Controlled reduction preparation method of iridium trichloride

A technology of iridium trichloride and reducing agent is applied in chemical instruments and methods, inorganic chemistry, ruthenium/rhodium/palladium/osmium/iridium/platinum halide, etc. control, high product purity and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

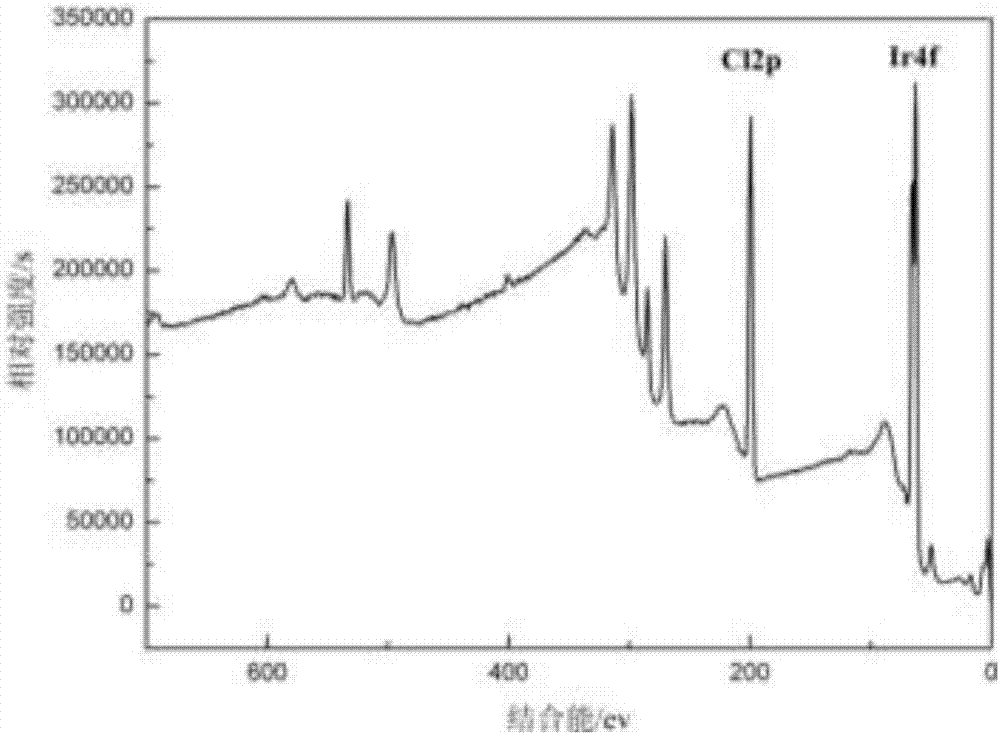

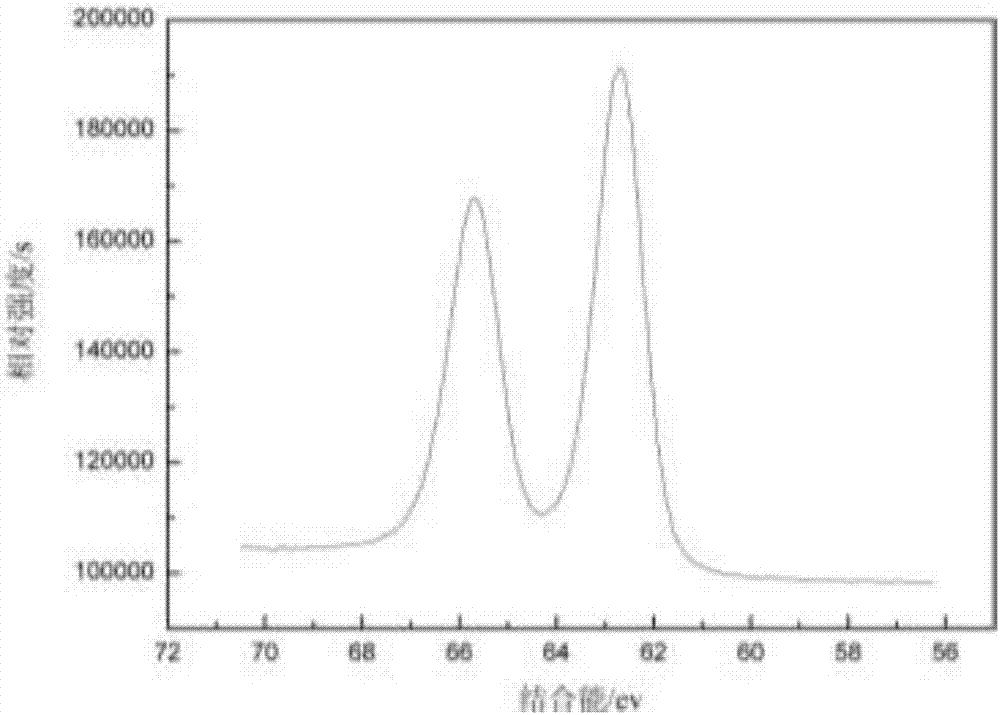

[0017] The invention provides a method for preparing iridium trichloride by controlled reduction. The invention will be further described below in conjunction with the accompanying drawings and examples.

[0018] The operation steps that chloroiridic acid is reduced to iridium trichloride are as follows:

[0019] Step 1, reduction: add 100 grams of chloroiridic acid, 2 g of propanol as a reducing agent, 1.5 g of hydrazine hydrochloride, and 6.5 g of ascorbic acid into a three-necked flask placed in a constant temperature water bath equipment, and control the temperature in the constant temperature water bath equipment at 75 to 100 ℃, turn on the magnetic stirring system, carry out constant temperature stirring, constant temperature reduction for 3 hours until all tetravalent iridium in the solution is converted to trivalent;

[0020] The 2nd step, concentration: the obtained trivalent iridium aqueous solution is concentrated, and excessive water is distilled off, obtains triva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com