Harmless treatment method of aluminum ash

A harmless treatment, aluminum ash slag technology, applied in the direction of alumina/aluminum hydroxide, aluminum chloride, aluminum halide, etc., can solve the problems of potential safety hazards, human and environmental damage, colorless and odorless hydrogen, etc., to achieve effective The effect of recycling and reuse, avoiding flammable and explosive, and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

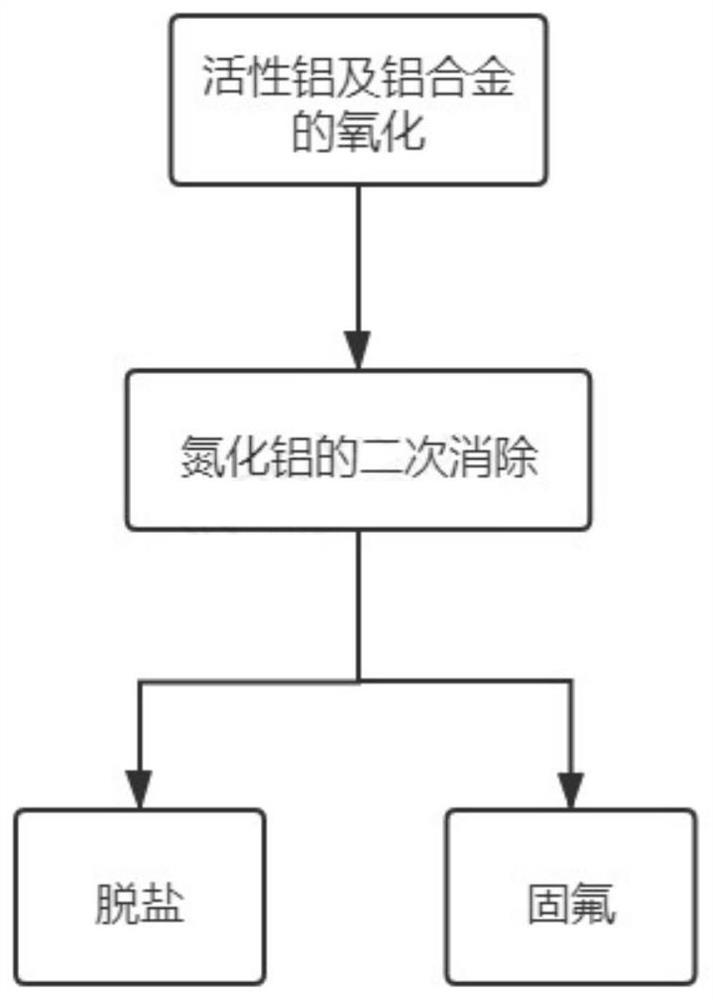

[0038] Aiming at the aluminum ash recovery product that needs salt control, this embodiment provides a harmless treatment method for aluminum ash, including the following processing steps:

[0039] S1: Oxidation of active aluminum and aluminum alloy: calcining the aluminum ash slag, the active aluminum and aluminum alloy in the aluminum ash slag are oxidized, and at the same time, part of the aluminum nitride in the aluminum ash slag is oxidized, and the calcination temperature is controlled at 750°C. Calcination time is 2h;

[0040] S2: Secondary elimination of aluminum nitride: add water and oxidant to the calcined aluminum ash slag, aluminum nitride and water react under the action of oxidant to form aluminum hydroxide and nitrogen, and obtain aluminum ash suspension after the reaction;

[0041]S3: Desalting: subjecting the aluminum ash suspension to centrifugation to obtain desalted aluminum ash and centrifuged liquid, and evaporating and concentrating the centrifuged liqu...

Embodiment 2

[0043] Aiming at the recovered products of aluminum ash that need fluorine fixation, this embodiment provides a harmless treatment method for aluminum ash, including the following processing steps:

[0044] S1: Oxidation of active aluminum and aluminum alloy: Calcining the aluminum ash slag The active aluminum and aluminum alloy in the aluminum ash slag are oxidized, and at the same time, part of the aluminum nitride in the aluminum ash slag is oxidized, and the calcination temperature is controlled at 1100°C. Calcination time is 4h;

[0045] S2: Secondary elimination of aluminum nitride: Add water and oxidant to the calcined aluminum ash slag, aluminum nitride and water react under the action of oxidant to generate aluminum hydroxide and nitrogen, and aluminum ash suspension is obtained after the reaction;

[0046] S3: Fluorine fixation: Calcium oxide is added to the aluminum ash suspension to introduce calcium ions, and the fluoride ions in the aluminum ash suspension react ...

Embodiment 3

[0048] Aiming at the aluminum ash recovery products that need both salt control and fluorine fixation, this embodiment provides a harmless treatment method for aluminum ash, including the following processing steps:

[0049] S1: Oxidation of active aluminum and aluminum alloy: Calcining the aluminum ash slag The active aluminum and aluminum alloy in the aluminum ash slag are oxidized, and at the same time, part of the aluminum nitride in the aluminum ash slag is oxidized, and the calcination temperature is controlled at 950°C. Calcination time is 3h;

[0050] S2: Secondary elimination of aluminum nitride: Add water and oxidant to the calcined aluminum ash slag, aluminum nitride and water react under the action of oxidant to generate aluminum hydroxide and nitrogen, and aluminum ash suspension is obtained after the reaction;

[0051] S3: Fluorine fixation: Calcium oxide is added to the aluminum ash suspension to introduce calcium ions, and the fluoride ions in the aluminum ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com