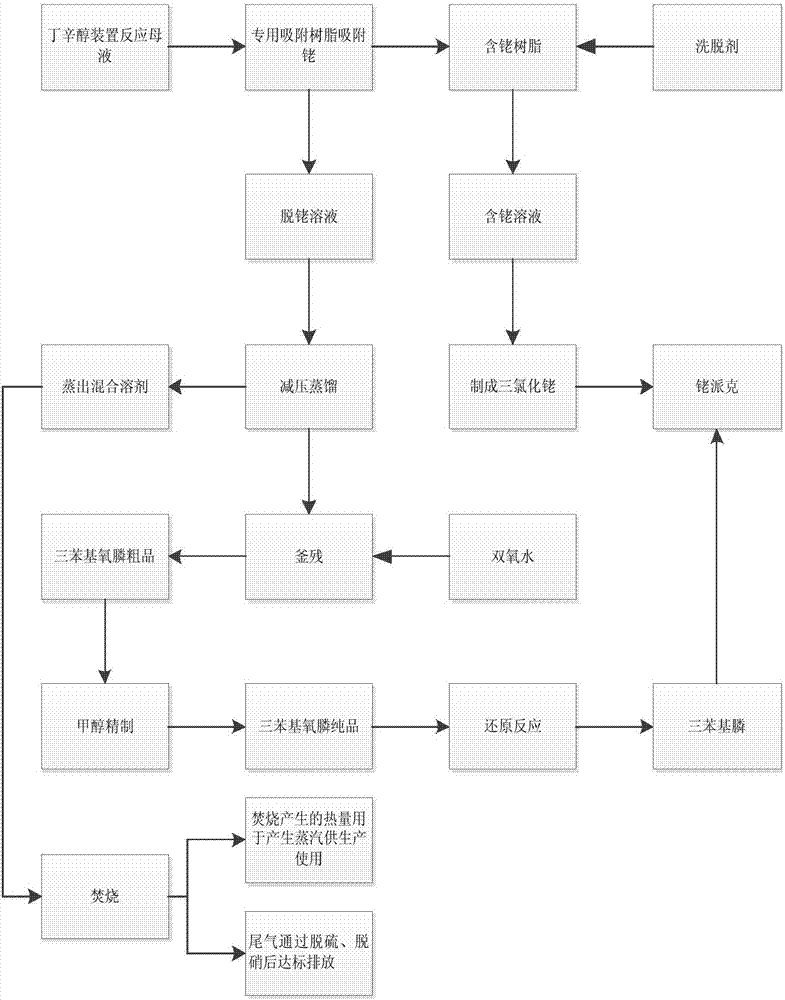

Image

Examples

Embodiment 1

[0037] (1) recovery of rhodium in reaction mother liquor

[0038] 10kg butanol device rhodium-containing waste liquid (rhodium content 0.15%) is adsorbed circularly with polystyrene resin containing active mercapto functional groups as the adsorption resin until the rhodium content in the solution is lower than 5ppm. Then the adsorption resin is eluted and analyzed with the prepared eluent, and the deliquified solution becomes a rhodium-containing solution. Add water and hydrochloric acid in rhodium-containing solution, reflux, rhodium complex hydrolyzes and generates rhodium sulfide to separate out, filters, and the filtered solid is added in 125g concentrated hydrochloric acid and refluxes to generate rhodium chloride, and refluxes until no hydrogen sulfide emerges (with Calcium hydroxide absorbs hydrogen sulfide), the rhodium chloride solution is concentrated and crystallized to separate out rhodium chloride hydrate, and the mother liquor is reserved for batch application. ...

Embodiment 2

[0050] (1) recovery of rhodium in reaction mother liquor:

[0051] a) 4000kg butanol device rhodium-containing waste liquid (0.15% rhodium content) is pumped into the rhodium adsorption device that the polystyrene resin that contains active mercapto functional group is housed as adsorption resin circulation from raw material storage tank, circulates Adsorption, until the content of rhodium in the solution is lower than 5ppm.

[0052] b) After the adsorption resin is eluted and analyzed with an eluent, the eluent becomes a rhodium-containing solution. Add water and hydrochloric acid in the rhodium-containing solution, reflux, the rhodium complex hydrolyzes and generates rhodium sulfide to separate out, filters, adds the filtered solid to 50kg concentrated hydrochloric acid and refluxes to generate rhodium chloride, and refluxes until no hydrogen sulfide emerges (with hydrogen Calcium oxide absorbs hydrogen sulfide), the rhodium chloride solution is concentrated and crystallize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com